<< Previous 1 [2] 3 4 5 Next >>

1987 Jeep YJ Wrangler with 2.5L TBI four-cylinder engine. This engine package first appears in the 1984 Jeep XJ Cherokee.

Caution: If your vehicle must comply with emission regulations or inspections, confirm the emission legality of any EFI conversion or aftermarket carburetor. If considering a kit like MSD Atomic EFI, California and many other states require equipment approval for your specific vehicle and engine type. Review the manufacturer’s literature. If you intend to register/license your Jeep for use in California, any EFI conversion kit or aftermarket carburetor must have a Clean Air Resources Board (CARB) Executive Order exemption number that approves the product’s use for your specific vehicle and engine type. Other states have adopted similar regulations. Check with state and local requirements before purchasing any EFI conversion kit or retrofit aftermarket carburetor.

AMC/Jeep 2.5L four-cylinder engines enjoyed the benefits of OEM throttle body injection (TBI) beginning with the 1984 XJ Cherokee. The trend continued with the 1987-90 YJ Wrangler 2.5L four. From 1987-up, all 4.0L inline sixes offered multi-point injection, first the Renix system (1987-90), then the Chrysler MPI system introduced in 1991 4.0L inline sixes and 2.5L fours.

From 1991 forward, the Jeep 2.5L four and 4.0L inline six each use Chrysler’s MPI electronic fuel-and-spark management. ‘LA’ pushrod V-8 5.2L and 5.9L engines, beginning with 1993-up Grand Cherokee models, also use Mopar MPI fuel injection systems.

Inspired by the dramatic gains of EFI, Mopar Performance marketed the first popular retrofit TBI system for the 4.2L inline six. The results were startling: a stone stock 4.2L with nothing more than an EFI conversion immediately gained 50 horsepower—and a cleaner tailpipe.

There were efforts with EFI retrofit kits prior to this first Mopar offering. In the late 1980s, Jack Clifford experimented with a retrofit AirSensors-based EFI system at Clifford Performance. (See that system in Moses Ludel’s Jeep® Owner’s Bible™.) The core was a Ford central-fuel injection (CFI) unit from a 1980s 302 Ford V-8.

Around that same time, Lee Hurley (HESCO) utilized Electromotive’s laptop programmable EFI on Jeep MPI six-cylinder race engines. (We discussed Lee’s work at Walker Evans’ race shop.) Lee custom-programmed Jeep inline sixes for Baja racing and Archer Brothers’ MJ Comanche pickups, which won the SCCA Race Truck Challenge.

Similarly, Steve Dose experimented with an Electromotive-based system around 1990, using a G.M. TBI unit. We collaborated on an OFF-ROAD Magazine project, a 4.2L CJ-5 Jeep that I drove from Oakridge, Oregon to the SCORE Show at Anaheim, California—and back.

Each of these systems pre-dated the Mopar Performance-Electromotive TBI/EFI venture, which clearly had Lee Hurley’s handprint. This first Mopar Performance retrofit TBI system relied upon programmable Electromotive fuel-and-spark management.

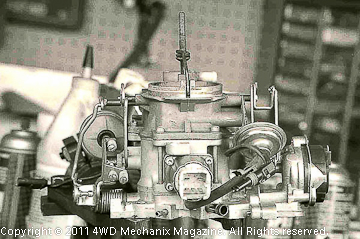

The Mopar Performance TBI retrofit system used a Holley OEM-type TBI unit. Spark timing was electronically controlled by the Electromotive microprocessor, which also controlled throttle body fuel flow. EFI quickly revealed its benefits over the factory BBD carburetor that had been smothered by its emission control constraints.

If your Jeep engine must use the Carter BBD system, see the magazine’s blueprint for reliable performance from a stock 4.2L BBD carburetor. We drove 4.2L Jeep CJ and YJ Wrangler 4x4s over the Rubicon Trail ‘in the day’. Restored to factory tune, the Carter BBD can work as well as other carburetor types—granted, with all the inherent quirks and off-road limitations of carburetion!

By the mid-‘90s, Mopar Performance seized on the benefits of OEM type MPI as a retrofit for the 1981-90 Jeep 4.2L inline sixes. The Mopar Performance MPI/EFI Conversion Kit is a 50-state legal, California CARB E.O. package.

The Mopar kit uses a slightly modified OEM 4.0L intake manifold and complete multi-point (six injector) injection system, a PCM-controlled ignition distributor and wires, air intake pieces, a retrofit wiring harness, a high-pressure two-rail fuel delivery system, necessary sensors, the PCM computer and all required emission control devices.

Mopar EFI Conversion on a fresh Jeep inline six goes into a 1987 Jeep YJ Wrangler. This kit builds around Jeep OEM components for parts availability, reliability and Jeep dealership DRB scan tool troubleshooting. Chassis/engine combination and induction system meet California CARB requirements.

For simplicity and ready parts access, the core Mopar Performance components were originally ‘off-the-shelf’ 1994-95 4.0L Wrangler or XJ Cherokee (two-rail fuel supply) pieces.

Later Mopar Performance kits follow the single-rail 1997-up 4.0L fuel delivery approach and use a modified, late style pressure regulator. The system has a MIL engine check provision plus embedded PCM “factory” diagnostic troubleshooting codes (DTCs) for scan tool use.

Mopar Performance MPI retrofit for the 4.2L inline sixes have been ‘how-to’ segments within Moses Ludel’s Jeep® Owner’s Bible™ (now in 3rdEdition) and the Jeep® CJ Rebuilder’s Manual: 1972-86 (Bentley Publishers, Cambridge, MA).

More recently, others have developed cost-effective TBI solutions for the Jeep 4.2L inline six. Notably, the Howell Engine Developments system is 50-state legal with a California CARB E.O. number.

Howell Engine Developments, Inc. offers this 50-state legal EFI conversion for ’81-’86 Jeep CJ 4.2L inline six-cylinder engines. Howell kit meets California CARB E.O. requirements and works independently of the stock Jeep Motorcraft ignition system—which can be retained. (Photo courtesy of Howell Engine Developments, Inc.)

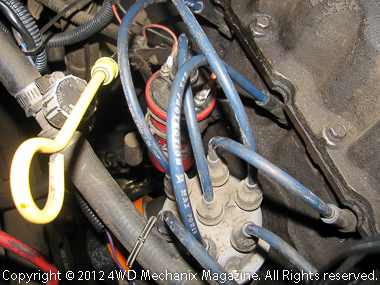

Both the Howell and MSD systems can work in conjunction with an OEM Jeep Motorcraft ignition distributor. Additionally, the MSD Atomic EFI can work with an MSD AMC/Jeep 8516 Pro-Billet distributor. By itself, the MSD 8516 Pro-Billet distributor holds a California CARB E.O. number. So does the MSD Blaster 2 ignition coil (seen above).

Atomic EFI requires either an MSD 6-series box or a ‘Ready-to-Run’ distributor. A Pro-Billet distributor and MSD 6-series box make it possible to use the Atomic EFI’s electronic spark timing control option.

Our Tailpipe Emissions Strategy

Our installation strategy was simple: We would keep the Jeep 4.2L inline six’s stock intake manifold, exhaust manifold and all compatible emissions devices. Use of stock manifolds enables use of the OEM exhaust gas recirculation (EGR) system

. EGR is a key emission device.

The EGR system is often misunderstood. This device dilutes the incoming air/fuel charge under specific engine operating conditions. The aim of EGR is to drop combustion (upper cylinder) temperatures below 2500-degrees F.

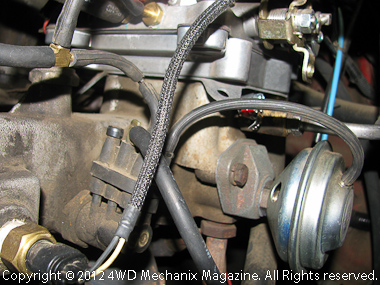

Here, the EGR valve has been removed from the intake manifold casting. (Two ports are visible.) Below the EGR valve is the exhaust manifold’s oxygen sensor port with a new wide-band MSD oxygen sensor fitted.

An EGR valve typically operates or receives an opening signal from ported vacuum. The valve opens at throttle tip-in, remains open through partial throttle, and closes as the throttle opens wider. Like ignition distributor ported vacuum, EGR should not open when the engine is at idle.

EGR targets NOx tailpipe emissions, which increase above 2500-degrees F. Without EGR, combustion chamber temperatures on an older carbureted engine with a conventional distributor can soar to 4,800-degrees F. Some types of aluminum will melt at one-fourth this temperature!

To meet emission requirements, get a “free” drop in upper cylinder temperatures, plus reduce the risk of ping or detonation, leave the EGR system in place and operative. On this Jeep 4.2L EFI project, we did!

Our chassis prototype, a 1989 Jeep YJ Wrangler, requires a catalytic converter. We retained the entire stock exhaust system, including the OEM cat.

The stock cat uses a ‘Pulse Air’ passive air supplement. Mopar and Howell find Pulse Air and air injection undesirable and unnecessary for meeting emission standards with EFI. Each of these EFI retrofit kits earned CARB E.O. numbers without the use of Pulse Air or an air injection pump system.

We left the stock catalytic converter in place and fully functional. Following the Howell and Mopar examples, the Pulse Air inlet tube to the cat got sealed off. So did this upstream exhaust pipe’s pulse port.

A quick way to seal off the catalytic converter’s air inlet is to either cap the tube or pinch the tube’s end and run a simple weld bead on the pinch seam (below). A muffler shop can perform this task in minutes.

The catalytic converter retains full function minus the air supplement. This is emission legal for both Howell and Mopar Performance retrofit EFI systems under their California CARB E.O. requirements.

By contrast, for a stock OEM carbureted engine, if the emission control system originally had air injection, pulse air, any other kind of catalytic equipment, an EGR valve, oxygen sensor, any feedback sensors, a thermal air cleaner assembly or any vacuum devices, each device must be complete, intact and operational in order to pass an emission compliance test. All intended OEM emission components must be in place and operating.

Vehicles with a non-approved aftermarket air cleaner, non-OEM dual exhaust or header, a non-approved ignition distributor, intake manifold, or even an incorrect replacement gas cap, will fail a California Smog Check visual inspection. Each emission-related component must look right and function properly.

Products with a California CARB E.O. number can be installed, but only in accord with the manufacturer’s instructions. If any required part is missing from the OEM emission system or modified, the vehicle will fail the visual inspection during a Smog Check for vehicle registration.

During a California smog check, if a non-CARB approved fuel, vapor, spark, emission, exhaust or induction system component is on the vehicle or engine, the vehicle will fail the visual inspection. This is true regardless of the tailpipe emissions readings.

<< Previous 1 [2] 3 4 5 Next >>

Composed with HTML Editor