In Part 1 of this two-part video ‘how-to’ series, James at Dynamic Diesel, Inc., discusses fuel demands and the fuel supply upgrades that make sense.

Part 2 is the exclusive, YouTube HD video presentation and ‘how-to’ overview covering an actual lift pump kit installation. The HD video shoot took place at Dynamic Diesel, Inc., Sparks, Nevada.

In the spring of 2010, I drove our Ram 3500 to Moab, Utah, for the Jeep Safari, allowing plenty of time to meet a busy schedule there. En route East on I-80 through northeastern Nevada, I took the Pequop Summit exit for a short break. As I rolled off the interstate, I spied a Dodge Ram truck parked with its hood up. Two brothers from British Columbia were making an unsuccessful attempt to restart the 2001 model 2500 truck, which was hauling a piece of hefty equipment on a low-bed trailer. The starter spun, the Cummins 5.9L diesel would not start…We spent the next three hours, including my drive to Wendover and back for a new fuel filter, getting that truck to run…The issue of proper fuel filtration, adequate fuel supply volume and the merits of an upgrade lift pump were clear…To avoid expensive injection pump and injector damage, change your fuel filters regularly. Consider upgrading the system with a quality aftermarket lift pump system to prevent this kind of trouble on the road!—Moses Ludel

Dodge Ram 5.9L and 6.7L Cummins engines provide an unbeatable powertrain for hauling a load. The Cummins engine revived the Dodge truck brand in the late 1980s, distinguishing the “Ram” badge as the premier light truck hauling machine.

“Hauling” means increased fuel needs. The stock fuel supply system from the tank to the injector pump can often fall short. High trailering loads, pulling long grades under load and use of performance chips will step up the engine’s fuel demands. Under these conditions, the OEM lift pump may not deliver an adequate fuel supply to the injector pump.

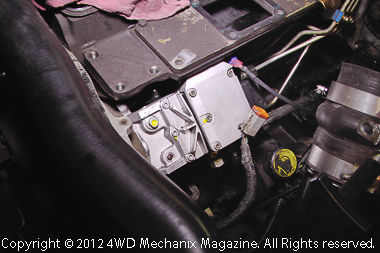

This freshly installed injector pump and a failed injector were the direct result of inadequate fuel supply to the original pump. Aeration and insufficient fuel volume raise havoc with expensive injection pumps!

Whether mechanical (shown here) or electronically pulsed, injectors are expensive to replace. Simply changing the fuel filter(s) regularly helps the Cummins diesel engine survive. This injector became damaged from intermittent fuel starvation.

Replacement of the injector pump and one injector were required before the installation of a FASS upgrade lift pump system. See these two HD videos for all of the details!

The fuel filter on a Dodge-Ram Cummins engine is the first line of protection for the diesel injector pump. Change this filter on a regular basis. Click here for Dodge Ram routine filter service details.

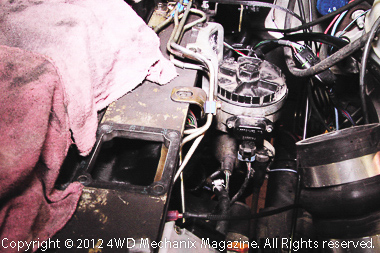

Replacing the injector pump and an injector made the valve rocker arms accessible. Dynamic Diesel, Inc., performed a valve adjustment at this service point. Preventive care can keep a Cummins diesel running properly for well over 300,000 miles. Some Cummins engines make it to 500,000 miles without a major rebuild. That’s our goal with the 2005 Ram 3500!

For details on expert diesel repairs, contact Dynamic Diesel, Inc., at Sparks, Nevada…Phone (775) 359-4477.