Enjoy the many detailed, traditional ‘Q&A’ exchanges in these article columns…’Q & A’ has now moved to open, interactive forum discussions. Visit the forums, you’ll want to join—for free!

Have technical questions about your Jeep 4×4, popular 4WD truck, SUV, ATV, UTV or dirt motorcycle—or welding and metal fabrication? The 4WD Mechanix Magazine ‘Tech and Travel’ Forums now feature enthusiastic discussions and input from members and our staff—comments from Moses Ludel…

Want to discuss your technical and outdoor interests with like-minded enthusiasts? Check out the 4WD Mechanix ‘Tech and Travel’ Forums! Click here for a guest visit to the forums!

NP231 Shifting and AC-Heating Issue

From: John R.

Sent: Sunday, October 02, 2011 11:59 AM

To: 4WD Mechanix Magazine

Subject: ’91 XJ NP 231

Hello Moses,

I recently purchased my first Jeep and more recently a second “donor Jeep” as the first has some issues, nothing drastic though considering it’s a 91 with 258k on it. The issue/s that I could use your advice with are #1 the transfer case seems to work good in LOW range but in HI range it wants to jump in and out of gear and when it does lock in there seems to be an excessive amount of drag in the driveline almost to the point of brake application. My question is would it be an internal issue or is there a switc going /gone bad in the system, vacuum leak, or ????? I have had other 4X4 vehicles and never had this type of issue present itself. The other issue is in the heat/ac system, there is a gremlin that likes to change the air flow from the floor to the defroster and back depending on accelerator pedal pressurer. I have changed the check valve on the intake manifold as that would be the most common suspect but the villian is still at large.

Any advice on this would be greatly appreciated since winter is fast approaching the Inland Northwest.

John

A. Hi, John…Sounds like the NP231 (presumed unit) is not engaging High Range completely. The bind is a between-gears position of the shift mechanism. Check the obvious and accessible first: binding external shift linkage, linkage interference preventing full engagement, etc. If none of these remedy the situation, there is an internal linkage issue and time for a teardown. This is not likely a chain or planetary issue but will become one from driving in this condition.

Interesting that you should have the AC/heater flow issue. This has developed on the ’99 XJ, and I need to remedy it! The center flow suddenly stops, then resumes flow if the throttle is released. This is clearly a manifold vacuum or system vacuum issue. You did the smart thing by replacing the check valve, although there is also a vacuum reservoir and hoses that can impact the vacuum supply. In my case, I know this is a vacuum issue, as decelerating will open the flap.

Check the AC/heat vacuum system with a hand vacuum pump that can simulate vacuum supply. See if and where a leak occurs in the reservoir, check valve or vacuum hose circuit. Also make sure the door opening motor (vacuum) is not leaking. There could be a diaphragm leak here. Let me know what you find, we’re both in the same dilemma, and winter can mean sub-zero temps by January in our neighborhood!

Regards,

Moses

Picking the Right XJ Cherokee!

Hi, Chad…Nice to get your updates! See my comments below…

Regards,

Moses

—–Original Message—–

From: Chad A.

Sent: Friday, September 23, 2011 6:38 AM

To: 4WD Mechanix Magazine

Subject: XJ Cherokee

Q. Moses,

I am looking at buying an XJ Cherokee for a commuter vehicle. Are there any specific years that are better than others? My plan is to keep it fairly stock.

Chad

A. 1998-2001 would be my best picks and choices for a “debugged” XJ Cherokee. Best years and cost effective: 1998-99. We have a ’99 with 136K miles (see column’s lead photo), just took it 720 miles on a two-day trip to California, high ambient temperatures, lots of traffic, steep mountains, you name it—very reliable and sturdy, still on the original powertrain. We take on some serious, rocky trails as well.

XJ Cherokee Project Prospects

My brother bought a 1992 XJ Cherokee 4-door new, and it now has 260K miles. He plans to buy a new vehicle this spring. I’ve been offered the Cherokee at no cost. I always liked the vehicle and enjoyed projects like your ’99 XJ Cherokee Trail Runner. Should I take my brother’s XJ and make it a project off-roader? The vehicle is in good-to-decent condition, all original except for the water pump and the obvious—brakes, battery, tires, shocks, etc. It does need some TLC and minor interior work but seems mechanically sound. I am worried about the electrical system and other unknowns that may pop up after I start putting money into the truck. What should I expect to change or repair? What are your thoughts about this year and model Cherokee?

Thanks,

Joe Mac

Joe, the number of XJs produced from 1984-2001 was huge—over two-million units. This makes the XJ one of the most popular platforms in Jeep history and a coup in terms of donor vehicles, parts sources and aftermarket attention. The used XJ entry cost is always reasonable—often better than the utility model CJs and Wranglers. Shared parts with the YJ and TJ Wrangler keep vital replacement pieces available and relatively inexpensive, especially when compared to models like the Grand Cherokee, a Toyota product or even G.M. and Ford SUVs. The stats suggested it, and the XJ Cherokee has always been a great vehicle—both on- and off-road

Yes, this is the same ‘XJ!’ We found the stock ’99 with only 94K miles on the odometer and a $5600 price tag—worth every dime! Once home, $8,600 in parts and 160 hours of labor later, we’re at Moab! Is this what you have in mind? All it takes is time and money!

My first “compact” Cherokee test came about when AMC introduced the 4.0L Renix MPI engine in 1987. I wheeled a spanking new XJ from Southern California to the Jeep Cup Rally near Placerville, California. What immediately struck me was the handling, on the highway and in the off-road sections of the rally—so much better than the white knuckle 80”-97” wheelbase Jeep utility 4×4 models! Despite speculation that a unibody was too “car like” for a Jeep, the design provided a power-to-weight ratio substantially better than competitive 4×4 SUVs of the period. The engine boasted 177 horsepower and easily compensated for altitude with its feedback looped EFI and oxygen sensor.

That said, there are several category years for the XJ. The first was the V-6 G.M. powered era, 1984-86, plagued by the same issues G.M. had with the 2.8L six in its own vehicles. Severe rear main seal and crankshaft failure problems were partially remedied by G.M.’s ’85-’86 model years with a better crankshaft design. However, the ’84 models suffered from crankshaft failures, and the ’85 engines still used a poor two-piece rear main seal design. I know this well. As a fledgling freelance journalist, I moonlighted at a GMC truck dealership and did warranty work on 1983-84 models. Crankshafts broke on these engines when barely out of the showroom, typically an A/C equipped engine.

It’s surprising that AMC did not use its own 4.2L six in the Cherokee initially. The 4.0L that emerged in ’87 was essentially a 4.2L derivative. The standard, peppy AMC carbureted 2.5L four went to TBI in ’86, and in ’87, MPI appeared on the “new” 4.0L XJ inline six. The engine is standard issue AMC inline 199/232/258 design, and from ’87-’90 uses the French Renix MPI system, not bad, a product of the AMC/Renault joint venture. When Chrysler purchased AMC-Jeep, they kept the Renix systems through 1990, then in 1991, the AMC 2.5L four got Mopar MPI and the 4.0L gained a Mopar system, too. This bodes well for your 1992 XJ prospect…

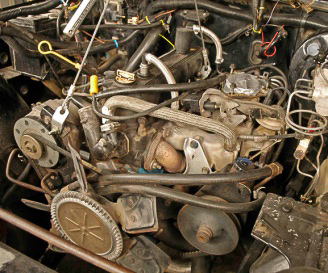

Here, I’m pulling this 2.5L AMC TBI four from an ‘87 YJ Wrangler. AMC was smart, sharing many components between the Wrangler and XJ Cherokee. Wide use and economies of scale keep maintenance costs and current parts availability reasonable. The rugged 2.5L four held up far better than the 2.8L G.M. V-6!

The ’87-up XJs also feature the AW-4 automatic. This is a virtually bulletproof transmission, a good match for the essentially bulletproof 4.0L engine. Japanese built by Aisin-Warner, the 4-speed overdrive unit serves in XJs through 2001, improved steadily over that long season. Maintained properly, these AW-4s give very little trouble. Your brother’s XJ likely has the Dana 35 rear axle if equipped with ABS. The Chrysler 8.25” is also used in ’92, and our ’99 has that axle. I like the 8.25” for its beefiness. An ARB Air Locker is available for either the 8.25” or the Dana 35. One alternative for each of these axles has been the now scarce MJ Comanche pickup’s 8.5” Dana 44 swap. Your usage and tire size will dictate whether that retrofit is practical.

At the front, the XJ axle is a Dana 30 open knuckle design much like those found in the ’72-up CJs or the YJ and TJ Wranglers. AMC built XJ and YJ axles with a unique disconnect feature that mimics some of the gains of earlier free-wheeling/locking hubs. The system had so many trade-offs that by 1991, both the Wrangler and Cherokee eliminated the right-side axle disconnect system. The ’91-up XJ Cherokees are better off for it!

At left is the Dana 30 front axle shaft disconnecting system on an ‘87 Wrangler. Many XJ Cherokees have this feature prior to ’91. By disconnecting the right front axle shaft during non-4WD use, drag is reduced somewhat. The result, though, is a set of differential gears spinning twice as fast as normal, since the axle shafts are splined to the wheel hubs. Water seeped into this axle housing from stream fording and a worn axle shaft seal. Water can cause extensive damage in an axle.

Federally mandated on-board diagnostics (OBD-I) were included with the ’91 Mopar MPI. OBD-II did not come into play until the ’96 models. In ‘96, the XJ has a transition wiring system to accommodate OBD-II JTEC, and ’97-up JTEC has better reliability. Your 1992 XJ prospect has an ‘SBEC’ 60-way powertrain control module (PCM computer), a reliable package. 60-way also worked well through ’95 on YJ Wranglers. This PCM also provides a platform for Mopar’s EFI Conversion kit to replace carburetion on ’81-’90 4.2L inline sixes.

Mopar Performance offers this great alternative to carburetion for ’81-’90 AMC 4.2L inline sixes. The system employs ’94-’95 YJ Wrangler or XJ Cherokee features. The 60-way (wire) PCM computer is central to the 1991-95 XJ models. There are several part numbers due to programming for emissions.

So, overall, the ’92 model has good stuff. As for weak areas in general, keep in mind that this is a unitized, essentially sheet metal body/frame. If from a rust region, structural damage should be considered. Look closely at body panels and the frame superstructure. You want a solid platform to build on. Also check wiring integrity, although the chassis harnesses are fairly well done, there is always the issue of corrosion.

A chronic area of concern is the engine cooling system. There is a lot of anecdotal commentary about XJs and poor cooling, some believing that the ’97-up models were better than the earlier years. I’ll share the simplest formula for cooling: horsepower = BTUs. BTUs must be dissipated from the engine, and in this case, the ‘HO’ output is 190 horsepower and more BTUs to draw away than earlier models!

The 4.0L was a shoehorn fit into the XJ chassis, and the stubby engine fan crowds to the right, with an auxiliary electric booster fan on the left side. This electric fan works steadily when the A/C or defroster is on. It also gets a workout when off-road, as slow-speed driving minimizes air flow through the radiator’s short core. The fan shrouds do not cover the whole core, either, which further challenges cooling.

Complicating this further are the “burp” needs of the remote recovery tank and sealed radiator on pre-’91 XJ 4.0L models. These applications do not have a radiator fill cap. (2.5L four-cylinder models do, fortunately.) Summing it up, the cooling systems have always been marginal on 4.0L XJs in terms of radiator flow capacity, shrouding and fan draw. Suggested remedies include a high flow water pump in conjunction with increased radiator capacity, lower thermostat settings and special coolants. The 195-degree F factory thermostat setting meets EFI and emission requirements. This leaves little room before overheating occurs. Horsepower demand increases BTUs. High horsepower draw means higher heat to dissipate through the cooling system.

For desert trail use or pulling a trailer, the most common nemeses of an XJ’s cooling system, I would toss the factory radiator and replace it with a custom aftermarket unit capable of handling far more BTUs. Modern “dimple tube” technology allows for far better cooling without increasing the radiator core size much. (The XJ does not allow for a much thicker core.) With increased radiator flow capacity, you can benefit from the popular addition of an aftermarket high-output water pump. Some find that the addition of Turbo City’s thermostat housing also improves flow.

Officially, the thermostat should be 195-degrees F for emissions and PCM signal demands. Using a 180-degree F thermostat, some claim, leads to better fuel efficiency and cooler overall operating temperatures. If use of a 180-degree F thermostat still permits the engine to come off its cold-start cycle, this claim is likely true.

The 180-degree F thermostat needs to be tested on an emissions dynamometer to rule out the possibility of continued fuel enrichment after the engine warms up. Efficiency does improve when you reduce excess upper cylinder heat and detonation (ping). There are also rumors that a 160-degree F thermostat works even better. I am firmly against that notion, as complete combustion will not occur at these low temperatures. Over time, carbon will build up in the upper cylinders.

As a final cooling note, I prefer a copper/brass radiator to aluminum. Aluminum is great for NASCAR and high air flow environments, also a nice weight saving factor; however, heat dissipation at low speeds with lighter fan CFM can be an issue. Any improvement in the XJ’s fan and shrouding arrangement would also help. The XJ’s cooling issue deserves a tech feature!

With all of the generalities out of the way, let’s assess the condition of that ’92 XJ—or any other used Jeep vehicle. This list is important for CJ, Wrangler, J-truck, ZJ, WJ and other Jeep 4WD models. You can use this approach to decide whether your brother’s XJ is right for your off-road 4×4 project. Here’s the inspection checklist, Joe:

Engine—Check for engine oil leaks, especially the rear main seal, which is not that easy to replace on a 4.0L engine. Run a cylinder leakdown test—do not bother with a “compression test.” The leakdown test is far more reliable and a better diagnostic tool. Look for signs of sludge in the valve cover (peek through the oil filler cap at least). Run the engine with the filler cap removed and the PCV valve disconnected. This will reveal oil burning blow-by better than any other quick method. Listen for knocks, clicking and rattles on start-up cold, a sign of excessive bearing clearance or lifter trouble. 4.0L engines in your year range can have piston-to-cylinder wall noise that disappears once the engine is warm, not a major issue. Make sure this is not bearing or wrist pin noise.

The AW-4 automatic was used exclusively by the XJ Cherokee 4.0L six-cylinder models from 1987-2001, a very wise choice that contributes to the XJ’s reputation for reliability and longevity. I upgrade the AW-4 for JeepSpeed™ or rock crawling. At right is a durable Chrysler-type 3-speed automatic, popular in the CJs, YJs and earlier TJ Wranglers.

Transmission and transfer case—If the XJ has the AW-4 automatic, check for the acrid scent of overheats. Dirty fluid is not a good sign, burned fluid even worse. Check for seal leaks. Seepage at the front of the transmission is the front pump seal. If no leaks or shift problems, no slippage between gear changes, consider a professional flush-and-replenish that includes the torque converter.

If a manual five-speed, the AX-15 is rugged and either working right or not. Listen for whining, bearing sounds or synchronizer balking on shifts. Change the gear lube, using only Mopar’s recommended AX-15 oil. Note signs of clutch slip, roughness or shudder on engagement. The transfer case should shift properly and not whine. Check for chain play by rocking the front driveshaft back-and-forth with the transmission in gear (manual) or Park (automatic) and the transfer case low-range engaged. If a part-time NP231, you can rebuild the unit when you install the slip yoke eliminator (SYE) kit and CV-rear driveline required with a chassis lift. The NP242 can be checked similarly and will also require an SYE with a lift.

Axles—Rear axle shafts have C-clips, so check for axle shaft endplay. Check pinion gear backlash by rotating the driveline and noting play. Check for fluid leaks. Check the front axle shaft joints for wear or signs of dryness and fatigue. Check for steering knuckle ball-joint play. Expect front wheel hub wear and plan on replacing both front hubs. Check lube condition in the axles and change the gear lube if you are not rebuilding these axles. If a limited slip rear, use friction modifier supplement with the gear lube. I recommend Mopar’s limited slip additive. Fortunately, the front axle of a ’92 XJ does not have a vacuum disconnect system.

Steering—Saginaw steering gears last a very long time, however, I would check for sector/cross-shaft play with steering in the straight ahead position. These gears often need rebuilding at the mileage you describe, at least a complete reseal and restoration of tolerances. Steering linkage is another wear point; check tie-rod ends for looseness.

Saginaw power steering was available throughout the XJ years. Rotary design is bulletproof. A reseal and tolerance adjustments can often rejuvenate a unit. Here, a similar YJ application shows signs of upper seal leak at higher mileage. I rebuilt the unit.

Brakes—Customary brake needs include new rotors, calipers and rear drums at this mileage. Despite regular brake work, unless these items have been replaced, they will need replacement. Hoses and the master cylinder should be shot. The ABS system is another area of concern and expensive to restore.

Springs and suspension—Leaf spring bushings are likely shot. Leaf springs fatigue, too. If you plan a lift kit (mandatory for 31” or bigger tires on an XJ), get a kit that renews the rear springs and bushings. A quality lift kit will include front coil springs. New rear leaf springs will restore ride quality and off-road capability. Worn springs would likely break.

Body and frame—I cannot emphasize enough the importance of a stable, rust-free frame and body. Fatigue is another issue; hardcore wheeling can flex and crack an XJ frame. Long-arm suspension helps alleviate this kind of stress; aftermarket stiff springs with short arm front suspension can be brutal on an XJ’s unibody.

Electrical components wear out, too, as induction test at left confirms! At right is Mopar’s factory rebuilt starter motor by Mitsubishi. A high quality part, the unit restores starting to like-new performance. Mopar ‘Reman’ can supply many of the electrical components that commonly wear out. See your local Jeep dealership’s parts department.

Wiring and electrics—No man’s land! You want the wires to be intact, not cut up or spliced from cheap aftermarket add-ons, not brittle, not corroded, clearly with a look of originality. You do not want to “re-wire” an XJ! Assume that the alternator, starter motor, wiper motors and cooling fan motor may need replacing unless already done. Mopar’s rebuild program can provide many quality parts. Avoid cheap aftermarket alternatives if you want reliability. The sound system should be at the end of its duty cycle as well.

Emissions and fuel system—Often overlooked is the need for engine emission system work. In states with emissions inspection, many aging XJs have ended up in recycling yards. The PCM, feedback sensors, especially the oxygen sensor, are likely at the end of their duty cycle. The evaporative emissions system always needs attention at this mileage. An electric fuel pump is in the fuel tank and suspect as well. Check for fuel tank leaks.

Upholstery, paint, steering wheel and cosmetics—this is all obvious stuff and subjective. Take the cosmetic issue to whatever level you want. Consider a roll cage if you plan any serious off-roading.

These checks should provide a sobering view of the XJ. The tremendous lifespan of these vehicles is due largely to the mix of car and truck-based engineering. In particular, the axles are light truck beam design; the transfer case is shared with counterpart YJs and TJs. AMC inline, seven-main bearing sixes are incredibly reliable. All of this plays well for XJ Cherokee buyers; however, 260K miles suggest the end of the trail for most of the vehicle’s wear components.

If you want a “kick-around” vehicle, one approach would be to not modify the vehicle but rather drive it to the end of its useful life. If this is a platform worth using for a JeepSpeed prototype off-road project, then plan on axle rebuilding, engine rebuilding (perhaps Mopar’s nice exchange long-block program), an AW-4 overhaul, cooling system upgrades, complete suspension revamp, steering system rebuilding, including steering knuckles, driveline replacement/rebuilding, and so forth. There’s no middle ground with an XJ unless you want to stick with 31” tires maximum. Once you target 33” tires, you can expect to do largely the same things that I have done with our ’99 XJ Cherokee Trail Runner project.

Aftermarket Alarm System Angst

From: C M

Sent: Sunday, December 19, 2010 8:06 PM

To: 4WD Mechanix Magazine

Subject: XJ – mystery

Moses,

This is Craig from the Hill Angels 4×4 Club. I picked up an ’01 Cherokee Limited this summer and all the usual upgrades are done. 3″ Skyjacker full spring lift, Rancho shocks, 31’s, adjustable track bar, skids on the gas tank, T-case, side rails, cooling system upgraded and tranny cooler (I read your article!) mounted BELOW the radiator with an auxiliary fan.

Here’s the mystery: I also added a security system with the usual sensivities and remote door locks and starter killer relay. When the rig is off and locked there seems to be something that cycles once in a while usually at night. This draws the prerequisite voltage necessary to trip the alarm annoyingly, so I disconnected the siren. For now it just blinks the lights in silence. I was under the rig a while back and heard something go “click” immediately followed by the alarm relay activating for its 1 minute tantrum. My only thought is the fuel pump cycling to maintain line pressure. Any clues??? Fixes??

Thanks,

Craig

Reply from Moses Ludel:

Hi, Craig! Nice Cherokee from your description, we sure like ours…Other than the ridiculously low amp draw of a stereo or PCM clock, there should really be no voltage drop enough to trigger the alarm—other than the purge for the evaporative emissions system. The Natural Vacuum Leak Detection (NVLD) system on late Jeep models, which involves a pump and solenoid switch, could fault and draw enough amperage (1.5 amps at the solenoid’s initial click-in) to trigger the alarm system. One cause could be the atmospheric temperature change as ambient air cools down.

Also, with the cold weather, the battery’s own voltage can drop as the temperature declines. I use a Battery Tender on both the ’99 XJ Cherokee and the Dodge Ram Cummins (dual batteries). This has been a boon to battery life and assures fresh starts on cold mornings in our area.

I run a hard-wired lead from the battery to the grille area. These leads are a Battery Tender accessory with a two-wire plug. (I get them through Batteries Plus). I use a 25-foot lead to the Battery Tender, which enables parking outside under carports. If you have a garage, you can get by with just the leads from the Battery Tender to the battery lead. Amperage draw with the tender is minimal, and this device will not reduce battery water/electrolyte while reducing risk of battery sulfating.

Claims of 3-5 years more life from a battery are realistic. The biggest killers of batteries are the start-up after a cold cycle voltage drop and the effects of cold temperatures as a whole. Icy start-up causes a huge voltage surge to the battery from the alternator, and this breaks down the battery over time.

I mention all of this because the Battery Tender lead from the battery to the grille would also offer a great place to check battery voltage with the hood closed. I would test the battery voltage at shut-off and battery voltage when the alarm falses. You may discover enough of a voltage drop to cause the alarm to false. Most security systems look for a voltage drop, caused by doors opening (dome light activation), a hood light activating, the tailgate opening (activating the dome light) and so forth. Unless your system is “hard wired” on its own circuit for door switches, a hood switch, tailgate switch or ignition/starter activation, it might be looking for a voltage drop. This can include the battery dropping voltage on a cold night.

Without more information on the components installed with your security system, and a wiring schematic, it is hard to guess the source of the false alarms. I would add that late model Jeep security systems are key-matched to the PCM. (I was advised by Mopar folks that if I install a diesel engine and PCM from a Liberty or J-8 export model into the ’99 Cherokee, the donor PCM would be looking for a security match between the ignition switch assembly and the PCM. They suggest installing the entire steering column from the same Liberty chassis as the donor engine/PCM!) If the last two years of the XJ (2000-2001) included this late technology, there would be room for issues between the factory security measures at the PCM/ignition and an aftermarket alarm system.

Look into the Battery Tender, at least the hard lead from the battery to the grille area. I’m going to do a short piece on “winterizing” a Jeep, as I recently installed a block heater (freeze plug style) and really value the 130-140 degree F startups. This takes a tremendous load off the engine, providing warmer oil and block temperatures when parked outside. Even in a garage at 40-degrees F, we use the Cummins block heater on the Dodge Ram.

The setup included a wall plug timer, set to activate the block heater a few hours before starting the engine on a cold morning. Now parked under a carport, the Dodge-Cummins block heater gets plugged in the evening before a trip. The Battery Tender remains on the Dodge truck between driving stints, which can be as long as weeks apart. With two expensive batteries, the Battery Tender has more than paid for itself. We’re still on the original 2005 Mopar batteries!

If the battery voltage drop is the cause, have your battery tested for a dead cell. Test the battery under load. Check specific gravity on individual cells. You may have a defective battery. If the battery is okay, and the problem is battery drain from a device, check over the wiring schematic for the alarm system. A component may be drawing down voltage or incorrectly wired for your XJ Cherokee’s electrical system.

Let me know the outcome, Craig!

Composed with HTML Editor