Four-wheeling in the Sweetwater Range or Nevada’s remote high desert country, the Jeep Cherokee must perform reliably. Genuine Mopar parts can make the difference…

Tuning and troubleshooting a Jeep engine means more than just parts replacing. Mis-diagnosis or use of wrong parts can lead to wasted time and unreliable performance.

While modern Jeep vehicles have onboard diagnostics (OBDII-up), these systems cannot pinpoint every trouble. Some troubles require use of a precision scan tool, seldom available in the backcountry. Some oxygen sensor troubles do throw a code (DTC) on the dashboard MIL or “Engine Check” light. Sometimes, however, a defective or improperly calibrated oxygen sensor can create a major drivability problem without ever sending a code to the dashboard MIL.

One difficult scenario is a defective or incorrect replacement part that will not throw a trouble code (DTC). We typically assume that a new part moves that item out of the trouble category. While this is true for genuine Mopar replacement parts, there is often less certainty with aftermarket, generic parts.

A Glaring Example

A case scenario is the magazine’s 1999 Jeep XJ Cherokee 4.0L. When the Cherokee’s original upstream #1 oxygen sensor seemed due for a routine replacement (at 135,000 miles), I decided to replace the device.

The well-used sensor is the OEM for the 4.0L engine. This device still provided service at 135,000 miles. Inside is the new, aftermarket sensor, the second new aftermarket sensor (from the same brand-X manufacturer) to create a dead throttle after an engine restart—either hot or cold.

I have always valued and recommended Mopar replacement parts for our Chrysler-built vehicles—and for good reason. Servicing the Cherokee on a weekend, when the Jeep dealership’s parts department was closed, I ignored my better judgment and purchased an aftermarket oxygen sensor from the local automotive chain store.

Shortly after the new sensor’s installation, the 4.0L engine developed a throttle flat spot. From just off-idle to approximately 1/4 throttle opening, the problem occurred on an engine restart, around the temperature where the fuel-and-spark management shifts from “open loop” (cold/warm-up phase) to “closed loop” (warmed engine). The idle was smooth, without stalling.

The problem was severe. Unless you pressed the throttle past this position, the engine would lean backfire and act fuel-starved. In traffic, this created a hazard. Once pushed past the throttle flat spot, the engine smoothed out and performed properly—until the next restart and warm-up cycle. Then the dead throttle symptom would repeat itself.

This is the OEM Mopar sensor in place. Bench testing revealed a still-functional device at 135,000 miles! The replacement brand-X device faulted shortly after installation. A second brand-X device did the same—immediately.

I have never been a “parts replacer” kind of mechanic. Thorough troubleshooting is always important, and in this case, I began systematically checking over the engine devices and sensors, without suspecting the new oxygen sensor as a trouble source.

Given the warm-up issue and the throttle involvement, I naturally focused on the throttle position sensor (TPS) and two temperature sensors (coolant and manifold intake air). Since the engine ran fine once past the initial flat spot cycle, I ruled out the MAP and MAF devices.

Considering the 135,000 miles on the vehicle, these were logical places to troubleshoot. Each of these devices can be bench tested. The coolant and air temp sensors have parameter tests, performed with an ohmmeter. The TPS is a variable voltage test, performed at different throttle openings.

Each of these devices tested moderately out of range (based upon the ohms or volts indicated in the factory Jeep service manual or data found at the Mopar TechAuthority II subscriber website). Given the symptoms and a fresh oxygen sensor, I replaced each temperature sensor and the throttle position sensor. This did not solve the problem.

Since the problem with the first aftermarket sensor did not occur with a warmed engine, I ruled out the MAP, MAF and other devices as possible trouble sources.

Note: This guesswork would not have been necessary with the use of a DRBIII scan tool. In many instances, it proves cost effective to sublet troubleshooting to your local Chrysler dealership. They have diagnostic tools like the DRBIII, StarScan and, most recently, WiTech.

These are the OEM Mopar pieces. Note the plastic intermediate sleeve and precision, four-prong plug. Aftermarket parts may not be this precise and often lack the fit of genuine Mopar replacement parts.

After a telephone discussion with a friend and Five-Star dealership Jeep technician, I opted for a continuity and ohms resistance test of the recently installed oxygen sensor. My friend had run into this problem before. He took a misbehaving (new at the time) 1999 TJ Wrangler for a test drive with the DRBIII in “pilot mode”. He discovered a subtle oxygen-sensor “blip” as the engine tipped over from open loop to closed loop…The problem went away by replacing just the oxygen sensor—with a genuine Mopar warranty part.

The ohms and voltage tests revealed a discrepancy. When I returned to the parts store, the manager studied the sensor and determined that the store had sold me the wrong item. He asked me to install another sensor, with a different part number. We would see if that solved the problem.

The second aftermarket oxygen sensor also failed. Parts replacing, without clear test results, is no way to troubleshoot or eliminate problems and symptoms.

Installing the new aftermarket part, which incidentally fit a wide variety of engine applications, the symptom persisted—only this time, the dead throttle occurred whether the engine was cold, warming or fully warmed.

For proper fit, correct calibration and reliability, use a genuine Mopar replacement sensor. Look for the “Mopar™” logo on these parts.

The OE oxygen sensor was an NTK unit from Japan, genuine Mopar part #56041212AE for this 1999 XJ Cherokee 4.0L application. Despite the passage of a dozen model years, the new Mopar replacement part looks just like the original part. Connections identical, not generic, the device fits just like the original upstream oxygen sensor.

Startup, warmup, driving in all modes, the engine now performs optimally. Although there are other items that can cause the symptoms described, in this situation, the problem was the oxygen sensor—specifically, an aftermarket, brand-X sensor!

Tightening a new Mopar oxygen sensor in place is time well spent. This device will perform as the engineers at Jeep and Mopar intended.

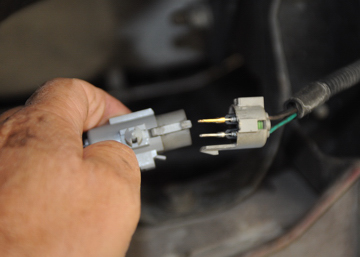

Pin alignment is critical during sensor installation. This is a genuine Mopar sensor attaching to the original lead with four pins. The upstream oxygen sensor is a heated type with four color-coded wires.

A DRBIII or equivalent scan tool can help pin down a faulty oxygen sensor during a real-world set of tests. Without these troubleshooting tools, there are bench tests for faulty devices. When you detect a problem, use OEM Mopar replacement parts that fit properly and offer proper calibration. These are signals that the EFI/MPI system can understand!

Note: When troubleshooting points to a specific device, assure your project’s success by using genuine Mopar replacement parts.

An advantage with the Mopar part is direct fit to the factory engine bracket. The oxygen sensor will align with the engine and chassis as intended.

Here, the new Mopar oxygen sensor plug fits precisely to the OEM engine bracket. The wire will stay out of harm’s way.

Envision these parts in Jeep 4WD service, both on- and off-highway. Take care to route wire aware from the manifold’s heat. As an extra precaution, secure the wire heat shield with a tie-strap. This will prevent the sleeve from sliding and exposing wires to extreme exhaust manifold heat.