Tuning Jeep Inline Six Stroker Motors with EFI or MPI Fuel Injection

Converting a Jeep 4.2L/258 inline six from carburetion to multi-point fuel injection (MPI) gains an immediate 50 horsepower. For those building a stroker motor hybrid from 258 and 4.0L parts, the use of MPI or TBI is always a practical choice.

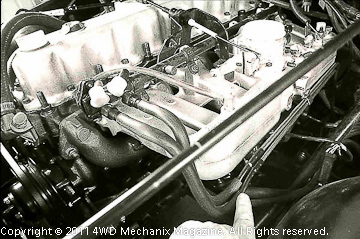

Mopar’s mid-’90s prototype MPI/EFI Conversion for the 4.2L six has provided a sensible alternative for CJ and early YJ Wrangler owners. When building a stroker 4.6L six, it is practical to convert these models to EFI or MPI.

The Mopar EFI Conversion Kit (above) prototype was originally the 1995 Wrangler 4.0L fuel-and-spark management system. Later, 1997-99 single-rail 4.0L OEM components provided the kit’s platform.

For all 4.0L inline six models (the XJ Cherokee, Grand Cherokee and Wrangler), MPI is original equipment. 1987-90 XJ Cherokees use the AMC/Renix system. All 1991-up Jeep 4.0L engines have Chrysler designed MPI. The 4.0L cylinder heads are high and low port designs. Improved, high-port heads are available from 1991-up.

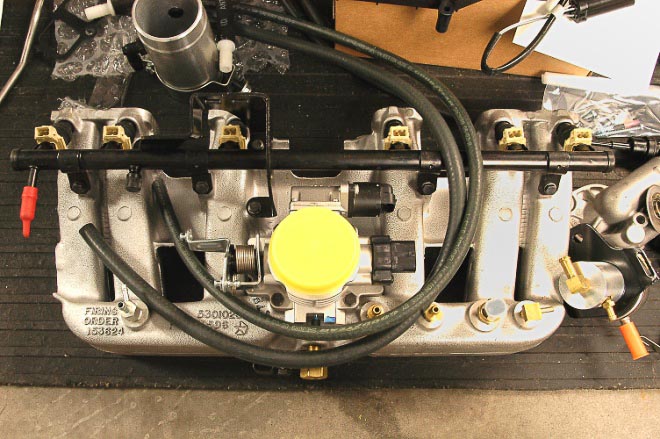

There are two distinctions in the Jeep/Chrysler (1991-up) 4.0L MPI fuel-and-spark management systems:

1) 1991-95 applications have a dual-rail fuel system with a return line from the engine to the tank. They have a pressure regulator at the MPI fuel rail.

2) 1996-2006 4.0L engines have the pressure regulator atop the fuel tank pump module and a single fuel rail system without a return line from the engine.

These systems operate at high pressure. The 1991-95 systems (two-rail) regulate at 39-41 psi during cranking and 31 psi once vacuum applies at the pressure regulator. At an idle warm, this system will read 31 psi at the test port. Disconnecting the vacuum line at the pressure regulator raises an idling engine to 39 psi at the fuel rail test point.

The 1996-up (OBDII era) single rail systems, with the pressure regulator at the fuel pump module of the fuel tank, operate at a higher 49.2 psi +/- 5 psi. (Lowest pressure with engine idling would be 44.2 psi.) Pressure can regulate to as high as 54.2 psi. The fuel pump on either single rail or two-rail systems produces more than the peak operating pressure for the system.

EFI/MPI: Stroker Motor Needs

The stroker motor run with a stock Jeep 4.0L MPI system (or a Mopar Performance EFI Conversion package) has specific needs. For years, an aftermarket, adjustable pressure regulator from HESCO has enabled the 4.0L two-rail systems to get a pressure boost for improved performance. This allows for stabilizing and adjusting fuel pressure as needed for peak performance.

For a stroker motor with a mild camshaft and compression ratio, fuel pressure and flow is less of an issue than with a higher horsepower engine build. Available fuel flow and necessary injector sizing is governed strictly by horsepower requirements.

It takes a certain fuel amount (pounds of fuel per hour) to sustain a given amount of horsepower. Each horsepower level requires injectors of a specific flow capacity.

The milder engine build that Tony Hewes and I discuss will produce around 240 horsepower. Based upon one six-cylinder formula for injector flow (horsepower divided by 12 = needed injector flow), it will take 20 lb/hr fuel flow to sustain the 240 horsepower demand.

There are continual references to 24 lb/hr retrofit injectors used with Jeep stroker inline sixes. We find it practical to run 24 lb/hr injectors, even in a street-and-trail Jeep 4×4. Although this engine application typically idles and runs to a maximum of 3,000 rpm, there are occasional “red line” bursts to 4,000-5000 rpm that will demand more fuel flow. The 24-pound injectors are simply a hedge against fuel starvation, and they do not cause the engine to run “rich”. A/F ratio is still maintained by the oxygen sensor signals and PCM fuel allocation.

Here, we’ll share the experience of several engine builders. (Click here for a popular website that describes several Jeep inline six stroker engine buildups.) Injector choices and parts lists accompany each level of engine build.

At Dino’s site, the engine builds closest to the Tony Hewes approach would be the “rockcrawler” and lower cost builds. For these engines, 24 lb/hr Ford injectors appear to work. These are common 302 Ford V-8 MPI injectors, available online as new, rebuilt and even “good used” varieties.

For those who like to “do the math” and validate the reasoning behind EFI/MPI injector choices, consider Stan Weiss’ EFI flow data table. Click here for direct access to fuel flow formulas, tables and actual part numbers for a variety of injectors—including Ford, Bosch, Mopar, Holley, Accel and MSD.

There’s a lot of work presented at each of these websites. Dino’s effort includes a great deal of commentary on Jeep inline six stroker motor options and component choices. Such research and the effort to present reliable material is of great value. Thanks, Dino and Stan Weiss!

Here are camshaft choice and tuning comments from a Moses Ludel topic post at the 4WD Mechanix ‘Tech and Travel’ Forums. Join the forums and participate in these discussions:

“At the magazine, building a Jeep inline 4.0L six with a 4.2L crankshaft (stroker motor) is very popular. Tony Hewes (Hewes Performance, Reno, Nevada) and I did a series of HD videos and shared our favorite components for a 4.6L (0.030” overbore with the 4.2L crankshaft) stroker motor build for combined street and trail use.

Since then, we have received a lot of feedback and continue to address the tuning and camshaft requirements of these engines. From our testing, the pre-coil pack (1998 TJ and older 4.0L) engines with older style injectors do very well with Ford 5.0L V-8 24-pound injectors—no emission quirks, “Engine Check” lights or other issues when tuned correctly. Ford part number F1TE-D5A or Bosch number 280 150 947 is the specific injector type. These engines work well with the 252H CompCams grind camshaft and 8.7:1 compression.

Later, 1999-up TJ Wrangler and 2000-2001 Cherokee engines with coil-pack ignition have square injector connector plugs. For these engines, stroker builders use the Dodge Ram 5.9L V-8 injectors listed for 2000-up with coil pack. This is the injector that HESCO calls a “24-pound/hour”. HESCO supplies rebuilt GB injectors, although new Mopar OEM part numbers are available. This injector also crosses over to the aftermarket Bosch Fuel Injector #62005 offered at Summit Racing for a significant price per injector.

Here is the GB website: http://www.gbreman.com/index.html. The 5.9L Ram truck V-8 application is the GB812-12132 injectors for engines to 2003.

I researched further and came up with the OEM 5.9L Mopar V-8 injector part number: 53031740AA. (I used 2001 as a clear year for coil-pack and square injector plug.) This OEM Mopar injector is 23.61 pound/hour rated at 43.5 PSI. This is a “high impedance” injector design with a square plug socket.

The OEM injector on a coil-pack engine rates 22.5 pounds/hour at 49.0 PSI fuel pressure, which may work okay on a coil pack stroker engine unless the cylinder head, compression or camshaft/head combination is an issue for the PCM. Fuel rail pressure of 49.2 +/- 2 PSI should be confirmed by factory testing method.

Click here for an instructional PDF for running fuel rail pressure tests on Jeep MPI. This is the 1997-up XJ Cherokee and TJ Wrangler type with fuel tank mounted pressure regulator and single-rail injection.

In the late ’90s, my engineer friends, Jeep performance enthusiasts at Mopar, were talking about 5.9L Mopar V-8 injectors for 4.0L/4.6L stroker engine builds. This has apparently been a route to go, with a 24-pound/hour injector rating.

I researched the Jeep ZJ Grand Cherokee 5.2L/5.9L V-8 injectors from the mid-‘90s: 1995 Jeep 5.2 ZJ/Dodge 5.9L V-8 injectors are Part #53030262 and rated to flow 24.6-pound/hour at 39 PSI. By 1996, the Jeep V-8 injectors rated 23.2 pounds at 49 PSI. The 1995 Mopar injectors (24.6#/hour @ 39 PSI) could be an alternative to the 302 Ford injectors for a stroker build in a 1991-95 Jeep 4.0L MPI chassis application if the engine demands that kind of flow.

Summing it up, if GB is accurate, using the right injector cores and parts for this application, HESCO is marketing a “24-pound/hour @ 43.5 PSI injector for a stroker inline six. A caution here is that the ’97-up Jeep TJ Wrangler and XJ Cherokee have a 49.2 +/- 5 PSI rail pressure. Flow could be higher than 24 pounds/hour at this 49.2 +/- 5 PSI rail pressure.

If the GB812-12132 injector is okay for a coil pack later engine with the later cylinder head casting, the GB812-12132 square plug injector would be the choice for later coil-pack engines. There are a number of sources for these GB injectors.

The 1997-up TJ Wrangler and Cherokees with the tank-mounted fuel regulator use higher fuel pump/line pressure. I would stick with Mopar 53030262 or Ford 302 V-8 type injectors* on the 1997-98 TJ Wranglers and Cherokees through 1999 (without the coil pack system).

*Footnote: 24-pound 302 5.0L V-8 injectors fit the pre-coil pack engines; coil pack engine injectors have a square plug connector.

Below are some useful links and comments at the magazine site:

https://www.4wdmechanix.com/Jeep-Fuel-Pressure-Requirements.html [I detail pressure ratings and designs for Jeep engines equipped with MPI/EFI. 1997-up single rail systems with tank-mounted pressure regulator are higher pressure, running rail/injector pressures typically around 49.2 PSI +/- 2 PSI. This includes the coil pack engines with square wire plug injectors.]

https://www.4wdmechanix.com/YJ-&-TJ-Jeep-Stroker-Six-Upgrade.html

https://www.4wdmechanix.com/Jeep-TBI-&-MPI-Advanced-Troubleshooting.html [Overview of OEM tuning methods and factory diagnostic tools required.]

https://www.4wdmechanix.com/Vlog-Why-Build-a-Jeep-4.6L-Stroker-Inline-Six.html [Video vlog comments.]

https://www.4wdmechanix.com/How-to-Tuning-the-Fuel-Injected-Jeep-Inline-Six-Stroker-Motor.html

http://users.erols.com/srweiss/tableifc.htm [A useful third-party website for every popular OEM fuel injector’s flow ratings.]

https://www.4wdmechanix.com/Vlog-Road-Testing-Jeep-4.6L-Stroker-Inline-Six.html [My video comments on Brent H.’s Cherokee 4.6L build and its drivability. This is a video vlog plus a list of key components used in this Hewes Performance buildup for a 1998 Jeep XJ Cherokee chassis.]

Of course, there’s also the entire 4.6L Tony Hewes interview series of HD videos, six individual videos covering the build of a stroker inline six-cylinder Jeep engine!” —Moses Ludel

Basic Street/Trail Stroker Needs

For the moderate compression ratio, mild camshaft engine discussed and recommended in the Hewes Performance interview, there are few tuning changes required. The 4.6L stroker motor described will work with the stock 4.0L electric fuel pump; an adjustable pressure regulator (if necessary) for ’91-’95 two-rail systems; the factory PCM; and retrofit 24 lb/hr fuel injectors.

The Ford injectors seem readily available and inexpensive. (Ford injectors were mentioned in several prototype engines at Dino’s website.) 24 lb/hr injectors are also available from other sources.

Tuning and troubleshooting will be possible with a DRBIII scan tool or a quality generic scanner—if the engine build is milder.

It’s not until horsepower creeps into the 275-300 horsepower realm that the PCM needs programming changes. At higher horsepower levels, injector flow requirements move to 26 lb/hr and the PCM will need program changes. Unless you have plans for a high compression, “big camshaft” build, something in the line of an off-road racing prototype, these extra measures should not be necessary.

For the Renix (1987-90 XJ Cherokee 4.0L) and Chrysler two-rail systems (1991-95 4.0L engines), it is practical to use an adjustable pressure regulator. This offers fine tuning and the option of both flow increases and a means for PSI adjustment. Both the 4.0L Renix and the two-rail Chrysler MPI systems can be regulated. See the HESCO website (www.hesco.us) catalog listing for pressure regulators.

Emission Inspections and Legality

If your engine must pass emissions inspection, be conservative on the buildup. You best likelihood of passing is a lower compression ratio and mild camshaft, stock PCM calibration and a fully legal exhaust system. All OEM emission devices must be in place and functioning.

Any modifications must not affect air/fuel ratio readings or tailpipe polution levels. Increasing engine displacement does not matter to the PCM, it will still strive for clean tailpipe air/fuel ratios and emission-compliant performance.

If you’re looking for a 49-State catalytic converter solution, see the Random Technology how-to article. These units work, cleaning up the downstream readings while offering the least restrictive exhaust flow.

A Borla, Banks, Edelbrock or Clifford header will help, too. In most cases, the Jeep OEM exhaust manifold is cracked and needs replacing, anyway! Make sure a header is emission compliant if your vehicle requires pollution control inspections.

As for spark timing, the PCM has this handled with feedback from the stock engine sensors. Using the 1991-up 4.0L stock cast iron head or an aluminum HESCO head, there should be no detonation (ping), especially if you run a lower compression ratio with a stock or milder camshaft.

For those wanting a streetable, trail-ready stroker motor for better torque and decent fuel efficiency, a mild engine build holds the most promise. A camshaft that keeps manifold vacuum high at low and cruise speed rpm will always improve engine efficiency and usable torque.

The milder engine build, with a stock PCM and sensors, also offers a high likelihood of passing an emission test. The wild card is injector flow rate changes and fuel pressure settings. Minor modifications create the least issues.