Enerpulse Technologies’ Pulstar® PlasmaCore spark plug technology is at the leading edge of internal combustion engine performance gains and emissions reduction. This advanced spark plug design features an embedded capacitor that increases the flame kernal size, enhances combustion and releases more energy by altering the molecular structure of the fuel. The result is an increased, sustained power release from the ignition and combustion of fuel. In this HD video coverage, see the difference this technology makes as we test Pulstar® spark plugs in the real world!

The Pulstar® spark plugs come with detailed installation instructions backed by additional website information and a tech support line. Spark plug installation is identical to conventional spark plugs. Use care handling and gapping these spark plugs, they have an internal capacitor. Follow instructions.

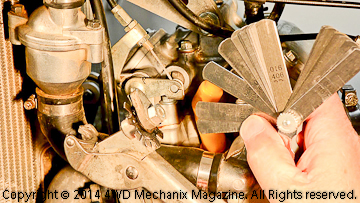

There are two common ways to gap spark plugs. At left is a plug gapping tool that assures parallel gap surfaces between the center electrode and the ground strap. This tool should not be used on smaller diameter electrodes, as the electrode can bend or become damaged. A blade feeler gauge set can measuring gaps like valve clearance or spark plugs. After installing the Pulstar® spark plug in our Honda XR650R motorcycle engine, we experienced a one-kick start!

A single cylinder motorcycle is an optimal test for a spark plug. In road and dirt testing, the Enerpulse Pulstar® Plasma Core spark plug produced noticeably more power from the Honda XR650R engine. This engine, in proper tune and with a fresh top-end rebuild, delivers 55-plus horsepower. The Pulstar® spark plug makes this engine pull even better. Fuel efficiency, a chronic challenge for large-bore thumpers, has improved. An added advantage is less concern around the fixed carburetor jetting and altitude changes.

Our 1999 Jeep XJ Cherokee 4.0L 4×4 is a trail/street machine and representative of millions of Jeep multipurpose powerplants. The switch to Pulstar® spark plugs, by the second tank of fuel, made a marked difference. Tip-in throttle response and cruise speed throttle input have both improved. A gas mileage increase is noticeable and will be monitored closely. This engine is in good condition, with normal compression and a very clean burn before the plug change—optimal for testing! At right, we check the spark plug leads for ohms resistance to make sure our tests are accurate.

At left, the spark plug gapping tool is used prudently, without excessive force. The Pulstar® spark plug has a substantial electrode in this spark plug application. For the motorcycle engines with the smaller diameter electrodes, we use the traditional notched bending tool for opening and closing the ground strap gap to the electrode. In either case, the aim is a gap as parallel and even as possible. Follow the Pulstar® instructions to prevent damaging a new spark plug. Gaps were OEM, and the spark plug torque setting is also factory—as per Pulstar® instructions.

The Honda XR350R is an optimal test bed for the Pulstar® spark plug. The engine is twin-carbureted with fixed jets. Our engine has excellent compression, normal spark and spark timing, and the valve clearances are spot on. The off-pavement testing ran between 4000 and 6000 feet elevation, which drops horsepower considerably as the air thins. This extensive on-the-throttle testing is part of the HD video coverage. See for yourself how these Pulstar® spark plugs perform under load and at altitude! Summing Up: Our Pulstar® Spark Plug Test Results Tested in the three magazine vehicles, the Enerpulse Pulstar® spark plugs delivered! Here are our findings for each vehicle:

1999 Jeep XJ Cherokee 4×4 4.0L—This inline six-cylinder engine is nearly stock. The addition of a Borla header, Random Technologies’ performance catalytic converter and the Hypertech ‘Max Energy’ program tuning are the only modifications. The vehicle’s approximate curb weight of 3,800 pounds with a Warn front winch and an aftermarket ARB front bumper and Warn rear heavy duty bumper. The axles have 4.10:1 ring and pinions to compensate for the 33″ diameter tires and a 6-inch long-arm suspension lift. Prior to testing with the Pulstar® spark plugs, this vehicle operated with Bosch spark plugs that burned well with a fully functional ignition and EFI/MPI system. There were no issues with ignition misfire or EFI fuel supply problems, and this engine has normal, uniform compression and cylinder seal. The change to Pulstar® plugs gapped to factory 0.035″ was the only change made for this test. We waited for the first tank of fuel to burn through before making comparisons. At that point there were several distinct improvements:

1) Better tip-in throttle response at any road speed and under heavy acceleration.

2) Less throttle needed to sustain normal “cruise” road speeds.

3) Less downshifting on grades with cruise control applied. Acceleration improved with both forced and cruise control downshifts.

4) Distinct improvement in fuel efficiency; approximately one mile per gallon improvement (5.5%) under “city” and “highway” or interstate test conditions.

5) Starts immediate; this engine has always started well.

Honda XR650R Motorcycle—This bike is a highway legal dual-sport conversion and ongoing project feature at the magazine. The top-engine is freshly rebuilt to “blueprint” standards, featuring a cylinder head overhaul by L.A. Sleeve Company and a moly-chrome cylinder liner with new piston and rings. We performed all work as a how-to project that became a feature HD instructional video at Vimeo On Demand. The head and upper engine work includes a Hot Cams Stage 1 camshaft. Spark timing and valve timing are “stock” with Honda Power-Up Kit tuning. This popular “uncorking” of the engine’s jetting, induction system and exhaust have each been covered in detail at the magazine and the magazine’s forums. This iconic motorcycle model has a large following, as the XR650R is the largest displacement enduro single cylinder bike built by Honda specifically to win the Baja 1000 and other open desert races. The magazine’s viewers and forum members have followed the performance gains made with this engine build-up and tuning. The addition of the Enerpulse Pulstar® spark plug provided these noticeable results:

1) Since the rebuild and tuning, the engine has produced superior torque (49 lb-ft estimated) and a high horsepower output (approximately 55 horsepower). Along with the Pulstar® spark plug change, we added a 6.3 gallon fuel tank (5 extra gallons of fuel at approximated 40 pounds net weight gain between the fuel and the large tank) to the motorcycle. Testing the Pulstar® spark plug, performance with the additional weight is slightly better than with the lighter 2.6 gallon factory fuel tank. 40 extra pounds is significant for a dirt enduro motorcycle. When we reinstalled the 2.6 gallon tank for further testing, acceleration and throttle response showed noticeable improvement. Torque increased, and fewer downshifts were necessary under load. 2) A converted dual-sport, highway legal machine, the XR650R is kick start only. Tuning has enabled ready starts with a stock-type NGK spark plug. The Pulstar® spark plug fires the engine with equal ease. 3) Flooding is always a concern on a large displacement single cylinder motorcycle engine. The Pulstar® spark plug strongly resists fuel fouling. The spark plug readily fires through richer mixtures at altitude. 4) This engine has a fixed-jet factory Keihin slide-type carburetor. Altitude sensitivity is always an issue with fixed jets. Larger displacement engines are more susceptible to fuel fouling at higher altitudes. The Pulstar® spark plug, with superior spark output and more complete fuel burn, clearly maximizes performance over a wider range of altitude—even with a fixed jet carburetor. During the road and dirt testing, this motorcycle operated between 4,400 and 7,600 feet elevation with no sign of “rich” mixture spark plug fouling. The fixed carburetor jet setting is for 1,500 and 5,000 feet elevation. Clearly, the Pulstar® spark plugs burn cleaner and more efficiently, producing better power and performance at higher altitudes.

Honda XR350R Motorcycle—This OHV bike is strictly set up for dirt riding. The stock motorcycle was upgraded for desert hare-and-hound scrambles, tuned and jetted for optimal performance at 4,400 feet altitude with the stock factory dual Keihin carburetors. In top condition, with normal compression and peak tuning, the only change was the switch to a Pulstar® spark plug. Our extensive testing in the high desert and mountains spans from 4,000 feet elevation to 6,500 feet elevation. A single cylinder, air cooled engine provides an optimal test bed for combustion and fuel burn comparisons. Pulstar® spark plug test conclusions:

1) Starting is easy whether cold or hot. Starts readily with the choke on. Warms normally as with the stock type NGK spark plug. 2) Throttle response is crisp and noticeably improved. Engine stability under load has improved, requiring less downshifting to compensate for load. (Watch the video.)

3) Again, the most significant gain is less sensitivity to altitude changes with fixed jets in these two carburetors. We operated the motorcycle from 4,000-6,500 feet without adjusting the carburetors or altering the jets. The motorcycle performed flawlessly. 4) This motorcycle has always been miserly on fuel compared to two-stroke engines or larger displacement four-stroke thumpers. Testing revealed a noticeable improvement in fuel efficiency. The motorcycle ran our pre-determined course under load and used less fuel-per-hour than with the stock-type NGK spark plug. This improvement can only be attributed to the Enerpulse Pulstar® spark plug.

For More Details About Enerpulse Pulstar® Spark Plugs, Visit the Pulstar® Website at: https://www.pulstar.com