Jeep 4WD How-to: Front Wheel Alignment Using Affordable, Accurate Equipment!

Wheel alignment is a basic Jeep 4WD maintenance need. Suspension modifications, normal chassis and steering linkage wear, off-pavement trail pounding and the use of oversized tires can each impact the front wheel alignment.

Also see the Jeep 4×4 wheel alignment ‘how-to’ HD video, click here!

The popular, time‐honored Jeep off‐pavement trail runners have a beam (“solid”) live front axle. More civilized Jeep models with independent front suspension (IFS) include the KJ Liberty, 2005‐up Grand Cherokee and the Commander. Each of these Jeep 4WD vehicles has a hypoid, solid rear axle assembly. The 2014-up Cherokee features four-wheel independent suspension.

Since most trail vehicles upgrade to expensive, oversized traction tires, premature wear of tires is always a concern. Periodic tire rotation and proper wheel alignment are basic safeguards to prevent abnormal tire wear.

The less complicated Jeep 4WD beam front axle is not just strong and durable. It also has fewer maintenance requirements. Camber is set at the factory with the jig‐welding of the beam. Caster is adjustable for the slight sagging of aged springs or the settling of spring or link arm bushings. For all Jeep vehicles, a common alignment need is toe‐set.

Caution: Wheel alignment is never a substitute for replacing worn or damaged parts. A bent steering knuckle, tie‐rod or axle beam needs replacement. Straightening trail damaged steering linkage or a bent knuckle is not safe practice.

Periodic Alignment Needs

Wheel alignment at the modern shop most often includes four‐wheel “thrust” inspection and a check of the caster, camber and toe-set. Some shops can perform a true “four‐wheel alignment,” but this is generally not necessary on the trail oriented Jeep 4WD models unless an aftermarket lift kit has adjustable rear wheel link arms or there is suspicion of a bent rear axle or frame damage.

Thrust alignment does take rear axle shift, worn springs, bad bushings or a bent frame into account. A shop that performs either four-wheel or thrust alignment can handle any vehicle with a solid, hypoid rear axle system.

To push the vehicle forward in a straight line, rear axle thrust must be perpendicular to the centerline of the frame. When thrust is correct, a front wheel alignment assures precise steering and a normal steering wheel position.

On turns, the inside wheel has a tighter turning angle than the outside wheel. This is “Ackerman steer,” the result of the steering knuckle’s kingpin inclination, caster angle and the steering axis inclination (‘SAI’). Each of these variables affect steering and the vehicle’s behavior when turning.

Caster is often adjustable. When SAI is incorrect, however, the most common cause is a damaged steering knuckle or bent spindle.

Note: If you have no reason to suspect knuckle or spindle damage, checking the SAI is of lesser importance. If your Jeep rear axle is square with the frame and not bent, there is not a call for thrust alignment. At the ‘Workshop’ areas of this website/magazine, I share information on how to set up a lift kit and adjust link arms to assure proper thrust and axle alignment with the frame.

Toe-Set

Toe set is the most common measurement associated with front wheel alignment. Normal chassis and linkage wear, plus the characteristic pounding that 4x4s get on rough trails, make toe-set a periodic maintenance chore.

Toe-in is the precise angle of the front wheels when the steering and wheels aim straight ahead. While parallel front wheels would seem ideal, the front wheels seldom call for zero-degrees of toe set. The basic wheel alignment is toe-set.

Due to the thrust loads of the vehicle moving forward (especially with oversized tires!) and the slight movement of steering joints under load, toe is actually set so that tires “toe-in” slightly when static. Toe-in is measurable at the forward side of the front tires.

The tires’ design dictates toe-in requirements. Bias-ply tires have a tendency to thrust outward under load. The classic Willys or Jeep CJ with OEM type, bias‐ply tires should follow factory alignment specifications. That toe-in might be in the 1/16”‐3/16” range, typically a 1/8” setting.

If using modern radial tires, toe-in should be near zero, something like 1/32” for stock tires. (Modern alignment racks measure in tenths of a degree, not inches.) The higher-end alignment equipment can check toe-set with projectors and electronic beams. As you will see in this technical article, toe-in can also be checked with basic tools.

Camber

With the chassis weighted and the front tires pointing straight ahead, each tire should stand nearly vertical. Viewed from the front of the vehicle, camber degrees are the tilt of the tires, inward or outward, from a vertical centerline. If the top of the tire tilts outward, camber is “positive.” If the top of the tire tilts inward, camber is “negative.”

Jeep beam type axles with leaf springs or link arms have fixed camber. As the vehicle’s frame and body lean on corners, the axle stays parallel with the ground. With this design, there is no provision for adjusting the camber.* Unless the axle housing is bent, or worn ball-joints cause knuckle sagging, the axle maintains its original camber settings.

*Note: Camber can be corrected with aftermarket offset ball-joints or eccentric ball stud seats. There is, however, no OEM provision for adjusting camber on a solid beam Jeep 4WD front axle.

By contrast, each front wheel on an IFS suspension, like the Jeep 4WD Liberty or late Grand Cherokee models, moves up or down independently. Short (upper) and long (lower) control arm “SLA” suspension compensates for body/frame lean on corners.

As the vehicle corners, the body/frame rolls, causing the outside wheels to compress the springs. This moves the wheels upward into the fenderwells. The unloading (inside) wheels drop as the body rolls outward. A functioning sway bar helps minimize this body/frame roll.

On SLA suspension like the Jeep Liberty 4WD, late GrandCherokee or Commander, tire track width remains relatively constant during this process. The arc of wheel travel is precisely engineered for maximum control and long tire life.

Solid, beam front axle Jeep 4WD vehicles have a simpler approach. As the frame/body rolls on turns, the axle, wheels and tires stay parallel to the ground—unless we’re rock crawling with wheels in the air! The outside leaf springs or coil springs compress, as the suspension allows for this roll.

As the outside wheel compresses the suspension, the sway bar makes the vehicle squat—pulling the chassis downward, lessening the body/frame roll and lowering the center of gravity. The sway bar has a clear purpose, especially on the highway and when cornering at speed.

Caution: If your Jeep 4WD has a factory sway bar, it should be connected for highway driving! Sway bar disconnects allow more axle articulation off-pavement, which is their intended use. On-highway, the sway bar is a valuable asset.

Caster

Caster plays an important role in vehicle handling. Caster is the tilt of the kingpin or ball-joint centerlines when viewed from the side. Imagine a line drawn through the center of the upper and lower ball joints (or the kingpin/knuckle bearings on a vintage Willys or Kaiser era Jeep 4WD). That is the kingpin centerline. The forward or rearward tilt of this centerline, measured in degrees, is the caster angle.

The kingpin or ball-joint centerline tilts inward as well, but this is not caster. Inward tilt is kingpin inclination, a measurement that affects the steering axis inclination (SAI). When caster and camber are within specification, SAI should be as well. If not, suspect a bent or defective spindle or steering knuckle.

Typical front suspension calls for positive degrees of caster. Positive caster means that the upper end of the kingpin or ball‐joint centerline tilts toward the rear of the vehicle. Caster has a very important function: helping the front wheels come back to center after turns.

When there is too little caster angle, the most notable symptom is the need to actually steer the vehicle back to center as the Jeep exits a turn. Correct caster settings also help steer the vehicle straight ahead, helping to overcome the effects of the road crown. (Camber plays a role here, too.)

Caster angle helps prevent pull and reduces the risk of kingpin or ball-shimmy. Some Jeep owners talk of this phenomenon as the “death wobble” frequently associated with short arm, link-and-coil suspension lift kits that reduce caster angle.

For the Jeep vehicle with a beam front axle, toe-in is often the only adjustment needed if: 1) the frame and axle beam are straight, 2) the springs set evenly, 3) the knuckles and joints are in good condition, and 4) caster and camber meet specification.

Whether setting up a modified suspension or simply restoring your Jeep vehicle’s steering, always consider caster, camber and toe-set. Changing the spring length or arch, changing the link arms, and other measures involved with lifting the chassis—each requires an alignment check and corrections.

Every Jeep owner wants improved steering control, safe handling and maximum tire life. Performing your own wheel alignment and steering or suspension diagnostics can save money and bring a valuable resource into your shop or home garage.

‘SPC’ Makes Wheel Alignment Easy!

With a beam axle, it is possible to do on the spot toe-set adjustments. Alongside the trail, I’ve set basic toe with nothing more than a tape measure and hand wrenches. For home use, a simple toe‐bar and tire centerline scribe can be purchased through automotive tool suppliers.

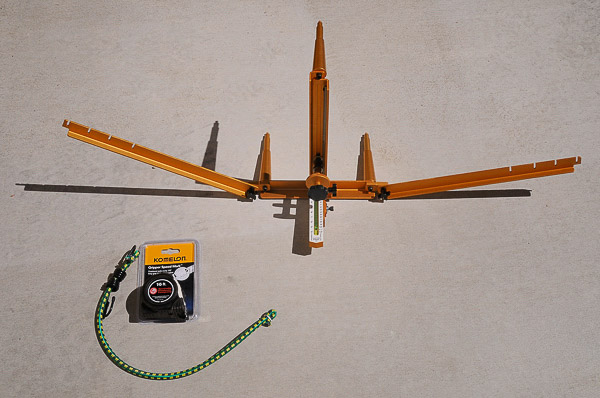

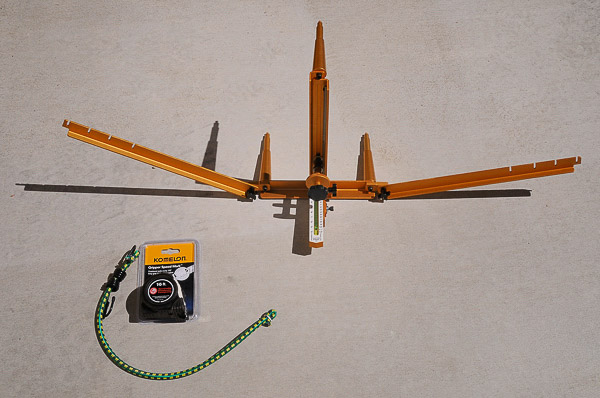

For an affordable, far more thorough approach, there is Specialty Products Company’s FasTrax® alignment equipment. The FasTrax® 91025 ‘Off‐Road’ alignment gauge kit provides a portable, fast and accurate way to measure toe-set, caster and camber on vehicles with larger tire packages.

As a budding mechanic in the ‘sixties, I was fascinated by the early wheel alignment equipment that was still in service. For decades, both before and after WWII, magnetic and clamp-on caster and camber gauges were common. These gauges, with a simple toe-set bar and turn plates, met the garage, dealership and body shop standards of that era. In the right hands, these tools provided accurate wheel service for trucks, cars and, yes, the vintage Jeep 4WD vehicles!

I ran a modern Hunter alignment rack at a truck dealership in the early 1980s. From 1999-2004, I instructed automotive/diesel technology at the adult vocational education level, involving more contemporary wheel alignment equipment. Today, $40K alignment systems with electronically controlled projection heads, drive-on ramp racks, degree’d turn plates and computer data stations are common at alignment shops.

Clearly, modern electronic equipment offers pinpoint accuracy. For a beam axle Jeep 4WD that often plies backcountry trails, however, simpler equipment can do a reasonably accurate, far less costly job! SPC’s portable equipment, at 1% the cost of a high-end alignment system, targets smaller automotive shops, home garages, fleet operators and racing teams. Large-tire Jeep 4WDs are another niche. The SPC Model 91025 Off-Road wheel alignment system aims at off-road vehicles with oversized wheels and tires.

The portable SPC 91025 package is an accurate way to check wheel alignment, including camber, caster and toe-set (with the toe-arms shown here). For large tires, this is the kit. As an added benefit, the equipment also works well as a quick diagnostic tool.

For safe handling, minimizing tire wear or customer satisfaction, this fast, accurate alignment equipment demands attention! Four-wheelers who pound around on rocky trails, or the 4WD shop that regularly installs lift kits, oversized wheels and big tires, will value SPC equipment. Used properly, this is a practical alternative to expensive alignment shop sublets. As you will see, it also makes a useful troubleshooting tool!

1: To demonstrate a home-like setting, I parked the XJ Cherokee on a recently poured driveway slab. The FasTrax® 91025 comes with a floor calibrated base. Since the aim is to read angles on a bubble level gauge, the level must be parallel to the floor at each wheel. Here, I set a level on the slab to get a sense for the floor’s level. (The gauges will work on an uneven surface.) Begin the alignment with the front wheels pointed straight ahead…

2: The use of sheet plastic beneath each tire is a budget conscious alternative to turn plates. (If you can afford turn plates, get them!) Plastic reduces friction while turning the wheels left-straight-right. Set FasTrax® base just outboard the plastic and square with the tire’s face. Level the bubble to “0” on the camber scale.

Note: Inexpensive turn plates like the Gil Smith set shown at my Dodge Ram alignment work very nicely and are affordable! I ordered a set and was pleased how they work.

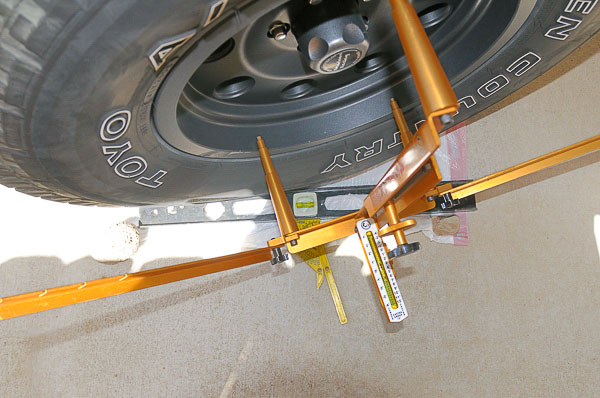

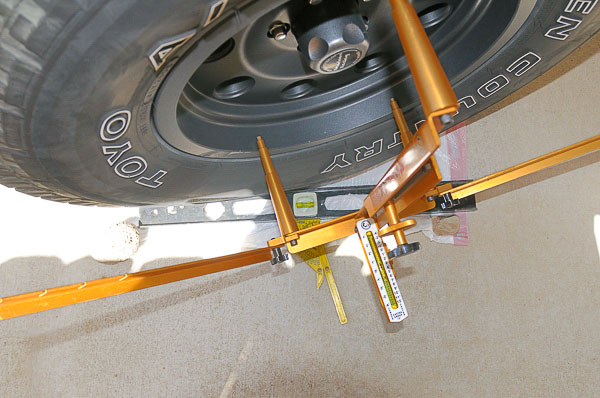

3: The two arms that come with the 91025 Off‐Road kit are for toe-set. I place them on the gauge assembly before mounting the fixture on the wheel. The 3‐point fixture clamps internally, tightened with a rack gear and knob system on the fixture. American Racing wheels have spot-on machining, which makes it easy to center the gauge fixture and know that the gauge sets true.

4: When mounting the 3‐arm fixture, a straight-edged spirit level helps align the gauge vertically. This assures accuracy, as the gauge is now on plane vertically and horizontally. The first measurement, with the wheels pointed precisely straight ahead, is camber. This is a beam axle in good condition; camber should be a non-issue. I quickly find this not to be the case, though!

5: Minus 3‐degrees (negative) camber! The factory setting is minus 0.25-degrees with a range or tolerance of 0.75-degrees negative to 0.5-degrees positive. This is the right side wheel, which tolerates a bit of extra camber; however, there’s an extra 2.25-degrees negative. The gauge, calibrated with the ground, reveals the negative camber. Some jump to the conclusion that this means a bent axle housing, but there are other possibilities as well.

6: Five minutes into the process, and the SPC alignment gauge serves as a precise diagnostic tool for front end troubles! The excess negative camber reflects a tilting steering knuckle. This could be caused by a bent axle housing, but the history of this vehicle does not suggest that kind of trouble. As the Dana beam axles do run to the limit of tolerance, sometimes even exceeding it, some of this error could be inherent to the axle beam.

Considering the XJ Cherokee’s 122K miles and the use of large tires with shallower wheel backspacing than stock, there is plenty of loading on the knuckle ball joints. These are the original joints. If loose, the natural slant of the knuckle will be negative degrees, just like the reading found here. So, before scrapping out an axle housing (although a Dana 44 upgrade would be nice!), I will jack up each side of the axle beam and check the ball joints for wear or looseness. For the record, this vehicle steers quite nicely, without signs of wobble…Given the lack of symptoms, the SPC alignment gauge has proven useful as a preventive maintenance tool!

7: Accurately checking caster without turn plates does require innovation! The system calls for turning the wheels 15 degrees each way from center (straight ahead) during caster check. Opting for the “plastic bag” approach, I placed the straight edge (on ground) parallel with the tire. Then I placed a protractor, set at fifteen degrees, square with the straight edge. The idea is to provide an accurate reference line.

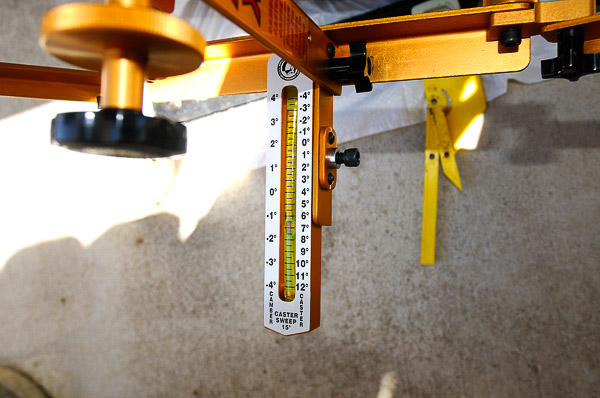

8: I fired the engine to apply power steering and turn the wheels. At the right side of the vehicle, the turn was right, to 15-degrees. Here, the alignment gauge is parallel with the 15-degree position at the yellow protractor. In that position, set the bubble level on the SPC gauge to a precise “0” along the caster scale.

9: Now turn the front wheels left to an angle15 degrees left of the straight ahead position…At this point, the right wheel’s caster will read in degrees along the caster scale of the bubble gauge.

10: The bubble is very clearly at 7.5-degrees positive caster. (Zoom-in for detail!) This measurement is excellent. Factory preferred caster is 7.0-degrees positive. Range is 5.25-degrees positive to 8.5‐degrees positive. Caster provides the desired return‐to‐center, and this XJ Cherokee has been easy to drive and steer…Next, straighten the steering to center (straight ahead). Move the gauge assembly to the left front wheel.

11: At the left front wheel, the gauge is set flatly on the ground, just outboard of the wheel/tire. Zero the bubble gauge on the Fastrax® 91025 gauge. Carefully raise the gauge into position and mount it on the wheel rim. Handle the fixture as you would a precision instrument. Do not disturb the bubble gauge when clamping the assembly onto the wheel.

12: The gauge mounts squarely, shouldered evenly against the wheel rim. Avoid clamping the fixture at rim sections with wheel weights or abrasions that might distort the angle. I again use the straight-edge spirit level to align the fixture vertically. Once the fixture is squarely mounted to the wheel, you can read camber on the gauge.

13: Read the left side camber measurement. (You can zoom-in for detail.) This side reads nearly 2.5-degrees negative camber, well beyond the OEM limits of 0.75-degrees negative.

Note: At 20,000-plus miles on these Toyo tires, wear is uniform and nominal. Tire rotation at 5K‐7K miles has minimized wear. Despite the poor camber readings, the vehicle steers well. This camber check has exposed a vital concern, however. While a bent axle housing or knuckle can cause negative camber, there is no evidence to support that kind of abuse. The likely culprit could be worn ball joints at the steering knuckles, which would require attention. This kind of discovery quickly pays for the FasTrax® tool!

14: Caster can now be checked on the left side. Wheels pointed straight ahead, the straight edge is set parallel to the tire. Once again, the protractor provides the line for 15 degrees of left turn angle.

Note: Degree’d, floating turn plates would simplify this part of the alignment, also eliminating the need for plastic sheets under the tires. SPC does sell portable turn plates. Used plates can sometimes be found at auctions or on Ebay! For my shop’s occasional use of plates, I opted for the Gil Smith Racing portable plates.

15: Protractor set to 15-degrees left of the straight ahead wheel position, turn wheels until the bubble gauge is exactly parallel to the 15-degree line of the protractor.

Note: Again, turn plates would be helpful. Plates have detailed degree marks and a pointer. They allow the front wheels and tires to “float,” relieving thrust pressure and allowing easy left-to-right turning of the wheels. On turn plates, wheels can usually be turned left and right by hand, gripping the tire without using the steering wheel. (Make sure the steering wheel is unlocked!) SPC offers turn plates as do others like Gil Smith Racing. Consider them!

16: Once again, turn the wheels out 15 degrees. (This is the left/driver’s side, so turn left.) At the turned out position, move the bubble gauge to “0” on the caster scale.

17: Here is the left front wheel turned outward to the 15 degree point. Note that the bubble gauge has been set to read “0” on the “Caster Sweep” 15-degree scale. The gauge is very clear and responsive. I am confident that for Jeep 4WD vehicles, especially those with a beam axle, this is a reliable approach. In addition to alignment, the tool demystifies front end, steering and axle troubles.

18: Now the final reading for caster. With the front wheels turned 15 degrees right, the caster sweep measurement is exactly 7-degrees positive caster. The caster at each side reads well within specification.Factory allowance is a maximum right-to-left “difference” of 1.25 degrees. Actual caster measurements are within 0.5 degrees of each other. This is optimal.

19: Reading is 7-degrees positive caster at the left front wheel. With these figures, steering is safe and positive with optimal return to center feel. Caster angle also dictates the driveline pinion angle. On vintage Jeep 4WD vehicles with single Cardan U-joints, front end caster is less. This reduces the angle of the front U-joint.

Note:Earlier Jeep beam axles call for 4‐degrees positive caster. Chart below depicts a late model Wrangler with an OEM, double Cardan (CV) joint at the transfer case end of the front driveshaft. Note the use of more caster, which is desirable for vehicle handling and tighter steering angles.

Factory Front Wheel Alignment Specs

Note: I use a 2005 JeepTJ Wrangler as an example here, a popular and newer Jeep 4×4 with a beam axle. See your model’s Jeep workshop manual for specifications.

Beam Axle Limits:

PREFERRED CASTER: + 7.0° ±1.0°

CAMBER (fixed angle): 0.25° Negative ± 0.63°

TOTAL TOE-IN: 0.15° (each front wheel) ±0.06°

MAX RT/LT DIFFERENCE:

Caster: 0.65°

Camber: ±1.0°

Toe-in: .06°

The Rear Axle has preferred OEM alignment specifications, also measurable with the SPC FasTrax® gauges:

CASTER: Not Applicable. The only concern is pinion angle for U-joint alignment.

CAMBER: –0.25° with 0° to –.50° Allowable

TOTAL TOE-IN: 0.25° with 0° to 0.5° Allowable

THRUST ANGLE 0° ± 0.25°

20: For setting toe-in, turn front wheels directly back to straight ahead. The two wing arms on the 91025 system have slots for various diameter tires. Designed for off‐road vehicles, there are slots that easily match the oversized, 33” tires on the XJ Cherokee. I like to measure toe as close to the horizontal centerline of the tires as practical. Make sure that the tape can cross to the opposite side without bowing or hitting obstructions. Keep tape parallel to the ground and just outboard of tire tread.

21: For toe‐set, the tape goes straight across to the passenger side tire. Measure width at the rear and front of the tires. The difference is toe. Shorter at the front than rear is “toe-in.” Shorter at the rear of the tires is “toe-out.” Stock radial tires call for “0-degrees” toe on this XJ Cherokee. With large tires, wide rims, shallower back spacing and lots of unsprung weight mass, these tires will naturally toe outward as the vehicle moves forward. From experience, I set a toe-in of 3/32” to compensate with oversized tires.

22: Some use two 91025 kits and measure between the four toe arms. With one kit, I measure toe from the left side arms to either a scribed centerline at the right side tire or a common tread pattern point. Here, a reference point is established at the rear of the right front tire. Remove tape slack but do not pull hard. The extended toe arms will bow if you apply too much pressure. For accuracy, match the tape tension during the front and rear measurement checks.

23: Some place the toe arms near the floor. I set the FasTrax® toe arms near the middle of the tire as shown. The tape parallel with the ground, reach across to the opposite tire. Pick a matching tire tread pattern point at the front of the tire; measure the distance. In this case, the front measurement is slightly shorter as desired. This indicates toe-in instead of toe-out.

Note: Picking a matching tread point can be tricky. The tape should be as level as possible. Make sure the tread reference patterns are identical, front and rear.

24: At the front side of the front tires, the measurement is 72-1/8”. At the rear, the measurement to the same tread pattern point is slightly under 72-1/4”. The difference is 3/32”—shorter at the front side of the front tires. Front measurement being shorter, this wheel alignment has “toe-in.” Slight toe-in will work well for the tire size and vehicle’s weight distribution; the heavy winch and bumper place additional load on the front axle.

Steering Wheel Alignment

When aligning the front wheels, make sure the steering wheel aligns with the steering gear’s center point. If the steering wheel centers with the steering gear, do not remove and reposition the steering wheel to center it during a wheel alignment!

Instead, point the front wheels straight ahead. After adjusting toe, center the steering wheel by adjusting the short tie rod or draglink. Road test and readjust again if necessary. Do not change the front wheel toe setting in the process. Re-check toe-in if necessary.

Note: The only Jeep vehicles that require repositioning the steering wheel are early model Willys trucks equipped with a non-adjustable, fixed length draglink. On these models, the steering gear must still be very close to its center point (the over-center high point) when the front wheels point straight ahead.

Adjusted properly, the steering wheel should be on center with the front wheels steering straight ahead. The steering gear should be at its over-center high point (midway between left and right turning extremes) when the front wheels point straight ahead. By design, this will provide the least amount of steering backlash or play when the vehicle steers straight down the road.

Sierra Stomper Dan Wilson took his 1988 XJ Cherokee on trail recently. Portable wheel alignment gauges would be a valuable tool at Dan’s home shop! (Photo courtesy of Dan Wilson. All other photography by Moses Ludel.)

FasTrax® 91015 Caster-Camber-Toe Gauge Evaluation

The Specialty Products Company’s Model 91025 alignment kit works very well! Portable and light in weight, the gauge’s quality construction maintains calibration and tolerance. Alignment chores are easy with this kit. The design incorporates proven features like a bubble caster and camber gauge.

A precisely machined, gear drive clamping fixture, attractively anodized, should deliver reliable service over time. SPC’s 91025 FasTrax® kit for Off‐Road vehicles is an optimal investment for the aftermarket suspension installation shop or any serious racer/trail runner who wants maximum handling and performance from a Jeep 4WD.This is a useful troubleshooting tool as well, capable of quickly revealing suspension, live beam axle and steering system damage…

Unless you have the shop space and an unlimited budget for electronic alignment equipment with a four-wheel alignment rack, consider the FasTrax® 91025 a cost-effective, sensible alternative. Accurate, portable and designed to set up quickly on any flat surface, the Specialty Products Company’s FasTrax® 91025 should be a fixture at the garage and pit area of every off-road race crew.

Serious trail runners and any Jeep owner who does his or her own service work will find this tool valuable. Save tires, save time and diagnose trouble at the earliest point with this versatile tool. For the fleet truck shop with a preventive maintenance and service program, the FasTrax® could pay for itself in a week!

SPC specializes in niche suspension and steering parts for Jeep 4WDs, popular trucks, SUVs, passenger cars and off-road racing vehicles. Products include offset ball-joints and eccentric seats for adjusting caster and camber. The catalog features unique alignment shims and eccentric bolts for adjusting link arms, plus coil spring spacers and bushings.

Supplying a variety of specialty tools and parts, SPC also heads up the “Light Racing” parts program. Popular among rock crawlers and professional desert racers, Light Racing offers special hardware and suspension components.

‘SPC’ has a demonstration video available for the 91000-series FasTrax® tools in operation. Visit the website for access. In business since 1972, Specialty Products Company has a full product line for Jeep 4WD owners and 4X4 specialty shops. You can download the SPC catalogs or get more information at the Specialty Products Company website.