Q&A: Jeep YJ & TJ Wrangler Axles, Transmissions and Transfer Cases

Enjoy the detailed, traditional ‘Q&A’ exchanges in this article column from the early magazine website. (Some links have been lost in the shift from .html to .php at WordPress in 2015. Link content may be available…Try a search at the magazine’s search box. ) ‘Q & A’ has now moved to open, interactive forum discussions. Visit the forums, you’ll want to join—for free!

Have technical questions about your Jeep 4×4, popular 4WD truck, SUV, ATV, UTV or dirt motorcycle—or welding and metal fabrication? The 4WD Mechanix Magazine ‘Tech and Travel’ Forums now feature enthusiastic discussions and input from members and a steady flow of content from Moses Ludel.

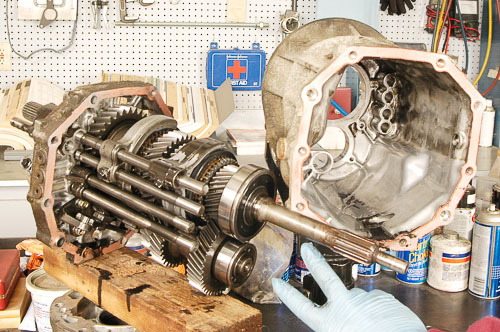

NV3550 Rebuild Goes Sideways

From: Pat S.

Sent: Tuesday, October 23, 2012 11:24 AM

To: 4WD Mechanix Magazine

Subject: Transmission gears

Hello, I recently felt ambitious enough to replace the synchros in my 2004 jeep wrangler (4.0L with 5spd manual; nv3550); all was going well in terms of the tear down and disassembly until I got to the removal of the 3rd gear on the input shaft. I used the wrong puller by accident (OTC 1128 instead of the 1130). The end result I chipped 2nd and 3rd input gears and making the job a touch more expensive. I was wondering If you sold those gears by chance and how much they would cost.

Thanks in advance,

Pat S.

Hi, Pat…Sorry to hear of your gear dilemma. Lesson learned, enough said there.

As for NV3550 gear parts, I do not sell parts. I quickly found a source, though. You may be able to do better through Jeep/Mopar at the local dealership level. The part numbers in the aftermarket look OEM (Jeep/Mopar), so that’s helpful. 2nd gear, if needed, does appear expensive.

Another approach: Advance Adapters is a direct dealer for New Venture and may have access to parts…A/A has also offered complete NV3550 transmissions—new. Try Advance Adapters. Share that I suggested you call.

Let me know if you need more information.

Regards,

Moses

AX15 Transmission Appropriate Lubricant

From: Dodge Dakota AX15

Sent: Monday, October 22, 2012 2:14 PM

To: 4WD Mechanix Magazine

Subject: Info please

Hello

I have a ’98 Dodge Dakota with the 2.5L engine and the AX 15 trans. If you could answer please: My AX 15 has always been hard to get into 2nd gear when cold as it warms up she shifts fine I don’t think it’s a syncro as as it warms up she shifts good.

What is causing the hard shifting when cold?

Also is it a problem that will get worse or stay the same as I said it has been like this for years. One other problem I have had from day one is its just impossible to get into reverse usually it takes 5 to 15 tries to finally get it into reverse the most frustrating thing about this trans.

Thanks for any info you may provide me.

Jeff S

Hi, Jeff…We’re going to be optimists in this case and assume that your synchros have not been damaged by wear or the balky cold shifts. The AX15 is hypersensitive to lubricant type and viscosity. It sounds like you have the wrong lube, which could be either too stiff when cold or incorrect viscosity.

Mopar actually used a private label approach with the AX5 and AX15, bottling a lube under a Mopar part number. That lube has been available for years through Jeep dealerships and likely Dodge-Ram. See if you can find the recommended Mopar lube. If not, the spec for the lube is 75W-90 API Grade GL-3, according to the Jeep factory manual for 1998. 4WD models take 3.27 qt. or 3.10 liters. 2WD models take 3.15 liters or 3.32 quarts.

Another possibility, a less likely long shot, is a hydraulic clutch system that either leaks down or needs bleeding. Try the lube first, especially if the current lube is not what I described above.

If a change of lube does not cure the problem, we can move to the next step…Let me know how this turns out!

Regards,

Moses

Exchange continues…

From: Jeff with AX15

Sent: Monday, October 22, 2012 6:25 PM

To: 4WD Q & A

Subject: Re: Info please

Well, you will not like this but I use the Mobil 1 75W-90 GL-5, the stuff that supposedly eats up the brass syncros its been in my trans for 4 years. I never force the shift I take it easy on it till it warms up usually only a 5 minute drive does it then it shifts easy.

Oh, by the way even with the stock dealer oil in it it would do the same thing that’s why I changed to the Mobil 1 oil and it did show a small improvement in my shifting.

I have been thinking of replacing it with Redline MTL or MT 90 the MTL for cold weather my clutch is 3 years old so its nothing to do with the clutch.

It’s a 2WD not a 4X4. I like my 2.5 and AX-15 Dakota.

Jeff S

From: 4WD Q & A

Sent: Tuesday, October 23, 2012 7:55 AM

To: Jeff S.

Subject: RE: Info please

Jeff, the problem I’ve found with synthetics is that they work “too well”. Too much lubricity prevents the synchro rings from providing braking action, and there is clash on shifts. I’ve not heard of synchros being eaten up, but that would occur if they constantly balk; the damage would be on the teeth, not the braking grooves.

I’ve had good luck with the Mopar branded oil for AX5 and AX15 transmissions. (I also like Mobil synthetic products.) My choice in a case like this is the Mopar oil, however, as this transmission is known for lube sensitivity.

Moses

From: Jeff S.

Sent: Tuesday, October 23, 2012 9:09 AM

To: 4WD Q & A

Subject: Re: Info please

Ok Wow

That’s way different from every Jeep forum I have ever read concerning the AX-15 the majority say MT 90 is the best thing for the AX-15 now some say just use regular Mobile 1 30W engine oil is the best others say syncromesh is the best.

I would say the MT 90 is recommended the most. I know when you talk any kind of oil things can get heated everyone claims what they use is the best. The Mobil 1 75W-90 has been good so far except when it gets cold outside then it shifts harder for about 5 to 10 minutes I just don’t force it till it warms up and in Arizona you don’t get too many cold days and nights.

Thanks,

Jeff S

Eliminating Vacuum Disconnect at Front Axle of YJ Wrangler

From: Jay O.

Sent: Thursday, August 30, 2012 3:40 AM

To: 4WD Mechanix Magazine

Subject: Welding slide gear

The pinion gear on my 91 yj Jeep it is a Dana 30 reverse cut axle in the front, on the passenger side it has a two piece axle there is a air activated fork that slides a gear over the two of them to make it a one piece axle, so my question is can the slide gear be welded so it stays as a one piece axle all the time? Thanks for your time and thoughts jay

Hi, Jay…You describe the vacuum disconnect axle shaft, right side. Years ago, I dealt with this problem by installing a one-piece Superior Axle & Gear axle shaft and making a simple cover plate for the vacuum control opening. The issue is that this setup places the axle shaft seal outboard of the vacuum shifter. The Dana 30 without the vacuum shift unit has both axle shaft seals at the inboard ends of the axle shaft. On models without the vacuum disconnect, you remove the differential carrier and ring gear to install the inboard axle shaft seals.

At the time I did this modification, the retrofit axle shaft did not have a machined surface outboard of the vacuum shifter. I polished the axle shaft at the section outboard of the vacuum shifter and installed a seal at that point in the axle housing, the same seal position as the factory seal. I picked a seal by the O.D. of the original axle shaft seal, with the I.D. matched to the polished section on the axle shaft. Finding a seal was not an issue, double-lip oil seals can be found in most any I.D./O.D. You provide the shaft diameter to determine the seal I.D. size; catalog listings account for proper oil sealing tension.

Superior Axle & Gear lists an axle shaft for the ’87-up XJ Cherokee and YJ Wrangler under part number DC6115 for 27-spline. They also offer 30-spline and other options. Give them a ring at 1-888-845-0470 and ask tech how they deal with the XJ Cherokee and YJ Wrangler vacuum shifter axle shaft, specifically, how they handle the right side axle shaft seal issue for that conversion. These axle shafts fit a number of models, as the length and inner spline design is common.

Let me know if Superior is polishing or machining the one-piece axle shaft to accommodate your outboard axle shaft seal. If the Superior axle shaft solves the problem, making the cover plate is simple enough. Use 1/8” or so sheet metal, cut to size, round the corners, match and drill bolt holes in the plate.

Trust this helps…

Moses

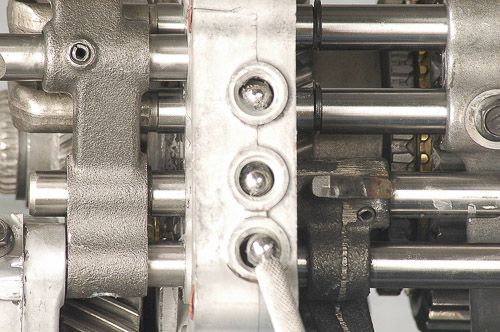

AX15 Transmission Synchro Ring Positions

From: Bert H.

Sent: Wednesday, August 01, 2012 4:25 PM

To: 4WD Mechanix Magazine

Subject: AX15 rebuild issues

Hello, Moses,

First of all, I would like to thank you for your detailed online AX15 rebuild guide. The instructions and illustrations proved very helpful.

I have done a complete rebuild of my 1997 Jeep TJ including transfer case and transmission. I also rebuilt a 6.5L GM diesel and installed into the Jeep using Novak adapter plate to the AX15. The conversion has gone quite well for the most part, but I have an issue with the transmission rebuild that I would like your input.

I replaced all bearings and synchros as well as 1st and 2nd gear to tighten up the thrust clearances to within spec. However, now that I am mobile I find that the shift lever “pops” out of 5th gear upon deceleration. The feel of the stickshift is like the 5th synchro sleeve is not engaging completely. I tried tightening up the detent springs by putting a small washer behind the detent plugs but that didn’t help any.

I noticed on the exploded view on the 4WD website shows the 5th synchro may or may not be the same as the 3rd/4th synchros (2 possible part numbers). Mine seemed to be identical. Would there be a visible difference if I were incorrect? I used synthetic 75W90 GL-5 lubricant.

Any suggestions would be appreciated.

Thank you,

Bert

Hi, Bert…Pleased that the instructions proved helpful, this is a “textbook” approach that adheres to AX15 OEM guidelines. According to the parts listings, synchro blocking rings are different all along the gear train. Trust that this information helps, Bert.

Slipping out of gear is usually caused by shift fork misalignment or insufficient movement of the fork, a loose synchro clutch hub, synchro keys and springs not holding the clutch hub outer sleeve, worn or mis-assembled detents, parts in the wrong sequence or a loose parts/clearance issue. Proper end play or clearance between the synchro hub and the gear(s) or thrusts is important.

A “wrong synchro ring” causes grinding on the shift but generally does not cause slipping out of gear. The sleeve not centering on the hub or the hub floating on the shaft (with too much end clearance) are more likely causes.

I am very curious about your 6.5L diesel installation and want to know how the project turns out. The AX15 and 231 transfer case behind a 6.5L is an interesting approach…Keep me posted, Bert!

Regards,

Moses

Moses adds this footnote…

Bert, regarding your description of the symptoms, if the synchro ring is too big in diameter, the sleeve would not be able to slide over the ring teeth. This would also prevent the sleeve from properly engaging the teeth on the 5th gear. The synchro ring pressed against the hub of 5th gear might actually spin the gear. When you decelerate, force reverses slightly, which breaks the synchro ring loose from the 5th gear hub. The transmission goes to neutral.

A test for this is to see how little movement of the shifter is needed to disengage 5th gear. If very little, there is insufficient engagement of the sleeve with the 5th gear synchro teeth. This could indicate a synchro (blocking) ring problem as described.

One more scenario: Typically, when a shaft is rocking (like loose pilot bearings), it will kick a synchro sleeve out of engagement with the gear teeth. A synchro ring rocking between the synchro hub and the gear hub could create a similar issue. The synchro ring would tilt under deceleration and kick the sleeve back to the neutral position on the synchro hub.

The wrong size synchro ring could cause this trouble. Since there is no parts reference to diameters, depth, thickness or inner braking surface angle, you’d need to lay the correct synchro rings alongside each other to make sense of the 5th gear issue. One clue is that 5th gear does not feel fully in position at the shift lever.

Compare a set of synchro rings before disassembling the transmission. Try to pinpoint the 5th gear issue. Let me know what you find.—Moses

32RH Transmission Needs Cooling Lines!

From: Gary W.

Sent: Tuesday, July 03, 2012 12:56 PM

To: 4WD Mechanix Magazine

Subject: Why not hook up the transmission to the cooler in the bottom of the radiator?

I have a 97 TJ Jeep automatic transmission 4×4…Someone has disconnected the transmission lines that go to the radiator. Is there any reason for this? I thought they should be reconnected. The nipples are there. They had just put a fuel hose ‘U’ shape on the 2 lines….

Yes, Gary, you do need these lines connected…These lines go to the cooler inside the radiator. Even though the radiator has hot coolant, this is still a place to dissipate high heat from the transmission fluid. The fluid runs inside the transmission cooler, isolated from the engine coolant.

I suggest pressure checking the cooler in the radiator before attaching the lines. Make sure there is not a leak from the coolant into the cooler and vice versa. Once you know that the cooler works okay, you can hook up the lines…

As a final thought, why were the lines disconnected? Is the radiator plugged or in need of service? If so, consider servicing or flushing the radiator before attaching the lines. There might be a reason for the disconnect.

A radiator shop can perform tests or “rod” (clean) the radiator if necessary…

Trust this helps, Gary!

Moses

3-Speed ‘RH’ Automatic Knocking

From: Joop D.

Sent: Monday, May 28, 2012 9:56 AM

To: ‘4WD Q & A’

Subject: RE: Automatic Transmission problems

Moses,

Just thought I’d give you a quick update. Over the winter I changed the oil and oil filter in my ’99 TJ Wrangler automatic transmission. So I hoped this would cure the knocking sound. But when we started driving again it came back, not all the time, just now and then. Mostly on hot days.

I remembered an article on a Jeep forum about loose bolts on the flexplate. There were also some YouTube videos with the exact same tapping noise, and loose bolts on the flexplate should be the fix.

So this afternoon I removed the dust cover and found out that the bolts of the flexplate were just hand tight. They came loose very easily. I had also read in that Jeep forum to torque them down to 110 ft-lbs, so I used a torque wrench to tighten them up. I did not go as far as 110, afraid I would break the bolts. It’s a lot tighter than before, that’s for sure!

I took the Jeep out for a test drive, and the sound wasn’t there. The car runs at 2000 rpm at 60 mph, and that is quiet and fuel-efficient on the highway. I think I will stick to my present gearing for now.

I included a photo of the Jeep.

Kind regards,

Joop D.

The Netherlands

Reply from Moses…

Joop, this is great, what an easy fix! I suggest taking the time to put Loctite 242 or even 271 (red) on the bolt threads. Otherwise, the loosening might happen again. The correct torque for the 32/30RH torque converter-to-flexplate bolts is actually much lower than 110 ft. lbs. Here are the factory settings (directly from my 1998 Jeep TJ official Chrysler shop manual) for various torque converter types:

1) 9.5” diameter 3-lug torque converter—40 ft. lbs.

2) 9.5” diameter 4-lug torque converter—55 ft. lbs.

3) 10.0” diameter 4-lug torque converter—55 ft. lbs.

4) 10.75” diameter with 4-lug torque converter—270 in. lbs. or 23 ft. lbs.

5) The flexplate (“drive plate”) to crankshaft bolts require only 55 ft. lbs. torque for your Jeep engine.

6) The 110 ft. lbs. is for manual transmission flywheel-to-crankshaft bolts.

Note: I recommend thread locker on any of these bolts.

Good that you did not follow the forum advice, or the threads would be stripped for sure. The best way to judge the torque setting limit is the size of the bolt stud and thread pitch. Bolts are likely Grade 8 (U.S.) or 10.9 metric. I have charts for torque if there is doubt here. We can decide correct torque based upon the dimensions of the bolt threads and the grading. Take the time to add the thread locker compound, you can do this one bolt at a time.

The Jeep is really good looking, Joop…Pleased to share your photo!

Regards,

Moses

AX-15 Front Bearing Retainer: Conversion to External Slave Cylinder

From: Sam M.

Sent: Tuesday, April 17, 2012 9:39 AM

To: 4WD Mechanix Magazine

Subject: YJ Jeep (1993) clutch external slave conversion project help!!

Hi. I finally got some money ($1500 budget) to convert my internal clutch slave on the AX-15 bellhousing to an external slave, but I’m not sure how to determine the precise parts numbers list, so I can go order the parts (before finding a competent mechanic in Northern California/Bay Area to do the job for me). Can you assist please?

I know that I need the AX-15 bellhousing w/ external slave from a 94-95 Wrangler that has the crankshaft position sensor in the 10 o’clock position. I’m not sure of the other parts though. Finally, how can I track down all of the part numbers for the 94-95 Wrangler conversion parts that I will need for my 93 YJ conversion project?

– Sam M

Hi, Sam…You’re on the right track if you want to do the conversion. The front bearing retainer for the external slave has been available from Advance Adapters, and they likely can walk you through the rest of the pieces needed as well. Give Advance Adapters a call, talk to tech at 1-800-350-2223. If you have further questions after that conversation, please feel free to write me again…

Regards,

Moses Ludel

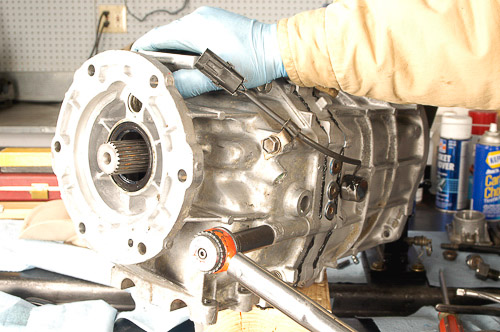

AX15 Rebuild: Try a Heating Pad!

From: Colin E.

Sent: Saturday, February 25, 2012 1:08 PM

To: 4WD Mechanix Magazine

Subject: AX-15 rebuild help

4WD mechanix,

I’ve been following your rebuild page for my AX-15 transmission. So far so good, but now I’ve removed the front bearing and counter gear bearing snap rings, but the front bearing lip won’t clear the front case to separate from the intermediate plate.

Can you offer any help to get this case free?

Thanks,

Colin E.

Hi, Colin…Unless the gear assembly is binding, the two front bearings should move inward through the case at the same pace—as you tap both the input gear and the counter gear from the bearing retainer end. Bearings should stay on these shafts.

Note that in my #22, #23 and #24 illustrations, the gear train slides out of the front case intact, with all gears and shafts still in alignment. If the counter gear bearing moves without the input gear moving an equal amount, a parts bind will occur.

Let me know if these comments help…We can discuss this further.

Regards,

Moses

From: Colin E.

Sent: Saturday, February 25, 2012 7:32 PM

To: 4WD Q & A

Subject: RE: AX-15 rebuild help

I figured it out! It was just a bit to cold in my garage, so the case was contracted some. I put a heating pad on it and it freed up with a little tap. Thanks for the quick response, and the great write-up.

Colin

Good job, Colin! Pleased to share your tip with others! Enjoy the magazine…

Moses

TJ Wrangler 32RH Transmission Woes

From: Joop D.

Sent: Friday, January 20, 2012 11:53 AM

To: 4WD Mechanix Magazine

Subject: Automatic Transmission problems

Good day Sirs,

The problem that mr H. Wooders describe is the same problem that I heard twice in my ’99 3-speed auto Jeep TJ.

Like mr H. Wooders I am planning on changing the automatic oil and filter and perhaps build in a cooler, but perhaps this wont help at all.

Has mr H Wooders solved his problem? And if so, what was the defect?

Thank you for any help and information.

Kind Regards,

Joop D.

The Netherlands

Joop…Is your 3-speed a 30/32RH design? If so, the oil and filter change with a careful band adjustment would be the place to start. For the 30/32RH, see my article on Sonnax upgrades in the automatic transmission workshop section of the magazine…The AW-4 with overdrive (XJ Cherokee models) has no band adjustment.

Let me know what develops after servicing the transmission…

Regards,

Moses Ludel

AX15 Rebuild by the Article!

From: Michael F.

Sent: Tuesday, January 17, 2012 12:46 PM

To: 4WD Mechanix Magazine

Subject: 1991 Jeep YJ AX-15 5th gear

I am in the process of rebuilding my ax-15 transmission, thanks to your very detailed article describing each and every step. I ordered parts to replace all blocking rings, bearings, seals, all items that you recommended. Most parts did come from 4wd hardware as you recommended, I have used 4wd and quadratec for several years for my many jeep projects. My question involves the fifth gear counter synchronizer assembly. Apparently, around 1991 and serial number 00705124, a change was made to this assembly. My case is stamped with 00605444. The 4wd website indicates that the synchro springs for the serial numbers before 00705124 will be the same for 1st,2nd, and 5th Gears. There are also different syncho keys and the ring itself is different again based on your serial number. I ordered my parts for the “before serial number 00705124” from 4wd website. The syncho springs came in bags labeled 1st,2nd, 5th . They are much too large to fit in the 5th gear hub. The old original springs are the same size as the 3rd and 4th gear springs. I also ordered the new keys from 4wd, they do not match my original parts either. I did discover that the picture of the syncho keys for the “after 00705124” do match my original keys and the springs seem to be the same as 3rd and 4th for “after 00705124”. This is very confusing, I know! I have since re-ordered a complete 5th gear counter update kit with new counter gear and hub along with new springs and keys. Can you shed any light on this mystery? What was the update? Did the size of the synchro hub change? Did the tooth count change? My counter gear has 47 teeth. The only problem this transmission had was fifth gear, it would not go into 5th gear at normal speed. It would shift smoothly while idling.

Thank you very much for your help on this issue as well as all of your helpful articles,

Michael F.

Hello, Michael…A mystery, indeed…Did you purchase the YJ new?

There are many instances where transitions to a new design take place in stages. Without drifting far from your issue, I recall the “upgrading” of Toyota pickup truck transmissions in the early ‘80s. It took three generations of changes to reach the final, stronger design for 4x4s and diesel models.

Perhaps this occurred with Aisin on the AX-15’s transition to a stronger fifth gear. Fifth is always the weakest gear in a five-speed overdrive transmission.

If your AX-15 has been rebuilt, it’s also possible that a mix of parts were involved. Regardless, if the transmission can benefit from an available 5th gear upgrade, consider doing it. As you note, you’ll need to match up related pieces and make sure that they are compatible.

See whether the various synchronizer pieces were used with different gearsets. Aside from actually counting teeth or measuring gear diameters and thicknesses, some research on AX-15 ratios may cast light. If you need details here, I can make some ratio comparisons from year/model data.

Regards,

Moses

42RLE Compression Braking Question

From: Norm F.

Sent: Monday, December 19, 2011 1:57 PM

To: ‘4WD Q & A’

Subject: RE: The 42RLE

Moses,

Thanks for the info and recommendation on the Full-Traction. I believe you mentioned Full-Traction in you ‘Jeep Bible.’ I am still curious as to your thoughts on the long arm kit. I believe the long arm kit would provide great off-road capabilities, but how about the highway friendliness?

I wish the 42RLE transmission had more down hill engine braking in 4-wheel low than it does. Do you know of any kit or upgrade that is available for this transmission that would enhance the downhill engine braking function of the 42RLE????

Norm

Reply from Moses…Gearing and Automatic Transmission Compression Braking:

You’re welcome…One issue with any automatic is that the converter’s stall speed must be low enough to keep the torque converter hooked up during compression braking. Converter slip at idle coupled with very slow vehicle speed create a coast mode with virtually no compression braking. If you were to raise the engine rpm to engage the converter, with stock gearing and bigger tires, the vehicle would accelerate rather than have compression braking.

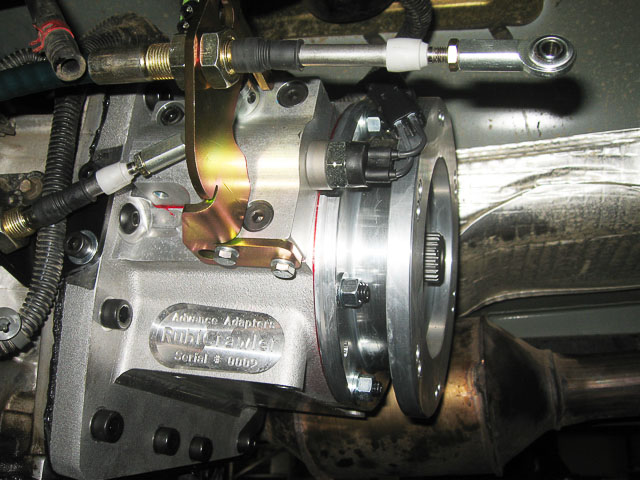

So, the sensible fix, considering available torque converters and practical stall speeds, is to lower the transfer case low-range ratio, especially if you go to oversized tires with stock axle ratios. A lower low-range gear ratio would keep the converter engaged under compression braking, also enabling a very slow crawl speed.

You’re in luck here if you want to go the expense: The Rubicrawler from Advance Adapters, which happens to fit your TJ Rubicon model with 42RLE! This would dramatically lower your low range reduction, allowing the engine and converter speeds to engage the converter during compression braking—even with 35” tires and stock axle gearing. (You might want lower axle gearing, like 4.56:1, if you run 35” or larger tires; however, this would be for highway performance.) You would have ample compression braking effect with the Rubicrawler gearing.

Moses

2WD Versus 4WD AX15 Transmissions

From: adam c.

Sent: Thursday, December 08, 2011 12:23 PM

To: 4WD Mechanix Magazine

Subject: ax15 transmission

i have been reading the moses ludel’s teardown on the ax15 transmission and i have my case off. I have several gears torn up and have been looking for a used transmission. My question is can i take a ax15 2 wheel drive and put my case on it to all my transfer case bolt up or will there be more changes that will have to be made? thank you

Reply from Moses…

Hi, Adam…The issue here would be the output/mainshaft and the transfer case adapter. You need to confirm this before considering the 2WD version. If your mainshaft and adapter will match up with 2WD internal parts, you could consider rebuilding your existing transmission using needed gears from the 2WD transmission. Make sure ratios (tooth counts) and other details match before attempting this.

An easier approach would be finding a used AX15 from a 4WD Wrangler or XJ Cherokee that will directly replace your current transmission. The AX-15 for an NV/NP231 transfer case is not scarce. These transmissions were used from 1989 to the introduction of the NV3550 in 2000. Here are details from Advance Adapters, they carry brand new (not rebuilt) replacement AX-15 units in stock. New might be wise if you plan to keep the Jeep (assuming this is a Jeep, not a Toyota) for a long time visit the Advance Adapters website.

Trust this helps, Adam…

Moses

YJ Clutch Stack Height in Error?

From: Brian W.

Sent: Monday, July 11, 2011 3:36 PM

To: 4WD Mechanix Magazine

Subject: Clutch Problems

I need some serious help…. I recently replaced my transmission in my 92 YJ 5 speed manual along with new clutch and slave cylinder. Once installed, I only had about 1 inch (at best) of clutch, I bled the system about 5-6 times and still the same. I replaced the slave cylinder two additional times along with the master cylinder. I still have no more than an inch of pedal. once I drive it for about 5 mins I have no pedal.

I don’t know what else to do…. Is there a chance that the bell housing may be longer on the new trans, or possibly a bad clutch kit?…. Any help or ideas would be great. I’ve been working on this problem for about a month now and getting very discouraged. Thanks in advance.

Brian

Hi, Brian…Glad to assist…If you do not have enough release bearing travel to release the clutch fingers, there are several possibilities: 1) the clutch cover fingers are not reaching outward far enough, 2) the release bearing collar is too short, 3) specified clutch pedal height is important, 4) the master cylinder piston must be able to retract completely for a full piston stroke and 5) the system must be properly bled.

Since you have a model with the hydraulic release bearing, verify that this part has the correct length collar. The bearing should rest just off the release fingers with the clutch pedal fully raised. Make sure the clutch disc is installed correctly, with the splined hub facing the correct way! In backwards, the hub will effectively “thicken” the disc stack height and make the clutch cover fingers retract. This would increase the distance of travel for the release bearing.

Measure the height of the clutch pedal from the floorboard to be sure you’re getting adequate piston/fluid charge when you depress the clutch pedal. You should have a specified pedal height and specified release bearing free play when you first touch the pedal lightly. You need enough movement of the clutch cover’s release fingers to disengage the clutch.

I’m assuming that you have bled the system each time you open it up. There is a tube coming out of the bellhousing with a bleeder screw. Bleeding is similar to a brake bleeding method.

Let’s go from here…I’m available!

Regards,

Moses

Hydraulic Clutch Linkage and Release Mechanisms

From: Clarence L.

Sent: Saturday, May 14, 2011 3:47 PM

To: 4WD Mechanix Magazine

Subject:

Hello, I am considering buying an 89 Wrangler with straight 6, Is there a kit available to change the internal hydraulic clutch release to an external one,right now its not working and have to pump it to disengage clutch. Thank you for your time.

Clarence

—– Original Message —–

From: 4WD Mechanix Magazine

To: Clarence L.

Sent: Sunday, May 15, 2011 10:05 AM

Subject: RE:

Hi, Clarence…I have made this changeover with the use of a TJ Wrangler (’97 to 2006) bellhousing, slave cylinder, cross-housing release arm and so forth. The change requires the TJ’s bellhousing, slave cylinder, release arm, pivot ball, hydraulic line/tubing and so forth.

This is considerable work, at least as much as replacing the current hydraulic release bearing. Considering parts involved and cost, it would be less expensive to just repair/replace the current hydraulic release bearing and stick with that design.

If you have further questions, please ask, Clarence…I can furnish a parts diagram of the TJ Wrangler parts involved.

Regards,

Moses

From: Clarence L.

Sent: Sunday, May 15, 2011 8:16 AM

To: 4WD Q & A

Subject: Re:

Thanks alot for the info. If you have the time could you send me a parts list.There are alot of older YJ’s around the area I live some are pretty beat up.If the new release bearing lasts just as long or longer than the original I guess it would not be worth it. I just do not like that part inside the bell housing. I’d like to inspect it often with a quick look under the Jeep.

Clarence

Reply from Moses:

Hi, Clarence…Attached are two sets of clutch linkage and hydraulics diagrams, one for the 1989 YJ Wrangler and the other for the 1997 TJ Wrangler. You can compare the parts differences involved:

1989 YJ Clutch Linkage and Hydraulics.pdf

1997 TJ Wrangler Clutch Linkage & Hydraulics.pdf

These charts provide genuine Mopar part numbers for pieces you need. Also, you will need to use the correct clutch disk and cover. I have added pages covering the clutch details:

1987-90 YJ Wrangler Clutch Assembly.pdf

If you buy a quality replacement release bearing and install then bleed it carefully, you’ll be happy with the results. These units can last over 100,000 miles.

Regards,

Moses

AX-15 Transmission Oil Deflector Shield

From: Richard P.

Sent: Wednesday, April 13, 2011 8:58 AM

To: 4WD Mechanix Magazine

Subject: Shift tower plate ax-15

I have removed my transmission for rebuild, and in the process of removing the shift tower on the ax-15, there was a thin metal plate, rectangular in shape under the shift tower, 4 holes in the corners where the bolts went through, with a round hole the size of the shifter shaft end coupler ball cup, and it had a flared edge around the round hole, this piece was bent badly and the round hole was out of round where the shift arm had dented it in after the bushing had worn out.

I reasoned that this was some sort of splash cover, but I can not find it on any mopar parts list. And I have lost this plate to show the parts house, they think I am crazy at this point. Can you help me i.d. this plate please?

Richard P.

Reply from Moses:

Hi, Richard…The tin plate you describe is called a “shield” or oil deflector. I searched each of the AX15 years to find the later listing for the part you want: “Mopar #04864224 Shield, Transmission”. I generated and attached a PDF of the 13 pages involved with the AX15. Note that the layout mixes AX5 and AX15, so the part you need is on the last page.

You were not imagining, the late AX15 uses this deflector instead of the cut paper gasket. There must have been an effort to reduce oil throw into the tower, although the earlier versions with the square, open gasket seem to work well. In any event, your local Jeep dealer should be able to help with that part number. By application, I used a 1999 TJ Wrangler.

Moses

RE/RH Automatic Transmission Quirks

From: Jack F.

Sent: Wednesday, April 13, 2011 4:28 PM

To: 4WD Mechanix Magazine

Subject: Re: 1999 Jeep Wrangler Question

Hi Moses,

My TJ Wrangler has a transmission “slip” when I get in the Jeep after it sets for a week. When I first start it and put it in reverse there seems to be a “slipping” which is probably more like a hesitation. The people at the transmission shop say that it might just be that it takes a few moments for the fluid to get up to pressure after sitting that long. So either I give it extra time to warm up or it has been foxed.

I use to do a lot of extreme exploring when I had my first 1974 CJ-5 and then got the used 1969 CJ-5 in the 1970’s and 1980’s, but these days with the 99 Wrangler and what I do in the way of exploring and photography, it is mostly just old roads and trails. Most of those places are in National Parks and Preserves so you can’t find too many crazy places to go anyway.

Thanks again for all your help!

Jack

Reply from Moses:

Hi, Jack…The hesitation after setting for some time is that the torque converter does not charge with fluid in the Park position on these transmissions. I just did an upgrade on our ‘05 Dodge Ram 3500 Cummins 4WD (bought new, 96K miles now) that we use for the magazine’s hauling chores.

The issue is that the converter is not charged, and the front pump bushing can fail from lack of lube. This occurs if the vehicle starts in Park position (which everyone does normally!) after setting for a period. To test the effect, start the engine in Neutral instead of Park. The converter will quickly charge and provide fluid to the transmission’s components. You should discover that the Jeep will shift into gear “immediately”, without the hesitation. The article will clarify and, optimistically, save a lot of readers’ RH and RE Chrysler transmissions!

Will pick it up after Moab…

Chrysler RE and RH transmissions are prone to this problem, and I will address the issue on behalf of Jeep Wrangler owners (30/32RH transmissions). I took photos as I rebuilt the valve body and installed upgrade components that eliminate this trouble. This is not a “high performance” upgrade, merely a save-the-transmission from failing prematurely set of aftermarket pieces. When I get back from the Moab EJS, and the dust settles, expect that article!

Moses

Correct Lube for YJ Wrangler AX Transmissions and More!

Hi, Dave…Regarding transmission fluid, Mopar (Chrysler) has offered a special gear lube for the AX-5 and AX-15 transmissions. The middle item in Illus. 55 is the Mopar lube for the AX transmissions. If this lube is not available, seek a lube equivalent. Toyota and others use the AX-series transmissions, so there are OEM and aftermarket sources. The main concern is lubricity and the compatibility of the lube with the synchronizers. If too viscous, the synchros will balk from not providing proper braking action. Make sure the lube is specified for AX units.

Often the grinding associated with shifts on a YJ Wrangler are clutch release issues. The clutch is not disengaging completely, and that can be a hydraulic release bearing problem or even air in the clutch system that requires bleeding (like brakes). Try “pumping” the clutch pedal a few times before moving the shifter, and see if the grinding resolves. If so, look to the release bearing or slave cylinder/master cylinder, with bleeding the first remedy. Replacing the hydraulic release bearing involves the same measures as a clutch replacement, so the clutch is often replaced at the same time.

As for the transfer case, the 2-inch drop of the skid plate would be the first place to look. This would misalign the shifter with the console positions and possibly inhibit shifter movement. It is also possible that the shifter cannot move far enough to engage. A simple check: Disconnect the linkage at the transfer case and manually shift the transfer case into its various modes. If each mode works, and the shift detents hold their gear position, the problem is linkage related. You may need to reshape the shift lever if you keep the skid plate drop.

Dropping the skid plate two inches is substantial. Check the driveline/U-joint angles. The recommended approach with a four-inch lift is a CV rear driveline and a slip yoke eliminator. See my 4WD Mechanix Magazine article on the NP231 SYE kit installation (article at the YJ/TJ Workshop). You will also see the CV-driveline installation. If you need to rebuild the transfer case, consider a rear CV-driveline and SYE kit at the same time.

A CV-driveline with SYE can eliminate the skid plate drop. The process involves rotating the rear axle pinion upward as part of the conversion. (With a CV-driveline conversion, the rear driveline’s rear U-joint angle should be 1.5-2 degrees. The CV-joint’s angle will self-cancel.) With a 4-inch lift, the front driveline-to-skid plate clearance may require slight skid plate modification when you remove the spacers.

I’m happy to answer further questions or clarify, Dave…

Regards,

Moses

From: Dave C.

Sent: Friday, May 13, 2011 7:43 PM

To: 4WD Mechanix Magazine

Subject: Questions

Mr. Ludel,

I have two questions I’m not sure of the answer. I’m fairly sure my 1991 Wrangler has an AX-5 tranny, its mounted on a four cylinder. This jeep is new to us and no manual was with it and I haven’t been able to find good solid answers on the internet so far.

Question 1.

What is the correct transmission fluid that should be used in my manual 5 speed? I’m getting a slight grind when shifting from gear to gear, no other noises present while driving. History of jeep is unknown.

It does have a four inch leaf spring lift and it appears the last owner dropped the center skid plate with transmission two inches to make up for the lift to reduce the shaft angle.

Question 2.

I have attempted to adjust the transfer case shifter repeatedly and can’t seem to get to the position of 4 wheel low. When I go to 4 wheel high it doesn’t seem to be in the correct position in the z-slot. It’s in between the positions. I have heard of several possible issues. Bent fork, missing or worn bushing on forks, loose or worn linkage.

Your assistance in these issue would be greatly helpful.

Thank you in advance.

Dave C.

YJ Axle Disconnect Vacuum Troubleshooting

Tim…Attached are the front axle vacuum diagram and two helpful troubleshooting charts. The vacuum source is the intake manifold, presumed to be a fitting directly into the intake manifold—another good reason to eliminate your intake manifold gasket leak.

[Click here to download the vacuum disconnect PDF: YJ Axle Vacuum Circuits.pdf]

The flow chart is valuable; the vacuum diagrams are vague but at least an overview. In the third page (4WD troubleshooting flow chart), at the right side, lower two items, the blocks read:

1) “Remove shift motor housing cover. Connect vacuum pump to shift motor port. Replace shift motor if armature [actuator for shifting] does not move in and out freely.”

2) “Front axle will not connect.”

Note the use of that “vacuum pump”. This is a common diagnostic tool for vacuum actuated devices and engine performance diagnostics. The typical tool will read vacuum (like a vacuum gauge) and also create measurable vacuum with its built-in hand pump.

Moses

From: Tim H.

Sent: Thursday, May 12, 2011 6:58 PM

To: 4WD Q & A

Subject: Re: shocks

I cannot determine the front axle disconnect vacuum circuit for my ’89 Wrangler. I would like to fix this once and for all. Can you provide details?

AX-15 Shifts Hard—Transmission Issue or What Else?

—–Original Message—–

From: Kevin W.

Sent: Monday, March 14, 2011 6:01 PM

To: 4WD Mechanix Magazine

Subject: ax15 transmission

In step 10 of the attached link you mention the detent plugs, springs

and balls. Where can these items be purchased? I have searched the net far and wide and found nothing…

any help appreciated

Kevin

Moses replies:

Mar 14, 2011 09:15:41 PM, 4WD Mechanix Magazine wrote:

Kevin, I thought there would be a quick aftermarket answer, but no such thing! A good source for AX-15 parts, I went to 4WD Hardware’s site and looked up the AX-15 transmission:

http://www.4wd.com/HardParts/HPDetail.aspx?hpID=89&hpDID=88

You can get virtually everything—except the detent plugs and springs! These springs and plugs are typically provided in a “small parts kit” for transmission rebuilding. Such kits are sold either by the manufacturer or through aftermarket sources.

To simplify your search, I have attached a 1999 TJ Wrangler AX-15 parts diagram with the factory part numbers (Chrysler/Mopar) listed. Your local Jeep dealer should be able to order these numbers and source the springs, plugs and detent parts. If not available, the numbers will be useful when looking for a small parts kit through an official Aisin Warner warehouse supplier.

Advance Adapters deals directly with Aisin Warner (selling new AX-15 transmissions at a smoking deal!). They may be able to recommend an Aisin Warner distributor for parts.

I chose 1999 at random, as you did not mention what year Wrangler or Cherokee you own. I can furnish other model years, older if necessary, although these parts should interchange.

Trust this helps!

Moses

Reply from Kevin W.:

From: Kevin W.

Sent: Tuesday, March 15, 2011 9:46 AM

To: 4WD Mechanix Magazine

Subject: Re: RE: ax15 transmission

I actually found them on www.vintagejeepparts.com. The hardest part was determining what they were called on the parts diagrams. I have seen them referred to as locker balls, poppet lock balls and springs, etc. When I saw your site last night and read “detent springs and balls”, i started searching on that, then cross-referenced a couple of parts diagrams and web sites, and found what I was looking for—with the exception of the reverse detent spring (it is smaller than the other 3). Once I had a real part number, I searched for a site with reasonable cost and shipping and VJP seemed a decent choice. I will do a little more searching for the reverse spring tonight. Although shifting into reverse was not a problem, it was getting into the forward gears (and sometimes out) that was the issue. I just hope that these parts are the problem (someone told me this was a common problem, and the springs and balls were sometimes a solution). I do not want to buy a tranny if I can help it!

If this is not the problem, do you have any other ideas on what the issue could be? In general the problem I have is it’s hard to shift into the gears (I think 3rd was the worst, or maybe 2nd, it’s been awhile since I drove it). But once in gear, it runs fine. When shifting it seems to go in easier if I wait a couple of seconds after pushing in the clutch pedal and then pulling it into gear. I have already put in a new clutch and slave cylinder with no change.

It is a 1991 wrangler BTW.

Thanks for your help

Kevin

Moses adds some additional YJ Wrangler possibilities:

From: 4WD Q & A

Sent: Tuesday, March 15, 2011 10:53 AM

To:’Kevin W.’

Subject: RE: RE: ax15 transmission

Kevin…Does the Jeep have gear clash noises when shifting between gears or is it just difficult shifting? It sounds like insufficient clutch plate disengagement from the flywheel or crankshaft pilot bearing drag. Clutch disk drag will cause the symptoms you describe.

Did you have the flywheel resurfaced? Did you carefully bleed the slave throwout bearing? Try pumping the clutch pedal several times, and see if the shifter moves more easily into gear. If so, there is either air in the clutch system, or the clutch master cylinder is leaking down.

Pumping the clutch pedal can sometimes overcome air in the system or a weak seal at the clutch master cylinder. As another clutch-related note, if your crankshaft pilot bearing drags on the nose end of the input gear of the transmission, the symptom will be similar to the clutch not disengaging. This time delay for a smooth shift could be the input gear still rotating with the clutch pedal depressed. When you depress the clutch pedal, the input gear should come to a reasonably quick stop, as the pilot bearing allows the crankshaft to rotate. If this is not the case, shifting will be difficult.

If there is gear clash despite a clear separation (clearance) between the clutch disk and flywheel with the clutch pedal depressed, the problem could be worn or damaged transmission synchronizers. However, if the transmission shifts between gears without clash (once it actually shifts), the synchros are not the culprit. Make sure there are no bearing noises coming from within the transmission. Bad bearings can cause shaft and gear misalignment, which creates difficult shifting.

Unless the synchro rings have become damaged from shifts without full clutch disengagement, your problem sounds more like a dragging clutch disk or partial clutch disengagement. The cause could be insufficient hydraulic release bearing travel, a dragging pilot or a warped flywheel. The detents and springs would be least likely to be the problem on a transmission that has not been apart. If rebuilt somewhere along the way, that’s another story…

If you believe the transmission synchros are okay, begin with the hydraulic clutch prospects. If the crankshaft pilot bearing, clutch assembly, hydraulic release bearing and flywheel are okay, perform the clutch master cylinder tests.

Accessing the pilot bearing requires removal of the transmission and transfer case—a lot of work! Rule out other possibilities before plunging into the pilot bearing or flywheel. Avoid replacing parts needlessly or performing unnecessary labor. Take this one step at a time.

Keep me posted, Kevin…

Moses

Identifying the Supply Cooler Line on a 42RLE Automatic

From: Mike W.

Sent: Saturday, March 05, 2011 10:26 PM

To: 4WD Mechanix Magazine

Subject: Jeep Wrangler 42rle

I have never been able to get a definitive answer to this question. On my 2004 Jeep Wrangler Rubicon 4.0L, which is the hot out and cool in lines on the transmission? There is one line fitting higher than the other. I think the cool in fitting is the higher of the two. Am I correct?

Thanks,

Mike W.

Response from Moses:

Hi, Mike…Good question! There is absolutely no reference to the port orientation anywhere in the Jeep factory service or parts literature—I looked thoroughly at TJ, JK and KJ model information! From the transmission and cooler layout, the upper rear port should be the supply line to the cooler. The lower (slightly forward) port should be the return.

Perform this check: With the transmission warmed from a short drive (not hot from a heavy load) and the engine running at an idle in Park, carefully feel the two lines. Be sure you’re in Park and set the parking brake securely before crawling under the vehicle! Caution: The supply line will be very hot if the transmission has been under load, so be careful.

The supply line should be noticeably warmer. If you have access to a heat sensing gun, you can perform this test without touching the lines and get a true sense for how well the cooler works. Perform a heat gun check at the tubes near the cooler to see the exact number of degrees difference the cooler makes.

Regards,

Moses

Additional question from Mike W.:

—–Original Message—–

From: Mike W.

Sent: Monday, March 14, 2011 11:13 AM

To: 4WD Q & A

Subject: Re: Jeep Wrangler 42rle

Moses,

I have not gotten around to the transmission yet. I was wondering what you think the longest run for transmission cooler lines could be. I want to move my TC to the rear of my Jeep.

Mike W.

Reply from Moses:

From: 4WD Q & A

Sent: Monday, March 14, 2011 1:11 PM

To: ‘Mike W’

Subject: RE: Jeep Wrangler 42rle

Good question, Mike…Since you’re relying upon transmission pump pressure to circulate fluid, there is a slight pressure drop and extra load with distance. One gain is that the lines themselves would dissipate additional heat, although not a gross amount.

There are two traditional mounting strategies with a transmission cooler: 1) using the engine’s cooling system and fan to draw air through the cooler and 2) a freestanding cooler relying upon ambient air for surface to air cooling. I have always mounted the cooler behind the radiator. Although air heats as it passes through the radiator core, this is still better than heating up the engine by placing the cooler in front of the radiator core. My approach is to use constantly moving air while minimizing the effect of heated radiator air…Considering that the Jeep is crawling at a snail’s pace when the heat is highest, additional air flow is essential!

Another approach worth considering is a Derale auxiliary cooler with an electric fan system: https://www.derale.com/. Derale has kits for YJ and TJ Wrangler models. You may get some ideas here. By using its own fan, the cooler does not impact or rely upon the OEM radiator and cooling system. You could even use a thermal switch to cycle the trans cooler fan automatically. Take a look at this approach.

Let me know how you do this!

Moses

Differences Between the Chrysler 999 and 32RH Automatics

From: Norman M.

Sent: Monday, February 28, 2011 10:59 AM

To: 4WD Mechanix Magazine

Subject: JEEP

Hi Moses,

Love your website. I have a question about Jeep Automatic transmission compatibility. I have a 1991 YJ, automatic with a 4.0L engine. I found a good used automatic transmission locally that is from a 98 TJ Jeep wrangler w/ 4.0L engine. Are they going to be the same transmission? Or at least, will it bolt up and work with my Jeep? If so, is it a straight bolt up job, or do I have a swap a few things? Thank you kindly.

Norman

On Feb 28, 2011, at 11:43 AM, Moses Ludel at “4WD Q & A” 4WD Mechanix Magazine replies:

Thanks for the kudos, Norman! Enjoy the new forum and the variety of tech and special Jeep interest features at the website…

The ’91 YJ and ’98 TJ each use variations of the durable 904/999 Chrysler Torqueflite. The ’98, however, is electronically controlled. This is the model 32RH in 4.0L applications. Since your YJ has a 4.0L with pre-OBDII emissions and troubleshooting, you would not have the interface between your PCM (computer) and the later transmission. The PCMs and their pin-count differ, the wiring harnesses are different, and you would not get the 32RH shift functions to work in your earlier chassis.

So, despite the “bolt-up” similarities, these are distinctly different eras of electronics and shift controls. Some owners find it useful to swap the AW4 (Aisin-Warner four-speed with overdrive) from an XJ Cherokee into the Wrangler. This gains an overdrive, and the AW4 is a rugged unit. If you stick with a 1995-back transmission, the PCMs would be similar, too. Take a look at the many XJ Cherokees at recycling yards and compare the differences. Measure the length of the transmission and adapter, from the engine block to the back of the transfer case, and compare. This should be very close if not right on. The YJ and XJ Cherokee share many components and fit ups.

I trust this helps. My choice would be the gain of an AW4’s overdrive, especially with current fuel prices!

Regards,

Moses

Further reply from Norman M.:

From: Norman M.

Sent: Monday, February 28, 2011 2:51 PM

To: 4WD Q & A

Subject: Re: JEEP

Moses, what you said makes complete sense. Now, the shift points in the OBDII trans are controlled by the pcm, correct? Not a seperate TCU? So, that means there are shift solenoids on the newer trans’s valve body, that the old one doesnt have. Could this possibly be the only difference, and a simple swapping of valve bodies from old to new could make it work? Im only pushing this because im getting the ’98 trans for free, so i would like to try and make it work. Thanks again!

Norman

Sent from my iPhone

Answer from Moses Ludel:

Hi, Norman…I understand the lure of the “price is right”…

Chrysler relates to the 30/32RH as a redesign of the A999. Officially the 32RH designation occurs in late 1991. (Check your YJ’s build date.) This early version is a non-lock-up converter. All TJ applications through 2002 are 32RH with lockup converter and electronic controls. To clarify, I have attached PDFs of an OEM parts list for 1991 (A999) and drawing breakouts of the earlier and later 32RH. Compare these applications and illustrations by their individual part numbers. See what differs and which pieces interchange.

Personally, I would invest in a rebuild kit and go through your YJ’s automatic transmission. Freshened up, it will last indefinitely. One observation about the TJ era 32RH is its passion for cavitating on steep slopes, starving the transmission for oil and cooking the clutches, bushings and bands. Even if free and allegedly in good condition, a 30/32RH should be checked over thoroughly for signs of off-road damage. Start with looking at the fluid and smelling for burnt oil and frictions. Debris in the oil pan should be checked carefully.

Happy to continue this exchange if you need more details, Norman. I have a horde of information on hand…

Regards,

Moses

Father and Son Project: 1991 YJ Wrangler

From: David C.

Sent: Monday, February 07, 2011 4:22 PM

To: 4WD Mechanix Magazine

Subject: 1991 YJ Wrangler question

Mr. Ludel, My son just purchased his first Jeep and I need to purchase a manual for it. Can you recommend the best maintenance manual for his YJ Wrangler? I am having some 4wd engagement issues. Sometimes it will engage and sometimes it won’t. I have determined it’s in the transmission. It’s been a long time since I have worked on a Jeep in fact my last Jeep was a 1971 Renegade II with the V-6. The YJ does have a manual transmission. Looking forward to hearing from you.

Thank You, Dave & Kurtis

Reply from Moses Ludel:

Hi, Dave and Kurtis…Sounds like a lot of fun ahead! The ’91 is an excellent model. MPI (EFI) was a substantial improvement for the inline sixes and an upgrade for the 2.5L fours. The 4.0L and 2.5L are each excellent powerplants.

My first recommendation is always a factory (Mopar/genuine Jeep) service manual. Your book may be available at the TechAuthority II website. There is a full page discussion of TechAuthority at the magazine website, click here for details.

If a new manual (print or CD form) is not available through TechAuthority, you can often find factory shop manuals at Ebay and the many used automotive book outlets online. I recommend sticking with the official Jeep shop manual, not an aftermarket manual, for the kind of information that you want. A YJ Wrangler service manual in the 1991-95 range will serve you well.

Use my magazine Q & A when necessary. There is a new reader forum at the website that just went up over the weekend. You can also run a “wanted” ad in the free private party classifieds at the website (for the service manual or other used items).

As a tip, two 1991 YJ Wrangler areas that you might assess are the front axle’s vacuum disconnect system and the hydraulic clutch release bearing. The hydraulic release bearing may need attention, possibly not disengaging the clutch fully. The front axle disconnect has vacuum actuation and often gets out of sorts and neglected…

TJ Wrangler Could Use a Rubicrawler!

From: John W.

Sent: Friday, January 14, 2011 7:38 PM

To: 4WD Mechanix Magazine

Subject: jeep tj

HI I HAVE A 1998 JEEP TJ 4.0 WITH A AX15. I WOULD LIKE TO KNOW IF I CAN REPLACE THE AX15 WITH A 42RLE SO I CAN USE THE RUBI CRAWLER. I HAVE A A/A 5.0 T-CASE. WILL THIS WORK? OR SHOULD I JUST BUY A 03 JEEP WITH 42RLE? THANK YOU JOHN

Reply from Moses Ludel:

Hi, John…The changeover with your current Jeep would be involved. You would need all of the hardware (PCM), wiring, the 42RLE, the shift mechanism (you might use the Advance Adapters shifter), the flexplate/starter ring, and on and on. Also, the ’98 engine has a distributor ignition, the ’03 would have coil-on-plug. This would be an interface issue for the computer. Given all of the obvious and hidden challenges, I would look for a 2003-up model with 42RLE, preferably a Rubicon TJ, to get the front and rear lockers and Dana 44 axles. Sounds like the only item you might want to keep would be the A/A transfer case, although the Rubicon has a hefty transfer case with 4:1 low range already; with the use of a Rubicrawler, you would have remarkably low gearing. The Rubicon TJ also has 4.10 axle gearing. Sounds good, I’d say!

Considering the Jeep Wrangler Automatic Transmission Adjustment Needs

From: Paul M.

Sent: Sunday, December 12, 2010 4:23 PM

To: 4WD Mechanix Magazine

Subject: Tj wrangler question

hey, i had a transmission question on my 98 tj automatic wrangler 4.0. I have read your technical layout on how to adjust the bands in the transmission, but im not sure which exactly transmissoin i have? Is it a must to torque the screw adjusters or is it possible to go by a number of turns on the screw. I dont have a torque wrench.

The problem im having is a slight slippage when the vehicle is in drive and i increase the the throttle and accelerate from 10 to 20mph after that the vehicle runs great. Do you have any suggestions on what may be wrong? Oil has recently been changed and is filled properly.

thanks, Paul

From: 4WD Q & A

Sent: Sunday, December 12, 2010 7:04 PM

To: Paul M.

Subject: RE: Tj wrangler question

Hi, Paul…Your Wrangler’s transmission is a 32RH design. This is essentially an electronically controlled version of the Chrysler 999/904. Despite their 3-speed without overdrive arrangement, the 30RH and 32RH units are rugged and reliable. One issue has been cavitation or aeration of fluid when the transmission starves for fluid on extreme inclines. This can cause damage if the transmission slips under load while starving for fluid. I look for this kind of trauma in a used 30RH/32RH equipped model.

If your problem is 2nd gear related, it could be a front band adjustment need. Slip in any drive position can be a worn rear clutch pack, which requires rebuilding to remedy. You do not mention engine speed flare-up on shifts or otherwise, and this is a good sign. If there is flare-up, the clutches and/or bands are usually beyond saving. Burnt fluid is a sign of a worn out clutch pack(s) and/or bands.

In any case, since the fluid and filter (presumably) are fresh, I would adjust the bands to spec. For band adjustment, the torque wrench is to seat the band lightly and precisely before backing out the adjuster screw a specific number of turns. If you can approximate the torque called for when seating the band, go for it. If you doubt your ability to simulate this amount of torque, then you do need an inch-pound torque wrench.

Use the Chrysler/Jeep specifications for number of turns to back off the adjuster. Always hold the adjuster steadily while tightening/torquing the jam nut. The number of turns is exact, so don’t guess on this one. Band adjustment determines the “timing” of the band take-up and also determines how well the band grips the drum. Each band has its own clearance-to-drum, determined by the number of turns backed off from a seated position…

Generally, if a band(s) require much adjustment, there is a problem. Adjustment is slight over the entire lifespan of an automatic transmission. (This is not like a manual clutch with its thick lining and big surface area!) If an automatic transmission band exhibits any more than slight wear, it’s in trouble! Note the amount of adjustment needed—that indicates the wear.

Do you have the band adjustment specs for your 32RH? If not write me back…

Regards,

Moses Ludel

From: Paul M.

Sent: Monday, December 13, 2010 4:54 AM

To: 4WD Mechanix Magazine

Subject: Re: Tj wrangler question

Moses,

I do not have the band adjustment specs for the trsnsmission. I would appreciate if you had any information that would be useful in making these adjustments.

The transmission does fine when i accelerate from a really slow speed from 0-20 mph and also does fine at higher speeds, even in the upper 60 and 70 mph.

I do not hear any high reving when the trany is shifting from one gear to another. 1st and 2nd gears do fine. The only problem i am noticing is when i acelerate from 0 to about 20 mph at a pretty fast rpm range, when i go slow it seems fine.Its alomost as if you can feel the belts trying to (grab and slip grab and slip) kind of action and a little bit of a jerking. Does this sound like any problems that you have encounterd and do you think the band adjustment will prevent this.

Thank you for your fast response,

-Paul

From: 4WD Q & A

Sent: Monday, December 13, 2010 8:22 AM

To: Paul M.

Subject: RE: Tj wrangler question

You’re welcome, Paul…The “slip” under throttle and not when coaxed up to speed can be rear clutch slippage. This would require an overhaul to repair. When an automatic transmission slips, band or clutch damage builds up quickly. The plates are sensitive and thinly lined; the bands have limited lining and room for only minor adjustment.

When you changed fluid, was the fluid dark (not reddish) or did it smell burnt? That would be a sign of clutch and band slip. Also, was there friction material, in quantity, in the oil pan of the transmission? If so, not a good sign. These are signs of fatigue and significant wear. Slight friction material, those darker streaks of oil at the base of the pan, is normal. Friction material that you can feel between your fingers is not…Metal in any quantity is always suspect, especially fragments or chunks.

If a band is slipping under load, adjusting right away can sometimes be the fix. You cannot “adjust” the clutch packs, they are hydraulically actuated and spring counterbalanced. If you adjust the bands and the problem persists at the speed you describe, I would suspect a rear clutch issue.

A topic we did not discuss was the throttle valve linkage. Check this cable linkage and its adjustment. If downshifts and “passing gear” do not work well, suspect a throttle valve cable adjustment or cable wear problem. Unless damaged or loosened from the engine, these cables usually do not cause trouble, but slippage raises the question of throttle valve pressure.

Try adjusting the bands regardless. Carefully note the number of turns inward to seat each band. If the turns inward to gently seat each band exceed the factory adjustment turns by a lot, there is significant band wear.

I have attached the adjustment procedures* for your 32RH transmission. Adjustments that could affect the shifts and slippage include the gearshift cable (must be indexing each gear properly), the throttle valve cable, the front and rear bands, and the control pressure adjustment, which is rare but significant. You will see these steps and descriptions in my attachment. If adjustments do not stop the problem, suspect an internal clutch pack and/or band problem that requires a transmission overhaul.

This should help separate issues and nail down your 32RH troubles. As a footnote, make sure the transmission cooler works well. If you do work on your TJ Wrangler often, try to locate a factory 1998 Jeep Wrangler Service Manual. These manuals pop up used on Ebay and are available through used automotive book sources as well. (Mopar may still offer a printed or CD version of this manual.) I buy these manuals for reference books whenever they are available (often at an automotive swap meet). They are packed full of details and procedures…

Regards,

Moses Ludel

‘97 Jeep TJ Automatic Transmission Buildup

Hi, I have a ‘97 TJ with a bad transmission. We drive it on the street and mountain trails with rock climbing. It has a 4.0L engine, Dana 44’s w/4:88’s running 39″ Swampers and a 10” long-arm suspension lift. I purchased it set up this way. I’d like a quote to rebuild the transmission, both stock and a buildup based on your recommendations. I was told the transmission has a stall converter @ 2400 rpm, which I have no need for. Looking forward to hearing from you and thanks.

Curt G.

Curt, the stall speed is way too high for trail running and fuel efficiency. You have 4:88s to compensate for the tire diameters. The converter would need rebuilding and a restoration to a reasonable stall speed. Actually, I prefer an 800-950 rpm hold speed for preventing rollback on slopes at near idle speed and to provide proper compression braking. (Idle speed should be the determining factor.) I select a stall speed that will create this dynamic. A deeper sump oil pan and matching filter depth will help reduce risk of dangerous aeration on these early TJ units when climbing slopes.

On my bench, I would thoroughly restore your 32RH transmission using premium upgrade friction materials, quality bearings and thrusts. All tolerances would be restored and corrected. A “blueprint” rebuild would cost in the range of $2600-$3200 plus return freight and would include the custom converter work plus all available upgrades. (You have a lockup converter, which costs somewhat more to rebuild and balance.) This is ballpark figure dependent upon the condition of existing hard parts within the transmission, Curt. We would welcome your project.

Troubled YJ and TJ Automatic Transmissions

I have a ’97 Jeep Wrangler with a 32RH automatic, Currie high-pinion 9” axles and 4.56:1 gearing with ARB lockers, three-speed transfer stack-box and stock 4.0L engine. I need professional advice or suggestions about the best option: The 32RH has been good, but it has to come out. So, what would you do?—Nick

My ‘91 YJ 4.0L has an automatic. The transmission needs a rebuild. We use the Jeep for a combination of street-driving and off-road wheeling. We have the Rubicon in mind. I’m interested in upgrades you would suggest for the transmission. Are there shift kits available? Is it possible to change the gearing to provide better wheeling? Would changing 1st gear provide some gear ratio upgrades without the need to substantially change axle ratios? Sometime in the future, I also have a transfer case swap in mind, which should improve gearing as well.—Brad P.

Brad, your questions coincide with some of Nick’s concerns, so I’ll start by sharing that the YJ’s A999 three-speed is a non-electronic shift version of the transmission that Nick’s TJ uses. Both designs have roots in Chrysler’s rugged A904 Torqueflite three-speed, which worked well in full-size cars with lower output V-8s. While not quite the A727 Torqueflite of renown, the 904 did an excellent job for Chrysler and AMC. Brad, since you already have considered a transfer case swap, I suggest that unless you need overdrive, the quickest means for getting better off-pavement performance would be a blueprint build of the A999 with either a lower-gearing kit for your NP231 transfer case or an Advance Adapters’ Atlas assembly with lower gearing in low range. The blueprint rebuild of the A999 can include upgrades of all friction materials and even a mild “shift kit” for improved shift performance. As the torque converter needs a rebuild, there is room for a stall speed change here for improved back-country performance in terms of compression braking and crawling on rocks. Our shop can do blueprint rebuilding of these A999 and 32RH transmissions; we take care of the converter work and balancing, too…

Nick, you have a rugged TJ—nice equipment! I blueprint build both the 30RH and 32RH series automatics to perform very well in your driving environment. An option is the AW-4 conversion, mostly using XJ Cherokee components. I can build an AW-4 to perform well, too, and you would have the added bonus of overdrive…Regarding the AW-4 conversion, the concerns would be transmission length, linkage and driveline lengths. Electronics, including the engine management computer, also need consideration. Some XJ donor models use the same PCM plug and harness features as your TJ. Parts interchange to a large degree between the TJs and XJs; however, the AW-4 uses its own shift controller. I would build a “blueprint” AW-4, using premium parts intended for your TJ’s rugged service. The AW-4 is tough and could hold up well in your application. This might be a reasonable way to get a fresh transmission and an overdrive 4th gear. It would be necessary to iron out the PCM and wiring issues; perhaps an XJ harness and an XJ computer could be the bridge here. After testing and proving out the conversion thoroughly, if we were satisfied that this is a viable option, I would consider building up a core bank and peripheral parts for packaging such a conversion. Overall, I like the AW-4 transmission design and believe this could be the fix if a simpler “kit” approach were possible. TJ three-speed automatics are tough but lack an overdrive 4th gear for highway driving.

Another angle is the late TJ 42RLE automatic with overdrive—if this is not a major undertaking. The 42RLE is a tough unit, used in the KJ Liberty as well. A donor model would be the ’03-’06 TJ with low mileage. Such a swap begins with a thorough comparison of parts differences between a ’97 TJ and the last generation TJ. Items would include electronics, drivelines, shifter and transfer case positioning differences, wiring harnesses, shift module accommodations and the PCM. Powertrain management provides an engine and transmission interface via electronics. The sensors cover wheel speed, engine load, transmission gearing needs and a host of other inputs. Today, swapping an electronically controlled transmission is as much an electrical challenge as a mechanical feat. For that reason, it is sometimes easier to do a G.M. 700R-4 conversion into a TJ than to use a factory transmission that requires electronic circuits and a PCM interface…If owners have an interest in these automatic transmission conversions, I can cover them in tech features. Let me know!

JK Wrangler Rubicon Axles for a TJ or YJ?

I’ve heard that complete JK Rubicon axle assemblies are available from the factory. I have a ’98 TJ model, and one of our Jeep club members has a ’92 Wrangler. Would these axles fit? Are they complete with the lockers and disc brakes? How complete and what installation work is involved here? Will they fit both of our Jeep models?

Bob B.

Bob, you’ve heard about the best deal going! Mopar Performance began this program a few years ago. These axles are genuine Rubicon JK Dana 44s and other factory performance-oriented axles straight off the assembly line. Complete packages even include brake rotors and calipers—yes, a ready-to-go axle assembly!

The JK Rubicon assemblies have 61.9” track width, 4.10 gear sets and 5 on 5” wheel bolt patterns. A major advantage of this setup is off-the-shelf Mopar service parts access—exactly the parts you would order for a comparable JK Rubicon!

Wider than stock CJ, YJ, XJ or TJ axle housings, these axles help compensate for a vehicle height increase. Instead of relying solely on a change in wheel offset, you get approximately 2.5” of added axle width at each side! If you lift the vehicle to run large tires, wider axles are the best way to restore center-of-gravity. Ratios of 4.10:1 (Dana 44s and 60s) and 4.56:1 (Dana 60s) are available to meet users’ needs.

For those planning massive wheel and tire packages or out-and-out high performance use, check out the Dana 60 axles. These rugged axle assemblies meet rigorous Mopar Performance standards. Imagine the stamina of factory J8 or Ram Power Wagon® axles!

Current pricing is highly competitive. Best yet, these assemblies are the same engineering and quality you can expect from a spanking new Jeep Wrangler Rubicon model or Ram truck! Your local Jeep or Mopar Performance dealer can order any of the assemblies offered, and as official Mopar Performance products, the axles come with a Mopar parts warranty.

If you go this route, axle housing fitment to an earlier chassis is the purchaser’s responsibility. This can entail relocating or changing out spring pads and other attachments. Look at your current model’s chassis, and compare it to a stock JK Rubicon layout. Consider all of the needs, including the brake hoses, steering linkage, shock mounts, spring perches and track bar locations.

For this changeover, also take into account the rear axle pinion angle and front axle’s caster angle when setting up the chassis. Front axle caster angle and the pinion (driveline/U-joint) angles are critical. Follow the factory specifications for the chassis. Align the axles properly.

Mopar Performance targeted the CJ, YJ, TJ and JK models. (Some JK owners want Dana 60 axle upgrades.) Among the available packages are axles already set up for a TJ or JK chassis. For other installations, expect cutting, alignment and welding work. (If you do your own fabricating, the XJ Cherokee could be a candidate, too.) Make your axle installations safe and reliable! If you lack welding and fabricating skills—or equipment—consider subletting the axle installations to a welding and fabricating shop. Note: Welding and metals fabrication, including chassis work, are ongoing topics in 4WD Mechanix Magazine. You will need these skills for safe, reliable upgrades.

Mopar Performance now offers several cost-saving axle options, including extreme duty (J8 and Power Wagon) application Dana 60s. Look closely for the equipment, ratios and stamina that your Jeep requires. Consider these currently available packages and options:

P5153825—Rubicon front axle…(Superseded to P5155252.)

P5153826—Jeep Wrangler Rubicon axle with locking differential, locking sensor, 4.10 ratio, disc brakes and mounting brackets.

P5153827—This JK Rubicon 44 axle comes completely assembled with 4.10 gear, disc brakes, and locking differential.

P5155252—Axle, Front Assembly, Dana 44, 2007-09 Jeep Wrangler, 4.10 Locking Differential, Without Brakes

P5155256—Axle, Front Assembly, Dana 44, JK, Modified for TJ

P5155084— Axle, Front Assembly, J8, Dana 44, 5 on 5.5 Hub, with Open Differential

P5153826AB—Axle, Rear Assembly, 2007-09 Jeep Wrangler Rubicon, 4.10 Ratio, Locking Differential

P5155257—Axle, Rear Assembly, Dana 44, JK, Modified For TJ

P5155260—Axle, Rear Assembly, Dana 60, J8, 4.10 Limited Slip, 5 x 5.50″ and 5 x 5.0″ Bolt Pattern, Modified For JK

P5155083—Axle, Rear Assembly, J8, Dana 60, 5 on 5.5 Hub, Limited Slip Differential, Leaf Spring

P5155087AB—Axle, Front Assembly, Stock Power Wagon, 4.56 Ratio, With Locker

P5155088AB—Axle, Rear Assembly, Stock Power Wagon, 4.56 Ratio, With Locker

For more details on these axle products and the latest part number availability and supersedures, check out the Mopar Performance catalog. For access to the latest catalog, including the ‘Trail’ section for your Jeep 4×4, simply click here! Contact your local Jeep dealership or a Mopar Performance dealer for pricing.