Part 2: Installing FTS ‘Ultimate’ Rear Suspension System

Rear Suspension Work

Installation of the Full-Traction Suspension 4” Ultimate package includes a complete revamp of the TJ’s rear suspension. Steps involved also apply to rebuilding the stock suspension or the replacement of an OE axle assembly. Whether you intend to lift a TJ Wrangler, repair rear suspension damage or replace worn components, this section provides the step-by-step procedures and insights for successful rear suspension work.

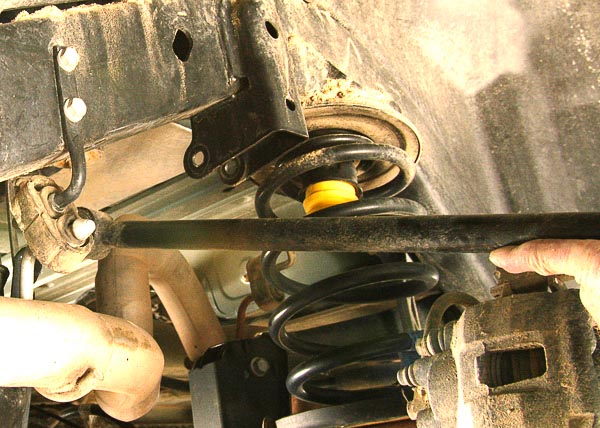

Illus. 74: Front suspension complete, the rear suspension work begins. Position jack stands beneath the axle housing. This right side shock absorber is under pressure. Lower the axle far enough to just unload the shock pressure. Unbolt the shock absorber. The shocks serve as the limiters for rear suspension drop. Once the shock is loose, the axle can be lowered further to release spring tension.

Illus. 75: Repeat the steps to remove the left shock absorber. Keep in mind that the shock absorber is under pressure. The shock is also the limiter for axle drop. Frame stands and floor jacks are another way to unload the shock absorber pressure. I use a chassis hoist to lift the vehicle and adjustable tripod stands to support and lower the axle housing.

Note: If you do not have a vehicle hoist and tripod stands, you can simulate this procedure. Support the frame with four floor jack stands. Raise and lower the axle housings with a pair of quality hydraulic floor jacks placed carefully beneath the axle housing. Always use caution around coil springs!

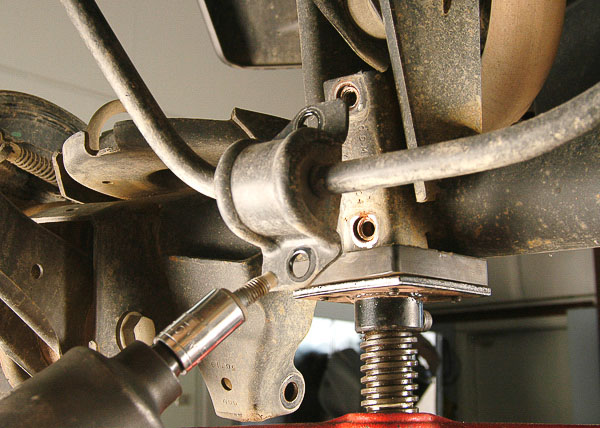

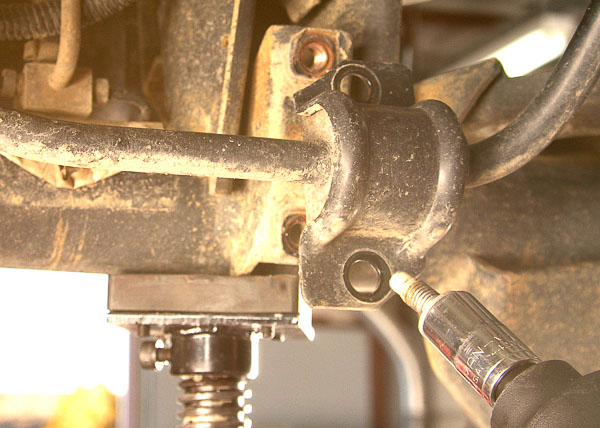

Illus. 76: Support the axle housing to permit loosening of the track bar. Here, OE hardware comes loose at the axle bracket for the track bar. Bolt head is a Torx size. Nut has a weld-on handle. Use the correct tools to detach hardware.

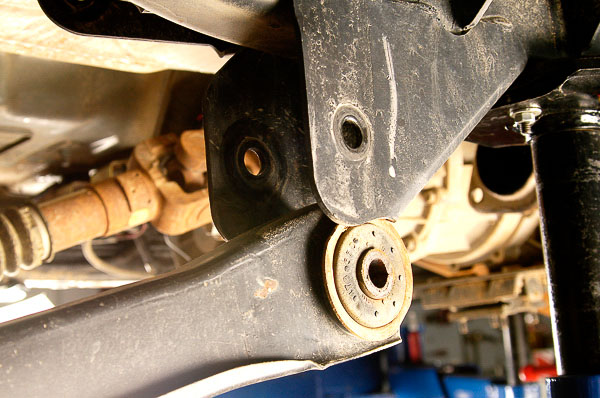

Illus. 77: Frame attachment bracket for the rear track bar is accessible. Loosen the bolt and nut here. Removal of the bolt will free the track bar. The FTS three-link rear suspension system does not use a track bar. If you have stock suspension or want to replace the rear track bar, the bar can be removed and installed in this manner. Once you remove this hardware, the track bar will slide loose.

Illus. 78: You can now carefully lower the axle housing. Watch the brake hose and cables. Do not stretch or stress parts. Lower the axle enough to unload the coil spring tension. Keep the axle housing stable to avoid dislodging the springs under load.

Beware: A coil spring stores considerable energy and can cause severe bodily injury if the force is not properly contained. Do not allow loaded springs to come loose. When in doubt, use coil spring compressors to control spring length and contain the coil springs’ energy.

Illus. 79: Without load on the track bar, the bar can be slid from its brackets. Remove the track bar completely. If track bar replacement were your goal, you could now install the new bar. On this innovative three-link suspension conversion, the FTS design and components eliminate the need for a track bar.

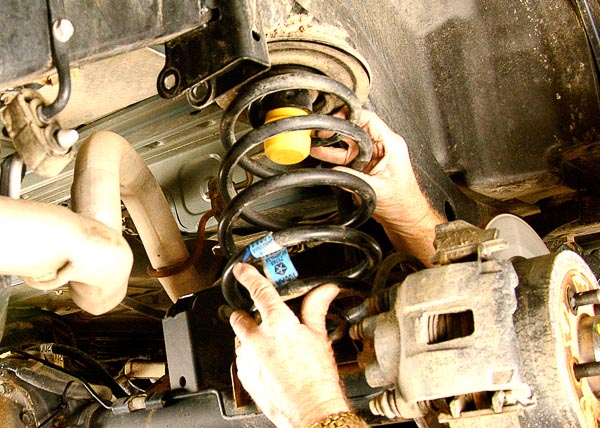

Illus. 80: Continue to unload the springs. Do so evenly. Keep the axle level as you release spring tension. At axle drop with the track bar out and the shock absorbers removed, the springs will be loose in their seats. There should be no need for a spring compressor here although that is always an option.

Important Notes: Suspension Lifts and Brake Safety Issues

Wrangler owners personalize their vehicles in many ways. Choices in recovery equipment, stowage racks, suspension products, tires, wheels and chassis components make these vehicles unique. For this reason, suspension system and lift kit installations require close attention to details. You will find notes and footnotes in the manufacturer’s installation instructions. There are also some general concerns that you should always consider. Among these concerns are brake hoses and brake lines.

Changes to the chassis, wheel/tire size changes and other modifications may affect brake components. The goal is to always maintain a safe brake system, consistent with original equipment engineering standards. Consider these points when installing a suspension lift kit or system:

*Whenever you install a lift kit of any kind, always check for sufficient brake hose clearance. Due to the varieties of springs, sway bar disconnects, axle layouts, wheel/tire combinations and chassis differences over model years, the brake hose lengths may need changing.

*Check brake hose length with the axle in full drop position. If you have sway bar disconnects, unhook disconnect links to increase drop. Allow for axle flex and articulation, which will increase the distance between the brake calipers or axle and the frame brake pipes. Turn the front wheels full left-to-right and observe the brake hose clearance.

*If the hoses are stressed or stretching to any degree, you need to install longer brake hoses. Braided steel hoses are available. OEM replacement hoses of similar design and fittings may be available through a local brake parts supplier or auto parts retailer. Savvy parts counter staff can often find longer length, OEM quality hoses of the same design and fittings as your Wrangler’s hoses.

*When installing longer hoses, make sure that they do not interfere with moving parts as the axle moves through its range of travel. Check the hoses at full drop. Take into consideration the full upward travel of the axles. Turn the front wheels left and right to extremes, observing hose clearance throughout the wheel turns. Be certain that the hoses will not rub or chafe against chassis parts, wheels/tires or steering linkage.

*Tighten the brake fittings properly to avoid fluid leaks. Fabricate brackets, if necessary, to position and support hoses out of harm’s way. Always bleed the brake system after installing hoses. Make sure the front and rear brakes work properly!

Brakes are a critical safety concern. When installing a lift of any kind, check for clearance and safe routing of brake hoses and brake lines at the front and rear axles, along the frame and to each brake cylinder and caliper—before driving your vehicle. Sometimes, the fix is as simple as installing the brake line drop brackets supplied with a suspension package. In other cases, new and longer brake hoses may be necessary. If you relocate or move any brake pipes, be certain that they route safely, away from rough edges or interference with other chassis parts. Visualize the movement and ways that parts may become damaged. Protect your Jeep’s brake system!

Illus. 81: Stock spring lifts from its perch. The axle housing is low enough for springs to actually rotate by hand. There is only slight pressure here. This is the right side rear spring.

Illus. 82: Axle in correct position at drop, the left spring should also rotate freely and lift from its perch. If there is still tension on the spring, look for a cause: There is something preventing the axle from dropping far enough. The axle housing should still be supported by the upper and lower link arms at this stage.

Illus. 83: There is a rear sway bar on the TJ Wrangler. The bar is very easy to identify and remove. Here, I loosen the sway bar support bracket at the right side of the axle housing. Note the hardware and its position for reassembly. The bracket is on the axle housing.

Illus. 84: The left side of the axle also has a support bracket for the sway bar. This matches the right side. The bar is much smaller in diameter than the front stabilizer bar. FTS reuses the OE sway bar. Follow this procedure for removing and replacing the bar.

Illus. 85: The sway bar links fit to the frame. These links are durable, flexible material; however, they can break after years of severe use or from trail abuse. Unbolt the links from their frame mounting points. There is a link at each end of the sway bar. Links use special hardware, including a handle nut and bolt. Always replace this hardware with like kind. Use Loctite 242 for added protection.

Illus. 86: The link frame nuts and bar are now loose. You can lift the bar from the chassis. Inspect, repair and replace components as necessary. Reinstall these parts using Loctite 242 on threads. Set torque to specification.

Illus. 87: Emergency brake cables, brake hose, wire looms and a bracket attach at the upper control arm on the left side. To remove the left upper control/link arm, first loosen the bracket supporting these components. If you are replacing the arm, note the positions of these attachments. Once free of attachments, the arm can be removed.

Illus. 88: Right side upper arm has an E-brake cable support bracket. Loosen the bracket from the control arm. Once the bracket is loose, you can unbolt the control arm at the axle and frame. Continue to carefully support the axle housing as you loosen the control arms. Prevent the axle housing from rotating.

Illus. 89: Here, the left upper control arm is loosened. The axle must be secure on stands as this arm comes loose. There should be no excess pressure on the axle assembly at this stage. With both upper arms loose, the axle housing will rest on the stands with only the lower arms and driveline keeping components in position. At this stage, I keep loosened bolts in the left upper arm to prevent the housing from rotating.

Illus. 90: Three stands support the axle and keep it from rotating. I have strapped the pinion nose to a weighted tripod stand. Once the axle assembly is clearly stable, I remove the remaining hardware from the upper control arms and lift the arms out of the way. Note that the lower control arms are still securely in place.

Illus. 91: To determine the needed degree of pinion/axle housing rotation for the lift suspension, I now remove the center skid plate and driveline. The exhaust system is also more accessible with the skid plate out of the way. A fourth tripod stand fits beneath the transmission at this stage. The axle housing, pinion nose of the housing and the transmission/transfer case are each supported.

Illus. 92: The Rubicon Edition has a factory air compressor mounted to the skid plate. This compressor powers the air locker differentials. When removing the skid plate, first detach the air compressor and wire tie the assembly aside.

Illus. 93: Remove the four transmission mount nuts below the skid plate. With the transmission supported securely, loosen the frame-to-skid plate attachment bolts at the frame rails while a helper or a transmission jack supports the skid plate. Lower the skid plate safely out of the way.

Illus. 94: Skid plate removed, the transmission, transfer case, driveline and exhaust system are now exposed. The driveline and cat-back exhaust system will be removed at this point. FTS 4” Ultimate suspension system requires a CV-type rear driveline and exhaust system changes.

Illus. 95: The exhaust system disconnects just after the catalytic converter. This makes the muffler and tailpipe part of a unit exhaust system. FTS offers a performance muffler and tailpipe to replace this section of the exhaust. For this installation, a local muffler shop can fabricate a muffler/tailpipe that works with the re-vamped FTS rear suspension system. (Check with FTS for available exhaust components.)

Illus. 96: To remove the exhaust system, loosen the hangers and support brackets. This is a modular exhaust system and easy to disassemble. With air tools, it will take only minutes to remove the muffler/tail pipe assembly.

Illus. 97: Exhaust system section on the floor, these pieces will not be refitted with the FTS suspension system. The tailpipe and muffler shape will differ with the three-link rear suspension in place. Removal of the exhaust system makes the axle and suspension more accessible.

Illus. 98: I now loosen the right upper control arm. Factory handle nuts are commonly used to speed assembly and disassembly. The arms come loose readily. Keep track of the hardware, its location and parts positioning.

Illus. 99: Here the left upper arm hardware comes loose. The arm is now loose of the bracket and also free of the attachments. At this point, the two lower arms are still in place and aligning the axle housing.

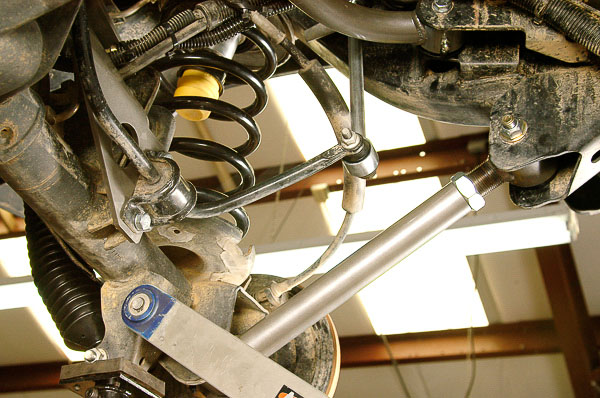

Illus. 100: Confirm that the axle is stable and supported before removing the lower control arms. Here, with shock absorbers, coil springs, upper arms, sway bar and exhaust components removed, the right side view is uncluttered. The lower control arm is accessible. Removing the lower control arms and driveline will detach the axle housing.

Illus. 101: I remove the lower control arm forward bolt. The link arm is now loose and free of the bracket. Keep the axle housing from rotating or shifting.

Illus. 102: Loosen the rear hardware on the lower control arm. The arm is now free, and the axle housing rides on the tripod stands. Opposite side lower control arm still provides some support. The driveline and support stands are in place. You can now repeat these steps at the left lower control arm, freeing the axle assembly from the suspension and frame attachments. Keep the axle stable and protect the hoses, cables, electrical attachments and driveline.

Illus. 103: The next step is installation of the support brace for the V-link suspension. This rugged bracket is precisely shaped to support the innovative three-link suspension system. Brace picks up the OE upper axle control arm bracket mounts, the differential cover bolts and the sway bar mounting point. Here, the bracket and sway bar attach to the OE sway bar mount points. Use Loctite 242 on bolt and nut threads and torque to specification.

Illus. 104: When you reuse OE hardware or add new Grade 8 hardware, always apply Loctite 242 to bolt threads. Use a torque wrench to bring hardware to final torque settings. This brace fits precisely and establishes the pivot point for the V-link brace. The brace pivots in the OE frame mount points for the original upper link arms. Three-link suspension provides exceptional axle articulation and eliminates the inherent binding of the OE four-link, hard bushing link arms.

Illus. 105: The three-link support brace is now in place. OE sway bar fits in its original location. Sway bar links will be replaced. FTS provides new steel links. The three-link support brace provides the mount point for the heavy-duty FTS Heim joint.

Illus. 106: Moly or silicone grease helps prevent bind of urethane bushings. Here, I coat the steel inner sleeve with high-moly content grease. Critical FTS joints have grease fittings. Once the entire system is installed, I will lube each of the grease fittings with a grease gun. My grease of choice will be Texaco Starplex II, highly resistance to heat, pounding and water.

Illus. 107: This is the V-link. It has grease fittings for the urethane bushings. There is a threaded tube section for the Heim joint. A pinch bolt secures the Heim joint once the joint threads into the correct position. These are high strength components with an important task: This brace provides axle articulation at the Heim joint while guiding up-and-down axle movement from the brace’s end bushings.

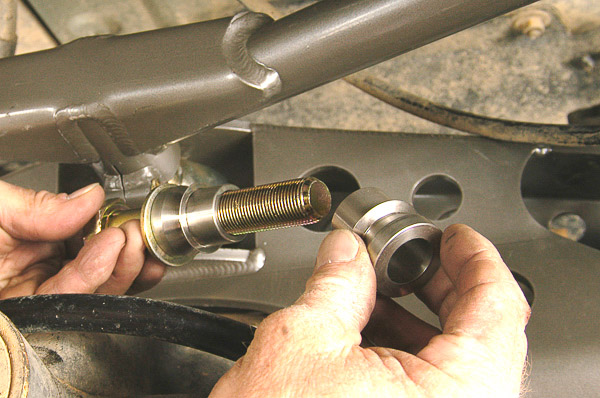

Illus. 108: The V-link’s Heim joint rides in these custom steel bushings. The large Grade 8 bolt runs into a self-locking steel nut welded to the differential housing support brace. These are high end components built to meet or exceed OE quality and longevity. Moving, wear components are serviceable if necessary—just like OE parts.

Illus. 109: Heim fits into the V-link threads to a point that aligns the axle housing with the proper wheelbase, correct tire/wheel positions in the wheel wells and the desired pinion angle. Heim threaded properly, the pinch bolt can be tightened. This secures the threaded section by compressing the tube at the split seam. Once secured with the joint on a level plane, the assembly can be fitted with the custom bushings and installed in the brace. Loctite 242 and proper torque will secure this large bolt.

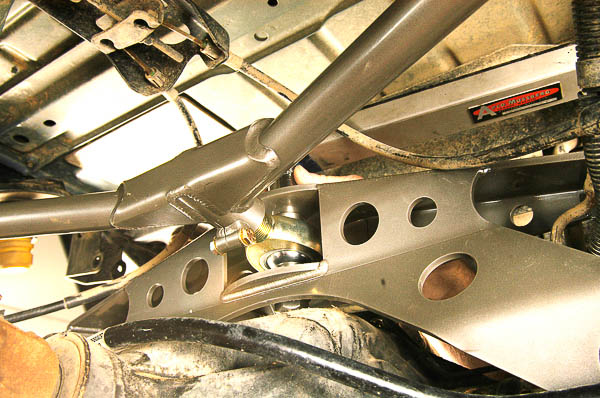

Illus. 110: V-link hardware attaches the V-link outer brace pivots at the OE upper link arm frame brackets. The sophistication of this package and its use of OE attachment points make this a “suspension system” rather than a simple lift kit. Consider the integrity of this package when selecting a lift or suspension system.

Illus. 111: The differential cover bolt holes provide additional support for this bolt-on package. Here, I have aligned and drilled the holes for the Dana 44 plate. (A Dana 35 plate is also provided in the package.) Bolts align the two-piece brace. I will flip these bolts over before installing the brace between the V-link support bracket and the differential cover bolt holes.

Illus. 112: Bolts oriented for clearance, the bracket is in place. The differential cover bolts pick up the bracket and differential cover. I reinstall the OE electrical connector with a slight modification to its mounting bracket. The forward section of the support bracket bears the nut for the Heim joint bolt.

Illus. 113: Heim joint bolt fits through the top of the support brace then a spacer bushing, the Heim center, through another spacer bushing, the lower rail of the support brace and into the nut that is part of the differential brace. The nut is welded to the brace plate and is of Grade 8 top-lock type. This is a sturdy mounting system and pivot point designed for severe off-road use.

Illus. 114: Torqued to specification, this assembly is a precise fit and provides the movement and alignment required. Stamina of such a joint is exceptional. I can fit my industrial strength torque wrench above the support brace to torque this bolt to specification. Heim-type joints were originally used in aircraft and precision machine applications.

Illus. 115: Hardware for outer V-link pivots can be torqued with a ½-inch beam bar torque wrench. I use Loctite 242 on all thread applications and torque the hardware to specification. Always re-check hardware torque after suspension has been cycled in service.

Illus. 116: Full-Traction Suspension provides skid plate drop spacers that have a unique cup and beveled washer design. These spacers will center up properly and torque to specification without risk of loosening. I install split ring lock washers of Grade 8 rating to match the Grade 8 bolts and flat washers provided with the hardware kit. Use Loctite 242 for additional insurance. The skid plate supports the transmission/transfer case, a big task to perform.

Note—These FTS spacers have been designed to work with skid plates that have recessed bolt pockets. All YJs and first-generation TJ models use special bolts with acorn seats. On such applications, the two-piece FTS spacers will sandwich the dished recess in the skid plate. Shown here is the later TJ application that uses a flat skid plate bolt surface. Both applications use the FTS Grade 8 bolts and washers supplied with the package.

Illus. 117: Loctite 242 on threads, the transmission/transfer case mount nuts now go back in place. Torque these nuts to specification.

Illus. 118: Rear axle bump stops also must be dropped when installing a lift. Here, the OE bump stop comes loose and exposes the bolt for the bump stop’s cup mount. Remove the bump stop cup. The new spacer fits between the cup and the upper coil spring seat.

Illus. 119: Use Loctite 242 on the new, longer bolt. Place the spacer between the cup and spring seat. Secure the bolt and torque it to specification. This dropped stop will prevent the suspension from hyper-compressing and damaging the shock absorbers, driveline and other components.

Illus. 120: With the rubber stop back in place, the new coil spring can be fitted. If the suspension drops enough as shown here, the spring can be worked into position by hand. These rear springs do not have a clamp or lock plate. They stay in place by spring tension and vehicle weight. Front springs have a stop edge at the lower spring seat to catch the spring end and prevent the spring from rotating. Rear springs do not have a stop edge.

Illus. 121: Left side spring fits into place without trouble. Axle housing sets low enough to allow easy fitment of the coil springs. Once springs are both in place, the shock absorber installation will limit the axle drop and prevent the springs from dislodging in service.

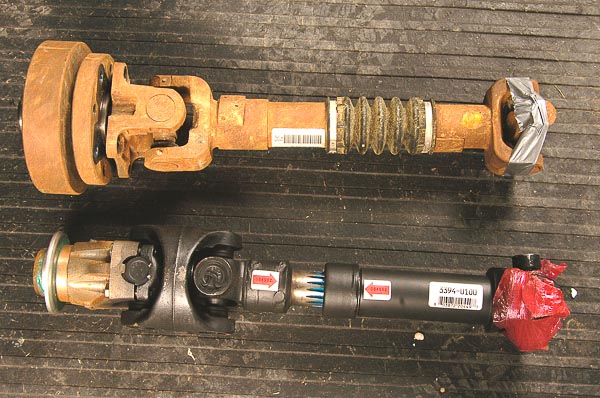

Illus. 122: Lower link arm from Full-Traction Suspension (upper) is clearly stouter than the OE link arm (bottom). This suspension system is built for off-pavement punishment. The arm will be adjusted to a slightly longer bolt-to-bolt fit than the OE link. These lower link arms control the pinion angle. I will adjust each arm evenly and set the pinion angle.

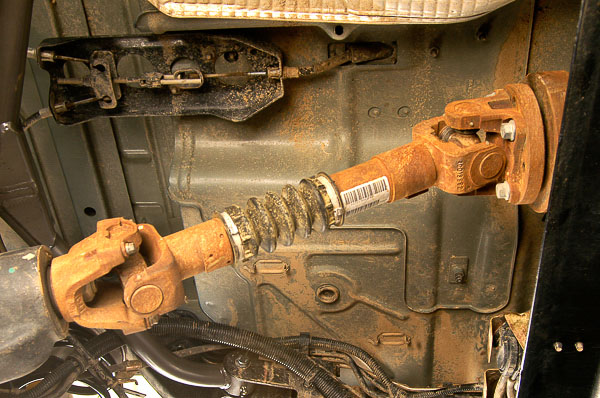

Illus. 123: Since pinion angle is crucial, I will replace the rear driveline before setting up the lower link arms. This is a Rubicon Edition rear driveline. A stout, non-CV type unit, the Rubicon shaft does not have the slip yoke at the front. Each joint is a single Cardan with a splined slip-coupler in the mid-shaft section. Joints are 1330 Spicer type. I will replace this driveline with a heavy-duty CV unit that uses 1330 joints.

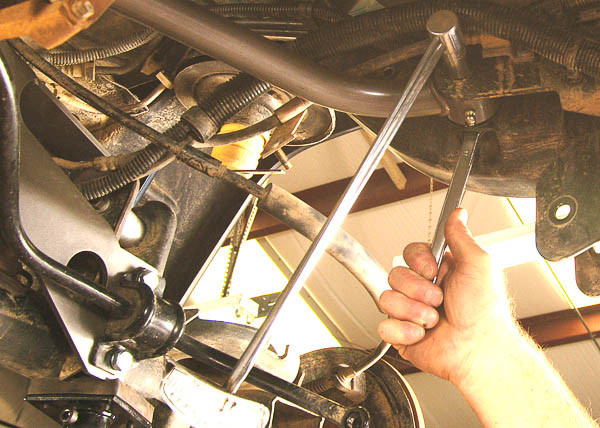

Illus. 124: The U-joint is strapped to the pinion yoke. These bolts have smaller heads that are best handled with a six-point socket. On the Rubicon 1330 application, I can use a 3/8”-drive socket and air ratchet. Air impact tools work nicely in these applications. For joints with less maneuvering room, an extension with ¼-inch drive ratchet and six-point socket will usually work.

Illus. 125: The Rubicon rear driveline uses a companion flange/damper to drive the U-joint flange. The U-joint flange unbolts from the companion flange. This provides access to the transfer case’s output shaft nut. Be prepared to support this drive shaft as it comes loose. Do not let the shaft hang, as joint damage can result.

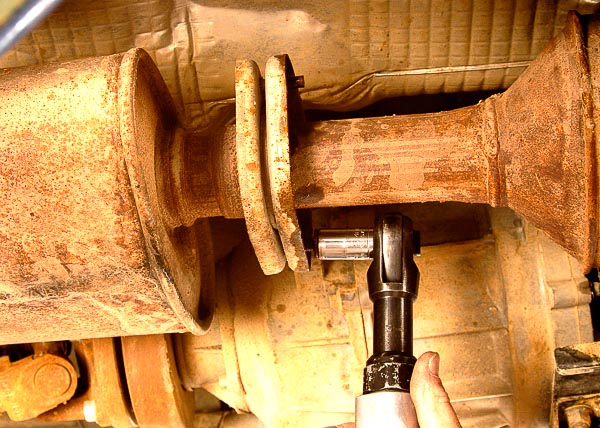

Illus. 126: TJ applications use a damper at the output shaft, whether or not there is a slip-yoke driveline or a companion flange. The damper helps reduce vibration. In applications where an aftermarket CV-type driveline replaces the stock drive shaft, the damper is removed. Here, I loosen the companion flange/output shaft nut with a six-point impact socket and air gun.

Illus. 127: A harmonic balancer puller is the tool of choice for removing the damper. Splines and shaft are straight, not tapered, so the force required is minimal. This damper comes loose readily. Only a slight amount of pulling effort, and the damper slides free.

Illus. 128: Damper loose, the splined shaft is visible. The Rubicon models use the NV241 transfer case with a short tailhousing. This is similar to the “slip-yoke eliminator” package used as a retrofit on the NP/NV231 transfer cases. A shorter tailhousing and output length allows for a longer rear driveshaft. On the factory lifted Rubicon, the longer driveline is desirable as a means for reducing the steeper driveline slope angle.

Note: Non-Rubicon models with the NP/NV231 transfer case will require a slip yoke eliminator (SYE) and CV rear driveline conversion. I cover the Advance Adapters SYE installation elsewhere in the Jeep YJ and TJ Wrangler ‘Workshop’ section at this 4WD Mechanix Magazine website.

Illus. 129: Here, the new CV driveline (bottom) is complete with the front yoke that will attach to the NV241 output shaft. Top shaft is the OE assembly with single Cardan type joints at each end and a damper. The new CV driveline, custom built by Powertrain Industries, features heavy-duty 1330 joints, thick tubing and a heavy-duty spline coupler. This is a rugged, high performance driveline built for severe service.

Illus. 130: I coat the splines and front mating surface of the new yoke with Super 300 sealant. This will keep fluid from wicking out of the splines. The seal is virtually new, as this Rubicon has only 6,000 miles on the odometer. There is no need to replace the seal. I grease the seal lip recess with chassis lube and slide the yoke carefully into place.

Illus. 131: A flange type nut is OE equipment. When a self-locking pinion or output nut is removed, it should be replaced with a new nut of like kind. I use Loctite 242 as both a sealant and thread locking agent. Run the nut onto the shaft and seat the yoke.

Illus. 132: A rag protects the yoke from nicking as I hold the yoke with a large pipe wrench. Do not apply force at the U-joint saddles or dust deflector.

Hold the yoke securely below the machined saddles. I use a 0-250 ft-lb torque wrench to bring the nut to torque specification. A special flange wrench is available to hold the yoke while setting torque.

Illus. 133: Here, with new rear straps and bolts torqued to specification and the joint secured in its saddles, the shaft is in place. The CV flange-to-front yoke bolts are Grade 8. I coat threads with Loctite 242 to assure that they will stay tight. Torque the hardware to specification. At the front bolts, I use a box wrench or box-end crow’s foot socket. Make certain bolts are torqued to specification. Powertrain Industries supplies these rugged driveline assemblies to Full-Traction Suspension.

Illus. 134: I temporarily install the lower arms, with hardware finger tight, to keep the axle in alignment. Install the rear shock absorbers, using floor jacks or adjustable stands to position the axle height. Jacks will compress the springs and allow for easier shock installation. Use Loctite 242 on threads, and torque all hardware. The shocks serve as axle drop limiters. Once the shock absorbers are safely bolted into place, the springs will be loaded and stay securely in place. Always use caution around loaded coil springs.

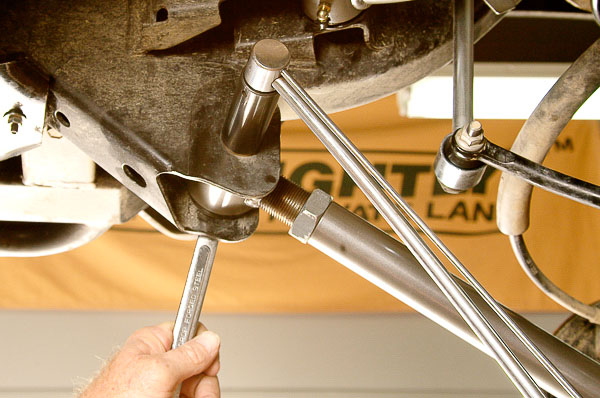

Illus. 135: Setting adjustable tripod stands beneath the axle housing once more, I carefully adjust the lower link arm lengths to establish the correct pinion angle. Note that the swivel joint is toward the axle end with the urethane bushing facing forward and upward. The offset of the arm’s tube faces downward. Pinion angle should be checked with the rear axle supporting the vehicle’s weight.

Note: When setting the rear pinion angle or front axle caster, I place stands under the front and rear axles. The full vehicle weight is supported on the stands to simulate static or “curb” height.

Illus. 136: Once the pinion angle is right and the axle housing checks plumb with the springs and its chassis/frame alignment, I install the new hardware with Loctite 242. Torque the bolts and nuts to specification. Nuts supplied are Grade 8 top-lock type.

Illus. 137: This end fits upward, with the tube offset to the lower side of the arm. I match the left and right arm lengths, continually noting the pinion angle. This is the same as adjusting front axle caster on a beam axle. The aim here is an axle that moves through its travel arc with axle/frame alignment similar to the OE axle positions. Once aligned with the frame and square, the axle’s final adjustment is pinion angle.

Caution—As the suspension compresses on link-and-coil systems, the front axle may move forward and the rear axle may move rearward, essentially increasing the vehicle’s wheelbase length. Be aware of this phenomenon. Cycle the suspension before installing the coil springs. With the link arms in place, you can determine the changes that will take place by moving (cycling) each of the axle housings over its range of suspension travel. Adjust the suspension accordingly, taking rear pinion angle, front axle caster angle and the driveline lengths into account. On extreme applications, body modifications may be necessary to prevent tire interference as the wheelbase elongates. Some aftermarket suspension packages and tire sizes require more wheel well clearance and additional driveline spline coupler length to compensate for the wheelbase changes.

Illus. 138: With the axle supporting the rear vehicle weight atop the tripod stands, I check the driveline pinion angle. A protractor provides accurate measurements. (There is also an inclinometer specifically used for this task.) At this stage, the Jeep sets with its weight on four stands, two under each axle to simulate the on-the-ground axle positions. I strive for 1.5 to 2-degrees of rear U-joint angle on this CV-type driveline.

Illus. 139: The axle should be square with the frame, aligned for wheelbase and wheel travel, with the correct pinion angle at the driveline. It may be necessary to go back and forth between the lower link arm adjustments to square the axle and establish correct pinion angle. Torque the hardware and jam nuts to specification once link arm length is correct and the arm ends are centered. Although busier than OE or fixed-length aftermarket arms, these adjustable arms provide a degree of suspension and chassis tuning that is not possible with fixed-length link arms. Alignment accuracy can be assured.

Illus. 140: This is the right lower link arm in its final adjustment mode. On a four-wheel alignment rack, the square and thrust angle of the axles will be checked and adjusted if necessary. Full-Traction Suspension provides baseline link arm length adjustments to help installers get the chassis ready for the alignment rack check and final tuning.

Note—Having run the alignment rack at a truck dealership years ago, I can bring a chassis very close to specification without sophisticated alignment equipment. I do discuss ‘DIY’ alignment in an article available at this 4WD Mechanix Magazine website. Click here to access that Jeep wheel alignment article—get a better understanding of alignment needs and affordable equipment.

‘Dropped Skid Plate’ Caution: On the Full-Traction Suspension 4” Ultimate and other aftermarket systems that lower the transfer case/transmission at the skid plate, adjustment of the transfer case shift linkage may be necessary. A shift linkage relocation bracket and hardware come with the FTS package and may be required. Check transfer case shifting and engagement. Be sure that linkage travel and body clearance are adequate. Take off-pavement twisting into account when testing linkage-to-body clearance and lever interference.

See ‘Part 3’ for Moses Ludel’s final tuning steps, including driveline, exhaust system and frame-and-alignment details for this installation!

When working on your Jeep TJ or LJ Unlimited Wrangler, refer to the factory (OE) Jeep® Service Manual for the vehicle model year. Torque specifications, frame specifications, the wheel alignment specifications, driveline torque specifications and suspension details—including torque settings and actual frame measurements—are available in the Jeep® official workshop manuals. I consider these manuals a “must” for any 4×4 shop or Jeep owner who is serious about performing professional level work. See your Mopar™ or Jeep® dealer for access to these manuals, available in paper-bound and CD format!

— Moses Ludel

Copyright 2010 © Moses Ludel…Enjoy this comprehensive, color-illustrated article and photography by Moses Ludel. The article is available solely at the 4WD Mechanix Magazine website and can be viewed here as often as you like. If you wish to share the article with friends or professional colleagues, please refer them to 4WD Mechanix Magazine website: www.4WDmechanix.com. As copyrighted material, this article and the photography cannot be copied or distributed in any other form.—Moses Ludel