<< Previous [1] 2 3 4 5 Next >>

At the 2011 SEMA Show, 4WD Mechanix Magazine video cammed new products for Jeep 4WD and Ram truck viewers. We sought out the most innovative and useful products in the market.

Caution: If your vehicle must comply with emission regulations or inspections, confirm the emission legality of this Atomic EFI system for your specific vehicle and engine type before installing Atomic EFI. Review the manufacturer’s literature. If you intend to register/license your Jeep for use in California, any EFI conversion kit or aftermarket carburetor must have a Clean Air Resources Board (CARB) Executive Order exemption number that approves the product’s use for your specific vehicle and engine type. Other states now have similar regulations. Check with state and local requirements before purchasing the MSD Atomic EFI kit.

Carburetion on Jeep 4.2L/258 inline sixes has been a concern since the 1980s. At the SEMA Show, MSD’s hottest new item caught everyone’s attention: “Atomic EFI” debuted, a retrofit four-throat fuel injection system that suits a broad range of engine types and driving environments—including popular Jeep® 4WD models.

A bolt-on EFI retrofit system, MSD’s Atomic EFI has potential for AMC/Jeep six-cylinder inline and V-8 engines—plus many Mopar V-8 engines! This installation enhances a trail running 4.2L Jeep inline six.

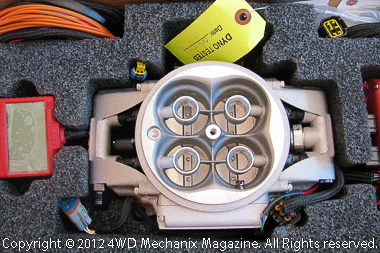

Uniquely, the MSD Atomic EFI unit houses many of the system’s features. The precisely metered fuel injection package includes the multi-component throttle body, a power module with wide-band oxygen sensor and a handheld controller. To keep the package compact, the throttle body mounts the ECU at its side.

Atomic EFI uses an array of sensor signals, similar to factory electronic fuel injection. A throttle position sensor (TPS), manifold absolute pressure (MAP) sensor, engine coolant temperature sensor (CTS), the wide-band oxygen sensor and a fuel pressure sensor are each part of the package.

Eliminating concerns about available fuel volume, the fuel delivery system features four precision, 80 psi injectors. These injectors use a reliable stainless steel ball-and-seat metering method for flow control and maximum internal sealing.

Avoiding the need for fittings that can leak, the built-in injectors use internal fuel rails. For complete fuel atomization, Atomic EFI uses annular booster rings at the bore tops, which assures optimal fuel mixtures. The result is a sleek, self-contained EFI unit.

When we first saw MSD’s Atomic EFI fuel injection at the SEMA Show, MSD staff talked enthusiastically about the new system. They spoke of potential applications, mentioning Jeep engines specifically.

This sanitary Jeep ‘FSJ’ Cherokee with an AMC/Jeep 401 V-8 and MSD Atomic EFI is among the proven, larger displacement applications. Flexibility (100-525 horsepower using the same EFI unit and supply pump) inspired us to do the 4.2L inline six-cylinder project. (Photo courtesy of MSD.)

The universal throttle body unit bolts directly to a common square-bore carburetor intake manifold. Equally well considered, Atomic EFI throttle linkage adapts to many carburetor and cable types.

For maximum durability, a backcountry must, the 1.75-inch diameter throttle inlets ride in precision roller bearings. This provides a smooth pedal transition, highly valuable when crawling your 4×4 in rocky, steep terrain!

Tuning has been simplified. The Atomic EFI’s TPS features a self-calibrating, non-contact sensor—one less calibration detail when setting the system up. For electrical circuitry, MSD incorporates the latest CAN-bus technology. This creates a single, reliable connection between components and feeds accurate information to the throttle body-mounted electronic control unit (ECU).

The MSD Atomic EFI package includes a remote-mounted power module and well-constructed wiring harnesses. The weather-tight connections are an off-road must!

In addition to the power module, the installer or tuner can set values for MSD Atomic EFI fuel injection functions. This is the hand-held monitor and programmer.

Once the EFI components, wiring and fuel delivery components have been installed, initial programming takes only five minutes. There are six questions to answer about your specific engine.

Following base tune, the engine can be monitored with the programming device in real time. This provides engine data for fine-tuning or troubleshooting the system. MSD’s Atomic EFI even features a removable micro-SD card to record and store data. This is a valuable tool for precise tuning, analysis or troubleshooting engine performance!

The precise fuel delivery and self-contained nature of the MSD Atomic EFI is impressive. A cure for carburetor woes, the MSD Atomic EFI Master Kit P/N 2900 deserved a Jeep 4.2L inline six pilot test!

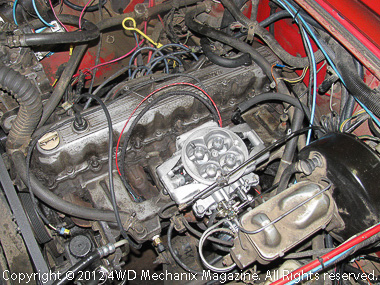

Compact design of MSD Atomic EFI is clear in this application. Our project adapts the system to a stock 4.2L AMC/Jeep inline six two-barrel intake manifold.

For the project, we picked a stock Jeep 4.2L inline six in a 1989 Jeep YJ Wrangler chassis. The Jeep came equipped with the BBD carburetor and a complement of ’80s emission controls. Our target goals: better performance, improved fuel efficiency and a cleaner tailpipe reading.

Why EFI Makes Carburetion Obsolete

From an emissions standpoint, EFI eliminates a fundamental carburetor issue: venturi effect. When a column of air passes through the narrowed-down venturi area(s) of a carburetor, a low pressure zone or vacuum results. This pulls fuel out of the float bowl via metering jets and passageways, into the carburetor’s venturi throat(s). Here, fuel mixes with moving air to achieve a fixed proportion of air/fuel (AFR).

Since venturi effect is independent of throttle plate position, fuel continues to flow for a short interval under deceleration, even with the throttle closed. This is not a function of engine manifold vacuum—it is a manifestation of venturi effect.

The result is a brief, rich fuel supply to the cylinders, which raises major challenges for tailpipe emissions. An additional obstacle is the conventional carburetor’s fixed-jet air/fuel ratios. Despite electronically actuated fuel metering (like the Carter BBD carburetor’s “Sole-Vac” system), tailpipe emission standards call for drastic controls.

By contrast, venturi effect is non-existent with EFI. When the throttle closes, the TPS, MAP and other signals switch off injection of fuel—electronically and in milliseconds. There is no uncontrolled flow of fuel to enrich the exhaust gases and raise emissions concerns.

EFI has played a vital role in meeting U.S. E.P.A. and California (CARB) clean air tailpipe requirements. Through continual electronic adjustment of the air-fuel ratio (AFR), EFI engines produce more horsepower, gain fuel efficiency and live longer—with reductions in cylinder wear, valve trouble and sludge.

Tailpipe emission requirements have progressed steadily since the 1960s. Only electronic fuel-and-spark management and catalytic exhaust treatment devices could keep up with U.S. EPA Clean Air standards and California’s CARB requirements.

In addition to clean air, EFI has spurred a second muscle car era over the last two decades. Worldwide, high horsepower and torque from smaller displacement, high-tech engines has become the norm for cars and trucks. The Jeep 3.6L V-6 Pentastar engine is a good example.

EFI instantly sets optimal air/fuel ratios for any driving condition. Pump gasoline burns best at 14.7:1 air-to-fuel ratio in a warmed engine. This optimal burn or “stoichiometric” also reduces tailpipe emissions at cruise speeds. When accelerating at wide open throttle (WOT), gasoline engines do require fuel enrichment; EFI/MPI can instantly provide precise, enriched AFR simply through software mapping and sensor feedback.

This MSD Atomic EFI wide-band oxygen sensor replaces the 4.2L OEM oxygen sensor. The Jeep OEM sensor sent feedback to a microprocessor that adjusted fuel metering, spark timing and several smog control functions. The aim was lower tailpipe emissions—not improved performance.

For OEM electronic fuel-and-spark management systems, engine tuning is the constant, onboard computer adjustment of air/fuel ratio and spark timing in response to engine loads, driving demands, altitude and engine temperature. Computer software mapping meets performance goals and tailpipe emissions demands.

(Illustration courtesy of MSD, zoom-in for details.)

This schematic shows full-function Atomic EFI with optional electronic spark timing control. If your engine type has an MSD ‘Pro-Billet’ distributor offering, you can add the Pro-Billet distributor to the EFI package and gain spark timing control benefits.

MSD Atomic EFI can be used as a fuel-and-spark control system. A modified two-pin Pro-Billet MSD distributor with an MSD 6-series digital box enables Atomic EFI to control spark timing. Functions include idle timing stabilization for a smoother idle plus the ability to set the spark timing degree range and rpm limits, essentially building the spark timing “curve”.

There are ‘Pro-Billet’ distributors available for the AMC/Jeep inline sixes and V-8s. This includes the MSD 8516 model distributor for Jeep 232 and 258/4.2L inline sixes. ‘Ready-to-Run’ MSD distributors will also work with Atomic EFI, including the Ready-to-Run E-curve timing units*.

(Photo courtesy of MSD.)

MSD 8516 Pro-Billet Distributor for AMC/Jeep 232 and 258 inline sixes can partner with the MSD Atomic EFI system. Add MSD’s outlined modifications, and a Pro-Billet distributor can also be part of Atomic EFI’s electronic spark timing control function.

<< Previous [1] 2 3 4 5 Next >>