How-to: Safer TIG Electrodes and the HTP America Tungsten Sharpener

In this HD video how-to, Moses Ludel discusses TIG tungsten electrode types and safer choices. He demonstrates the use of the HTP America Tungsten Sharpener and how to shape optimal tungsten tips for inverter TIG welding of aluminum, carbon steel, alloys, and stainless steel. (Open to 1080P full-screen mode for optimal viewing!)

HTP America supplies welders, accessories and consumables. At left are safer TIG lanthanated and ceriated alternatives to red thoriated (slightly radioactive) tungsten electrodes. Our shop uses an HTP America 221 inverter TIG machine that welds optimally with ceriated and lanthanated, non-radioactive electrodes. At right is the HTP America Tungsten Sharpener and a “green tip” pure tungsten electrode for traditional aluminum welding. With an A.C. inverter TIG welder, the tip can be sharpened to a truncated point for aluminum. With an A.C. capable machine like the HTP America 221, pointed ceriated or lanthanated electrodes now work better than traditional, pure “green” tip electrodes with a balled end!

Note: Color coding of current tungstens can be confusing. Red is always thoriated and slightly radioactive. Green is always pure tungsten or the traditional aluminum electrode (not true for contemporary inverter technology A.C.!). Gold should be lanthanated; orange should be ceriated, although ceriated can sometimes be gray. Zirconiated is often brown, and there are mixtures that blur the color lines. To avoid confusion, always get your electrodes by both the advertised composition and the tip color.

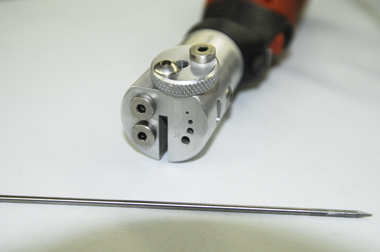

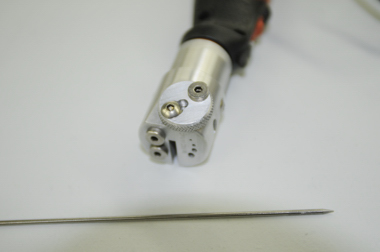

At left is the top view of the HTP America Tungsten Sharpener. This base model comes with three common collet sizes and a fixed 22-1/2 degree grinding angle, precise and suitable for most uses. The tip can be positioned for either angled grinding or for blunt end grinding (through the access holes at the top of the sharpener head). To extend service life, the grinding wheel can be turned over. At right, the slot at the side of the head is for notching damaged tungsten ends. After notching, the damaged tip section can be snapped off with a pliers. Starting with uncontaminated tungsten prevents damage to the grinding wheel from carbon steel or stainless steel.

At left is the adjustable tip positioning thumb-screw. This moves the tungsten to a fresh area of the grinding wheel. At right, the pure tungsten has been prepared for use with an HTP America 221 Inverter TIG machine. Traditionally, aluminum welding required “balling” the pure tungsten electrode end. With inverter TIG welding, sharpening the tungsten tip to a “truncated” point (slight blunt end) works much better than a sharp needle point—which can easily overheat, break loose and contaminate the weld!

With a contemporary A.C./D.C. inverter TIG machine and technology, ceriated and lanthanated electrodes work better for most aluminum welding than pure tungsten. For A.C. inverter machines, welding aluminum with these electrodes and a truncated, point-ground tip help maintain a superior, pinpoint arc.