Enjoy the detailed, traditional ‘Q&A’ exchanges in this article column from the early magazine website. Some pre-2015 links to .html are no longer valid. (The magazine changed to .php in WordPress.) ‘Q & A’ has now moved to open, interactive forum discussions. Visit the forums, you’ll want to join—for free!

Have technical questions about your Jeep 4×4, popular 4WD truck, SUV, ATV, UTV or dirt motorcycle—or welding and metal fabrication? The 4WD Mechanix Magazine ‘Tech and Travel’ Forums now feature enthusiastic discussions and input from members and a steady flow of content from Moses Ludel.

Want to discuss your technical and outdoor interests with like-minded enthusiasts? Check out the 4WD Mechanix ‘Tech and Travel’ Forums! Click here for a guest visit to the forums!

Mopar Willys Wagon Concept Vehicle Details

From: Gene M.

Sent: Wednesday, September 26, 2012 4:25 AM

To: 4WD Mechanix Magazine

Subject: ’62 wagon

Do you know if there are any articles on the build of the Mopar ’62 Wagon?

Thanks for your time,

Gene M.

Hi, Gene…The vehicle has circulated a bit and was built in the Mopar design/concept area by Jim Allen’s team. They had a great deal of fun with the project.

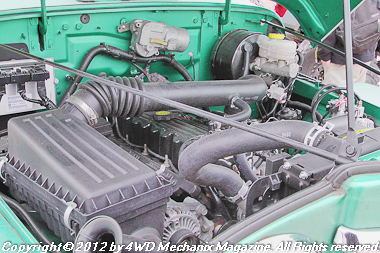

As for details, I know the Willys Wagon body was fitted to a Jeep TJ-era Wrangler “LJ” edition chassis. The LJ Unlimited has the right wheelbase for the body (104”) plus the inline 4.0L six engine. The fit was done nicely, with levers adapted to the LJ transfer case and manual transmission. Underhood, the 4.0L looks fairly “normal”, with tasteful placement of modern parts like the PCM and wiring. The original Willys steering column was shortened and adapted to work with the Wrangler’s steering shaft and power gear. They aimed at keeping the interior looking original with the modern powertrain, chassis and frame hiding beneath the Willys sheet metal.

Overall, the Mopar team caught the theme of the vintage Willys well. The vehicle drives and handles like a tall version of an LJ Wrangler Unlimited. (Beware of higher center-of-gravity here!) This must work much better on the highway.

Trust this helps clarify. Obviously, there’s a lot of work involved; however, the finished product is drivable with a completely modern end-to-end chassis, axles, steering, gear assemblies and powertrain.

Regards,

Moses

134 F-Head Main Seal Mentioned in Jeep CJ Rebuilder’s Manual

From: Bill K.

Sent: Tuesday, September 04, 2012 11:04 AM

To: 4WD Mechanix Magazine

Subject: Rear main seal question

Good Afternoon,

I have a question in reference to the part number on page 101 in the Jeep CJ Rebuilder’s Manual. The picture I am looking at is 2-131. What is the Fel-Pro gasket part number for the seal the man is holding?

Thank you very much,

Bill K.

Bill, I hunted and pecked, could not find anything current except “rope” type until I discovered this website listing:

http://www.kaiserwillys.com/category/willys-jeep-engine-gasket-sets-oil-seals-parts-accessories/a

Not sure of brand, origins, it is four-piece neoprene…See if this does the trick…

Moses

Going ‘Weber’ on a 258 Six?

From: Ronald A.

Sent: Monday, July 16, 2012 12:34 PM

To: 4WD Mechanix Magazine

Subject: Weber For 81-CJ

I have an ’81 CJ-7 with the 258-cu in I-6 engine, and I am looking to buy the Weber 32/36 DGES or the 38 DGES carburetor.

I’d like fuel injection but can’t afford the cost, so I’m better off with a new carb.

I am not sure which is better for my driving habits, but I want to match the carb to the current engine set-up so it performs efficiently [best power to gas economy – power being the more important].

Engine: The engine has a mild, some call it an “RV”, cam [but I don’t know much more about it]. I also have a set of headers on the engine. The engine has no other modifications but was rebuilt and I have roughly 15k miles on the rebuild.

Driveline [if this helps]: I run 33 x 12.5 tires.

I have 4-10 or 4.11 gears [can’t recall].

I have a T-18 truck transmission [mainly for rock crawling]. I like the current driveline set up as I get good highway speeds and great rock crawling performance.

Driving Habits: I mostly use the Jeep for rock-crawling [but we don’t do a lot of that these days], and minor daily driving when our other car is in for repairs.

Want: I want more torque/power without a large sacrifice on gas economy. However, the jeep was built to crawl not as a people mover. I’m hoping not to ‘over-carb’ the engine [Is that such a tag], but I don’t want to miss getting better all-around performance for the difference of maybe

$40 dollars.

Emissions: I’d keep the current carb and switch it over when SMOG is required, so that’s not an issue.

Intake Manifold: I understand I’d get even better performance with a matching manifold, but right now I can’t afford another component.

Weber Carb Selection: Weber has a model that uses the factory air cleaner from a CJ Jeep, and another model that replaces the factory air cleaner and instead uses a rectangular air cleaner. See any issues with one over the other?

Ronald A.

From: 4WD Q & A

Sent: Monday, July 16, 2012 1:22 PM

To: Ronald A.

Subject: RE: Weber For 81-CJ

Ronald, the 32/36 DGEV is the typical choice for a mild Jeep engine build like yours, especially with your fuel mileage and trail use goals. Be sure the carburetor is staged and jetted for your 258 six, as these are “classes” of Weber carburetors that vary in tuning. You will be happier with the smaller throttle valves for the driving you describe, and progressive linkage also makes sense, assuming that the Weber’s jetting and staging are correct.

You’re aware that any carburetor will be altitude sensitive, and jetting for sea level is not the same as jetting for the ‘Fourteeners in Colorado. Weber carburetors are relatively “forgiving” in this regard, although I recommend that you purchase a guide for tuning the 32/36 carburetor. Familiarity will make you adept at keeping your Jeep reliable, especially off-highway in rock crawling or at various climates and altitudes.

I like the idea of the stock air cleaner with adapter, as this should easily flow the CFM required yet provides better protection from dust and water than an open-faced air cleaner. Again, the 32/36 carburetor makes sense for a stock intake manifold and the rpm range anticipated.

Please let me know how this works out. I want your candid opinion of the change. If you have or can install a manifold vacuum gauge (like a “Motor Minder” from the day), I’d like to know how the Weber compares to the BBD Carter.

Regards,

Moses

Solving ‘Ping’ on a Stroker 4.6L Inline Six

From: Mark B.

Sent: Monday, May 21, 2012 11:40 AM

To: 4WD Mechanix Magazine

Subject: Ping

Hi, Moses:

Installed the 4.6L stroker inline six into the CJ-8 Jeep scrambler chassis. Added 5.0L Ford injectors. The engine has a Mopar EFI/MPI system that has always pinged, even with the tired 4.2L original engine.

Some say use even bigger injectors. Others say to shim the throttle or crank position sensor. Or use an adjustable fuel pressure regulator. Or grind off safety tabs at the distributor to allow indexing. Or get a computer from a 4.0L.

I’m stumped and hate to just throw parts at the project. Have a trip planned and will use 104 octane boost and see if that helps. Your thoughts?

Mark B.

Reply from Moses…

Mark, you could need an adjustable fuel regulator with the 5.0L Ford injectors. This will increase fuel volume/pressure and flow rate. Flow is inhibited if fuel pressure is too low.

At my magazine, I provide tuning direction for these inline 4.6L stroker sixes, including links to the flow-rate and pressure requirements. Here is the URL page:

https://www.4wdmechanix.com/How-to-Tuning-the-Fuel-Injected-Jeep-Inline-Six-Stroker-Motor.html

From that page, there is a link to a chart for all popular injectors, including your 5.0L type. (Verify which injectors you have by part number.) Fuel pressure settings for those injectors are listed here, go down the chart:

http://users.erols.com/srweiss/tableifc.htm

Have your tech check the current fuel pressure at the fuel rail and compare with the requirements for the 5.0L Ford injectors (by part number on the injectors). I would also check the fuel pump output pressure to make sure it is adequate to the rail.

Install a new inline fuel filter if not already done…If currently at low rail pressure, with sufficient pump pressure, an adjustable regulator will bring the system up to par if your version of the Mopar EFI can accept the adjustable regulator offered by HESCO.

Here’s the HESCO listing if you have the two-rail EFI/MPI version.

If the rail pressure and volume are off much, install the adjustable regulator. If not, save your money on that one.

As for your other comments:

1) Timing is from within the PCM. Distributor “indexing” is strictly to match TDC on #1 cylinder (the crank sensor pickup) and coordinate with the distributor position. Not a good idea to grind off tabs.

Note: Good idea to make sure the Mopar crankshaft position sensor indexes with #1 cylinder’s piston at TDC! This is done with a degree wheel if necessary or a timing light with built in advance: read actual degrees of advance at the PCM with scan tool; turn timing light to zero. Crank sensor should index with TDC. If not, move sensor to match TDC at crankshaft with zero degrees of timing.

2) Shimming or shifting the crank position sensor would alter the crank position regarding timing. Yes, this could change the spark timing if too far advanced. Worth a try if ignition timing is the issue. Verify TDC #1 piston alignment with the crank position sensor…A timing light can illustrate the range of timing currently employed.

3) You do have a computer from a 4.0L. The Mopar EFI/MPI two-rail system is a 1994-95 factory PCM for a Wrangler or Cherokee 4.0L.

4) A caveat from Mopar: Run at least 195-degrees F on the cooling system/thermostat. Otherwise, the engine’s PCM thinks the engine is still in warm-up mode and adjusts timing accordingly.

Many think “cooler is better”. In fact, the emissions requirements for a 4.0L engine require a minimum 195-degree F thermostat to meet tailpipe standards. That’s your PCM’s expectation.

Keep me posted…

Moses

Freshly Built 232 Snaps Rocker Bolts!

—–Original Message—–

From: Chad A.

Sent: Tuesday, May 15, 2012 5:55 AM

To: 4WD Mechanix Magazine

Subject: Rocker arm bolts

Moses,

Help…..Yesterday afternoon, I was breaking in my 232 in my CJ7. After about 10 minutes. The motor started to pop and died. I tried to restart with no luck. After some troubleshooting, I found that about 6 of my rocker arm bolts broke. They all broke flush with the head casting. Luckily, I was able to take a pick and turn them out.

The best reason I can come up with is that I over torqued the bolts. I use a torque wrench on everything but maybe I read the wrong torque and over tightened the bolts.

The bolts were stretched and not sheared that is why I think that I over torqued the bolts. Have you ever experienced this before? Is there anything else I should be looking at?

On another note, my kids and I have been enjoying the XJ. It is great for the family and the kids love running through any mud hole we can find. It has been great for commuting and even better squeezing into the campus parking lots.

Better get going. Now that school is out for the summer, I am back at work.

Chad

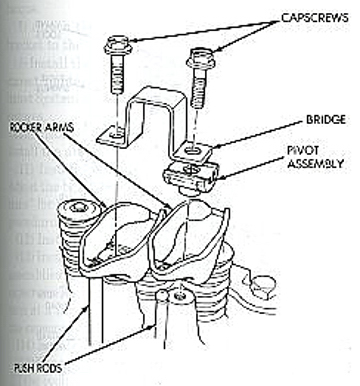

Hi, Chad…Thanks for giving me the whole picture. This could be over-torqued bolts but could also be a timing chain that jumped or is out-of-phase, causing the valves to interfere with the pistons. There is also the issue of pushrod length on an AMC engine. Unless you have adjustable rockers (early 232), the valve clearance is controlled by pushrod length or valve stem height. (Do you have adjustable rocker arms or fixed pedestal type?)

For AMC engines, there are various length pushrods available and even adjustable pushrods. (See Clifford Performance, they have been a source, possibly HESCO.) A decked cylinder head, the valves ground or replaced with new, valve seats cut or a head gasket of a different thickness—each impacts the hydraulic lifter clearance. This requires checking the plunger height in each lifter to assure adequate valve clearance. Hydraulic lifters require the plungers to “float” below the fully extended height, X-thousandths of an inch or a certain number of turns of the rocker adjuster on adjustable rocker arms. Solid lifter camshafts require actual clearance between the stem and rocker arm with the valve closed completely and the camshaft lobe on its heel.

The popping sounds like either unseated or unopened valves, or valves out of timing. Unseated could be wrong pushrod length, incorrect valve lifter plunger height, incorrect valve timing (chain and sprocket alignment) or as you suggest, dramatically over-tightened rocker studs that snapped (unlikely for six to break in short order, could happen, though). Two more possibilities: valve rocker arm bind on the valve stems or valve springs binding from inadequate range of travel. Rocker-to-stem alignment is critical through the range of travel. Spring bind results from springs being too short due to shortened valve stems or too much shimming beneath the springs.

Also, binding rocker arms from lack of oil can load the valve train pieces. Were the rockers getting oil? Do oil passages match in the cylinder head and block? Good oil flow?

I’m betting first on pushrod length being too long…Once the lifters began to pump up with oil, the clearance went away and valves would not seat completely. Did you use pushrods from another engine or source that be the wrong length? Valve stem height and deck clearance can alter the relationship of these parts, even with the “correct” pushrods. Check the pushrods for straightness. If the valves interfered with the pistons, the pushrods could be bent, even the valves can bend, and the load on rocker studs is huge.

If the pistons, valves and valve springs are not damaged, you can remedy the problem without removing the head. To check valve timing with relationship to crankshaft degrees, borrow a timing wheel if necessary and use opening and closing specs for your camshaft. You can check valve timing without removing the timing cover. Troubleshoot as much as possible without tearing down your fresh 232 engine build. You may find a simpler solution here.

This should help. We can discuss the situation further once you make findings…

Regards,

Moses

Rocker arm issue continued…

—–Original Message—–

From: Chad A.

Sent: Thursday, May 17, 2012 6:00 AM

To: 4WD Mechanix Magazine

Subject: RE: Rocker arm bolts

Moses,

My rockers are fixed pedestal and I reused the original push rods. My oil flow is good, I can see the oil fill the rockers. I think the popping was from losing the rockers and the valve seating. The engine purred until I started to lose rocker arm bolts.

Looks like I may be having a coil binding problem. I spoke with Comp Cams and found out I was supposed to use their valve springs for the Comp Cam I purchased. According to Comp Cams, the factory springs do not compress enough. In hindsight, I wish I had contacted Comp Cams directly to purchase the cam. The retailer I used did not list the valve springs as required.

Turning the engine over with the starter, I am not seeing the springs compress fully but, maybe once the lifters are pumped up that is the case.

Either way, I am going to replace the springs and look for any other possible causes. Hopefully, my new cam is not trashed. All this happened while breaking in the cam.

Breaking a new motor while you are breaking it in is a real bummer. And to top it off, when I was running back and forth to my large roll away tool box to troubleshoot the problem, I did not realize that I was opening drawers and not shutting them. I open my large top drawer to grab a socket and my tool box tipped over. I held it up for awhile and tried to get it upright but, after a few minutes I realized I was fighting a losing battle and had to let it hit the ground. Tools and parts scattered across my shop floor. Kind of funny now but not so much then.

Lucky for me, I consider both incidences learning opportunities.

Thank you for the help.

Chad

Hi, Chad…I did mention coil spring height as one of the many possibilities. Glad coil bind is the problem, as you probably did not experience valve-to-piston interference.

Here’s the good news: You can replace valve springs without removing the head. Remove rockers and use an over-the-top valve spring compressor. Make sure each piston is at its top when removing the pair of springs. That way, valves cannot drop into the cylinder. Use an air hold (homemade or in a cylinder leakdown kit; I can describe how to make one if necessary) to keep valves up while removing the springs. Use care, watch your guide seals, and change one cylinder’s springs at a time.

Check your pushrods for straight, and also check lifter clearance with spark plugs removed and pistons at their height. (I can describe how to do this if necessary.) Sounds like you should not have a pushrod length issue unless valve seat grinding or head decking threw off the rocker arm relationship to the camshaft. Measure valve stem height (valves closed) to make sure CompCams’ springs will not produce coil bind. I can provide height measurements if needed. Share engine year.

Let me know the outcome. This could be far worse. Trust you found all of your tools, I got the “visual” on that one. Oh, boy! I’ve had the heavy draws roll outward simultaneously and caught them in time, fortunately. Have experienced the adrenal rush this delivers…I place a metal riser strip under my box’s front wheels to tilt the draws slightly rearward. You know the caveat: Avoid opening more than one drawer at a time if possible.

As for camshaft break-in, this is a flat tappet lifter valvetrain. Contemporary oil does not contain zinc or other remedies for camshaft break-in. If you used assembly lube for the cam, that helps. I highly recommend a bottle of CompCams break-in oil additive.

Very pleased to hear how well adapted the XJ Cherokee is to family life. They are that way!

Regards,

Moses

Converting Early CJ5 to Modern Steering Gear

Q-1. From: Mark S.

Sent: Sunday, August 28, 2011 12:24 PM

To: 4WD Mechanix Magazine

Subject: 56 CJ-5 Steering

I have a quick question regarding a possible steering upgrade for my 56 CJ5. It is going to be my ranch/hunting rig and I would like to upgrade the steering but it has a large PTO driven winch on the front which I refuse to part with and precludes a Saginaw installation. So I was wondering which you think would be better… Rebuild the factory steering or fab up a rack&pinion set-up?

Thanks for the help!

Mark

A-1. On Sun, Aug 28, 2011 at 3:26 PM, 4WD Q & A qanda@4wdmechanix.com> wrote:

Mark, if you have a copy of my Jeep CJ Rebuilder’s Manual: 1946-71, I share a Saginaw manual gear installation that should work with a PTO winch. Please send me a photo(s) of the front bumper and frame section, including the left (driver’s side) of the winch and the PTO driveshaft…Let’s see if a Saginaw unit will work or not.

Regards,

Moses

Q-2. From: Mark S.

Sent: Monday, August 29, 2011 8:54 AM

To: 4WD Q & A

Subject: Re: 56 CJ5 Steering

Moses,

Thanks for the quick response. As a matter of fact I do have a copy of your CJ Rebuilder’s Manual as well as your Jeep Owner’s Bible, they are great resources!

Unfortunately I am currently traveling, so it will take a couple of weeks to get a photo taken. But the winch is rather large and sits inside the frame rails with the driveshaft coming right down the inside of the left frame rail right where a Saginaw box normally would sit. The only possible option I could see is mounting the steering gear outside the frame rail. Are you aware of any any Saginaw applications that mounted to the outside of the frame rail?.

Thanks again,

Mark

A-2. From: 4WD Q & A

Date: Mon, 29 Aug 2011 10:05:27 -0700

To: Mark S.

Subject: RE: 56 CJ5 Steering

Hi, Mark…Glad you have my books and find them useful.

Here’s an idea: There are Saginaw truck gears from the fore-aft draglink era, circa 1955 (2nd series) through 1959. These gears have the solid steering shaft and a closed column tube, commonly found in 1Ž2-ton and 3Ž4-ton Chevrolet and GMC truck models. The gear is a recirculating ball-and-nut Saginaw design, a great unit, and the column configuration is roughly what you have with the current Ross column and gear unit.

Of course, you can rebuild the Ross gear; however, if you prefer the Saginaw gains, there may be a way to go here. You would need to fabricate a drag link from the pitman arm to the current bellcrank on your vintage CJ. Look into this and consider the possibility. The column would need the correct mounting angle and length, measuring carefully and performing any modifications to a high safety standard.

I have scanned and attached an image of such a gear in a 1958 Chevy half-ton truck application. This is the recirculating ball design with a fixed column and a solid steering shaft.

Trust this will foster some ideas…We can discuss this further.

Moses

Q-3. From: Mark S.

Sent: Thursday, September 08, 2011 7:49 PM

To: 4WD Q & A

Subject: Re: 56 CJ5 Steering

Moses,

Thanks for the great idea, pictures always help:) While looking through old chevy truck sites at the set-up you described, I found that 68-76 2WD Chevy trucks had their steering gear mounted on the outside of the frame in front of the axle. In fact they sell a Power Steering Conversion Kit for 47-59 Chevy trucks that utilize this 2WD steering gear. The steering shaft will have to pass through the inner fender which isn’t a problem and it would allow me to eliminate the bellcrank, but I wonder about tire clearance.

I don’t plan on running huge tires, 31″ max (Probably 30×9.5 or 31×9.5R15 unless I make the move to 16″ rims and then 235/85R16). I do plan on doing a shackle swap and adding a little lift (but absolutely nothing over 2 inches total). So that may provide a little extra room… I imagine this just may require a mock-up as the Jeep is going back together to see what I have clearance for.

I’d love to hear your thoughts! Thanks again.

Mark

A-3. From: 4WD Q & A

Date: Fri, 9 Sep 2011 00:42:44 -0700

To: Mark S.

Subject: RE: 56 CJ5 Steering

Now you’re on it! That’s an open column arrangement that will provide some flexibility for the steering shaft(s) to an upper column. See my CJ Rebuilder’s Manual for ideas on the upper column and use of D-bar and universal joints.

The distinction is the box outside the frame rail. Imagine the suspension cycling to maximum axle travel. Make sure there is sufficient clearance for brakes and wheel/tires. If so, the draglink will move laterally in this arrangement, common with vintage changeovers to a “short tie-rod” and a one-piece tie-rod between the wheels. With the one-piece tie rod and no bellcrank, you will have tauter steering. The shackle reverse adds further stability to the steering. Advance Adapters sells the steering linkage; note their catalog suggestions, too.

Let me know how the fitment shapes up. You do have angles to overcome with the steering shafts and joints. Make sure joints are complementary angles to cancel each other out and prevent binding. Joints must be in phase, too.

Happy to clarify…

Moses

Q-4. From: Mark S.

Sent: Monday, October 24, 2011 6:28 PM

To: 4WD Q & A

Subject: Re: 56 CJ5 Steering

Moses,

Found a better option after some research. Either a steering gear box off of an International Scout II… Sits outside and above the frame rail with a forward facing pitman arm. Would solve the wheel clearance issues that would probably popup with the outside the rail ford box. See picture attached.

Mark

A.-4. Very smart, Mark! Is that a Ford or Saginaw power gear? It’s very compact and tight to the frame as you describe. Open steering shaft and column links make this install so much easier! Scout II looks like the way to go. This provides a number of pitman arm options, too, including dropped and proper lengths for the right ratio. The tie-rod is one-piece, the drag link one piece, eliminating the OE ’56 bellcrank.

As you note, the Scout II gear operates a forward mount pitman—somewhat rare! The OEM CJ Jeep-Saginaw 1972-up points the pitman arm rearward, the opposite pitman arm swing, mounting the gear way forward on the frame…I like the Scout II approach better if the aim is to move the gear outside the frame rail for either more engine bay clearance or to keep from modifying the front crossmember to accommodate a far-forward mounted ’72-up Jeep-type steering gear.

Keep me posted on how this turns out!

Moses

304 V-8 Distributor and Engine Oiling

From: G B

Sent: Wednesday, October 12, 2011 9:51 PM

To: 4WD Mechanix Magazine

Subject: 79 CJ7 304 V-8 Oiling Issues

Hello Mr. Ludel,

I cannot say enough about your Jeep CJ Rebuilder’s Manual 1972-1986! I have been around vehicles all of my life and have fond memories of my 1952 Willys truck and 1977 Jeep Cherokee Chief that I squeezed a Chevy 454 big block into.

I am in the process of doing a complete body off frame restoration and have a few questions on the engine rebuild, primarily the oiling of the 304 V8.

I disassembled the engine after it quit while driving to town. The teeth on the distributor drive gear on the camshaft were almost completely worn away! I installed an HEI distributor about a year ago. Could this have caused it? I have searched online and found the AMC V8’s to be very susceptible to oiling problems… is this true?

I have a new timing cover, new oil pump gears, new cam and distributor gears, and going to install an auxiliary oil feed line to the rear of the lifter galley from the threaded oil plugs at the front of the lifter galley.

Do you believe these steps will alleviate any future oiling problems? Any suggestions or tips for this and any other issues I should address while I’m building this 304?

Thank you so much for your time and wonderful books!

Gary B.

A. On Thu, Oct 13, 2011 at 6:29 AM, Q&A 4WD wrote:

Gary, thanks for the comments on the books…You have a really nice CJ! Your approach to the 304 is appropriate for eliminating oiling problems. You have covered all typical possibilities.

As a precaution, given the track record of the previous drive gear, make sure your HEI drive gear material is compatible with the camshaft material. (MSD offers various material types and suggestions about compatibility; consult your camshaft manufacturer if necessary.)

Also, you describe this as an “HEI” unit. Is this an AMC V-8 Motorcraft unit or an aftermarket distributor? Make sure the distributor shaft and gear depth is correctly aligned with the camshaft gear. You can run a tooth contact pattern if necessary.

A worn aluminum timing cover is the usual culprit for oiling and distributor runout issues. Changing the cover was smart. The oiler line sounds interesting; I’d like more details about this auxiliary feed line.

Regards,

Moses

Q-2: From: G B

Sent: Wednesday, October 19, 2011 6:26 PM

To: Q&A 4WD

Subject: Re: 79 CJ7 304 V-8 Oiling Issues

Thank you so much for the reply. The HEI unit is aftermarket designed to replace the Motorcraft unit with the GM style electronic ignition.

Excellent idea on the gear tooth pattern and depth. I will check that. I’ve included two pictures of the oil bypass method, one with flex line and one with steel hard line.

Thanks again for your time and interest. Gary

A. An aftermarket HEI could have questionable drive gear material. Good that you replaced the drive gear with a camshaft-compatible material. Also, there are diameter differences between AMC Motorcraft and HEI G.M. distributor gears.

Compare the diameters and tooth contact patterns carefully…

This is a very interesting solution to oiling. It is easy to implement and well-conceived. A heat and oil-resistant line would make the best sense. This particular area of the engine is hot and flooded with hot oil.

What is the history and origins of this upgrade? Is this an AMC V-8 racing technique from the Trans Am era or just some sensible rebuilding? What governs the oil volume flow? Is there a restrictor or full pressure between these two points?

The possibility of an oil pressure drop would be my concern here. Does the bypass create issues with oil volume, pressure or delivery at other areas of the engine—like the camshaft or crankshaft bearings? Any comments on these issues?

Presumably, the oiling system is boosted for high-volume flow. Is this approach for an oil pan and pump pickup system or for a dry-sump system?

Regards,

Moses

Exhaust System Upgrade for a 360 V-8

From: Mike S.

Sent: Monday, July 18, 2011 12:17 PM

To: 4WD Mechanix Magazine

Subject: Question about welding side exhaust pipe hangars

Dear Sir,

I am a fairly “mature” guy of 57 years old and the 1980 CJ7 that I am rebuilding has been a great project for me that I am doing basically by myself (with your book) and in my garage. I started with taking everything off the frame and having it sand-blasted and the rear frame rails welded with double-er plates and put a new rear cross-member on the frame. I had the sand-blaster hit the frame once more and then I applied Por-15. I found a 95 YJ tub in the salvage yard for $200 and bought it and had it painted a “Ford Red”. I got a 360 AMC on e-bay for $400 and retrieved it in my pick-up.

I found a T-18 tranny out of a 1976 Ford pick-up and I have the D300 transfer case which now has a twin shifter. Oh, in addition I had ARB lockers installed in the front Dana 30 and rear AMC 20 axles, so I will be running the air lines and installing the compressor soon. I am also installing a hydraulic clutch and VANCO hydra-boost brakes. I am going to 35”tires now, instead of the 32’” that I had before. The vehicle has a 3 ½” lift from Rough Country. The gearing has been changed…but I forget the ratio right now. Also went with solid axles and had the axle tubes welded on the AMC 20. I went with a chrome-moly axle up front.

I never did anything like this before, but always wanted to tackle it….other life events just keep grabbing the time away. I do find myself spending time thinking about things way too much which causes many delays but I am learning even more than I ever thought that I would. Right now and am preparing to attach hangars for the Hedman header/Side pipes that I got from 4WDH. I am not sure just how to attach these hangars. Should the side pipes be parallel with the frame and body? I have WARN Rock Sliders on the rocker panels and it looks like I could position a short length of steel angle off of the Rock Slider and bolt the hangar through that angle and weld the curved end to the side pipe? Would this be a good approach?

Thanks for any help that you can give me.

Michael S.

Hi, Mike…If mature means 57, I’m relieved to be a healthy 62-year-old, still riding a dirt bike and scaling rocks with cameras in tow. (My formula: Stay active, eat well and disregard your chronological age!) The YJ Wrangler tub makes your CJ/YJ unique and desirable; you have the trusty CJ-era frame and drive axles. I like the AMC 20 axle with one-piece axle shafts, and the Dana 30 low pinion will hold up well; however, I would limit the tire size to 33” unless you have 4.88:1 axle gearing. 4.10 to 4.56 will work better with 33”. You could get by with 35” and 4.56:1, although the Dana 30 is a small ring-and-pinion for that size tire. Remember, with the twin-stick on the D300, you have an issue: The system can operate in front drive only, which doubles the physical load on that Dana 30 front axle when used in that mode.

As you know from my book, I do like the T-18, and in combination with the D300, you’ve got plenty low gearing in low range, 1st gear. This is all good…

Regarding the Hedman headers and side pipes, I’m not a fan of side-exiting exhaust. I do like the headers, which provide gains. You’re running a 360 AMC V-8, and I would route exhaust pipes to the rear as either a large single pipe or duals. Otherwise, with side pipes exiting in front of the rear tires, trail crawling can load up the engine, exhaust fumes can creep into the tub, and occupants will get saturated with CO and HC.

Running mufflers out of the way and high is the best approach, clear of ground obstacles and not as apt to set the brush on fire. I would bring the exhaust under the chassis if the header exit points will allow it. (Please clarify the dump point, inboard or outboard of the frame rails.) In any case, I always take the tailpipes to the rear of the vehicle. If that means mufflers outboard of the frame rails or whatever, I find a way to route pipe back under the chassis for a rear exit.

A muffler shop can help bend and fabricate tubing accordingly. If you’re hanging pipe or mufflers yourself, always use a flexible, heavy-duty strap hanger to allow for motion, tub flex and the movement between the engine, frame and body.

I’m here for further questions…

Regards,

Moses

Mike has an additional question…

From: Mike S.

Sent: Wednesday, July 20, 2011 5:06 AM

To: 4WD Q & A

Subject: RE: Question about welding side exhaust pipe hangars

Moses,

Thanks for your quick reply. You asked about the Hedman headers…well it dumps outside of the frame rails. I have to tell you that I have probably spent $10K on this machine so I am at the point where I just want to minimize expenses, so I will probably just stay with the set-up that I have. I should have thought through this exhaust system with greater attention to running the pipes inside the rails. However, I ran the stainless steel hard lines for fuel and brakes inside of the driver’s side rail so I’m wondering how I could run those hot exhaust pipes there too???

The gearing that I had installed in my axles are 4.56 ratio. I’m wondering why these would not be good with the 35” tires. Given the small pinion on the Dana 30…would you suggest that I just forget the twin stick?

Thanks again. I refer to your book all the time…it has a prominent place in the garage! Or in the living room during the evening.

Mike S.

Moses replies…

Hi, Mike…I understand the cost factor. My approach at this point would be mufflers under the tub, outboard of the frame rails, with the hangers attached to the frame, not the body. Use a heavy-duty bracket per side that bolts or welds to the outside of the frame rails. Extend these brackets over the rear end of each muffler. Allow for the motion between the engine and frame by using muffler hangers that have heavy-duty straps.

I would then wrap the exhaust pipes under the frame at the rear axle kick-up point, forward of the axle and inboard of the wheels and tires. This sounds busy, but a muffler shop can implement these bends without creating restrictions or interference with brake or fuel lines. Experienced shops do magic here, routing the left and ride side tailpipes over the axle and out the rear of the vehicle. Since you have $10K invested, the tailpipes I describe are a minimal expense, and you’ll breathe/live long enough to get a return on your investment!

4.56 gears will pull the 35” tires. You do not have overdrive with the T18, so you will actually gain some overdriving effect from the 35” tires. You have a compound low 1st gear for crawling…As for the twin-stick, just use it prudently.

Regards,

Moses

Follow-up on 4.7L Stroker Long-Block

My old 1981 I-6 258 is tired and needs to be replaced. I added Mopar’s EFI kit several years back and that helped a lot, but it’s tired and is a slug on the road. (On trail, the 258 is a great mill.) You shared last month that Mopar has offered a 4.7L stroker long-block. Do you have personal observations on the actual performance gains? I will have to pull a number of items from the existing motor to get it running. The plan is to get a drop-in replacement long-block that will mate to the existing motor mounts and the T176 transmission bell housing.

Also, this winter I noticed that in low range under load, going down a steep hill, the Dana 300 transfer case would jump a gear, wanting either to pop out of gear or almost—very unnerving when that happens. Research shows the detent springs on the shift rails may be worn and this equals slop. I’m still using a single stick set up. When the motor is pulled, I can ‘R&R’ the t-case and might even go with Advance Adapters’ beefier in and out shafts. For now, the “poor boy” fix is to simply bungee the t-case lever fully forward, and that works.—Mark B.

I had the chance to drive Mopar’s XJ Cherokee with the 4.7L six at Moab. We drove in sand and high range 4WD. The dramatic increase in low-end torque becomes immediately clear. This is neither a 4.0L nor a 4.2L but rather an improvement over either of those engines. Although Mopar declines to offer dyne results (as these are often challenged and reflect a variety of tuning variables), here are credible comments that, based upon my experience, sound plausible. They come from thoughtful contributors and are courtesy of http://www.ajeepthing.com/stroker-motor.html. (See that website for further details and author credits.)

“I transformed a junkyard 4.0L short block plus a pile of parts into a rip-snorting torque monster with a displacement of 4563cc (4.6L)…My stroker engine’s producing a calculated 265 hp @ 4900 rpm and 325 lb-ft @ 3500 rpm. At least 278 lb-ft (1.0 lb-ft/cubic inch displacement) is available from 1500-5000 rpm, and over 300 lb-ft is on tap from 2000-4500 rpm. The difference in performance over the old modified 4.0L is very noticeable, particularly from 1500-4000 rpm where I need it most. Performance wise, this stroker engine has hit the bull’s eye!”

”A Hesco 4.7L stroker dyne’d 267 hp @ 4700 rpm and 332 lb-ft @ 3400 rpm at the flywheel…Another Hesco built 4.6L stroker did even better on the engine dyne, producing 269 hp @ 4800 rpm and 340 lb-ft @ 2500 rpm.”

“Limeyjeeper built the 4.0L engine from his ’99 WJ into a 4.6L stroker engine using this kit. It produced 210.5 hp @ 4800 rpm and 262.4 lb-ft @ 3800 rpm on the chassis dyne. Assuming a 20% drivetrain loss (RWD with automatic transmission), that’s 263 hp and 328 lb-ft at the flywheel…Specs are the same as a medium-buck stroker except for 0.030″ overbore, Ford Motorsport 24 lb/hr injectors, stock intake, and a 62mm [throttle body].”

The last engine likely produced even more power than assumed; 20% is a conservative adjustment for rear wheel versus flywheel horsepower with an automatic transmission. These results sound compelling.

A 4.0L block like the 4.7L will work with your bellhousing, spacer plate and T176. Yes, the long-block will fit, including the provision for your 4.2L bolt-on motor mount brackets. The crankshaft follows the stroke of the 4.2L but has later 4.0L pilot dimensions. A retrofit pilot bearing and your original flywheel will bridge the conversion. (See Hesco or Advance Adapters for the bushing.)

AMC’s coup was the use of bolt-on front engine brackets in addition to a common block bellhousing pattern for the 4.2L and 4.0L engines—and V-8s for that matter. The 258/4.2L CJ uses different bolt-on brackets than either the 4.2L or 4.0L YJ or the 4.0L TJ application. (An XJ Cherokee falls into this mix, too.) Your early brackets should fit the 4.0L/4.7L block.

Mopar does not address the issue of CJ chassis or T176 transmission fitment. The marketing approach is a direct replacement for three model applications of the 4.0L; each is a fuel-injected 1991-up model.

The oil filter mount and adapter will likely require use of the earlier (4.2L) pieces or a changeover to the 4.0L type. The key here is the by-pass valve design and thread type for the filter (U.S. or metric threads). CJ era differs from later YJ/TJ/XJ types…You will likely wind up using CJ 258 pieces (adapter, by-pass valve and stand) with an oil filter for the CJ 258 six. Be sure there is a by-pass/anti-drain back valve in place as required. These parts must be compatible with the oil filter type. You do not want the engine and filter to drain back oil upon shut-off as this will cause a dry start each time you crank the engine. Dry starts cause premature main and rod bearing failure. If you need part numbers for matching, compatible pieces, let me know.

As for gear jump and defective detents, that is seldom the case. In forty-two years of work with transmissions and transfer cases, I’ve found that jump-outs are most often the result of loose bearings and misaligned shafts, worn gears or defective synchronizer assemblies. (Hub misalignment can press against the shift fork, causing a partial disengagement of the gears, which results in jump out.) Worn needle, pilot or mainshaft bearings are common gear jump items.

With a Dana 300, look at the shaft bearings, the clutch sleeve and clutch engagement teeth on the gears. Any wear, movement or flexing of these parts or shafts will cause the clutch fork to move the clutch hub. Partial engagement is the jump-out trigger and very stressful to clutch hub engagement teeth.

Everything I describe requires disassembly, inspection, measurement for wear and, ultimately, a restoration. The only “easy fix” is linkage interference (floor mats, floor hole cutouts and such) that will not allow the gears to engage completely or, in the case of an aftermarket twin-stick, one or the other stick might be out of alignment or suffering from linkage binding or interference.

To isolate detent spring/ball defects, the test is simple: you’ll feel less tension at the stick(s) in the gear positions. A finger-tip push of the lever in either direction will be met with little or no resistance. No resistance means the lever will creep from the gear position. Wear that causes jump-out on helically cut gears is pronounced under deceleration or compression braking. The Dana 300 uses quieter helically cut gears, a plus as long as the transfer case is in good condition.

Your Dana 300 likely needs a rebuild. The best time to take care of this is when the engine/transmission is out of the chassis…

A Father-Son Jeep Project

My son just brought home a ‘68 Jeepster. The vehicle is a rusty mess (see photo) with a V-6 engine. We’re planning on an XJ Cherokee drivetrain. Will a Dana 300 bolt up to an AW4 with no adapter?—Tom H.

An XJ powertrain? That’s an inline six in a chassis designed for a four or V-6 unless you’re thinking of the ’84-’86 XJ G.M. 2.8L V-6. (This is unlikely since you mention the AW4, used only in ’87-up XJs.) The 4.0L is a rather long engine for this application, as the forward frame section design is for a four-cylinder’s bore centers. If it were an AMC Jeepster (’72-up), no problem, as the 232/258 was available with a longer front frame section.

The flange pattern for the Dana 300 is the same as an NP207 or NP231; however, the clock (mounting) positions differ between these two designs. Most Advance Adapters transmission-to-transfer case adapters are now drilled for both Dana 300 and the NP-series transfer cases.

Since spline count on the AW4 can be either 21- or 23-spline, be sure of the AW4’s spline count. The stock Dana 300 is common 23-spline. If you go this route, make sure the AW4 output shaft stick-out length and spline count are appropriate for the Dana 300 transfer case’s input.

I would consider a V-6 for this application, a V-8 if power is an issue. The 4.3L Chevy Vortec V-6 has been a popular swap over the years, and TBI or carburetor options exist. You can retrofit a 700R-4 or a THM350 automatic, using the Dana 300 case and Advance Adapters’ adapter. Since the Jeepster was available with the G.M. THM400 and Spicer 20 transfer case, also consider that possibility, using the common Chevy V-8 version of the Turbo 400 case—which will work with the Vortec V-6, too.

There’s also the issue of steering column clearance on these early Jeepster engine swaps. The typical approach is a conversion to the forward-mounted manual or power Saginaw gear with a one-piece tie-rod. Advance Adapters can provide the steering conversion kit and tie-rods.

Vintage CJ-5 Has a Vintage AMC 196 Engine Swap!

[Imported from the magazine’s Jeep 4WD Forum]

amc 196/ t98 question

Categories > 1945-86 Jeep CJ Models

i have a 64 cj5 that a previous owner has modified. It has a t98 coupled to an amc 196. The engine bay and firewall were modified to accept the longer engine. I would like to replace the 196 with an engine that has more parts availbility and carburetor options for incline and off camber situations. will other amc inline sixes be bolt-in replacements, or do i need to go another direction?

Jason T.

Nash/AMC 196 six dates from the L-head era and was a 1952 Nash ‘Statesman’ application. This is a rugged, very long-stroke (4.25″), smaller bore (3.125″) design, a true “stroker motor”! Not like the AMC 199 or 232/258 and 4.0L AMC seven-main bearing sixes popularized in Jeep vehicles, this vintage 196 came in three forms: L-head (side valve shown at right) and two Rambler OHV versions, one iron block (through 1965) and the ill-fated aluminum block version built from 1962-64. Jason has the two-barrel carbureted, OHV engine at left with an iron block and 8.7:1 compression, rated 138 horsepower @ 4,500 rpm and 185 lbs. ft. torque @ 1800 rpm. This is useful power for a 2,400 pound Jeep 4WD, an actual stump-puller!

Reply from Moses….

replyquote28 March 2011 03:08 PM 4wdforum

Admin – founder 28 posts 0 permalink

Hi…This is Moses…I happened to be working on the website and thought I’d jump into your question. I trust that others will have comments, too. Thanks for joining the forum!

The 196 was an early design block from the Nash era that came in L-head and overhead valve version by the end of its era. The bellhousing pattern and all other features of your four-main bearing engine differ from the 1964-up 199/232/258 and derivative 242/4.0L 7-main bearing sixes. For that reason, other than the current lengthening of your engine bay, the later inline six would not be a shoe-in swap. The T98 is a great transmission.

Jason, the iron block 196 is not a “bad” engine design. My Aunt Millie had a 1962 Rambler, bought new, with the aluminum block. That “revolutionary design” required constant cylinder head re-torquing. It was highly susceptible to blowing head gaskets. On a trip from L.A. to our place at northern Nevada, the Rambler engine burned a hole between two cylinders at the top of the block.

If you have the iron block, this engine could work. It’s a four-main bearing design but durable. OHV gives it 138 horsepower in its late (1962-64) two-barrel carburetor form at 8.7:1 compression. This is a classic stroker motor with a long stroke and smaller bore, producing more torque (185 ft-lb torque @ an impressively low 1,800 rpm), very nice for off-road use. Your engine is a 1964 according to the carburetor tag.

Your easier engine swap route would be a 4.3L G.M. Vortec V-6, carbureted or EFI. Howell makes EFI wire harnesses for this swap. Advance Adapters can fit the engine to the T98 with adapters. You could also consider the 3.8L Buick V-6 engine, carbureted or EFI version, although a wiring harness for EFI would be challenging.

Although the 7-main bearing inline sixes are great, the V-6 would provide a better fit—with one exception: the steering column, if original, can interfere with a larger V-6 or V-8 swap. The usual fix here is the Advance Adapters conversion to Saginaw manual or power steering. These ideas can be expored in the Advance Adapters catalog, available at www.advanceadapters.com.

I trust this helps and that others will jump into the forum discussion. You have a great Jeep model! I will be detailing the Buick V-6 swap soon in an article at the website. (The 3.8L V-6 is now in the chassis of our ’55 CJ-5.) I discuss this swap in my Jeep CJ Rebuilder’s Manual: 1946-71.

Owner of 196 Hybrid CJ-5 continues the dialogue…

From: Jason T.

Sent: Monday, March 28, 2011 10:00 AM

To: 4WD Mechanix Magazine

Subject: ’64 CJ5

Mr. Ludel,

I own two of your books and appreciate your writing and website. You just answered my question about my ’64 CJ5 with a swapped in AMC 196 inline six. You suggest a V6 swap. I was hoping to stay with an inline motor to avoid changing the steering that was rebuilt a short time ago. Is there an inline swap that makes sense in this situation? (The clutch is bad, and I was considering an engine swap in conjunction with the clutch repair.)

Thank you,

Jason T.

Reply from Moses…

Hi, Jason…I understand the inline six/steering clearance issue. Since you have the extra engine bay spacing, you might take some measurements of the 4.3L Vortec or 3.8L Buick V-6s. Typically, the clearance issue with the steering gear is the exhaust manifold or header system. 3.8L Buick V-6 manifolds lay close to the block, unlike the vintage CJ’s 225 Buick V-6 manifolds. Often, you can install a 3.8L with the correct exhaust manifolds and clear the steering column…It’s worth measuring carefully to see how viable these V-6 swaps might be…Look at a ’66-’71 CJ with the Buick 225 for ideas.

If you’re determined to use an inline engine, I have some thoughts:

1) A diesel like the Isuzu 3.9L 4BD (can be coupled to a 700R-4 automatic) with wiring…Even a Volkswagen TDI engine would be a consideration, requires wiring and computer

2) The AMC 232/258 six or 4.0L if length is not an issue (possibly longer than your 196); mate-up to a T98 would not be problematic

3) Vintage long shots: 195 Pontiac slant four (half of a 389 V-8), leans away from the steering gear! Rare but once a viable Jeep conversion; I-H did the same with its 196 four, half of a 392 V-8, the T98 mate-up is not difficult

4) The current G.M. 5-cylinder high tech engine with electronics and its computer/wiring

Some of these ideas involve more work than others, obviously. Happy to discuss this further.

Regards,

Moses

Continuing the 196 AMC Swap Saga!

From: Jason T.

Sent: Saturday, April 09, 2011 5:14 PM

To: 4WD Q & A

Subject: Re: ’64 CJ5

Mr. Ludel,

I am in the middle of my clutch replacement. I think I have found the reason for the failure; the jeep had no pilot bushing. The hub on the clutch disk was destroyed. I am having a little trouble finding a clutch kit that has the correct parts, so I have to piece one together (I have to call Novak on Monday. I need to find a pilot bushing that is an inch outside measurement and 5/8 inside measurement).

Mostly I wanted to show you the pictures of the adapter that was used as you said you were interested in it. After cleaning it, I hit the adapter with some paint because I was concerned about rusting. The bell housing has a number inside it that is 3171785. I couldn’t find a number on the adapter, but it kind of looks like the stock F134 adapter.

I have attached pictures of the bellhousing and adapter.

Jason T.

From: 4WD Q & A

Sent: Saturday, April 09, 2011 7:39 PM

To: ‘Jason T.’

Subject: RE: ’64 CJ5

Hi, Jason…This is interesting…AMC used Borg-Warner transmissions like the T86 and also the T90 (similar to a Jeep application and mounting pattern). So, there is the tie-in for the F-134/T98 adapter plate! It fits to the 196 bellhousing just as it would to the stock F-head housing for a T98 four-speed. (See bellhousing photo below.)

Jason, on closer look, this gets even easier: American Motors used the T90 on “heavy duty” three speed six-cylinder engine applications from 1959-67. The other transmission application is the T86. One clutch housing for ’64-’65 is listed as a #3171965. (Could that be yours? If not, the number you have could be similar.) Aluminum is typically later model, in this case ’62-’65 for the 196 engine. Between Jeep CJ and American Motors components, this is a virtual bolt-in swap—using original equipment parts…Someone did his homework!

As you note, the pilot bearing is essential to clutch disk alignment. Either Novak or Advance Adapters should be able to come up with a pilot bushing by size. Make sure the nose of the T98 input reaches into the pilot properly. Advance Adapters has stick-out pilots that accommodate shorter input shaft lengths if there is an issue here. Measure the “stack height” and depth of the input shaft…The clutch hub must not interfere with the pilot bushing, yet the pilot must support the nose of the input gear.

This is really a sensible, vintage swap. Please share how involved the engine bay modifications were, how the radiator fits up, whether there is adequate space for the mechanical (engine-driven) fan, and so forth. Please send additional photos of the engine installed in the chassis. I’m finding this an overlooked and obvious vintage swap. With the higher CJ-5 hood, there is likely no issue with the OHV head.

Forty years ago, I went wheeling with a flat-fender owner who had an L-head Studebaker six in his CJ-2A. The fit was also good, as this was a smaller engine without excessive length. Naturally, he fought the radiator/fan issue, but it all worked out. Studebaker also used B-W transmissions similar to Jeep, and this allowed a nice mate-up for the T90 transmission. Another popular swap in the postwar period was a Ford flathead V-8 into a Jeep chassis…

Innovation is nothing new! These smaller inline, four-main bearing sixes were durable, easy on fuel, and for a lightweight CJ, they probably made a substantial gain in performance. When AMC went to its inline sixes in 1972, they stretched the frame 3” to accommodate the longer 232/258 engines. In your case, with the Kaiser-era 81” wheelbase CJ-5, the shorter 196 sounds practical. Makes one wonder why Kaiser did not consider this option before the Buick V-6 models. They did use the AMC 232 in J-pickups and Wagoneers from ’65 up…A durable, inline 196 six in the ’55-’65 CJ-5/CJ-6 would have satisfied many owners.

I will update the Q & A when you can provide engine installation photos…On that note, if you document the swap and installation, I’ll do an article on your Jeep’s powertrain (engine/transmission).

Regards,

Moses

Vintage CJ Continues: Always Needs a Pilot Bushing

From: Jason T.

Sent: Saturday, April 09, 2011 5:14 PM

To: 4WD Q & A

Subject: Re: ’64 CJ5

Mr. Ludel,

I am in the middle of my clutch replacement. I think I have found the reason for the failure; the jeep had no pilot bushing. The hub on the clutch disk was destroyed. I am having a little trouble finding a clutch kit that has the correct parts, so I have to piece one together (I have to call Novak on Monday. I need to find a pilot bushing that is an inch outside measurement and 5/8 inside measurement).

Mostly I wanted to show you the pictures of the adapter that was used as you said you were interested in it. After cleaning it, I hit the adapter with some paint because I was concerned about rusting. The bell housing has a number inside it that is 3171785. I couldn’t find a number on the adapter, but it kind of looks like the stock F134 adapter.

I have attached pictures of the bellhousing and adapter.

Jason T.

Jason, this is really an interesting swap! I’m actually impressed with the ease and simplicity of the conversion. It looks like the funneling sheet metal that’s part of the stock radiator core support has been removed. A homemade aluminum box takes its place…

The pilot allows adequate wall thickness for the bushing: approximately 3/16”, as you describe. Place some high-temp grease inside the pilot pocket, not too much or it will prevent the input shaft from seating. Use just enough to wick onto the bushing if needed, heat being the catalyst. Oilite bushings last a long time if the pores are not damaged from burnishing or reaming. Get the correct size bushing to avoid trouble. Advance Adapters (likely Novak, too) generally recommends soaking the bushing in oil before installing.

The disk and clutch cover can be purchased by diameter and bolt circle. This setup should go together easily. Use a new release bearing to prevent having to revisit this clutch any time soon. The vintage CJs use a return spring on the release arm to assure clearance between the throw-out bearing and clutch cover’s fingers when the clutch pedal is released.

Keep me posted. You have a novel setup here. With our enthusiasm and publicizing of the 196/CJ, maybe we’ll start a run on ’64-’65 two-barrel Rambler all-iron 196 inlines! There may be others out there as eccentric as we are!

Moses

Finding a pilot bushing…

From: Jason T.

Sent: Wednesday, April 13, 2011 6:34 AM

To: 4WD Q & A

Subject: Re: P.S. from Moses…

Mr. Ludel,

I have spoken to both AA and Novak and neither is able to help me with the pilot bushing. I talked to a company in Pocatello called Motion Industries that specializes in industrial bearings and bushings. I gave them the specs. They might be able to get a bushing for me, but it won’t come in until Friday. If that doesn’t fit, I may be stumped on the pilot bushing.

Thank you for the information. Thank you for your enthusiasm also. I suddenly have an attachment to this motor and have a strong desire get it moving again.

Jason T.

Jason, try your local NAPA store. Ask them to look up pilot bushings by size: O.D., I.D. and length. NAPA catalogs typically have a section devoted to product by size and description. Also try the tractor supply companies (John Deere, New Holland, Massey, etc.). A savvy parts person may have seen a crankshaft pilot bushing this size in the inventory, or again, they may have a catalog by sizing.

You want a crankshaft pilot bushing by design, as it operates in a non-lubricating environment. A standard, low speed or constantly lubricated bronze bushing may not be suitable.

Do you plan to rebuild the carburetor now? Echlin/NAPA carburetor kits are generally quite good…Let’s see where a refreshed and properly adjusted carburetor leads.

Moses

Getting the AMC 196/CJ-5 Hybrid Back Together

From: Jason T.

Sent: Saturday, April 09, 2011 5:14 PM

To: 4WD Q & A

Subject: Re: ’64 CJ5

Mr. Ludel,

I wanted to show you the pictures of the adapter that was used as you said you were interested in it. After cleaning it, I hit the adapter with some paint because I was concerned about rusting. The bell housing has a number inside it that is 3171785. I couldn’t find a number on the adapter, but it kind of looks like the stock F134 adapter.

I have attached pictures of the bellhousing and adapter:

This is the hybrid 196 AMC inline six Jason’s 1964 CJ-5 chassis. When Jason gets this gem running, I’ll do an article about the unusual conversion. The number of these engines available would be small, so the aim is not to start a rush on 196 AMC swaps but rather to illustrate parts interchangeability and the ingenuity that has existed since the earliest Jeep models.

Thanks,

Jason T.

From:4WD Q & A

Sent:Tuesday, April 12, 2011 11:47 PM

To:‘Jason T.’

Subject:RE: ’64 CJ5

Jason, this is really an interesting swap! I’m actually impressed with the ease and simplicity of the conversion. It looks like the funneling sheet metal that’s part of the stock radiator core support has been removed. A homemade aluminum box takes its place…

The pilot allows adequate wall thickness for the bushing: approximately 3/16”, as you describe. Place some high-temp grease inside the pilot pocket, not too much or it will prevent the input shaft from seating. Use just enough to wick onto the bushing if needed, heat being the catalyst. Oilite bushings last a long time if the pores are not damaged from burnishing or reaming. Get the correct size bushing to avoid trouble. Advance Adapters (likely Novak, too) generally recommends soaking the bushing in oil before installing.

The disk and clutch cover can be purchased by diameter and bolt circle. This setup should go together easily. Use a new release bearing to prevent having to revisit this clutch any time soon. The vintage CJs use a return spring on the release arm to assure clearance between the throw-out bearing and clutch cover’s fingers when the clutch pedal is released.

Keep me posted. You have a novel setup here. With our enthusiasm and publicizing of the 196/CJ, maybe we’ll start a run on ’64-’65 two-barrel Rambler all-iron 196 inlines! There may be others out there as eccentric as we are!

When you get this all back together, get some shots from directly over the engine (front of grill to firewall span) and also the motor mounts, transmission and transfer case…I’ll do a pictorial article or slideshow about this conversion and see that you get photo credits.

I’m actually surprised that this swap was not performed more often…Prior to the Buick V-6 and aluminum 215 V-8 swaps, this should have been a popular way to gain horsepower with significant torque—in a relatively light engine…As a footnote, Buick’s predecessor to the 225 iron V-6 was a tiny 198 cubic inch version (over-square bore/stroke), close to your Rambler 196’s displacement. For old-fashioned torque, you simply cannot beat the under-square 3.125” bore/4.25” stroke of the 196, which produces more torque at lower speeds than the “modern” Buick 198. The Buick engine peaks torque at 2400 rpm (205 ft-lbs). Also, the earlier Buick V-6 engines are notorious for odd-firing vibration (caused by paired rods at the crankshaft’s rod pins). By contrast, an inline six is “inherently balanced”! While I knock the four-main bearing layout, the bearing sizes on the crankshaft of the 196 are substantial.

When you get the Jeep running, we’ll see if that carburetor can behave itself on a slope. If not, after making adjustments, we’ll talk…I have a number of alternative suggestions.