The YJ and TJ Wrangler manual transmission and clutch systems are similar and easy to identify. By the late YJ Wrangler era (1993-95), the transmission and clutch platform for YJ models took an identical form to the TJ Wrangler models that followed in 1997. The clutch linkage type, clutch and release bearing layouts and even the specific manual transmission offerings were established during the YJ Wrangler years. Similarly, 3-speed automatic transmissions that were popular during the 1987-95 years carried forward into the TJ Wrangler models.

Use of hydraulic clutch linkage began in the AMC CJ model era, first with GM transplant 2.5L ‘Iron Duke’ engines and later with the AMC engines. Hydraulic linkage extended to the AMC 2.5L four and, eventually, even 4.2L six-cylinder models. These CJ systems relied upon a conventional clutch linkage layout, using a traditional release arm with an externally mounted slave cylinder. A master cylinder at the firewall provided the hydraulic force. A pushrod link from the clutch pedal delivered pressure to the master cylinder apply piston.

The pedal linkage and master cylinder survive from the CJ through the YJ and TJ Wrangler era. The linkage at the clutch and clutch housing, however, changed abruptly in 1987 with the introduction of the YJ Wrangler model. Common to that era, an internal clutch release bearing/slave cylinder replaced the conventional slave cylinder, release arm and release bearing.

In concept, the compact slave/release bearing design eliminates all mechanical arms and links, relying upon the clutch release bearing and its built-in slave cylinder to deliver release force. The system requires only a master cylinder, hydraulic lines and the slave/bearing. This assembly is “self-adjusting” and requires no more attention than topping off or periodically changing the DOT-3 brake fluid in the hydraulic system.

In theory, the design served well. Its downfall was two-fold: 1) if the unit leaked or began to fail in service, the fluid would saturate the clutch disc and cause failure of the clutch assembly and 2) a failed release bearing/slave cylinder required the same labor as a conventional clutch release bearing to replace. In the case of a Jeep 4×4 with a transfer case and two drivelines, the prospect of replacing the slave/bearing assembly duplicated the significant labor involved with a clutch replacement.

By contrast, the 1993 introduction of an external slave cylinder once again restored the Jeep clutch linkage system to a conventional design. A pivot-type release arm and familiar, fully-mechanical release bearing returned. The slave cylinder moved outside the clutch housing and became an easily accessed and serviced unit. In fact, the entire hydraulic linkage system can be readily replaced without disturbing the transfer case, drivelines, transmission or clutch. In the field, you could perform such repairs with minimal tools and resources.

Internal versus External Clutch Slave Cylinders

1987-92 YJ Wranglers use an internal clutch release bearing with a built-in slave cylinder. Whether the model has the “Peugeot” BA 10/5, AX-4, AX-5 or AX-15 transmission, the slave cylinder is an integral part of the release bearing assembly and fits within the enclosed clutch housing assembly. Beginning in 1993, the YJ Wrangler clutch linkage switches to the “external slave cylinder” design, a proven and readily serviceable system.

The example for this article is a 1987 YJ Wrangler, its original engine was a throttle-body injection 2.5L four. This package came with an AX-5 light duty five-speed transmission. In the process of building a vehicle to meet more challenging backcountry environments, oversized tires, family-packed excursions, highway demands, a hardtop and the prospect of toting a cargo trailer, I replace the original 2.5L four with the popular 4.0L inline EFI/MPI six. A more rugged YJ/XJ/TJ type Aisin AX-15 transmission replaces the original AX-5. An additional upgrade is the use of the external slave cylinder package found on later YJs and the TJ Wrangler models.

Illus. 1: During transmission removal, the older AX-5 release bearing/slave cylinder is visible. This system will not be used upon reassembly. Within this chapter, you will find the step-by-step rebuild of the AX-15 transmission and installation/upgrade of the front bearing retainer. This will accommodate the external slave cylinder used with a 1993-up YJ and the TJ clutch housings.

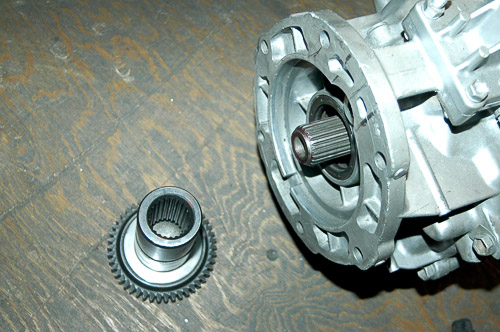

Illus. 2: This is the ’93-up YJ and TJ Wrangler clutch housing with a mechanical release arm and a conventional clutch release bearing. These components and an external slave cylinder will eliminate use of the internal slave/bearing assembly. The transmission requires a new iron front bearing retainer to accommodate the release bearing design. (See new bearing retainer in the assembly of the AX-15 transmission.)

Illus. 3: This is the external slave cylinder clutch housing found on ’93 up 4.0L engines. The transmission pattern is an AX-15 or NV3550 type. The slave cylinder mounts outboard of the clutch housing, easily accessible and simple to remove and replace. Note the pushrod—this part engages the cross-type mechanical release arm at a point opposite the pivot stud.

Manual Transmissions Used in Jeep YJ and TJ Wranglers

At the time Chrysler Corporation purchased AMC/Jeep, the YJ Wrangler was already in production. The partnership of AMC and Renault had produced a variety of innovative products, and parts from Europe found their way into the Jeep Corporation products. Among the obvious components was the introduction of the Peugeot BA 10/5 manual transmission found in 4.2L six-cylinder YJs.

The BA 10/5 is actually a reasonably robust unit and boasts a 22% fifth-gear overdrive. Classified as a light-duty transmission, engineered for a vehicle in the YJ Wrangler’s weight and load class, the Peugeot transmission has provided good service and even proved a candidate for lighter output V-8 engine transplants.

Today, the shortfalls of this unit are parts availability and the likelihood that existing Peugeot transmissions have acquired substantial miles and wear. As a result, the BA 10/5 is often discarded, replaced by the more common AX-15 or later NV3550 transmission. Such swaps entail clutch housing and clutch linkage changes, making this prospect a full-on factory parts “swap” before the project ends. The BA 10/5 does not appear in YJ Wrangler models after 1989. During 1989 production, the Aisin AX-15 came on line.

At the outset of YJ Wrangler production, four-cylinder models received the Aisin AX-4/5 transmissions. (AX-4s were modest four-speed units with 4th gear overdrive and quickly gave way to the AX-5 in U.S. models.) The AX-5 with its 15% 5th gear overdrive survives from the earliest YJ models through the 2002 TJ Wranglers with four-cylinder engines. Built in Japan, the Aisin “AX” transmissions are actually quite durable. They readily match the performance demands of their assigned YJ and TJ Wrangler models.

The Aisin AX-15 has served behind the 4.2L and 4.0L six-cylinder engines in YJ Wranglers and the 4.0L six in XJ Cherokee and TJ Wrangler models. The AX-15 would fit the traditional “light-duty truck” transmission category. As you will discover in the AX-15 rebuilding process, this is a very rugged transmission and should hold up well even with horsepower in the 250-300 range—assuming the transmission is in good condition or rebuilt. I am very impressed with the AX-15’s use of caged needle roller bearings, heavy roller and ball bearings, and its close, selective fit tolerances. Good gear stamina is obvious. Unless you have the need for a retrofit and massive NV4500 truck transmission, the AX-15 gearbox will work well for a long time!

In model year 2000, the TJ Wrangler six-cylinder models switched to the New Venture 3550 transmission. This is also a rugged, light-duty truck type, comparable to the AX-15. The NV3500, a similar design, has served in the Dodge Dakota pickup and similar industry applications. Used behind the 4.0L Jeep engine, the NV3550 will hold up well and also tolerate larger output engine swaps. I would trust this unit, if in good condition or rebuilt, behind a 250-300 horsepower small-block V-8.

YJ and TJ Wrangler Manual Transmission Identification

The manual transmission types used in the YJ and TJ Wrangler are easy to spot. These illustrations will help sort out the differences between the units.

Illus. 4: At left is the AX-15 transmission with an internal slave/release bearing front retainer. In the middle is the AX-5 with an iron front bearing retainer slipped in place to show the difference between internal and external slave designs. (Note the sleeve where the release bearing rides; an internal slave/bearing retainer would lie in front of the transmission.) At right is the Peugeot BA 10/5 unit used from 1987-89 in 4.2L six-cylinder models. It, too, has the internal slave/bearing front retainer plate. Note the shape of the front faces and cases. The AX-15 has an aluminum intermediate plate between the front case and extension/adapter housing. The AX-5 uses an iron plate here.

Illus. 5: The release bearing assembly, separate from the clutch housing and front of the transmission, shows the relationship between the pipes, bearing and hydraulic slave. The assembly is replaced as a rather pricey release bearing/slave unit. Hydraulic pieces are much like a brake system, with a master cylinder and pipes. Fluid is brake type. I use DOT-4 type (compatible with factory recommended DOT-3 type) to resist engine and clutch heat. Recommended DOT-3 will work.

Illus. 6: NV4500 transmission (iron unit at back, rated for 14,500 pound loads) is found in Dodge and GM ¾-ton and 1-ton trucks! Massive, with huge gear sets, these units have found their way into YJ and TJ Wrangler models as the ultimate torque monster. The later, more common units boast a 5.61:1 first gear plus a 27% overdrive fifth. At front is the TJ’s NV3550 (without its front/release bearing retainer).

Late TJ models receive a light-duty NV1500 transmission coupled to the ‘Power Tech’ 2.4L engine. For model year 2005 and newer, all TJ Wrangler applications use the NSG370 six-speed manual transmission. The NV3550, NV1500 and NSG370 units have good warranty records to date. These late units, still under long factory warranties at this time, will be available from the Jeep®/Mopar Remanufactured parts program in the years ahead. Service parts will be available to the aftermarket; however, I would advise your consideration of a Mopar rebuilt/exchange transmission when working with the NV1500, NV3550 or NSG370 gearboxes.

Spline Count Concerns When Upgrading to the AX-15, NV3550, NV4500 and Other Transmissions

The AX-5 is a light duty transmission, and I recommend upgrading to the AX-15 transmission on 2.5L four-cylinder models used for moderate to rugged trail service. This can be done with the use of a 1990s 2.5L Dodge Dakota four-cylinder clutch housing and clutch linkage components.

Illus. 7: Be aware that the AX-15 and NV3550 have a 23-spline output. The AX-5 and Peugeot BA 10/5 units have a 21-spline output. If you upgrade from the AX-4, AX-5 or BA 10/5 to an AX-15, plan on either 1) swapping the NP/NV231 transfer case into the early YJ four-cylinder model equipped with the factory NP207 AMC unit, or 2) purchasing a 23-spline transfer case input for the NP207 from Advance Adapters—while supplies last. (The NP231 swap is my recommendation, a version with provision for shifting the vacuum disconnect front axle.) Shown here is an AX-15 with nearly ½-inch stick-out length of the output shaft (beyond the face of the extension housing). You must use a 23-spline transfer case input gear on the NP231 that matches the transmission’s spline count and also the output stick-out length.

If you plan more than just routine driving and light trail use with your 2.5L four, consider the AX-15 swap. I do not include the rebuild of the AX-5 unit in this book, although the principles involved in AX-15 transmission work will prove helpful. Always use a factory-level service manual when working with an unfamiliar, technical system like the AX-5 or a BA 10/5 transmission.

The NV3550 is also available for retrofitting in place of the AX-15 in six-cylinder models, using factory or recycled OEM pieces from an NV3550 or AX-15 equipped model. (All NV3550 transmissions use an external slave cylinder arrangement and a mechanical release arm for the release bearing.) Keep in mind that the transfer case input and transmission output shaft splines must be compatible in tooth count and stick-out dimensions. For the ultimate torque and horsepower loads, some turn to the NV4500 truck transmission swap, a somewhat complex conversion for a 94-inch wheelbase Jeep 4×4.

Copyright 2010 © Moses Ludel…Enjoy this comprehensive, color-illustrated article and photography by Moses Ludel. The article is available solely at the 4WD Mechanix Magazine website and can be viewed here as often as you like. If you wish to share the article with friends or professional colleagues, please refer them to 4WD Mechanix Magazine website: www.4WDmechanix.com. As copyrighted material, this article and the photography cannot be copied or distributed in any other form.—Moses Ludel