HD Video Interview: Jeep 4.6L Stroker Inline Six Camshaft Choices!

This series includes six HD video interviews with Tony Hewes…In addition to the video on this page, you will find the other five HD videos at the ‘4WD Tech How-to Channel’ playlist! In this HD Video, Tony Hewes and Moses Ludel compare 4.0L/4.6L camshaft choices for multipurpose trail-and-street use, fuel efficiency and high-altitude torque.

Note: See the CompCams discussion with Daniel Prate within this article (below). There are concerns with Coil-On-Plug (1999-2006) engines and camshaft choices. At the time of our discussion, Daniel Prate recommended a custom grind for these engines to avoid engine codes related to camshaft position. Read the details below and visit the CompCams website or contact CompCams for the latest updates.

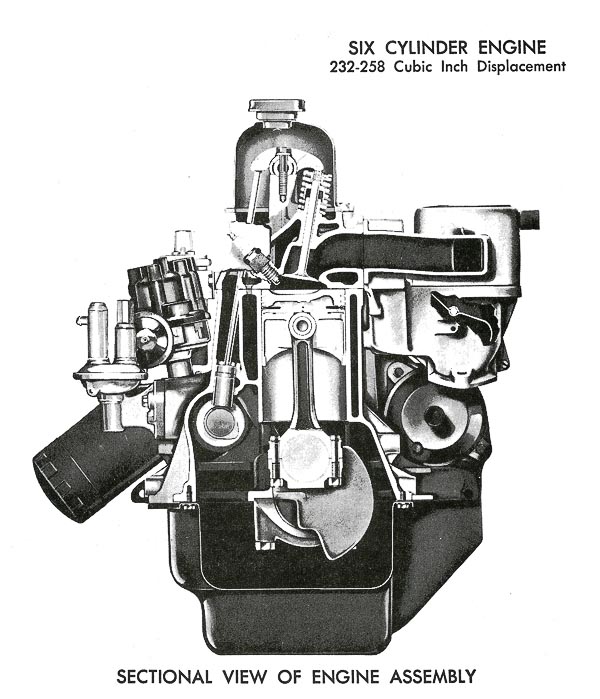

The 4.0L valvetrain (above) is typical of the later AMC 4.2L/258 designs. This a common engine for modern rebuilders. Builder choices are around compression ratios and camshaft design. Below is a drawing of the earlier AMC version of the 232/258 engine with its rocker shaft assembly and rocker arms. The later 232/258 (4.2L) and 4.0L use a lighter, stamped steel rocker arm system with bolt-down pivots and strap bridges.

Earlier 232/258 AMC inline six with a rocker shaft and arm assembly.

Often, a quality Jeep 4.0L engine build falls short of expectation due to the wrong camshaft choice or too high compression. It is easy to think “big” when building a 4.0L engine into a 4.6L stroker. However, trail use and rock crawling are a far cry from desert racing or mud bogging.

In this critical HD video segment with Tony Hewes, Moses Ludel and Tony share their views of camshaft choices. The targets are a 4.6L inline six stroker motor and other Jeep inline six-cylinder applications intended for off-pavement trail running and street legal use.

There are solid reasons for going “mild” with the camshaft choice if you truly want rock-crawling, stump-pulling low end torque. Low-end torque also adds to optimal fuel efficiency…Watch the video and hear Tony and Moses compare details!

Here are links to CompCams’ 252H grind discussed in the video…This camshaft has performed and tested well in pre-coil pack 4.0L stroker builds. The 1999-up TJ Wrangler and 2000-up XJ Cherokee builds with the late coil-pack ignition and cylinder head redesign require a different lobe separation than the traditional 252H grind. Below these two links is an exchange with CompCams about a similar yet suitable camshaft for these later coil-on-plug engines:

http://www.compcams.com/Company/CC/cam-specs/Details.aspx?csid=8&sb=2

Discussion with CompCams: A Custom Grind Camshaft is Available for the 1999-2006 ‘Coil-On-Plug’ Ignition 4.0L and Stroker Inline Sixes

Update on CompCams choices for 1999-up 4.0L inline sixes: We have closely followed the camshaft and PCM compatibly concerns around 1999-up Jeep TJ and other 4.0L inline sixes. CompCams now offers a specific camshaft grind for these 1999-2006 engine applications: https://www.compcams.com/xtreme-4×4-205-213-450-450-hydraulic-cam-for-jeep-amc-6-cyl-1999-2006.html

This exchange with CompCams addresses the later coil-on-plug 4.0L engines and a suitable camshaft choice. Click here for a forum post discussing the camshaft needs of the later coil-on-plug 4.0L inline six engines:

Moses: Do you recommend a custom alternative to the 252H cam for the stock 4.0L (late coil-on-plug inline six) engine and also the 4.6L stroker build on that platform? Does the cam perform like the traditional 252 grind, targeting low-end and mid-range power with good idle/lower speed manifold vacuum? Will you be making a catalog listing for this cam? How do the magazine’s reader/viewers access this camshaft? Is there a reference number or camshaft card number?

Daniel Prate, CompCams Tech Support: Moses, We have a custom grind that our customers have been very pleased with. It has a duration @ 0.050″ of 206/212, with valve lift being .435/.448, and a lobe separation angle of 113° (110-degree intake centerline). The cam price is $186.15 [as of January 2015]…Moses, I do recommend that cam for the stock 4.0L as well as the 4.6L. It performs like the 252 grind, and we do not have any information about whether or not this cam will become a catalog cam. You can order this camshaft directly through me, or any of us here in the tech office.

Here is Daniel Prate’s contact information. You can discuss this camshaft with anyone at CompCams Tech Support:

Daniel Prate, Technical Sales & Support

COMP Performance Group™

3406 Democrat Rd.

Memphis, TN 38118

Toll Free: (800) 365-9145 ext. 1516

Fax: (901)366-1807

Here are additional camshaft choice and tuning comments from a topic post at the 4WD Mechanix ‘Tech and Travel’ Forums:

“At the magazine, building a Jeep inline 4.0L six with a 4.2L crankshaft (stroker motor) is very popular. Tony Hewes (Hewes Performance, Reno, Nevada) and I did a series of HD videos and shared our favorite components for a 4.6L (0.030” overbore with the 4.2L crankshaft) stroker motor build for combined street and trail use.

Since then, we have received a lot of feedback and continue to address the tuning and camshaft requirements of these engines. From our testing, the pre-coil pack (1998 TJ and older 4.0L) engines with older style injectors do very well with Ford 5.0L V-8 24-pound injectors—no emission quirks, “Engine Check” lights or other issues when tuned correctly. Ford part number F1TE-D5A or Bosch number 280 150 947 is the specific injector type. These engines work well with the 252H CompCams grind camshaft and 8.7:1 compression.

Later, 1999-up TJ Wrangler and 2000-2001 Cherokee engines with coil-pack ignition have square injector connector plugs. For these engines, stroker builders use the Dodge Ram 5.9L V-8 injectors listed for 2000-up with coil pack. This is the injector that HESCO calls a “24-pound/hour”. HESCO supplies rebuilt GB injectors, although new Mopar OEM part numbers are available. This injector also crosses over to the aftermarket Bosch Fuel Injector #62005 offered at Summit Racing for a significant price per injector.

Here is the GB website: http://www.gbreman.com/index.html. The 5.9L Ram truck V-8 application is the GB812-12132 injectors for engines to 2003.

I researched further and came up with the OEM 5.9L Mopar V-8 injector part number: 53031740AA. (I used 2001 as a clear year for coil-pack and square injector plug.) This OEM Mopar injector is 23.61 pound/hour rated at 43.5 PSI. This is a “high impedance” injector design with a square plug socket.

The OEM injector on a coil-pack engine rates 22.5 pounds/hour at 49.0 PSI fuel pressure, which may work okay on a coil pack stroker engine unless the cylinder head, compression or camshaft/head combination is an issue for the PCM. Fuel rail pressure of 49.2 +/- 2 PSI should be confirmed by factory testing method.

Click here for an instructional PDF for running fuel rail pressure tests on Jeep MPI. This is the 1997-up XJ Cherokee and TJ Wrangler type with fuel tank mounted pressure regulator and single-rail injection.

In the late ’90s, my engineer friends, Jeep performance enthusiasts at Mopar, were talking about 5.9L Mopar V-8 injectors for 4.0L/4.6L stroker engine builds. This has apparently been a route to go, with a 24-pound/hour injector rating.

I researched the Jeep ZJ Grand Cherokee 5.2L/5.9L V-8 injectors from the mid-‘90s: 1995 Jeep 5.2 ZJ/Dodge 5.9L V-8 injectors are Part #53030262 and rated to flow 24.6-pound/hour at 39 PSI. By 1996, the Jeep V-8 injectors rated 23.2 pounds at 49 PSI. The 1995 Mopar injectors (24.6#/hour @ 39 PSI) could be an alternative to the 302 Ford injectors for a stroker build in a 1991-95 Jeep 4.0L MPI chassis application if the engine demands that kind of flow.

Summing it up, if GB is accurate, using the right injector cores and parts for this application, HESCO is marketing a “24-pound/hour @ 43.5 PSI injector for a stroker inline six. A caution here is that the ’97-up Jeep TJ Wrangler and XJ Cherokee have a 49.2 +/- 5 PSI rail pressure. Flow could be higher than 24 pounds/hour at this 49.2 +/- 5 PSI rail pressure.

If the GB812-12132 injector is okay for a coil pack later engine with the later cylinder head casting, the GB812-12132 square plug injector would be the choice for later coil-pack engines. There are a number of sources for these GB injectors.

We’re still testing the CompCams 252H camshaft in a later 4.0L (1999-up TJ Wrangler/2000-up XJ Cherokee) engine with the redesigned head and coil pack ignition. Tony and I will update on these late 4.0L/stroker engines. The pre-’99 stroker engines and stock PCMs have worked well with this camshaft grind. We’re consulting with CompCams about a possible new grind for later coil-pack ignition stroker engines. [See CompCams/Daniel Prate’s comments earlier in this article regarding later COP engines (4.0L 1999-2006 without distributor ignition) and camshaft choices.]

The 1997-up TJ Wrangler and Cherokees with the tank-mounted fuel regulator use higher fuel pump/line pressure. I would stick with Mopar 53030262 or Ford 302 V-8 type injectors* on the 1997-98 TJ Wranglers and Cherokees through 1999 (without the coil pack system).

*Footnote: 24-pound 302 5.0L V-8 injectors fit the pre-coil pack engines; coil pack engine injectors have a square plug connector.

Below are some useful links and comments at the magazine site:

https://www.4wdmechanix.com/Jeep-Fuel-Pressure-Requirements.html [I detail pressure ratings and designs for Jeep engines equipped with MPI/EFI. 1997-up single rail systems with tank-mounted pressure regulator are higher pressure, running rail/injector pressures typically around 49.2 PSI +/- 2 PSI. This includes the coil pack engines with square wire plug injectors.]

https://www.4wdmechanix.com/YJ-&-TJ-Jeep-Stroker-Six-Upgrade.html

https://www.4wdmechanix.com/Jeep-TBI-&-MPI-Advanced-Troubleshooting.html [Overview of OEM tuning methods and factory diagnostic tools required.]

https://www.4wdmechanix.com/Vlog-Why-Build-a-Jeep-4.6L-Stroker-Inline-Six.html [Video vlog comments.]

https://www.4wdmechanix.com/How-to-Tuning-the-Fuel-Injected-Jeep-Inline-Six-Stroker-Motor.html

http://users.erols.com/srweiss/tableifc.htm [A useful third-party website for every popular OEM fuel injector’s flow ratings.]

https://www.4wdmechanix.com/Vlog-Road-Testing-Jeep-4.6L-Stroker-Inline-Six.html [My video comments on Brent H.’s Cherokee 4.6L build and its drivability. This is a video vlog plus a list of key components used in this Hewes Performance buildup for a 1998 Jeep XJ Cherokee chassis.]

Of course, there’s also the entire 4.6L Tony Hewes interview series of HD videos, six individual videos covering the build of a stroker inline six-cylinder Jeep engine!” —Moses Ludel

Want quality automotive machine work or a precision engine build-up? See the Hewes Performance Machine website at:

http://www.hewesperformancemachine.com/