2005 Ram Gets Fluidampr® Harmonic Damper Upgrade

Upgrading to a Fluidampr® on the Ram Cummins 5.9L turbodiesel is assurance that the crankshaft will be protected from torsional vibration across the engine’s full rpm range. This is a significant improvement over the OEM damper.

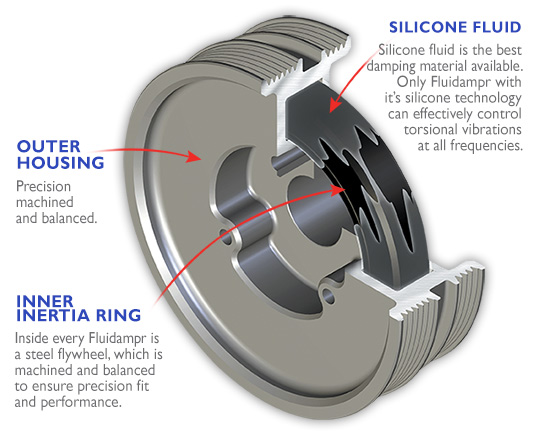

Why a Fluidampr®? This proven viscous damper design has an internal “flywheel” surrounded by silicone fluid. The Cummins/Mopar OEM two-piece damper with a rubber separation ring is engineered to cancel harmonic torsional vibration at one frequency. The floating flywheel in the Fluidampr® enables the silicone fluid’s shearing action to damping vibration across the entire operating rpm of the 5.9L turbodiesel engine.

Torsional vibration is “normal” in any engine. The power stroke twists the crankshaft, and the rebound oscillation creates harmful vibration at various frequencies and rpm levels. A viscous damper like the Fluidampr® cancels that vibration and offers protection from crankshaft damage, premature main bearing wear, valve timing error and power loss. Harmonic frequency vibration also robs the engine of its full torque potential.

At 182,930 miles, the Ram 3500 5.9L engine’s original damper was still functional. This is no ordinary feat, as most Gen 3 5.9L 24-valve turbodiesel dampers succumb by 100,000 miles. The damper’s inertia ring-to-hub offset is minimal and within the allowable 1/16-inch creep or shift. Despite the good news, these dampers are only good for canceling one rpm frequency of vibration. The factory tuning targets the worst vibration level or sometimes just the most glaring and noticeable vibration. Lack of harmonic damping elsewhere in the engine’s rpm range poses a threat to vital engine parts while also robbing torque. Premature lower engine wear can often be attributed to a defective damper.

In the video how-to, you will see the walkthrough of our new Fluidampr® installation. There is considerable debate about whether or not to fully remove the fan and shroud for a damper changeout on these Ram trucks. In the HD video coverage, you will see how necessary clearance and workspace can be gained by loosening and shifting the fan shroud and uncoupling the fan assembly. See how we saved time while assuring a professional grade installation.