Rebuilding the Honda XR650R Motorcycle Cylinder and Head at L.A. Sleeve Company!

The magazine’s Honda XR650R motorcycle came with very low hours on the bike. Unfortunately, the air filter had been sealing badly, and the result was an engine with damaged valves and excessively low compression. We turned to L.A. Sleeve Company for its Moly 2000 iron/chrome-moly alloy cylinder sleeve and cylinder head rebuilding. In this HD video, see what it takes to build an ultra reliable cylinder head and barrel at L.A. Sleeve Company. This bike will be used extensively as an HD video filming platform, and our aim is maximum dependability in remote backcountry!

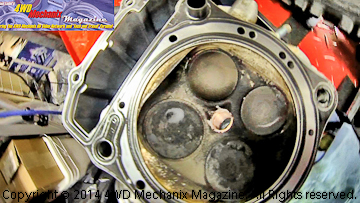

The cause of the low compression is evident: The valves are badly “coked up” with carbon and were not seating or sealing properly. A wrong main jet and lean air/fuel mixture contributed to excess heat and damage at the cylinder wall and piston. Major seepage of dirt around an aftermarket air filter led to a classic case of pitted and damaged valves—especially the intake valves!

Curious how this iconic and “bulletproof” Honda XR650R motorcycle engine got to this wear point in less than 1000 original miles? Get the whole story in Moses Ludel’s comments on carburetor jetting and air filtration—exclusively at this 4WD Mechanix ‘Tech & Travel Forums topic—click here!

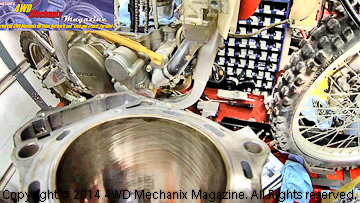

At left, the original cylinder wall is tough Nikasil plating yet shows scoring and heat damage. A lean fuel mixture on this size engine raises havoc with the valves and heated up this cylinder wall. Equally damaging, the engine was sucking dirt around the air filter element. At right, the cylinder barrel is carefully lifted away from the crankcase, the piston and rings during this upper cylinder rebuild. For rebuilders, a four-stroke engine requires considerably more work during major service than a two-stroke engine. (For rebuilding insights, see the two-part ‘how-to’ series here at 4WD Mechanix HD Video Network!)

The original cylinder shows a mix of factory cross-hatch and glazing from heat and dirt scouring. Fortunately, this is the only XR Honda engine built with liquid cooling. An air cooled XR would have seized a piston from the lean fuel mix. The piston does show considerable skirt wear, another result of heat exposure. Quality oil limited the damage to the valves, cylinder wall surface, piston skirts and rings. This damage could likely have been prevented with the use of a 175 main jet and proper air filtration. This low-mileage motorcycle illustrates the importance of proper air filtration and correct air-fuel mixtures and jetting.

The cylinder head and barrel went to L.A. Sleeve Company for reconditioning. The installation of a centrifugally-spun, Moly 2000 iron/chrome-moly alloy cylinder is a substantial upgrade. L.A. Sleeve Company’s machine work for OHV, automotive, truck and tractor engines is renown…See the details in the HD video at this page! Our next step is engine reassembly, see the two-part HD video how-to—available exclusively at the 4WD Mechanix HD Video Network! For more details on L.A. Sleeve Company machining services and available parts, visit the website at http://www.lasleeve.com or phone 1-800-822-6005. Mailing address:

Los Angeles Sleeve Company, Inc. 12051 Rivera Road

Santa Fe Springs, CA, 90670, USA