<< Previous 1 2 3 [4] 5 Next >>

MSD Atomic EFI: Our Installation Approach

Caution: If your vehicle must comply with emission regulations or inspections, confirm the emission legality of this Atomic EFI system for your specific vehicle and engine type before installing Atomic EFI. Review the manufacturer’s literature. If you intend to register/license your Jeep for use in California, any EFI conversion kit or aftermarket carburetor must have a Clean Air Resources Board (CARB) Executive Order exemption number that approves the product’s use for your specific vehicle and engine type. Other states now have similar regulations. Check with state and local requirements before purchasing the MSD Atomic EFI kit.

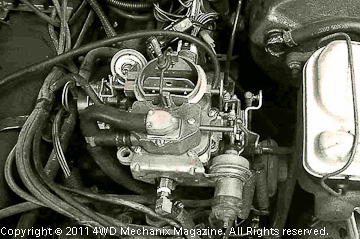

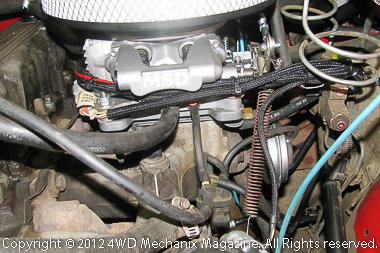

258/4.2L AMC/Jeep inline six-cylinder engines date back to 1971, first used in 1971 J-trucks then offered in 1972-up CJ models and a handful of I-H Scout II applications. Two-barrel manifolds on 258 engines can be found as early as some 1976-79 models. Shown here is a Jeep YJ Wrangler 258, the last use of carburetion on a Jeep inline six.

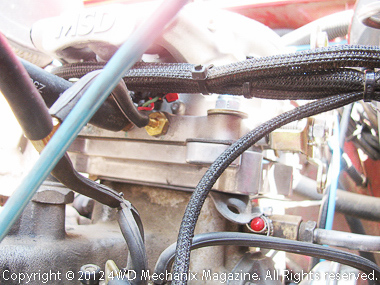

Our installation focused on the Jeep YJ Wrangler 4.2L inline six-cylinder engine and chassis (1987-90 model years). 1981-86 Jeep CJ 4.2L models are similar, also using the Carter BBD two-barrel carburetor and a hefty emission control package. These vehicles appear busy under the hood, with wiring, vacuum circuits and odd devices everywhere!

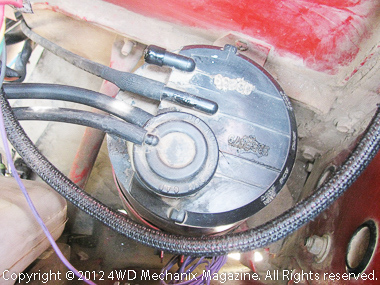

By 1980-81, 258 engines abandoned the one-barrel carburetor. The BBD(shown) became a mainstay for the last round of carbureted Jeep CJs and YJ Wrangler 258/4.2L engines.

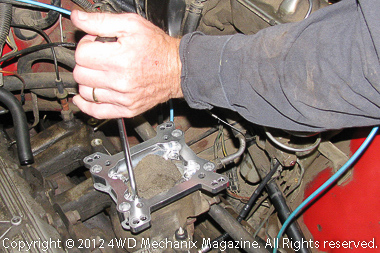

A two-barrel intake manifold was necessary for our method of adapting the MSD Atomic EFI. There are currently no aftermarket four-barrel intake manifolds with a California CARB E.O. number or provision for EGR.

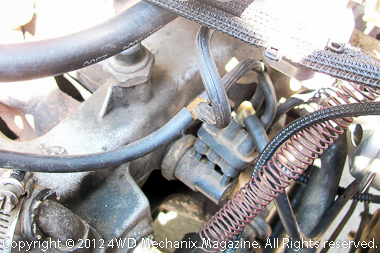

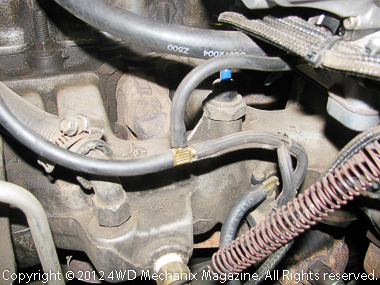

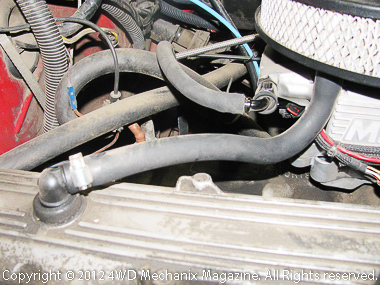

We kept the coolant temperature override switch (CTO). This factory device is a vacuum switch to operate ignition vacuum advance and EGR functions at specific engine temperatures.

The CTO fits at the intake manifold, between the coolant temperature sensor and the carburetor mounting surface. This OEM Jeep 4.2L CTO switch has five ports (three on the left; two on the right).

On the 1989 YJ Wrangler model, the first port on the left (closest to the manifold) is capped off for Jeep OEM use.

For the CTO vacuum source, we removed the plug from the “ported vacuum” port on the Atomic EFI throttle body and installed a 1/8” NPT x 1/8” barbed hose fitting. (Note the new brass fitting.) A short vacuum line connects that port to a 1/8” tee.

We ran one side of the tee to the vacuum advance unit on the distributor. The other side of the tee went to the third port on the left of the CTO. This port uses a factory tee that loops to the first port at the right side of the CTO.

For our approach, CTO and engine coolant temperature still govern distributor vacuum. This is just like the original Jeep 4.2L (OEM) vacuum circuit.

A vacuum line routes from the second port on the left side of the CTO to the evaporative canister port labeled “dist vac”. This CTO port is for distributor vacuum and vacuum to the EVAP canister’s “dist vac” port.

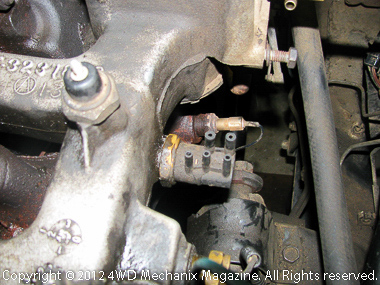

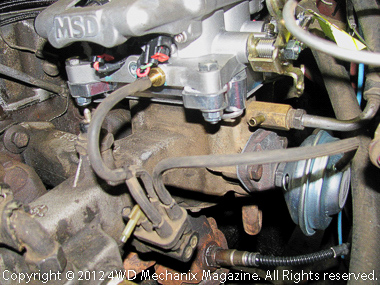

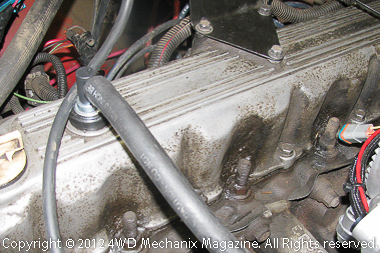

To maintain the OEM EGR system, the EGR valve remains on the intake manifold. The new OEM replacement EGR valve (shown) mounts below the Atomic EFI throttle body, similar to a carburetor application.

CTO hoses fitted at CTO switch. Ported vacuum comes from MSD Atomic EFI port with brass fitting. OEM fitting with steel pipe (above the EGR valve) provides brake booster manifold vacuum source with a port for PCV.

We routed a vacuum line from the EGR to the second port on the right side of the CTO. This vacuum hose routing strategy provides distributor and EGR vacuum through the engine coolant temperature override or original equipment (OEM) CTO switch.

At left is a new, OEM replacement EGR valve for the 4.2L inline six. At right is the device that may have been on this engine since 1989! The old valve has soot and carbon buildup that leads to sticking, leaking and engine tune issues—especially for EFI.

The evaporative canister has four ports. The “dist vac” port is one. Another, marked “pcv”, routes to the PCV (positive crankcase ventilation) system, which requires a manifold source vacuum signal.

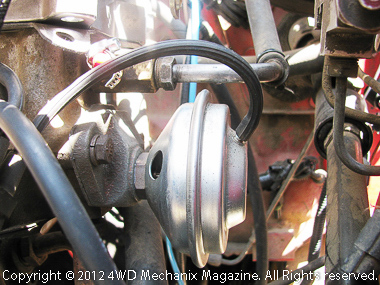

The PCV valve (shown) requires manifold vacuum. One source of manifold vacuum on the 4.2L six is a port and fitting located above the EGR valve. The power brake booster line attaches to that fitting. We chose to route PCV from the large port at the Atomic EFI base (below).

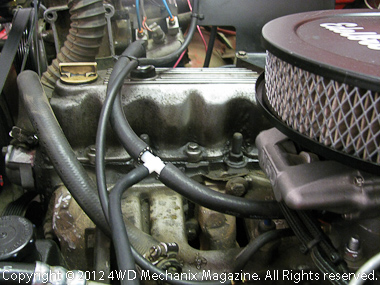

The manifold vacuum port (larger hose) on the MSD Atomic EFI throttle body comes plugged. We removed the plug to install a 1/4” NPT x 3/8” barbed fitting in its place. The larger hose runs to the PCV valve.

The Atomic EFI manifold vacuum port provides the 3/8” vacuum hose source for the PCV valve located at the front of the engine’s valve cover. A “T” in that hose can provide an additional vacuum source for the PCV port at the EVAP canister. (See below.)

For the PCV valve and “pcv” port at the EVAP canister, manifold vacuum can be sourced at the bigger manifold vacuum port on the Atomic EFI. A “T” splits this hose to the PCV valve and the evaporative (EVAP) canister’s “pcv” port.

To complete the closed crankcase ventilation system, route a hose from the fresh air intake (located on the valve cover at the back of the engine) to the air cleaner. For this crankcase fresh air source, we used an aftermarket air cleaner with a hose fitting located inboard of the air filter element.

Edelbrock’s Pro Flow air cleaner, part number 350-1203, has a knock-out in its base. An included hose fitting attaches at the opening. With the crankcase fresh air hose installed, the air cleaner filters air for both the EFI air intake and the crankcase fresh air supply.

There is also a port on the evaporative emissions (EVAP) canister marked “tank”. This remains a hose to the fuel tank and is important for the EVAP system’s operation. The “tank” hose and other EVAP hoses at the Jeep Wrangler’s fuel filler and fuel tank should be left in place; these hoses complete the EVAP’s closed evaporative emissions system.

The last EVAP canister port is marked “carb bowl”. Since the MSD Atomic EFI does not vent fumes from a float bowl, we capped off this port with a vacuum cap of the correct size. A hose clamp on the cap can assure a secure fit.

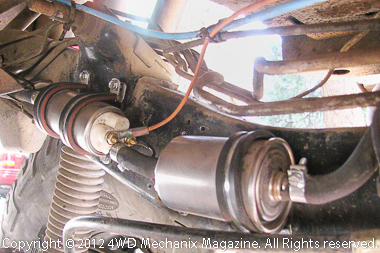

Fuel supply is from a high pressure fuel pump provided with the MSD Atomic EFI kit. There are two ways to use the fuel supply: with a return line to the fuel tank or without a return line. For our project, we elected to use the MSD fuel supply without a return line; however, either option was available.

Note that many emissions era Jeep 4.2L engines do have a return fuel line provision. On a 4.2L Jeep YJ Wrangler, the return is a third pipe/hose originating at the OEM fuel filter. Shown here is the single hose at the fuel pump supply end; the two hoses at the carburetor end of this filter are the fuel line to the carburetor and the return line to the fuel tank.

With carburetion, the return fuel flow keeps fuel cooler, prevents fuel stagnation and reduces risk of vapor lock. We had this return line option for the Atomic EFI but chose to try a single line first. To date, our system works fine with the single fuel supply line and no return.

MSD provides high grade EFI fuel hose and clamps. Especially on an off-road rock crawler, route hoses out of harm’s way!

Shown here is the MSD heavy-duty EFI fuel hose. Follow guidelines shared in the MSD instructions for this installation. For safety sake, secure all hoses and fittings as outlined in the MSD instructions.

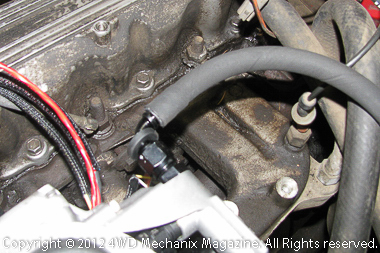

For wiring, we carefully reviewed the Jeep factory wiring schematics. Our installation required splicing into circuits that provide correct voltage readings for components like the MSD Blaster 2 coil (above) and digital MSD 6A box (below).

A volt-ohmmeter can verify voltage and trace circuits according to the MSD system requirements. There are specific modes to confirm: key on voltage, key in cranking mode voltage and key off to assure zero voltage.

The MSD 6-series box has its hookup, and we followed the useful MSD schematic for a typical Ford-DuraSpark system (similar to AMC/Jeep). The MSD Blaster 2 coil needs a pure 12V signal, not resisted current like the OEM coil. These concerns determined our various sources for fused power to the coil, the MSD box leads and the Atomic EFI leads—including the fuel pump signal.

MSD Atomic EFI wiring harnesses are well engineered with straightforward, easy hookup requirements. Make sure, however, that you test your Jeep voltage sources in the key-on, cranking and key off modes.

Our aim was to create a basic ignition system with correct spark advance functions. We also kept engine and chassis emission devices that did not conflict with the MSD Atomic EFI system.

Carburetor related solenoids were disconnected with vacuum sources capped. So were electric switches and vacuum circuits that would interfere with the fundamental needs or efficiency of the ignition circuit, the emission system or the Atomic EFI.

The EGR and distributor vacuum signals became streamlined, interrupted only by the CTO switch. We also eliminated sensor duplicity around items that Atomic EFI provides. Vacuum devices for the Sole-Vac functions and deceleration valve were taken off line. Any unused vacuum ports were capped to prevent leaks.

For the ignition distributor wiring with the MSD 6A digital box, we used the MSD wiring details for a Ford DuraSpark ignition. To see the MSD instruction manual for MSD Atomic EFI, available as a download from MSD, click here. For other installation schematics, like the MSD 6-series digital box wiring for a DuraSpark distributor, visit the MSD website.

The OEM Motorcraft distributor and ignition module fits Ford DuraSpark guidelines—and to some degree the wire color schemes. We constantly referred to the Jeep OEM shop manual diagrams for vacuum circuits, devices and wiring schematics.

The only other issue we encountered was the factory YJ Wrangler tachometer function. This was quickly remedied by MSD’s Tach Adapter P/N 8920, which serves as an interface between the MSD 6A box, the Motorcraft ignition distributor signals and the factory tachometer in the Jeep YJ Wrangler.

<< Previous 1 2 3 [4] 5 Next >>