Enjoy the many detailed, traditional ‘Q&A’ exchanges in these article columns…’Q & A’ has now moved to open, interactive forum discussions. Visit the forums, you’ll want to join—for free!

Have technical questions about your Jeep 4×4, popular 4WD truck, SUV, ATV, UTV or dirt motorcycle—or welding and metal fabrication? The 4WD Mechanix Magazine ‘Tech and Travel’ Forums now feature enthusiastic discussions and input from members and our staff—including comments from Moses Ludel…

Want to discuss your technical and outdoor interests with like-minded enthusiasts? Check out the 4WD Mechanix ‘Tech and Travel’ Forums! Click here for a guest visit to the forums!

4.0L MPI Six ‘Banging’ Without Warning!

From: John A.

Sent: Sunday, August 12, 2012 4:54 PM

To: 4WD Mechanix Magazine

Subject: Should I just shoot it?

Help! I have a 91 Comanche 4.0L 5-speed. Have owned for 4+ yrs. 260k miles. Good overall condition. Has always run great.

Did a full valve job, new lifters, oil pump about 2 yrs ago.

About 2 months ago engine started with an erratic miss. Kept getting worse, so, I started working on it. She “bucks” terribly at times, mainly when accelerating gently, but can be when cruising. Makes you feel like it is going to tear the driveshaft out from under the poor thing. Will jerk 2 or 3 times in one second. Not just a skip, but a hard “bang, bang, bang” on the entire drivetrain. You have to depress clutch fast to keep it from tearing something up. (have checked for a cracked flywheel, seems OK).

Replaced TPS, Idle Motor, Dist Cap, Plugs, Wires, Fuel Filter. No better, took it to a shop. They said ECM, so replaced that.

Back to shop, 3 mechanics and an analyzer. Smoke test, fuel pressure (35 psi), vacuum (15″). They have no clue.

Replaced O2 Sensor, Speed Sensor, Intake Temp. Sensor, NO better. Replaced distributor. Checked all grounds, fuses, relays.

Still doing the same thing. Cooling fan doesn’t run either, have it hot wired.

So, any suggestions? Anything will be much appreciated. Built an all-aluminum over cab topper recently. Am in process of total re-upholstering truck interior. Plan to keep, is my only vehicle.

Thank you in advance,

John A.

From: 4WD Q & A

Sent: Sunday, August 12, 2012 8:32 PM

To: ‘John A.’

Subject: RE: Should I just shoot it?

John, two things come quickly to mind:

1) Have you checked the crankshaft position sensor at the back of the block (upper converter/bellhousing, 11 o’clock looking from rear of engine)? A dirty sensor, or defective sensor, will cause these symptoms. Oil from the rear of the engine (main seal, typically) can even cause the sensor to fault. Check sensor wiring for a short, too.

2) You have fuel pressure…Do you have fuel volume, too? A clogged tank pickup or other restrictions, or even a defective fuel pressure regulator on your two-rail system, can cause a problem.

We can take this further if necessary…I’m full of ideas, just furnish details!

Moses

More 2.5L TBI Issues…

From: James M.

Sent: Friday, November 25, 2011 7:08 PM

To: 4WD Mechanix Magazine

Subject: Engine stalls and dies

I have an 86 comanche. it runs for a while then stalls (sputters when applying throttle) and then dies. turn off key and cranks right backup.

Any idea?

James M.

From: 4WD Q & A [mailto:qanda@4WDmechanix.com]

Sent: Saturday, November 26, 2011 4:01 PM

To: ‘James M’

Subject: RE: Engine stalls and dies

James…173 (2.8L) V-6? Sounds like an oxygen sensor or EGR valve issue. If a 2.8L, you have a carburetor with feedback…Does the engine run okay after the restart or run for a while and stall again?

Have you changed the fuel filter lately?

Moses

From: James M.

Sent: Saturday, November 26, 2011 4:31 PM

To: 4WD Q & A

Subject: Re: Engine stalls and dies

Fuel filter change was the first thing I did

It is a 2.5L. It runs fine after restart for about a mile then dies again.

Connected by DROID on Verizon Wireless

From: 4WD Mechanix Magazine

To: James M.

Subject: RE: Engine stalls and dies

Date: Sun, 27 Nov 2011 15:13:14 -0800

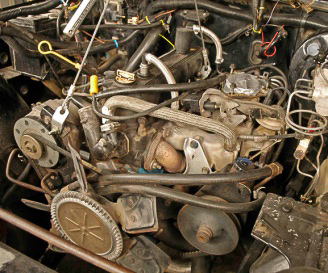

James, I have a lengthy 2.5L TBI article at the magazine. Give it a read:

https://www.4wdmechanix.com/Tuning-and-Troubleshooting-the-2.5L-Jeep-TBI-Four.html

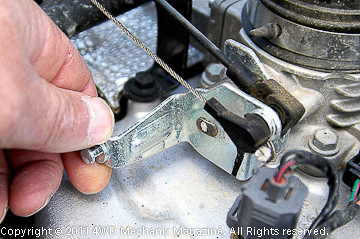

The crankshaft sensor pickup at the flywheel is a common trouble spot, often causing stall and other issues. Oil seepage or debris can cause trouble at the sensor pickup. I talk about the device in this article.

Moses

From: James M.

Sent: Monday, November 28, 2011 7:31 PM

To: 4WD Mechanix Magazine

Subject: RE: Engine stalls and dies

Thanks for the help. I have see it said to use O2 sensor safe cleaner. Is Sea Foam Deep Creep a good for this.

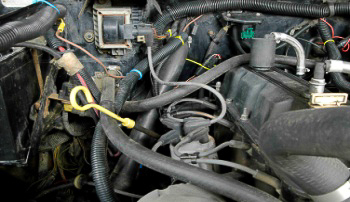

also can you look at the attached pic an help Identify these loose connections.

James M.

Reply from Moses…

Hi, James…Vacuum lines need a circuit diagram to trace out. Do you have a vacuum diagram?

Not sure about Sea Foam Deep Creep, haven’t used the product. You have a TBI system. Have you read the suggested material at the magazine site? Here’s the link:

https://www.4wdmechanix.com/Tuning-and-Troubleshooting-the-2.5L-Jeep-TBI-Four.html

Moses

TBI 2.5L Engine Tuning and Engine Performance Quirks

Hello! First, thanks for the great books, Moses, and for answering my questions! To begin, Mopar used to issue a book on Jeep engines, and I’m not sure how to get a copy. Any idea where to get a copy? I have a 1989 Wrangler YJ with the mighty TBI 2.5L AMC four!—Brian L.

Brian, the book is Mopar Jeep Engines, Speed Secrets & Racing Modifications for Jeep-Built 4, 6 & V-8 Engines, published as Mopar part #P4529529. It covers AMC-design engines, winning formulas from off-road and compact truck racing of the late ‘80s.

Compiled from factory workshop manuals and racing data, this is the only official reference to racing these AMC engines. If you cannot find a copy through used literature sources, secure a copy of the Mopar 1989 Jeep Service Manual, a two-book set that includes your YJ Wrangler.

Brian’s questions—continued…

My 2.5L has non-adjustable, stamped steel rocker arms. The Federal Mogul stock pushrods for this are 9.486″ length, and Clevite’s are 9.520″. What kind of lifter preload should I have when it comes to fitment of pushrods? I’m getting preload ranges from 0.085″ to 0.100″. It is my understanding that lifter preloads should be more in the 0.030”-0.040″ range, my reason for double-checking. The engine is a stock remanufactured long-block from ATK and now has 15K miles on it. The vehicle has just over 111K miles, and I installed the remanufactured engine at 97K. The camshaft is within a few thousandths of new specs for lobe height and duration. Questioning local engine machine shops has left me with a variety of answers, and I’m not too sure which ones to trust. (One shop reassembles everything and doesn’t check preloads.) It seems like this type of engine runs pretty warm although it may be just this particular unit. I have noticed that after 30 minutes or more of freeway driving, at idle, the oil pressure drops much lower (to 20-25 psi) than where it usually runs in town (40 psi). Bringing it just off-idle brings pressure back up to around 40 psi. It appears that this is due to the oil being so hot, as though its viscosity really thinned out temporarily. Once the motor idles for a while or is off for a bit, it returns and stays at the more normal 40 psi. Taking the vehicle on extensive or even moderate off-road use has the same effect in increasing the oil temp. When the engine gets this hot, and I notice the oil pressure, I can also tell that it is much more apt to want to knock/ping if I am doing something that requires mild lugging at idle. Is this high oil temp scenario typical for the 2.5 liter? Could the EGR valve and flame temps too high create abnormally high coolant and oil temps? I tried a new EGR valve, which didn’t seem to fix the temps. Should I install an oil cooler? The vehicle sees 90 degrees F to -45 degrees F. If an oil cooler is called for, which style may perform better: one with an electric fan and thermal switch or an older-fashioned unit with a built-in thermal valve assembly?

Moses replies…

Brian, oil temperature does play a role here. The “normal” factory-rated oil pressure for a 2.5L four of your vintage is a minimum of 13 psi @ 600 rpm and maximum of 37-75 psi @ 1600-plus rpm. (Normal at an 800 rpm warm idle speed is 25-35 psi, which your engine may also achieve.) Despite the drop you describe at idle when hot, this is still adequate for lubing the engine. An engine oil cooler, unless thermostatically controlled, would be overkill in your cold winter conditions…If you do either kind of thermal control, make sure that there is no winter issue with oil temps being too cold…Also, if you want to know how “hot” the oil is actually getting, try using an infrared-sensing thermometer to check the surface temp at the oil pan after running. You can spot check the engine at the valve cover, block and timing cover. The block surface temp should pinpoint effectiveness of the cooling system. Check the radiator for hot spots or lack of flow, using the infrared to track heat…This can be a simple and effective diagnostic tool! As for the EGR valve, this valve actually lowers the upper cylinder temps if working properly. Its purpose, reducing the NOx emissions, demands lowering the upper cylinder temps to below 2500-degrees F. Without the EGR working properly, temps can reach 4800-6000-degrees F, much like an acetylene torch! I always recommend leaving the EGR in place and making sure it functions correctly…Pushrod lengths, which affect the valve clearance, are critical. (If needed, adjustable pushrods are available from Clifford Performance for the 4.2L inline six and other AMC-derivative inline engines.)

There are two ways to measure lifter clearance: 1) preload, which is essentially zero valve lash with the plunger fully extended then add a fixed amount of compression of the lifter plunger and 2) lifter plunger travel, measured at the valve stem-to-rocker arm gap, with the lifter’s plunger fully collapsed. Non-adjustable stamped rockers usually can only be checked for lifter travel with the plunger collapsed. Correct specs for plunger or valve stem clearance (with the plunger collapsed fully) should be available through ATK or Clifford. Make sure you measure clearance at the correct reference point—specified typically as the valve stem-to-rocker arm gap with piston at TDC of its compression stroke, both valves closed and seated, the hydraulic lifter collapsed (without any oil in the lifter). Specified clearance should account for the valve rocker arm ratio. (The stock ratio is 1.6:1 for a 1989 2.5L Jeep engine.) The blueprint build of an AMC inline six or four should include cutting the installed valve stem heights to compensate for both the cylinder head resurfacing and the amount of valve seat inset from reconditioning the valve seats…A bled-down clearance of 0.085″-0.100″ at the rocker arm-to-stem gap is not out of the ordinary for modern hydraulic lifters. (Engines like Ford’s ‘FE’ big-block V-8s rely on pushrods in various lengths to correct lifter clearances.) Mopar manuals do not offer a specification; they assume that the cylinder head has not been surfaced excessively, pushrod lengths are correct, head gasket thickness is right, and the valve seat depths and valve stem heights are correct. It’s wise to confirm this and check actual bled-down lifter clearance if possible…Engines need adequate valve clearance to permit valves to seat. Shorter Federal-Mogul pushrods may be for remanufactured engines with a surfaced cylinder head and ground valves and seats. If your 0.085”-0.100” is clearance measured at valve stems-to-rocker arms with the lifter plungers collapsed, note that Ford ‘FE’ V-8s (with a 1.73:1 rocker ratio and non-adjustable rocker arms) call for 0.100”-0.150” gap at the valve stem-to-rocker arm with the lifter plunger collapsed. (Ford FE pushrods come in different lengths for adjusting valve clearance.)

Brian’s 2.5L tuning issues—continued…

I have found on this vehicle a normally energized-closed solenoid valve that controls vacuum to both the EGR valve and the fuel vapor charcoal canister. When I did the engine change, I put on a new EGR valve and replaced the rest of the engine sensors. Jeep discontinued supplying the G.M. Rochester vapor canister; it appeared to be intact. Recent troubleshooting led me to the canister’s vacuum-operated control diaphragm. It turns out that this little rubber diaphragm has holes in it from being 18 years old. With a breach in the diaphragm, the vacuum that is constantly applied at the canister purge port can leak through and back-feed through the diaphragm to the canister’s purge signal port. Instead of the EGR solenoid valve controlling the vacuum to the canister’s purge signal port, there was vacuum continuously coming from it. This was no real problem except that the EGR valve is also tee’d into the line for the signal port. When the canister back-fed vacuum, it constantly supplied vacuum to the EGR valve. This kept the EGR valve always on, during every aspect of driving. I don’t know how long this went on, but when I recently tested my EGR valve, it had failed. I have replaced it and now am shopping for a replacement canister. Even with the canister’s interlink to the EGR valve disabled so that the EGR solenoid controlled just the EGR and not the vapor canister, and even with a new Mopar EGR valve, the engine oil temp still gets so hot that it operates as I’ve described…Brian

Reply from Moses…

Brian, the EGR open at idle will dilute the mix and confuse the oxygen sensor into leaning out the air/fuel mixture…Such a lean mix can cause engine heat-up…This could cause the oil temp to rise, too. The EGR is a valuable device that lowers upper cylinder temperatures. It is also passive and has little impact on performance with the 2.5L four.—Moses

Brian added this question…

One last question that I don’t believe is related: This motor has vacuum fluctuations from 20″/hg to around 15″/hg. I can hear the idle hunt a bit, and see it on the tach—up to 200 rpm fluctuation at times, sometimes barely any. Any vacuum gauge sits there and flutters very fast. The vacuum flutter seems to narrow when the engine rpm is brought up, yet it still does it to some degree. After going through every vacuum line on the engine to hunt for possible leaks (hence finding the charcoal canister to be bad) and after double-checking intake and exhaust manifolds (the engine pipe and rest of the exhaust system are all new), I am unable to figure this one out. I have verified all my valvetrain to the point of degree’ing everything out, removing valve springs and checking stems-to-guides for any excessive wear, etc. Do I need to remove my exhaust manifold and check for cracks, as the factory manifolds love to crack at the Y’s, which are hidden by the preheat ducting? Is it possible that I am seeing the vacuum flutter from the power impulses since it’s just a 4 cylinder, whereas a 6 or 8 might be smoother? Would some small cracks in the exhaust manifold have any effect on intake vacuum?

Reply from Moses…

Four-cylinder power pulses should not be a factor. Vacuum flutter can be valves that do not seat completely. This can cause engine heat-up as well. Pushrod length and/or valve stem length control the lifter clearance on the AMC fours and sixes. The rebuilder must restore lifter clearance, and if valve clearance is too close, valves will not seat, which worsens at higher engine temps…This can cause heat buildup and eventually burn valves and seats.

The EGR not seating at idle/low speeds also causes a vacuum drop or vacuum fluctuation. Lean fuel mix, air leaks, ignition timing errors and degrees of spark advance will also affect vacuum. Ignition timing is electronically controlled on your engine, with sensors feeding input to the module. The oxy-sensor “averages” oxygen readings from all four cylinders and adjusts the air/fuel ratio accordingly. 2.5L fours are reasonably smooth by nature and shouldn’t pulse or surge dramatically. This, again, points to dilution from the EGR or a vacuum leak, which can also be caused by an EGR that does not seat properly at idle. Make sure that the throttle position sensor is working properly and giving the right voltage readings from idle through open throttle…A defective TPS can cause idle roughness, fuel mix problems and tip-in issues.

Since you’ve ruled out valve timing and lift issues, the best diagnostic steps now would be a cylinder leakdown test (engine still, with each piston