The how-to welding HD video series starts with safety…If you have sufficient bandwidth, these viewing frames can be set for 1080P quality and a full-screen view. Join the “How-to: Welding Class” here at 4WD Mechanix Magazine online!

Welding safety is as important as welding technique. At our shop, safety comes first. Even a two-minute mate up of metal parts or cutting chore calls for safety gear: a leather apron or coat, leather lace-up work boots, an ANSI certified helmet or goggles, and safe welding gloves.

A hot torch can cause burns or ignite debris around the shop. It’s enough to focus on your welding repair or fabrication work—without setting the shop on fire or suffering a dangerous skin burn.

Use a welding blanket to catch slag and hot metal. A Kevlar or fiberglass weave welding blanket, with a high temperature rating, works best. Avoid the use of asbestos in anything, this is a known safety hazard. Protect the shop floor from molten slag burns and damage.

Safety leather coat with apron is a worthwhile investment. Though hot in the summer while welding, the coat helps avoid burns, scrapes and glowing slag debris. Make it a priority: wear protection against hazards and ultra-violet rays that cause skin damage—and can even lead to cancer.

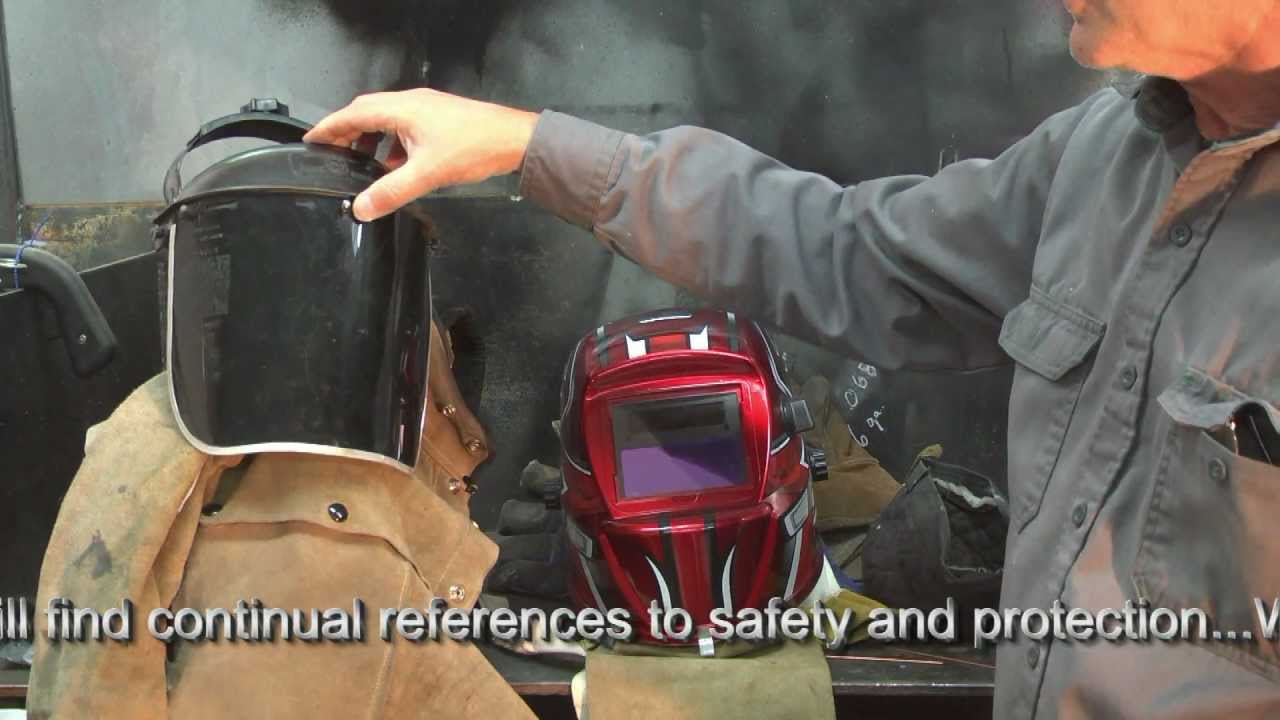

Your welding helmet should offer full protection from hot debris plus the shading required for the type of welding. There are fixed lens and automatic darkening helmets. At right is a helmet that darkens in 1/25,000th of a second to prevent eye damage, yet allows full view for setup of pieces prior to striking an arc. Make sure the helmet is ANSI rated for safety and protection. Shield at left is for gas welding and cutting only.

Click here for quick access to ‘Gas Welding Session One’!