<< Previous 1 2 [3] 4 5 Next >>

Installing the Atomic EFI Master Kit

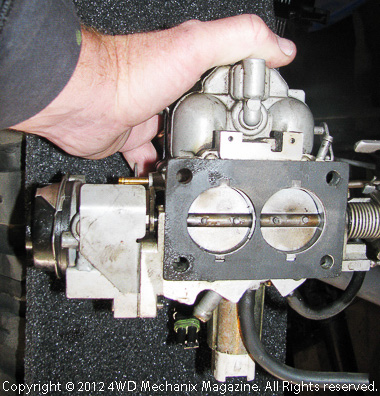

Carter BBD carburetor is a two-barrel design found on emission era AMC/Jeep inline 4.2L sixes. Its complexity reflects emission aims. The carburetor features a microprocessor-controlled fuel metering system, still short of true electronic fuel injection.

BBD two-barrel bores and throttle plate are dramatically smaller area than the Atomic EFI four-barrel. Despite square flange four-barrel pattern, MSD Atomic EFI is remarkably adaptive. The system will work with engines from 100-525 horsepower. Fuel supply options from MSD can bump that figure to 625 horsepower!

The adapter orientation is unusual: We are mounting a “four-barrel” EFI assembly atop a two-barrel BBD manifold. The square-flange of the MSD Atomic EFI is common to U.S. OEM and performance carburetors.

This is the Carter BBD two-barrel intake manifold carburetor mounting flange. For our intended use, we removed the carburetor mounting studs, using double-nut method.

“Universal” slots for a variety of carburetors overlap the Carter BBD base pattern. Note gaps at outer edges of elongated slots.

An immediate problem emerges during our trial fit up: Gaps at ends of the elongated slots will create vacuum leaks and permit debris to draw into the intake stream. These leaks would damage the engine and make Atomic EFI tuning impossible.

The ideal would be an adapter casting with holes matching the BBD mounting studs. For our tests, we will make insert plates and fill the slot gaps. Here, 14-gage sheet metal gets fabricated into plates.

Shape of four inserts matches steps of the slots. Plates must be stiff enough to hold shape when screws torque down to hold the adapter securely in place. Drilled holes match mounting screw diameters.

Here, fabricated inserts fill the slots. Prudent film of RTV sealant seals slot shelves. Avoid excess use of RTV, which can slough off and damage the oxygen sensor.

Loctite 242 (blue medium strength) on the screw threads keeps screws from loosening in service. These screws are in the manifold air stream near intake ports.

MSD Atomic EFI has a throttle arm design that works with many OEM cables and linkages. Features include kickdown linkage for automatic transmissions.

We found a “universal”, easy to adapt throttle cable kit at a local auto parts store. This cable kit worked with the Jeep pedal arrangement and the MSD Atomic EFI throttle linkage. Plenty of options here.

Universal throttle cable is secure at firewall and fits the Jeep OEM gas pedal. This is a safe, quick solution for cable linkage, with lots of adjustment options.

Aftermarket throttle cable and OEM return springs work well with the MSD Atomic EFI’s smooth throttle mechanism.

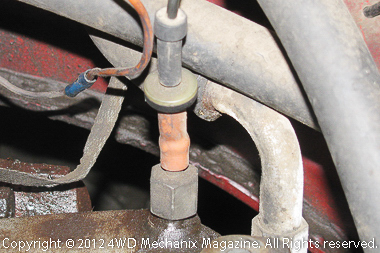

Here, we remove the OEM mechanical fuel pump. This pump is not required with the high-pressure MSD Atomic EFI fuel pump delivery system.

After removing the OEM mechanical fuel pump, we install a new fuel pump gasket (with a light coat of sealant on each side) and the block-off plate shown here. OEM parts get removed carefully and stored away. Some Jeep pieces from this era are nearly impossible to source and expensive on eBay!

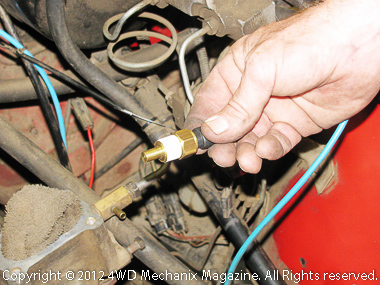

We installed the coolant temperature sensor provided in the MSD Atomic Master Kit. There were OEM locations for each of the engine sensors provided. MSD wide-band oxygen sensor replaced the OEM oxygen sensor.

MSD Atomic EFI Master Kit comes with sensors, hardware, fuel delivery pieces, and all parts needed for the EFI functions. You will purchase a separate MSD 6-series digital box to operate the system. Several OEM sensors are not needed with EFI. We kept the five-port coolant temperature override switch (CTO) at right.

Late 4.2L Jeep sixes with carburetors have a microprocessor and heavy dose of emission controls. Many devices are vacuum actuated. MSD Atomic EFI eliminates the need for several devices. While streamlining the underhood appearance, electronic fuel injection also reduces tailpipe pollution.

A factory vacuum diagram illustrates many emission control features in the engine bay. Most carburetor devices and emission controls rely upon vacuum signals.

Where overlap exists between the OEM hardware and MSD Atomic EFI components, it is helpful to know whether a device needs removal or deactivation. Click here for a schematic of late 1980s YJ Wrangler 4.2L engine vacuum circuits.

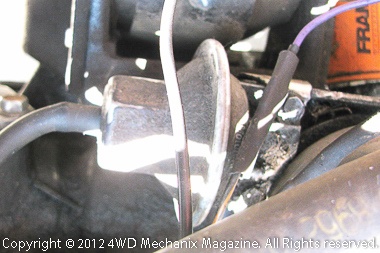

We followed the non-timing control approach when installing this MSD Atomic EFI system. Like the Howell system, we kept the OEM Jeep-Motorcraft distributor with its conventional spark timing controls: 1) a vacuum canister advance unit (seen below) and 2) the OEM centrifugal weight-and-spring spark timing advance mechanism.

Our approach is not a full fuel-and-spark management system like Mopar’s MPI conversion with its PCM-controlled spark timing plus EFI. We did have the option of upgrading to electronic timing control by using the MSD Pro-Billet 8516 distributor. MSD’s instructions clearly outline the required modifications to the 8516 unit and other “Pro-Billet” MSD distributors. For more details on MSD’s Atomic EFI, click to the official MSD Atomic EFI website.

To enhance performance of the ignition system and drive the MSD Atomic EFI, we installed the required MSD 6-series “box” and an MSD Blaster 2 coil (optional). The digital box and coil each have California CARB E.O. certification numbers.

Our prototype 1989 Jeep YJ Wrangler chassis entered the project as a California-legal carbureted model, successfully passing required testing at mandatory biennial smog checks. Smog Check includes an equipment visual inspection plus actual tailpipe testing to confirm that emissions are within requirements for the vehicle model and original engine type.

Note: California emission standards do allow for normal wear and mileage on older vehicles. Visual inspection is as important as the tailpipe readings.

Before starting the installation of MSD Atomic EFI, the vehicle was pre-tested with the stock, carbureted system in place: a Jeep/Carter BBD carburetor with Sole-Vac, stock air intake system, EGR, PCV, cat, EVAP system, Pulse Air, all of the OEM sensors, vacuum and deceleration devices plus the factory microprocessor. The Jeep passed both visual inspection and actual tailpipe emissions tests.

We approached this project with consideration for California CARB guidelines and the California Smog Check Program’s emissions testing process. As a result, we elected to keep as many stock emissions components as possible.

<< Previous 1 2 [3] 4 5 Next >>