How-to: Dirt Motorcycle Final Drive Chain and Sprockets Replacement!

Dirt and dual-sport motorcycles require routine chain maintenance and periodic parts replacement. In this 28-minute HD video, the magazine’s Honda XR650R enduro bike gets final drive attention. This presents an opportunity to upgrade the chain and sprockets. The detailed, step-by-step coverage of this important service provides tips on how to improve your dirt or dual-sport motorcycle’s reliability and stamina.

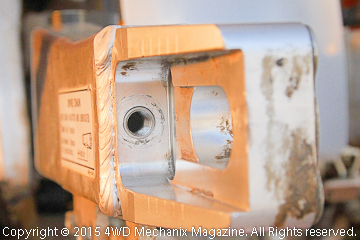

At left is the wiped out chain slider and wheel splash guard. This resulted from the side-whip caused by a worn out 520 chain. The primary sprocket is also worn badly from the chain and aluminum rear sprocket wear. Fortunately, the damage is limited to soft parts. The swingarm, countershaft and rear wheel hub did not sustain damage—a considerable cost savings in this restoration project!

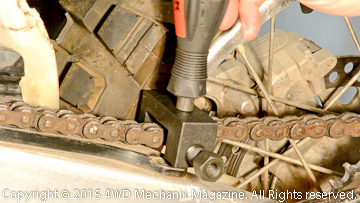

Chain breaking and riveting made easy—the RK Excel UTC2100 tool solution! Easy to use and confidence inspiring, this is the practical, durable tool needed for motorcycle chain service. 40 and 50 size chain breaking and precise press-fitting of the connecting link side plates on #40, #50 and #60 chain are each possible with this versatile tool.

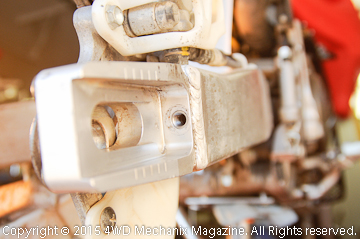

At left, the rear sprocket bolts are inaccessible with a socket. (An alternative is an offset crowfoot box ended “socket” that fits a standard ratchet or torque wrench.) At right is the Supersprox Stealth rear sprocket installation. This patented design provides lighter weight with the toughness of a steel outer sprocket. The magazine’s Honda XR650R motorcycle, uncorked and running a fresh top-end build with a Hot Cams Stage 1 camshaft, is cranking out 55 horsepower and 49 lb-ft of torque. At 310 wet pounds (with fuel in the 6-gallon Acerbis tank, no luggage, racks or field gear), this cycle needs a steel primary and rear sprocket—plus any weight savings possible! (Visit the Supersprox website at http://www.supersprox.com for more details.)

The RK GB520EXW chain came with a clip-type master link. OEM chain is endless, and the option exists for using a rivet-type connecting link on the RK chain. Since our cycle is on the highway and at remote venues where service parts are limited, the master link with clip is practical. For an OEM Honda chain, Honda recommends an endless chain with riveted connecting link. Added strength of the RK Excel chain provides the option of using the RK master link provided with this chain. For 520 chain, the RK Excel UTC2100 chain cutting and plate/rivet installation tool will handle either a master link or a continuous chain rivet-type connecting link. (For more details on RK Excel products, visit the http://www.rkexcelamerica.com website.)

Extra chain links are easily removed with the RK Excel UTC2100 tool. At right, the master link is visible with the closed end of the clip facing forward on the top run of the chain. Always install the clip in the correct direction, this is a safety concern.

When the swingarm axle adjuster bolts seized in their threads, the only option was to allow them to shear off. With care, each bolt was carefully drilled on center until hollow, using a titanium drill bit. Bolt material was removed just short of the swingarm aluminum thread crowns. An 8mm x 1.25mm tap could then be run through to clear out the remaining bolt thread material in an effort to restore the aluminum threads…

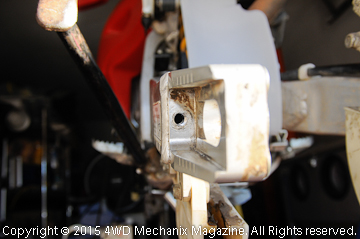

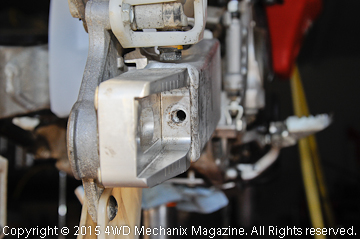

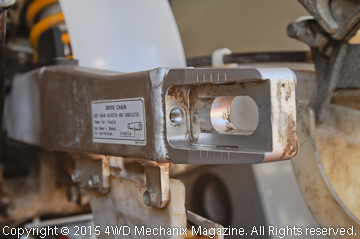

Threads were corroded by the bolt deterioration and seizing. Despite precise restoration of the threads, their strength was questionable. We turned to Time Fastener Company and Time-Sert® for a solution. The company saw a viable need and created a special kit to repair swingarm threads in 8mm x 1.25mm pitch. This kit requires longer tooling to clear the swingarm’s ends and to prevent the drill chuck from contacting the swingarm. Narrow side-spacing is also addressed with this custom tooling. Note: The swingarm/axle adjuster bolt thread kit can be ordered from Time Fastener Company (http://www.timesert.com) as P/N 1812ECORESS117. Stainless steel inserts are custom cut to fit the narrow swingarm spacing. Whether you want to save the $600-plus (U.S.) cost of a new fitted swingarm or prefer to upgrade threads at your dirt race bike shop, this is the precision, permanent solution!

The properly positioned collar of the drilling tool cuts a chamfered outer edge to match the angle of the thread insert’s shoulder. These inserts have expandable (cold rolled) lower threads that lock the insert into place as the insert driver presses through the lower threads. The insert is a permanent solution to a factory created issue. In any case, these adjuster bolts should be replaced periodically before they seize, especially on bikes subject to moisture, humidity or stream crossings!

Restored and upgraded, the final drive on the Honda XR650R is now ready for on- and off-road work! With its Acerbis 6.3 gallon fuel tank, TCI luggage racks and Nelson-Rigg luggage, loaded with video and outback gear, this converted dual-sport motorcycle can press 360 pounds plus rider. We need the reliability and stamina presented by the RK Excel chain, Supersprox sprockets and the Time-Sert® thread repair solution!