A great number of welders know little about metallurgy—the science of metals. Most metallurgical engineers have little experience at welding. Engineers do, however, know chemistry and the structural properties of metal when heated. And that’s what you should know if you want your metal projects to have predictable outcomes.

One of the trickiest weld repairs is cast iron. In fact, many prefer alternatives to weld repairs on castings. (They use bronzing, silver brazing, powder welding/brazing and even drilling and pinning.) For those who have a knowledge of metal properties and how heat will affect different grades and types of iron, there is the welding alternative.

Metallurgy provides the platform for making sound repairs. You can predict the outcome of welds, brazing and hard (high temperature or brazing type) soldering, if you know the metal properties. Should you weld that 4130 roll bar with 4130 welding rod? Is the tubing in an annealed state or heat treated? This makes a clear difference—and also determines the right filler rod to use.

Heat treating is often done as “case hardening,” like the treatment most transmission and transfer case gears receive. In this instance, the original metal, like 8620, is easier to machine in an annealed or softer state. Once the gears are sized and machined, they receive a surface heat treating that might be only 0.035″ in depth. This raises the hardness at the surface without distorting the machined areas.

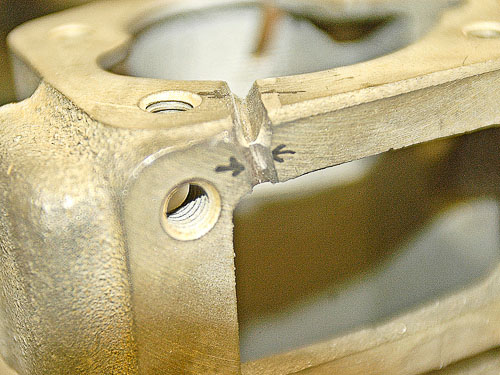

If you plan to repair an obsolete Jeep gear, you must (in sequence) 1) ‘normalize’ or soften the case hardening, 2) weld the damaged area with a metallurgically compatible filler material, 3) machine the part to specification and 4) heat treat the piece to restore the case hardening to proper depth. Normalizing, annealing and case hardening are each processes performed by a heat treating shop.

I have restored gears after first normalizing the casting. The filler rod must be chemically similar to the base metal if the plan is to re-heat treat the piece. A weld, alone, without normalizing or heat treating, would require different filler rod with higher “as welded” tensile strength. Welding on case hardened metal dramatically degrades the tensile strength of the case hardening near the weld. The gear above received new case hardening (heat treatment) after the welding and machine work.

Each metal working and welding decision involves metallurgy and a knowledge of heat treating. We will discuss heat treatment at length in this section. Have questions? Just ask!