“Part 1” of this HD video session covers gas brazing in a hands-on and detailed way. If you have sufficient band width, use ‘full screen’ and 1080P quality settings for maximum viewing.

Brazing is often misunderstood and under estimated! Many confuse brazing with soldering, and there are only some similarities. While brazing does rely on capillary reaction and surface bonding, this is where common threads between soldering and brazing end.

“Part 2” of the ‘Welding Class: Gas Brazing’ HD video session continues the process with brazing a “T” joint with two sheet metal plates. See the techique and learn details about the gas brazing process!

When brazing is performed properly, with closely fitted metal pieces, the results can be exceptionally strong. The high tensile strength of a brazed metal joint with 0.0015″ parts separation could be 135,000 PSI, while the same strength-based filler material and a separation of 0.024″ could drop tensile to 24,000 PSI! Capillary reaction plus closely fitted metals dramatically increase the bond and tensile of the brazed joint.

The other force involved with brazing process is the actual surface bond created by atomic attraction and diffusion. Depending upon the degree of surface porosity in the metals, this can be a mechanical and, more importantly, a chemical or molecular binding between the filler and adjacent metal surfaces. Bronze is commonly used for sheet steel and cast iron repairs.

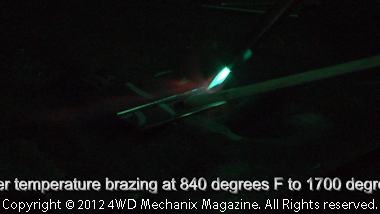

Brazing can take place as low as 840 degrees F and as high as just below the melting point of the metal. Bronze and silver or alloy brazing rod will typically melt between 1000 degrees F and 1700 degrees F. In any case, the filler melting point is well below ferrous metals like mild steel, cast iron and low alloy steel.

Brazing can be strong and useful, especially for smaller parts or metals that cannot afford a lot of heat exposure—like this sheet metal.

Tensile strength is a non-issue with this brazing rod! Weld Mold Company’s “26C” alloy brazing rod is for oxy-acetylene process brazing yet delivers over 100,000 PSI tensile strength for projects like this ‘semi-steel’ handle repair! In the HD videos at the ‘How-to: Welding Class’, you will see the actual break repair, using Weld Mold Company’s niche TIG filler rod. This cosmetic overlay in 26C, now finish ground and sanded, provides the texture and surface strength desired.

See the details of brazing in these two HD video sessions. Consider the value of the brazing process for niche and special applications. An older, ever reliable process for bonding metals, brazing can help preserve base metals and reduce risk of parts distortion.