Enjoy the detailed, traditional ‘Q&A’ exchanges in this article column from the early magazine website…’Q & A’ has now moved to open, interactive forum discussions. Visit the forums, you’ll want to join—for free!

Have technical questions about your Jeep 4×4, popular 4WD truck, SUV, ATV, UTV or dirt motorcycle—or welding and metal fabrication? The 4WD Mechanix Magazine ‘Tech and Travel’ Forums now feature enthusiastic discussions and input from members and a steady flow of content from Moses Ludel.

Want to discuss your technical and outdoor interests with like-minded enthusiasts? Check out the 4WD Mechanix ‘Tech and Travel’ Forums! Click here for a guest visit to the forums!

Back to the Ross TL Steering Gear

From: John F.

Sent: Sunday, April 15, 2012 4:03 PM

To: 4WD Mechanix Magazine

Subject: Ross steering box question

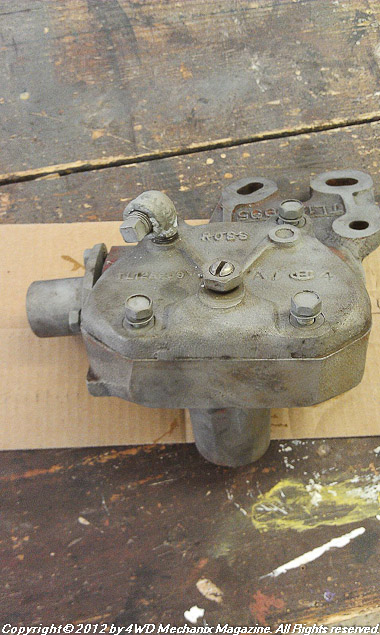

I am currently rebuilding a Ross steering box from a 1967 CJ5 Jeep with a V6 Dauntless engine. I watched your video and have a couple of questions. Every picture I see of a Ross box shows the fill plug on the top end of the box. As you can see from the photos I attached, mine has no fill plug in the original location and it looks like someone drilled and tapped the cover and put in an elbow with a plug to fill the box with. What’s the deal with this box? I am only the 2nd owner of this jeep which we purchased in the early 70s so I know it’s the original box and I didn’t put that elbow in. Can it be from the factory? Also I cant find a rebuild kit with a new sector shaft for the Ross box with the V6 Dauntless. Do you have a source?

Thank you,

John

From: 4WD Q & A

Sent: Monday, April 16, 2012 2:37 AM

To: ‘John F.’

Subject: RE: Ross steering box question

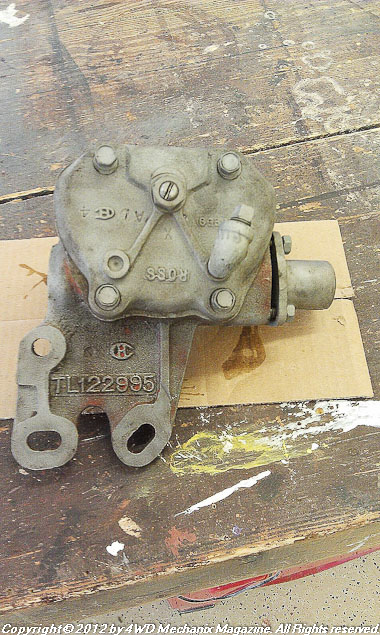

Hi, John…Your gear housing has the same casting number as a military M38A1. I ran into this when seeking a V-6 sector/lever shaft and bushings a few years ago. These gears use a long and short bushing set for the lever…I found a lever shaft (short shaft design) and bushings at Surplus City Jeep Parts: http://www.surplusjeep.com/. These folks were well-informed and could supply the correct pieces for a V-6 Ross TL gear. Share your findings with them when you call…

Not sure about the fill elbow. Maybe the V-6 engine and exhaust on civilian models leaves no room to access a top plug? Perhaps the military preferred the plug on the side to enable sealing the column and gear case for water fording?…If Surplus City Jeep Parts (or anyone else) can explain the “why” of the missing fill plug on top of the case, please share.

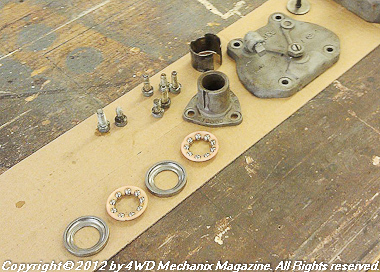

The cam/worm bearings in your gear do look like the later Ross type with the nylon spacers. It is likely that this gear has not been apart. I assume it has the short V-6 style sector/lever shaft, as the one bushing looks like the notched style for a V-6 short-lever case. The notch is to clear the oil feed hole in the housing. If your worm/cam bearing races are in good condition, they are likely better than the currently available “off-shore” replacement races.

Trust this helps…I’m here if you have comments or questions…

Moses

From: 4WD Q & A

Sent: Wednesday, April 18, 2012 7:41 PM

To: ‘John F.’

Subject: RE: Ross steering box question

Hi, John, see my comments below…Moses

From: John F.

Sent: Wednesday, April 18, 2012 12:24 PM

To: 4WD Q & A

Subject: Re: Ross steering box question

Thank you Moses for your quick reply, I really appreciate it.

I’m striking out on the sector shaft for this box, waiting for a couple more emails to locate one. I do have another question. How do I know if my parts are ok in the gear? I haven’t driven the Jeep in over 20 yrs but I don’t recall any issues with the steering when I parked it. I’m now doing a full restoration on it.

The short shaft is more difficult to find, although all TL parts are scarce now. Worse yet, there is a plethora of off-shore and even some Jeep/NOS parts that fall short of spec…Off-shore replacement parts, despite my suspicions, might be less risky. A quantity of defective U.S.-made parts found their way into official Jeep parts boxes in the early AMC era, and I’ve seen some of these parts.

The sector shaft does have flat spots on it but you have to feel them as they are hard to see. I used a dial indicator to check the lever clearance and I came up with 0.0004” of play. The bearings all look to be in good shape but the seal is leaking and will be replaced. All the tie rods, king pins and bearings will be new. The worm gear is in perfect shape.

0.004” or 0.0004”? (I’m guessing 0.004”, as conventional micrometers are somewhat inaccurate at 1/10,000ths inch.) Factory spec calls for minimum of 0.0005” (half of 1/1000th inch) and a maximum of 0.0025”. That noted, there is a likelihood of bushing wear, which could bring your 0.004” to within spec. It might be worth a bushing replacement, as bushings generally are undersized slightly, which allows for an even more precise fit in your application. Unless the lever cones are worn flat as I discuss in the presentation, you might be able to get by with the original sector/lever shaft. Most replacements involve lever pins/cones with distinctly flat wear points…I’d like to discuss this further once you look closer. By design, very slight pin wear is okay, more than that is not. Let’s consider this…

So I guess my question is since I’m doing a complete restoration, do I keep looking for the shaft and replace the bushings, bearings, seal and sector shaft to get it like new or do I put the box back together knowing the existing parts show little wear ? Or do I replace everything but the shaft since I cant seem to locate one ? I sent some photos of the shaft.

Is the lower pin worn less than it appears? Is that a flat, or am I seeing reflection? Try measuring the cones on a level radius (swing the micrometer around the pin on an even plane at several points). See if you can get a better idea of the wear. (Since hardening is deeper on these pins, there is little risk of faster wear at the stage shown.) Note that there is room for very slight adjustment/wear within the backlash setting if pin/cone wear is not excessive. Measurements will help determine actual wear…we’ll discuss your findings.

Note, too, that there are many causes of wander beyond the gear: loose tie-rod ends or bellcrank, loose draglink or other parts. Gear backlash is always set over-center. The gear/pitman must align with the center position of the steering gear when the front wheels point straight ahead. Misaligned, the normal backlash (off-center) will create wander. Although your focus is the steering gear, these other concerns need address as you complete this job. Front axle caster angle (affected by worn leaf springs) can also contribute to wander and shimmy; so can loose or damaged front knuckle/kingpin bearings…My Jeep CJ Rebuilder’s Manual (’46-’71) covers details…

From: John F.

Sent: Friday, April 20, 2012 8:17 AM

To: 4WD Q & A

Subject: Re: Ross steering box question

Hi Moses,

That is 0.004” sorry. I laid washers on each pin so I can put the caliper in the same spot and the photos show the result. There are definite flat spots on the pins but being this is my first attempt at this I don’t know whats ok and whats not. I’m thinking to replace the bushings, bearings and seal at this point. What are your thoughts based on the caliper readings ?

Also I’ve searched a ton of sites looking for the fill plug location and only found one site that shows the cover plate with the fill plug like mine, minus the elbow. Do these boxes require to be completely filled? Where my plug is it will only fill the box about a third.

Thanks again for your time.

John

Nice work, John, fairly accurate method of measurement, and close enough for our purposes…

0.55mm out-of-round is quite a spread. That’s over 0.020” wear overall. The problem is that any attempt at an over-center adjustment with these wear flats will make the lever bind as it rotates in the left-right directions. (The flats are always at the straight ahead position on these pins.) This is a high-friction steering gear design and why many non-restorers opt for a Saginaw recirculation ball-and-nut retrofit gear!

I’ve considered options to the off-shore replacement parts. One idea is to rotate the pins 90-degrees (drill back stamping and rotate) then TIG them at the back with an isolated heat approach to avoid removing the hardening from the pins. Thinking this through, however, this approach would increase clearance in the left-right turning positions. (Caster at the axle reduces the backlash effect, but there would still be some risk of wander and play.) So, that’s not high on my list of “experiments”.

Another approach, if there is enough interest and volume, would be to manufacture quality replacement pins and to rebuild these levers. (The cam seldom wears significantly, the lever shaft portion seldom wears appreciably, the wear point is the pins.) If this were a volume operation, I would emulate the factory pin installation method, which is either stamping or a carbon-arc pressure/melting approach at the backside of the lever. (I would research this process carefully, as the pins must retain their hardening after the installation.)

Anyway, let’s see what you find in the way of parts. Another approach would be to source the least expensive replacement sector/lever shaft, regardless of length. (TL pins should be the same.) Remove the new pins carefully from the lever and install them with TIG in your OEM lever shaft, isolating the heat to prevent heat treatment loss at the pins or shaft…Not sure what you think of this or whether you would find it cost effective…Let’s continue the dialogue…

Regards,

Moses

From: John F.

Sent: Wednesday, April 25, 2012 1:55 PM

To: 4WD Q & A

Subject: Re: Ross steering box question

Moses,

I found a kit with the correct shaft from Willys Overland. Doesn’t seem as beefy as the OEM but I don’t have a choice here. Wish me luck!

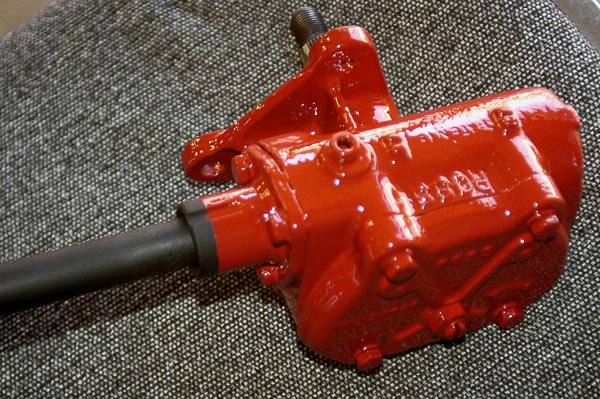

I’m kind of particular when it comes to doing everything to original factory specs. It looks like my Ross gear was reddish in color almost like a red oxide. was the original color the glyptal red as was on the inside, I hope not since it’s $ 50.00 a qt. What was the color ross painted these back in the day?

Thank you again,

John

From: 4WD Q & A

Sent: Wednesday, April 25, 2012 10:27 PM

To: John F.

Subject: RE: Ross steering box question

Hi, John…Take measurements on the new shaft and also check the pitman arm’s fit at the splines. See that the arm will fit up as the OEM did.

As for red outside paint on your gear, I would not be concerned. The glyptal on the inside of the housing should be left alone if intact and appearing original. Corrosion on the outside can be prevented with bead blasting (avoid stripping the interior of the case) and use of a modern epoxy primer if possible. The color coat should be compatible with the primer.

My video/slideshow and other info will be helpful. I assume you have OEM specs. When installing the bushings, avoid flattening the bushing ends. (You can use a shouldered driver cup as a press guide.) Align the bushings to the OE locations in the housing. Make sure you relieve the bushing at the oil hole if necessary…

You can true and finish bushings with a self-centering (tapered cone) kingpin reamer to near the minimum clearance, then make final finish/burnish with a stone brake hone and light oil or solvent. (0.001” dry is a nice shaft fit if bushing bores are precisely aligned with each other.)

Note: Do not remove too much material from bushings, or you will be buying another set. Automotive machine shops can use a piston pin or rod bushing hone for this operation, honing both bushings to size at the same time to avoid risk of misalignment. You might consider a sublet here.

I’m also “detail oriented” and build these units to blueprint standards—beyond what Ross delivered in most instances.

Regards,

Moses

From: John F.

Sent: Friday, April 27, 2012 1:37 PM

To: 4WD Q & A

Subject: Re: Ross steering box question

Success! I think Got everything together. Turns nice and smooth with slight resistance at the center point. Thanks again for your help. I’m sure I will pick your brain more in the future. I started a blog on the project if you’re interested.

Great, John…Looks like you came in at 0.0005” on the shaft clearance. Did you ream and finish to that spec, or were the bushings that close as installed? You have a quality spec for openers! How does the gear feel? Does the lever arm clear the side cover on full swings left to right? (It’s assumed that you used a new side cover gasket.) Over-center adjustment on spec? Looks great!

You were concerned about filling the gear with oil at the elbow’s low height…Here’s a thought: Point the elbow vertically up and add a stem pipe that stands at the height you want the gear oil to reach within the case. When you pour gear lube slowly into the stem pipe and elbow, the oil will find a matching level inside the gear case. You can set the lube height to wherever you want it!

Lastly, make sure the steering linkage has the wheels pointed straight ahead with the steering cam and lever on its center/high point. This will assure quality steering and the least amount of play at the straight ahead position. Check kingpin bearings and bellcrank for wear. Make sure caster angle of the axle is on spec. (See the alignment article at the magazine: https://www.4wdmechanix.com/’Do-It-Yourself’-Wheel-Alignment-&-Equipment.html . There’s also a video at: https://www.4wdmechanix.com/HD-Video-TJ-Wrangler-Wheel-Alignment-Basics.html .)

Regards,

Moses

Building a Trail CJ-7 Jeep Suspension—Shackle Reverse and ‘SOV’ Discussion!

From: Janet & Eric L.

Sent: Thursday, December 29, 2011 7:45 PM

To: 4WD Mechanix Magazine

Subject: CJ-7 suspension options

I have been a big Moses fan going way back and was happy to find this site. (I have a copy of an old Off Road magazine with Moses answering one of my questions!)

I am rebuilding a 1985 CJ-7. I’m putting in a TBI 350 and an NV4500 tranny out of the same donor vehicle. Because of the length of the tranny and the desire to lift it, I am going to use a Hi-9 rear end to get rid of some of the angle. 35″ tires are planned.

My question has to do with suspension options. I have pondered a shackle reversal with 4-6 in lift springs, a SOV with flat stock YJ springs and just the 4-6″ lift springs added in the current configuration.

Tons of opinions out there…the SOV is the best, the SOV is not safe and will wear out springs, the reversal is the best, the reversal will cause weird handling and will cause axle movement to the rear. I have developed paralysis from analysis…I can’t decide which way to proceed. Your opinion please…

Thanks,

Eric

Hi, Eric…“Thanks!” for your interest in my comments over the years.

To the point with your questions, the shackle reverse is always advisable at the front of a CJ or YJ Wrangler. The Jeep will have more stable steering on-highway and not be as vulnerable to harsh frame shock and poor ride quality off-pavement. With the reversal of shackle and anchor points, the front axle is not “pushed ahead” by the frame but simple trails in a more compliant way…I’m not a fan of spring-overs, though the longer, wider YJ springs do improve the ride and directional stability of a Jeep CJ. Many do the spring over conversion, a less costly approach in most cases.

As for the shackle reversal and front driveline—yes, the axle does swing rearward slightly upon the compression of the springs, which shortens the driveshaft. To avoid bottoming the driveshaft coupler and possible risk to the transfer case, allow enough spline coupler length and spline movement to cover the full range of front driveshaft stretch and compression. A custom driveline with adequate spline length, movement and engagement over the range of suspension travel should eliminate concerns here.

Another “handling” issue is caster angle. In any case of setting up a front end, the caster degrees must be correct over the range of suspension travel. The Jeep will steer well and return to center after cornering if the caster angle is correct. There is a slight caster geometry shift when doing a spring-over or a shackle reverse. Again, simply making sure that you have “factory” caster degrees at the vehicle’s static/loaded height should provide a range of caster that is acceptable—whether you do the shackle reverse or not.

Note: This is simple geometry. Visualize the spring/axle moving over its arc of travel, pivoting from the springs’ anchor points (at the front if shackle reversed). See how much the caster might change in the process…Also, problems can occur from altering the wheelbase length when setting up the front and rear springs and axles. Stay with the CJ-7 wheelbase, each axle at the factory point when the vehicle is on the ground and normally weighted.

Taking all of this into account, I would likely do the under-axle spring lift (4 or 6 inches as per your needs, 4-inches better if adequate for your tire diameter choice) with the shackle reversal. Make sure caster is correct as installed. Shim the axle with hard steel (not aluminum), tapered caster wedges if needed; increase the spring bolt head lengths to reach through the wedges and engage the spring perch holes properly.

With the new anchor points at the front of the front springs, the rear-of-spring shackles should be an “H” type, very stable laterally. Loose shackles defeat your stability aims, allowing lateral wander of the springs and axles. I try to minimize shackle height if possible, though this is often dictated by the caster or pinion angles and spring arch.

Lastly, make sure that the steering does not “bump” from a steep draglink (“short tie-rod”) angle. This is where a dropped pitman arm or K-link steering linkage comes into play. If using a dramatic drop on the pitman arm, brace the steering box-to-frame; otherwise, the gear will be at risk of breaking loose from the frame. Make sure the steering linkage works safely and does not bind or rub over the full range of suspension travel. See that the steering gear is on-center with the wheels pointed straight ahead.

I’m available for further questions…Not sure where “home” is for you folks…I will be at Johnson Valley for the King of the Hammers (February), the Moab Jeep Safari and surely SEMA. Perhaps we’ll connect at one of these events or on a trail…

Best,

Moses

From: Janet & Eric L.

Sent: Thursday, February 02, 2012 8:44 PM

To: 4WD Q & A

Subject: Re: CJ-7 suspension options

Moses, I have decided to go with the reversal, so, of course, I have a couple more questions:

1. I am going to go with the MORE kit. (No need to reinvent the wheel, I think they have really good products) They have two versions, one weld-in that does not lift the vehicle and one that is bolt on that lifts it 1.5″. I kind of like the idea of the 1.5″ lift so I can buy more mild 2.5″ lift springs and still get the 4″ lift I want. My question is how do I achieve the needed 1.5″ additional lift at the rear? Lift blocks are not so great…but maybe OK at the rear? I suppose I could try to get a lift company to sell me 4″ springs for the rear and 2.5 for the front…

The 4” pair of rear springs will work…Or you can get a spring company like National Spring to fab a pair to your specs…I like the less-arch approach…Also, some go to the YJ Wrangler style springs, longer and wider, to improve handling and ride quality. Talk with MORE about that option…

2. Odd question here: I have converted my D300 to twin stick with an additional modification to the rear shift rail which allows front Hi without removing the interlock pills (this is a very slick mod I found on-line, bench testing indicates it actually works, have you heard about it?) I want to add a line lock to the rear so that I can perform front digs using front Low (front pull arounds, whatever you want to call them). My question is that with a Detroit locker back there can I install a separate line lock for each side or do I need just one for the entire rear? Logically (at least to me) because the Detroit will allow one side to spin faster than the other, I should be able to employ line locks on both sides (to allow for easier digs) without destroying anything. I hope this question makes sense…

If you want steering brakes, consider two hand brakes like the Ultra4 race cars use (twin levers for pivoting). This requires hand master cylinders that can capture pressure when the lever(s) are released, so the normal brake system will still operate all four brakes…Explore Wilwood and other sources, let me know what you find.

As for the Detroit, it might want to power the un-braked side, although it may decide to ratchet around this. To be safer, I would run the hand steering brakes for pivoting with a Detroit, you can feather the brakes as required.

Let me know what you decide to run and your findings…

CJ Jeep: Rear Drum vs. Disc Brakes

From: Janet & Eric L.

Sent: Wednesday, February 29, 2012 9:03 PM

To: 4WD Q & A

Subject: Re: CJ-7 suspension options

My rebuild is progressing. Getting ready to paint the frame, then start slowly putting things back on…

Anyway, I am leaning towards a rear disk brake conversion. The question I have is about the proportioning valve and M/C. I have read everything from just removing the prop valve, to drilling out the guts of it. I think it has more importance than just disabling it. Also I have read that the front disk /rear drum M/C wont push enough fluid to the rear disk brakes. I have also read that it works fine. Lots of differing opinions. I am also contacting SSBC and Currie for their opinions, but was curious about yours. Also, this Jeep will just be a trail runner and mild rocks (maybe Rubicon), mostly road actually. Is even upgrading to disks overkill? I like the “wow” factory but don’t want to just throw money at it.

Thanks, Eric

Hi, Eric…I have used the disc front/drum rear master cylinder with disc rear brakes, using earlier GM S-truck, single piston calipers. (These are the calipers that Warn fitted with their disc conversions, visible in my Jeep CJ Rebuilder’s Manuals.) To be sure, you could use a master cylinder from a TJ Rubicon with four-wheel disc brakes.

The OEM proportioning valve on a disc/drum system helps apply the rear drum brakes slightly ahead of the disc front brakes to allow for shoe-to-drum take up. Disc brakes have virtually no take-up. To prevent front end dive, the proportioning valve allows rear brake shoes to move slightly ahead of front disc pad application.

If you do disc brakes at the rear, you may need a manual proportioning valve to balance front-to-rear braking. Do not confuse this with an OEM proportioning valve. The manual valve simply reduces apply volume/pressure, it does not affect pad or shoe application timing—all four brakes apply simultaneously. Some find that a short wheelbase Jeep with stiff springs and four-wheel disc brakes does not have as much dive tendency, hence references to removing the proportioning valve with a rear disc brake conversion. This is a safety matter, though, so address your vehicle’s particular needs and braking reactions.

Again, if you want “factory” brakes, the Rubicon master cylinder and proportioning valve might provide a solution. Use the correct master cylinder pushrod length with adequate pushrod-to-piston clearance. Follow TJ Rubicon guidelines here. Make sure the brakes release completely with the pedal released—without trapping fluid in the system. You may need to play with pedal height to achieve this on a CJ. You may also need to use the TJ brake booster and other parts.

If running an aftermarket manual valve, adjustment is a cautious affair. Begin with the brake pressure set light at the rear. This assures that the rear will not lock up and spin your short wheelbase vehicle around or worse. Gradually add more pressure to the rear, only to the point of balance, not to the point of premature rear wheel lockup on hard braking. Test brakes at a safe area, away from traffic or hazards.

You asked whether rear disc brakes are overkill…Drum brakes, especially 11” x 2” upgrade type, are very effective at the rear. My XJ Cherokee has its OEM drum brakes at the back. The only issue is water crossings, which lead to drum brake lack of response until the brakes dry. This can be anticipated and dealt with…Drag the brakes lightly after water crossings and allow the rear drum brakes to dry sufficiently…Let me know what SSBC and Currie have to share.

Best,

Moses

Disc Brake Retrofit Continued: Front-to-Rear Proportioning Controversy

From: Janet & Eric L.

Sent: Monday, March 05, 2012 9:00 PM

To: 4WD Q & A

Subject: Re: CJ-7 rear disk options

Moses, thanks so much for your very thoughtful responses. It’s like a throw back to your days at Off Road magazine…I just have no idea how many emails you get every day!

Past Q&A successes were my goal and impetus…

I got a response from SSBC and their answer was that the stock proportioning valve needs to be disabled. They don’t mention disabling the stock residual pressure valve in the MC, which I believe also needs to be done. I didn’t mention it, but I am not retaining the AMC 20, but going to an aftermarket Ford 9″. Basic needs must be the same.

In the Jeep CJ Rebuilder’s Manuals, I talk about the residual valves…Disc brake caliper seals do not require residual pressure like the sealing cups in drum brake wheel cylinders. Residual pressure keeps drum brake cup lips expanded to prevent leaks. (To prevent brake shoe drag with the pedal released, drum brakes have shoe retraction springs that counter the residual pressure.)

When retrofitting rear disc brakes on a Jeep CJ chassis with a disc/drum master cylinder, the rear drum brake check valve of the master cylinder must be removed. This residual check valve is usually found behind the flare nut seat at the master cylinder’s rear brake output port. (See a parts schematic of the master cylinder. Master cylinder rebuild kits include the check valves; the seat is removable, using care not to distort or damage parts. I can explain how to remove the flare seat.) With a drum brake residual check valve in place, retrofitted rear disc brake pads will drag against the rotors when the brake pedal is released. This causes brake heat, fade, premature pad wear and scored rotors.

Note: Some later four-wheel disc brake systems use a very slight amount of residual pressure; this is less pressure than drum brake check valve settings. The slight pressure keeps the disc pads aligned with the rotors and reduces application lag time; this slight, intended pressure will not create pad drag…Drum brake residual check valve settings are too high for disc brakes.

As I shared in comments about using a TJ Rubicon master cylinder, one solution is a master cylinder from a four-wheel disc brake model. The dual Wilwood cylinder idea can work, as long as the twin master cylinders meet your disc brake caliper fluid volume and piston stroke requirements. Wilwood offers adjustable stroke and leverage with these cylinders.

Totally losing the combination valve concerns me. I’m leaning toward using a Wilwood adjustable combination valve so I can still have the brake warning light and be able to tweak the rear brakes if needed. You can see it at this link:

http://www.amazon.com/Wilwood-Adjustable-Combination-Proportioning-Valve/dp/B003LT619Q

I like most features described in the Wilwood valve you share. Be aware that the preset proportioning is for a G.M. chassis with drum rear brakes and discs at the front. There is the option of manually tuning the rear brake proportioning…I like the isolated front and rear circuits and other OEM emulations. However, I would contact Wilwood and ask if the valve’s metering function works safely with four-wheel disc brakes. Metering helps prevent front dive tendencies on hard braking. Will the Wilwood disc/drum metering work safely with a disc brake retrofit at the rear, or would the four-wheel disc brake metering rate be different?

Keep in mind that dive is different for a longer wheelbase car or truck than a short wheelbase Jeep CJ with stiff leaf springs. On my short 81” wheelbase ’55 CJ with four-wheel retrofit disc brakes, using earlier G.M. S-truck single piston calipers all around and aftermarket springs, I fitted an AMC-era drum brake CJ (’72-’76 circa) master cylinder; with the residual check valves removed and a manual proportioning valve on the rear brake system, adjusted properly, there was no dive tendency—and I looked for it while testing the vehicle thoroughly and driving it since! I am not recommending that you do what I did on the ’55 CJ, but this is one case scenario that did work—for this vehicle. The anti-dive was not as much of an issue at 81” wheelbase, a light vehicle weight, stiff leaf springs, beam axles and with the rear brakes proportioned down in pressure.

With the rear brake manual valve adjusted properly, the ’55 CJ stops straight and without rear wheel lockup or hop—no dive on hard braking, good pedal response. No combination valve, separate front and rear hydraulic line systems, no rear-to-front metering, the system works safely and there is adequate fluid displacement from the drum brake master cylinder—for these size calipers. Since we’re talking about braking, however, the conservative approach is to be aware of all brake safety issues.

One point worth making is that a manual proportioning valve damps down the rear brake pressure. This helps prevent rear wheel lockup. Isolated rear lockup can spin a vehicle out of control. When adjusting and setting up a system, start with the rear brake pressure set low. Gradually add pressure to a point just below rear brake lockup on hard braking. Do not allow the rear brakes to lock up, independently of the front brakes, on hard application—solo rear brake lockup can spin the Jeep around and out of control. Test the vehicle in a deserted, safe environment, not in traffic or on a busy road!

Online, there is ongoing controversy and anecdotal information circulating on the brake proportioning and combination valve topic. You now have a “bigger picture” to consider. The safest, best tested brake system will emulate an OEM prototype, using all of the OEM components or similar aftermarket pieces—like my TJ Wrangler Rubicon four-wheel disc brake suggestion. Start with safe, proven engineering when building your brake system.

As shared earlier, you do have the option of drum rear brakes. Ford 9-inch axles were popular in pickups with 5-on-5-1/2” wheel patterns—like your Jeep CJ. Adequate 11” x 2” rear brakes or similar area sizes were available on F100/F150 trucks. Rear drum sizes from a disc front/drum rear pickup would be more than adequate…Disc brakes can be efficient, weigh the cost differences here. If you do the rear drums, the Wilwood Adjustable Combination Proportioning Valve might work well. Remember to use a master cylinder with a rear drum brake residual check valve if you use drum rear brakes—otherwise, the drum brake wheel cylinders will leak with the pedal released!

Your thoughts are appreciated.

Eric

Vintage CJ Needs Steering Gear Options

From: Mark & Lindsay S.

Sent: Sunday, August 28, 2011 12:24 PM

To: 4WD Mechanix Magazine

Subject: 56 CJ5 Steering

I have a quick question regarding a possible steering upgrade for my 56 CJ5. It is going to be my ranch/hunting rig and I would like to upgrade the steering but it has a large PTO driven winch on the front which I refuse to part with and precludes a Saginaw installation. So I was wondering which you think would be better… Rebuild the factory steering or fab up a rack&pinion set-up?

Thanks for the help!

Mark

On Sun, Aug 28, 2011 at 3:26 PM, 4WD Q & A wrote:

Mark, if you have a copy of my Jeep CJ Rebuilder’s Manual: 1946-71, I share a Saginaw manual gear installation that should work with a PTO winch. Please send me a photo(s) of the front bumper and frame section, including the left (driver’s side) of the winch and the PTO driveshaft…Let’s see if a Saginaw unit will work or not.

Moses

Mark back…

From: Mark S.

Sent: Monday, August 29, 2011 8:54 AM

To: 4WD Q & A

Subject: Re: 56 CJ5 Steering

Composed with HTML Editor

Moses,

Thanks for the quick response. As a matter of fact I do have a copy of your CJ Rebuilder’s Manual as well as your Jeep Owner’s Bible, they are great resources!

Unfortunately I am currently traveling (for the Navy) so it will take a couple of weeks to get a photo taken. But the winch is rather large and sits inside the frame rails with the driveshaft coming right down the inside of the left frame rail right where a Saginaw box normally would sit. The only possible option I could see is mounting the steering gear outside the frame rail. Are you aware of any any Saginaw applications that mounted to the outside of the frame rail?.

Thanks again,

Mark

Hi, Mark…Glad you have my books and find them useful.

Here’s an idea: There are Saginaw truck gears from the fore-aft draglink era, circa 1955 (2nd series) through 1959. These gears have the solid steering shaft and a closed column tube, commonly found in ½-ton and ¾-ton Chevrolet and GMC truck models. The gear is a recirculating ball-and-nut Saginaw design, a great unit, and the column configuration is roughly what you have with the current Ross column and gear unit.

Of course, you can rebuild the Ross gear; however, if you prefer the Saginaw gains, there may be a way to go here. You would need to fabricate a drag link from the pitman arm to the current bellcrank on your vintage CJ. Look into this and consider the possibility. The column would need the correct mounting angle and length, measuring carefully and performing any modifications to a high safety standard.

I have scanned and attached an image of such a gear in a 1958 Chevy half-ton truck application. This is the recirculating ball design with a fixed column and a solid steering shaft.

Trust this will foster some ideas…We can discuss this further.

Moses

’86 CJ Power Steering Belt Adjustment

From: John N.

Sent: Wednesday, July 20, 2011 4:47 PM

To: 4WD Mechanix Magazine

Subject: Hello from Lamoille, NV

Hello Mr. Ludel,

I am having a fit trying to adjust the power steering belt on my 1986 CJ7. I have a copy of your book but it is sketchy in this area. I can see why, any goof should be able to adjust a fan belt, right? The alternator belt is “duck soup”—typical, with a slotted bracket. The power steering unit is a mystery, nothing I have tried will get the power steering pump to rotate, HELP!

John

Moses replies…

Hi, John…It’s not that easy to determine the bolts involved or method of adjustment. I have attached a PDF with instructions for both the V-belt and serpentine belt adjustments for each of your engine’s belts (if “V” type, or one belt if it is of serpentine type).

The mystery is the swinging bracket, as you will discover. Look to the backside of the pump support bracket and consider the through-bolt at the timing cover. See the bracket as a moving member.

Regards,

Moses

Disc Brake Conversion Issues

—–Original Message—–

From: Larry F.

Sent: Wednesday, June 15, 2011 10:49 AM

To: 4WD Mechanix Magazine

Subject: Brake issues on a 66Jeep CJ-5

To whom it may concern,

I have a question about my brakes, and I was wondering if you could give some insight?

My situation is this, I have a 1966 Jeep CJ-5 with some braking issues.

Here is where I’m at, First off I removed the Dana 27 front axle and installed a Dana 30 from a 1974 CJ. I have converted this axle to disc brakes using parts from the “spindles out” off of a 1984 Jeep CJ Dana 30. So I hope that I’m on the right track so far given the similarity of the vehicles.

I’m running 33″ X 12″ X 15″ tires on 10″ aluminum wheels. In addition, I have replaced the single reservoir master cylinder with one of the kits from Herm The Overdrive Guy. I used this kit because my pedals still go through the floor. The master cylinder that I ordered was one for Disc/drum brakes non-power assist. I plumbed the brakes as follows. The front/bigger res. to the front brakes and the rear to rear respectively. I replaced all of the hard lines using 3/16″ lines, I hope this is not where I went wrong, because my rear brakes don’t seem to work really well. I have a SSBC adjustable proportioning valve in the rear line, and it’s presently wide open. The Jeep had a MICO lock so I plumbed it to the rear line as well. My rear brakes are the stock 10″ X 2″ no mods done to these.

On the front brakes I’ve used all new parts calipers, pads etc. I’m not sure of the material of the pads, but what I can tell you is that they’re real grabby & squeaky in the morning, and when it’s raining they seem to not work at all, and when the brakes get warm they’re not effective either.

From this point I’m not at all happy with the braking performance, and I almost wished that I stayed with the stock 10 X 2 drum brakes.

If you have any suggestions, or if you can tell me where I may have gone wrong with selection of parts/hardware. Should I consider upgrading the rear brakes to 11″ drum?

Any help is appreciated….

Thanks,

Larry F.

Moses replies…

Hi, Larry…After reading through your project description, I would run an actual pressure test (hydraulic) at the calipers and rear wheel cylinders. (There are professional brake pressure test kits available at a variety of costs.) If pressures are sufficient, the remaining two questions would be fluid volume and brake surface area.

Fluid volume is governed by the stroke of the master cylinder piston and whether the cylinders charge sufficiently with the brakes applied. This is almost certainly confirmed with a hydraulic pressure test: under applied pedal pressure, the pressure should be sufficient and hold steadily at each brake cylinder. You can also check the relationship between various pedal apply pressures (mechanical) and the hydraulic applied pressure at the cylinders.

3/16″ brake line is often sufficient for your brake cylinder volumes; some use 1/4″ to feed the front calipers. There is some discussion that front disc operation is smoother with 1/4″ pipe. If you want to demystify this, find out what the master cylinder application fits, consider the OEM brake pipe sizing for a 1984 CJ disc brake system, and match the pipe size to the OE for an ’84 CJ Jeep…Apply pressure is the relationship between the master cylinder’s piston size, the caliper and wheel cylinder bore sizes, and the pedal leverage and pushrod stroke length.

Note that the master cylinder should not have a drum brake residual check valve at the disc brake caliper port; it does need a residual check valve for the rear drum brake cylinders. Disc brakes will drag when released if there is residual pressure. (Some use very low residual pressure like 2 psi.) Drum brakes require residual pressure (typically 10-12 psi) to keep wheel cylinder cups expanded with the brake shoes retracted. (Rear brake shoe springs overcome this residual pressure and prevent shoes from dragging.) Your master cylinder requires the right valving.

Additionally, OEM Jeep drum/disc brake systems, like the ’84 CJ Jeep system you have emulated, use an inline combination valve that meters and proportions, providing proper take-up of the rear brakes—slightly before the front discs. This permits the brakes to apply safely, as the calipers will otherwise apply ahead of the drum brakes. (Drum brakes take more “time” to apply due to the shoe-to-drum clearance. The rear brakes should apply slightly ahead of the front to prevent dive.) The proportioning function prevents the rear brakes from locking up when the vehicle does dive…

The manual proportioning valve that you’re using merely adjusts apply pressure to the rear brakes; it has no effect on the timing of the fluid application rear-to-front. Without fluid metering, timing and proportioning, the front end can dive under hard braking; the rear wheels become unloaded, and rear wheel lockup occurs.

Here is a useful summation of what I’m sharing:

http://ecihotrodbrakes.com/brake_facts.html

Note the comments about a master cylinder mounted low. Your cylinder should be above the height of the front calipers.

In your case, the limited rear brake effect could be due to undersized rear brake shoes and drums. The 3/16″ pipe should be enough for the rear brakes…As you describe, the disc front brakes outperform the stopping power at the rear. 11″x2″ drum brakes could make up the difference. Use concentric drums, the right wheel cylinders and quality brake lining.

Begin with testing brake hydraulic pressure per wheel…Let me know how this works out, Larry…

Regards,

Moses

Heavy-Duty Front Shackle Brackets for CJ-7

In the Jeep Owner’s Bible, you show a shackle that I need for my 1982 CJ-7. Is that a D-ring shackle to fit the bracket on my front bumper? Where could I find that shackle?—Mike S.

Mike, I believe you’re describing the heavy duty replacement bracket that supports the front ends of each front spring. (Full-Traction Suspension may still stock these replacement brackets.) This is actually a heavy-duty shackle support, not a D-shackle attachment point, that corrects weakness in AMC-era ’76-’86 CJ front spring frame support brackets. The OEM bracket that bolts to the frame and serves as the pivot point for the upper shackle bushings is weakened by a factory punched hole that clears a frame rivet. Over time, the shackle bracket weakens from load and fatigue, and these brackets can bend or even break. The heavy-duty replacement bracket bolts to the stock bracket holes plus a front bumper bolt hole. They extend further forward and offer superior support. These aftermarket brackets are a practical solution to the weak factory bracket. There are variations on this theme from several aftermarket suppliers. 4WD Hardware might be a resource here.

The CJ Shackle Reverse Question

What do you think about shackle reversals on older CJs? I am mounting YJ leaf springs on a vintage CJ-6 chassis and want the best on-road manners that I can have with this old rig. I am not convinced that anchoring the springs out at the end of the frame is the way to go, but I value your opinion. I’m just now building the rear spring mounts and am going to make them outboard like a Jeepster for more stability. I have some Skyjacker leafs and need to find spring eye bushings with 1.5” outside diameter. Where’s a good source for urethane bushings?—Bill B.

I would do a front shackle reversal on any CJ. (There is some controversy about YJ Wrangler conversions.) With the YJ springs that far forward, make sure the frame boxing is sufficient. The spring anchors at the front should actually decrease stress on the frame, as the axle trails from the frame rather than being pushed forward from the stock (rear of spring) anchor points at the frame. However, if you’re mounting the long springs forward of the OE position, the frame horns do need substantial lateral support. I have added this kind of support by incorporating a winch mount (square) plate that laps each frame rail. (On ’76-up CJs, there is the factory plate, which sometimes needs embellishment.)

You will not regret the shackle reverse! Just make sure your front axle pinion/caster angle is correct and that the driveline will move within its spline coupler’s range over the rise-and-set cycling of the suspension. Configure the driveline angles and their lengths carefully; allow for the unique suspension movement and compression of the driveshaft.

As for urethane bushings, one time-honored source has been Energy Suspension. A catalog is available online at:

Jeep model applications are OEM replacement and not shown as size, so you may need to call them. With any urethane product, correct durometer (hardness) is always essential. Since you’re using Skyjacker springs, consider giving them a ring about bushings.

Assembling Vintage CJ-5 Leaf Springs

I just put some spring clamps on my mid-‘60s CJ springs. My front (10-leaf) springs have three “lips” on the leaves, two on one end, one on the other, presumably for the purposes of preventing the spring clamps from wiggling off. I only found two lips on the back springs (one on each end). As to how the front springs were oriented, I’m not sure. Were the two clamps oriented toward the front of the vehicle or the back?

I had a couple of axle shims and determined that they were mounted at the rear axle by the slight indentation marks visible on the rear springs. However, the center post for aligning the axle onto the spring isn’t long enough to accommodate the shim and be able to align and set the axle onto the spring with the shim in place. A friend suggested welding an extension onto the bolt nub; do you have any other ideas? Initially, this was a stock setup, but how (why?) did they use shims without being able to seat the axle into the spring so it was aligned properly?

Lastly, should I use grease on my spring clamps? What keeps the clamps from sliding on the leaf springs? These are fold-over replacement clamps…I have provided photos of my springs.—Ray B.

Ray, the plates do not have rolled end “lips,” as you describe, and the clamp style is an insulated, wrapped design. This is a contemporary spring design, not the classic Jeep “military” design with riveted, cross-bolt clamps and raised plate lips. Classic leafs with a factory clamp(s) typically have a drilled and chamfered hole for a rivet. The rivet holds the base of the clamp to a single leaf. The sides of the clamp simply rise alongside the plates. A cross bolt keeps the clamp from spreading; the cross bolt does not pinch the spring sides tightly, as that would restrict movement of the plates/leafs.

By design, the backside of the hole is chamfered to allow the flattened rivet to fit flush with the leaf. As the springs flex and change arc, the leaf plates must be able to move longitudinally without restriction or chafing, so the flattened rivet stud must be flush with the plate surface. The clamps keep plates aligned (sideways) without restricting flex as the leaf arcs change. The rivet affixes the clamp to a single leaf.

Later model clamps are often a jacketed rubber insulator. A tin strap folds around the spring stack. Some approaches do not even include the rubber insulator and are simply a tin (sheet metal) strap that wraps around the leaf stack, folds over and has a tab lock. Looks like you have this kind of clamp…There is not a considerable amount of longitudinal plate movement, but on a Jeep used off-road, the spring leafs can separate and change arc considerably when the axle “articulates” over rough terrain.

As for spring clamps on your Kaiser Era CJ, the vintage Jeep springs I have reworked each had clamps riveted to the leaf springs. The leaf was drilled to accept a rivet. On my ’55 CJ depicted in the Jeep CJ Rebuilder’s Manual, the original springs have multiple clamps facing each end of the spring. There is no relationship to rolled lip spring ends and the clamp positions; the clamps were riveted at flat-ended leaf plates. (Your springs’ rolled lip ends were likely for reducing friction as the plates slide normally in service.)

A spring shop creates rivet holes to affix clamps at the correct leaf. Clamps are for lateral alignment of the leaf, not for clamping plates together. Clamping plates together would restrict the spring plate movement, and clamps would break as the springs flex, anyway. (Rivets only hold the clamps to plates. Leaf plates are not riveted together!) The older U-shaped clamps have a cross-bolt that keeps the upright sides of the clamp from spreading.

I would place the two-lip/clamp end of each front spring toward the front of the vehicle. The rolled spring plate lips should prevent the strap-on clamps from sliding off the springs. At the base of your new strap clamps note that there is a tab designed to locate in the original rivet hole (if one exists). You bend the tab into the hole to keep the clip from sliding out of position. If there are no rivet holes, the curled lips should keep the clamps in place.

As for greasing leaf springs plates to reduce friction, don’t do it! Grease will attract dirt. If you use anything between the plates, make it a silicone or graphite, full-drying substance. A white grease like lithium might be okay if it dries completely. Any substance that attracts dirt, however, will cause problems. Be aware that any lubricant you apply is temporary, as moisture and debris will find their way through the leafs and grind out the lube.

A more sensible approach, if the leafs are apart or gapped, would be a durable enamel or a modern epoxy-based, two-part (catalyzed) primer. I use such a primer for transmission cases, axle housings and other parts. It is available in black and requires a respirator to shoot. Outdoor enamel in a thin application will also work. If you paint each side of each leaf without clamping them together first, make a point of re-torquing spring U-bolts after the paint settles. Paint pounds thin and creates space.

Regarding the short spring bolt heads and wedge shaped shims, there are spring bolts available with longer heads. These are designed for applications like yours that use a wedge shim. Check with NAPA or other retailers under the Dorman product line. When changing spring bolts, use pairs of heavy-duty clamps to keep the plates compressed. There can be a lot of force here, so be careful!

I would not weld on the bolt head as this can reduce a hardened bolt’s tensile. The proper solution is a bolt head long enough to fit through the shim and into the spring perch’s locating hole at the axle.

Be aware that wedge shaped shims are used to adjust the U-joint/pinion angle. On the front axle, they can also adjust the caster angle. This requires a U-joint angle gauge or alignment gauges to determine the correct axle tilt. Unless it is clear where these shims should fit, I recommend use of a U-joint angle gauge for setting up the rear axle wedges.

CJ-6 Gets Late JK Wrangler Front Suspension

I’m building a vintage CJ-6 to modern standards. The CJ rolling frame is done, coil springs in front and YJ-type leaf springs at the rear. (I’ve included photos that I took of the rolling chassis.) I am optimistic that I did my calculations right and that the chassis will handle well. However, I used the 4-link suspension calculators found on many online sites, and the findings are unclear.

The calculations did seem important—you input your parameters, and it tells you a value for anti-dive, anti-squat, roll center and so forth. If I mount my links one way I get an anti-dive value of 220; if I change the mounting, I get an anti-dive value of 60. What is right? There are no “desired” or “correct” values listed. In that regard, I found the exercise somewhat meaningless, so I tried to copy the JK geometry.—Tom H.

I looked at the websites, and the calculations do aim at four-wheel drive vehicle dynamics. Beam axles, by design, limit the variables used in these calculations. These are mathematical formulae and, to the extent that the variables permit, they reflect the “numbers” you describe.

To be more practical and specific to your project, let’s begin by assuming that the JK Wrangler was engineered properly. (This is Jeep engineering, after all!) Given that, begin by using JK-type link arms. Match up the frame and front axle attachment points. See that the link arms’ slope angles mimic a JK chassis. A key goal is to establish correct caster and arc of radius. Essentially, you want to create a JK equivalent front end.

For safety and handling, your setup should work well if:

1) you use JK or JK replacement link arms

2) you set up the arms so that front axle caster is correct at the static, weighted chassis height*

*Note: The JK arms should be set up at a neutral length to allow for fine-tuning and adjusting the caster and pinion angle.

3) axle travel and arc of radius follow the JK engineering*

*Note: Confirm by cycling the suspension with the coil springs removed, measuring caster over the range of axle travel. Test articulation of the axle, too. Make sure there is no binding or conflict between parts.

4) the front driveline slip coupler works with the established arc of radius and range of wheel travel

5) the track bar’s shape and bracket location permits axle movement—without creating lateral shift of the axle, “yaw” or bump steer

Since your rear leaf springs have YJ Wrangler-type anchors and hangers, there’s nothing more to setting up the rear than adjusting the pinion angle properly.Make sure the rear axle is centered and perpendicular to the frame’s centerline. This creates proper “thrust.” A square and centered rear axle serves as a reference for squaring and aligning the front axle’s position.

The calculation charts seem mathematically reliable. However, without describing optimal figures or how to adjust for them, the calculations simply provide a mathematical description of existing layouts. They describe what you have rather than what you need.

As I shared, using a beam front and rear axle constrains some variables: caster, camber, roll and lateral shift. Camber for a beam axle is determined by the straightness of the axle tubes and knuckles. Caster is typically uniform at each front wheel, since the axle beam and its steering knuckle supports are rigid. This simplified design eliminates several variables used in independent suspension.

Caster and pinion angle are easy to establish with a beam axle. Link arm design, in your case, was determined by the factory length and shape of the arms. So, the remaining concern is where to attach the arms at the frame. Start with a close comparison to a JK Wrangler chassis.

The goal with link arm pivot points is to provide ease of axle articulation (rise and drop at each side) and a normal “arc of radius.” The arc of radius is critical and should be a central concern in the design of an aftermarket lift kit for a Jeep 4WD vehicle.

Arc of radius is the arc of travel that the beam axle takes as the suspension rises and sets to its extremes. One of the best examples of poor arc of radius can be found in some “short arm” lift kits. If there is significant wheel travel, the stock or short arms (mounted at stock pivot points) create a considerable caster angle change as the axle moves up and down over its range of travel.

This caster change can adversely affect the handling and steering of the vehicle, since caster angle is crucial to the return-to-center feel of a vehicle when negotiating turns. Too little caster angle can lead to “kingpin shimmy” or the so-called “death wobble” ascribed to short arm, lifted Jeep 4x4s.

So, make sure that caster angles stay within acceptable tolerance over the range of axle, wheel and suspension travel. You can determine this with caster gauges as you cycle the suspension over its range of expected travel. (See this month’s “4WD Tech” section for details on wheel alignment.)

Raising a vehicle to install big tires is the primary reason for a lift in the first place. Given that, the use of big tires with a link arm suspension system begs the use of longer arms. Properly engineered, a long-arm suspension kit for a beam axle will provide acceptable caster angles over the range of wheel travel and arc-of-radius.

If your link arms are stock JK Wrangler Rubicon type, and if you have matched the pivot points at the frame and axle to a JK, then the suspension should work okay if you maintain proper caster angle with the vehicle at normal curb height.

With the coil springs removed and the track bar installed properly, you should be able to cycle (raise and lower) the suspension, simulating the full range of movement and articulation, without seeing a radical change in axle caster angle.Note that I include the track bar in this exercise.

The installation of the track bar must do two things:

1) Keep the beam axle from moving laterally (side-to-side) as the vehicle weight shifts and the frame rolls

2) Keep the axle beam in proper alignment with the frame and rear axle throughout the range of wheel travel

This also includes proper arcs of each wheel as the front axle beam articulates. If the track bar shape or attachment points are incorrect, the axle can shift laterally on turns, and it can move in irregular arcs that cause bump steer. Poor track bar location on a link arm suspension causes the vehicle to mishandle and steer erratically. It can even bind up the suspension or steering.

As for anti-dive and anti-lift, this has more to do with spring rates than any other factor. Dive can be affected by the length of link or radius arms; however, the degree of pitch under braking is still the result of how much spring force counteracts the tendency for the suspension to dive.

Major factors that affect anti-dive are total sprung weight of the vehicle, spring rates, acceleration of gravity, deceleration force during braking, and wheel base length. Lesser factors surrounding dive would be the distance from the vehicle’s center-of-gravity to the front and rear wheels. This is determined by vehicle height (center-of-gravity and roll center) and the wheelbase length.

Since you’re using leaf springs at the back, the issues of rear brake anti-lift and rear anti-squat during acceleration are largely governed by the leaf spring design and, once again, the spring rates.

Some short-arm suspension systems tend to wheel hop under braking on a rough surface, like a washboard or gravel road. A bit of front end dive will actually reduce this tendency and provide better braking under panic conditions. Too stiff, and the vehicle’s unsprung weight mass will want to press forward, while a desirable degree of dive permits the chassis to weight the front wheels, enough for better braking and control.

Note: For math’s sake, workable braking is usually in the 25%-50% anti-dive coefficient range. I can provide formulas for anti-dive coefficient if anyone wants to run these calculations. Suffice to say, a stiff chassis is more apt to skid than one that allows for some weight transfer to the front wheels under hard braking. Too much transfer is undesirable—under hard braking, it can cause rear wheel lift and loss of traction or skidding of the rear wheels.

While many variables can be adjusted, your CJ-6 and most other trail rigs have fairly rigid parameters: a predetermined wheelbase length, a desired ground clearance height, specific tire diameter and a fixed track width. Given that, the “safest vehicle” is a relative consideration, governed by these chosen constraints and parameters.

Do your best to make concessions toward safety! As a rule, widening the track width is always a good idea, it offsets the increased center-of-gravity height and helps stabilize body roll. Widening the spring mounting points to the YJ Wrangler’s position at the rear is also advantageous.

The Kaiser-era CJ-6 has a 101-inch wheelbase, and that’s far better than an 81-inch wheelbase CJ-5. Wider axles are a plus, as this is part of the wide track gains and reduces the need for shallow wheel backspacing. You’re on the right track…I’m here for more questions!

Past the Engine and Ready for a Tire Pick!

—–Original Message—–

From: Chad A.

Sent: Saturday, March 26, 2011 9:26 AM

To: Moses

Subject: Tire question

Moses,

I have another question. I keep going back and forth on tire selection. I want to find a very utilitarian tire. Size wise, I think I am going to go with a 31×10.50×15 on 15×8 wheels w/ 3.75 backspacing. Tire wise, I can’t decide. Here is what I am thinking about: BF Goodrich A/T KOs, Treadwright Wardens w/ Kedge Grip (BFG Retread w/ crushed glass and walnut shells imbeded in rubber), or Firestone Destination A/Ts. Do you have any experience with any of these tires? I keep leaning on the BFGs. The BFGs have a very utilitarian feel but they have mixed reviews on ice. I would really appreciate any insight you could provide.

I hope you don’t mind all of my emails. If they get to be too much, please let me know.

Thanks again for you time.

Chad

Reply from Moses…

Good question, Chad…For ice, you need sipes on the tread. Hardcore mud tires (broad, open cleats) clean out well but lack sipes and tread surface area. This means that they grip in mud and deeper snow but do poorly on an icy highway.

One of the best tires I ever used was an all around on- and off-road platform: the Goodyear GSA. It had three tread designs in one. With the GSA, the bigger the tire size, the better the mud or cleat action, as the tread blocks spread further apart. At 33″x12.5″x15″ diameter on a 10-inch rim, it excelled. Even in 31″x10.5″x15″, it would be useful.

There are tire niches for specific terrain, but your vehicle is driven on- and off-highway. Of the tires you describe, the BFG A/T would make better sense, although you should also look at the Toyo Open Country A/T (used on our XJ Cherokee for good all-around performance with excellent wear characteristics, good off-road traction and plenty of sipes) and, of course, Goodyear’s current offerings. Above is a photo of Goodyear’s AT/S line, derivative of the Aqua-Tred design. This tire works well on wet pavement, as it was originally engineered to resist hydroplaning.

I’m here when you’re narrowing your choices down…

Moses

Identifying a Ross ‘TL’ Willys Steering Gear

Moses, per your request, here is the steering gear housing casting number from my 1962 Willys PU Model 475—with the exception of the casting number, what appears are the letter “B” and the ‘Ross’ brand, no other numbers visible. If I discover any additional numbers after I remove the unit, I’ll copy you. Here is the casting number: TL122992…I plan to pull the gear this weekend and ship it your way early the following week. I’ll be sure to forward you the tracking number. Thanks…

Matt F.

Matt, thanks for the details. We like this sort of referencing before the gear arrives. I can get genuine Jeep/NOS parts lined up that way…Your gear is original for the Model 475. I have rebuilt many of these units. They always need a new sector/lever shaft, as the twin pins wear flat on one portion. (The light-duty Ross gears do not benefit from the rotating pins found in larger truck applications.) Studebaker also uses the ‘TL’ gear, and that ‘TL’ designation describes the size and type housing. Your worm-cam is likely okay unless there is chipping or corrosion. I glass-bead all parts before inspection. Cams, by design, do not have the marked wear commonly found at the lever shaft pins. Once all hard parts are glass-beaded, inspected and cabinet washed, I will install, align-hone and finish fit new bushings then reseal the unit. Worm-cam ball bearings will be renewed, using only OEM/NOS parts. Off-shore bearing races are of inferior quality and questionable hardness. I use only OEM pieces here, and they are getting scarce!

During assembly, I precisely adjust the worm bearings with a spring scale and backup torque wrench test method that I have devised for the TL gears. I do a similar approach with the critical over-center mesh adjustment at the sector/lever shaft and cam groove. Custom paint is an option, or I will final seal and detail your gear with epoxy primer and stock color. The gear will ship back looking and performing as new, ready for installation, Matt…Thanks for the business!

Frame Repairs and Upgrades for the ’72-’75 AMC/Jeep CJ

I have a 75 CJ5 with the 304 V8, Dana 44 rear, Dana 30 front, Dana 20 TC & T-14 tranny. It has a 2 1/2″ suspension lift and 33×12.5×15 tires. I’m in the process of a complete frame off rebuild. I’m just about down to the frame now and about ready to start working on the frame. It has a couple of minor cracks that need repair, then clean up and repaint.

I understand about checking the frame for square before proceeding, so I’ll do that. What I’m interested in is opinions on frame boxing vs just reinforcing. I’ve read a lot of varying opinions on this subject, but I’d like to hear what this forum has to say.

I plan to use the Jeep mainly off road – forest roads and mild rock climbing.

Thanks for any help you can give – Bill

Hi, Bill…I thought a quick two-cents worth might help here. I am thoroughly familiar with the ’72-’75 AMC/Jeep CJ frames and their quirks.

AMC boxed the front frame from the front bumper to just behind the front spring anchors. In off-road pounding, the force at the front springs drives through the spring anchors and into the frame section. Being open channel behind the boxed section, the frame tends to crack at this point between the boxed and C-channel sections.

Many assume that the weakness is the frame. Actually, the weakness is the anchor at the rear of the front springs. In my Jeep books, I talk to this issue and the use of a retrofit shackle reverse kit that will put the anchors at the front of the springs. This reduces frame stress at the original anchor point. The vehicle will steer better, too, as the axle “trails” from the reversed anchors instead of pushing the springs and front axle forward from the rear of the front springs—which is what the stock anchor orientation does.

So, my first priority would be a shackle reverse, making sure that the front axle, steering linkage and driveline each position properly. (The axle’s arc of travel must be consistent with the steering linkage position and front driveline’s range of travel.) Caster angle must be set properly, too. This reversed anchor orientation will take a good deal of load off the stock frame.

As for boxing, this rigidifies the frame. On the downside, the stiffness can lead to frame stress from the lack of torsional movement. Jeep CJ frames all flex end-to-end. Two people can hold a bare frame bumper-to-bumper and readily twist it—quite a bit! This frame flex seems like part of the “suspension” on ’75-back CJs! Notably, the older frames were riveted and more forgiving of this flex.

It does make sense that a stiffer frame is better, and this is demonstrated by the engineering on each of the Wrangler designs. The YJ, TJ and JK have progressively stiffer and more rigid frames, which is consistent with modern theory: A rigid, strong frame provides a solid platform, which makes suspension tuning and vehicle handling more precise. Link arms and coil suspension work best with a rigid frame.

In boxing the ’72-’75 CJ-5 or earlier CJ frames, the frame should end up rigid from bumper to bumper. If not, any open areas will be stressed by the inflexibility of the rigid sections. The weak points will be any area not boxed. These points will fatigue from flexing and eventually crack—just like the spot right behind the stock front boxed section on ’72-’75 CJ models.

Welding should mimick factory boxed section technique, which is generally long stitching and not continuous beads. Look over other Jeep frames, later ones in particular, to understand weld patterns. Use the right stick rod or MIG wire, and clean all surfaces of scale and rust before welding. If you have further questions about welding or the frame, I am available through the magazine’s ‘Q&A’.

Readers will benefit from your thoughtful post, Bill. Hey, CJ owners, add your comments! Welcome to the 4WD Mechanix Magazine forum…

Moses Ludel

The Exchange Continues…

Moses – Thanks for all the helpful information, especially the info on shackle reverse. I think I will go in that direction and forgo the frame boxing for now. With boxing the frame, I have concerns about creating a trap for mud, rust, etc. and creating a worse problem than I’m trying to correct. I’m told that the CJ was run pretty hard in the past and the frame is in good shape, except at the very front where I’m told a tree fell on it a few years ago. There I have a couple of cracks that will need repair and a slight twist which will need to be straightened.

I do have a question regarding shackle reverse kits though. I’m having a hard time finding one that fits the 75 with my 2 1/2″ lift. Everything that I’ve been able to find is for stock or 1 1/2″ lifts. Any recommendations of where to look?

Thanks again – Bill

[Continuing reply…]

Hi, Bill…Most marketed shackle reverse kits are for the ’76-up chassis. I worked with a design years ago and shared it in the Jeep Owner’s Bible and other books…If you can find a kit for stock or 1-1/2″ lift on a ’72-’75 CJ, one or the other kit will likely work. Your current 2.5″ lift is a spring arch lift that works with stock anchors…So, a stock shackle reverse might work with your 2.5″ spring lift. (You may need to experiment with shackle lengths.) When you reverse the anchor ends, be sure to maintain wheelbase and axle location, driveshaft coupler range and clearance for steering linkage and brake hoses. Maintaining axle caster angle is important, too.

In the extreme case, for your ’72-’75 chassis, you may need to fabricate a setup. In my new magazine section on the Dodge Ram tow vehicle, you will find an article about loading and hauling with a trailer. I show my ’55 CJ-5 on the trailer. The front shackles were factory reversed, actually due to the use of the M38A1 military frame on the earliest CJ-5. By 1956, this was changed to the rear anchor approach like your ’75. (There are many photos of that frame in my Jeep CJ Rebuilder’s Manual 1946-71. Perhaps you have access to that book, although the ’72-’86 edition is specifically for your Jeep CJ.)

Check out the article on trailering and look at the front spring anchors. This can provide some ideas. There is a lot less fabrication involved than boxing the frame. You can get ideas for the rear/shackle end of the springs from the shackle reverse kits available for ’72-’75 CJs, or review my ’46-’71 manual to see the 1955 CJ-5 setup. When setting up the springs, keep in mind the front axle caster angle, driveline angle and so forth.

Glad my comments helped, Bill…

Regards,

Moses

Worn ‘66 and ‘71 Jeep CJ-5 Steering Gears

Are you able to rebuild a ’66 Jeep CJ5 steering box? The chassis is a V-6 type, and I believe this is a Ross box. Is it wise to rebuild the gear?—Lavin C.

My 1971 Jeep CJ’s Ross steering box needs a rebuild or replacement. I can rotate the steering wheel 1/3 revolution before the front wheels actually begin to turn. I have another used box, seems tighter but the true condition is unknown. Does it pay to rebuild these gears?— Mark

Lavin and Mark, you have great CJs! The 225 V-6 and reasonable gear reduction make these a time-honored package. The ’66 and ’71 models should have Ross TL gears with a one-piece column. Basic and often considered primitive, cam-and-lever two pin gears served the CJs through the Willys and Kaiser period. By the end of the Kaiser era, Jeep began using popular G.M. Saginaw recirculating ball-and-nut gears. I rebuild the Ross gears for Willys models and Kaiser CJs, finding that in nearly every instance there is pin wear. Pins on these basic Ross gears wear flat on the sides, as they do not rotate and continually press against the cam at the same points on the pins. Adjusting the gear is hazardous if the gear has any more than the slightest amount of play on-center. (Off-center, there will be backlash, and this is normal. The gear’s adjustment is over-center to eliminate play only in this zone of steering.) Customarily, the project begins with hot cabinet washing and glass beading of all hard parts before inspection. In the build, the sector/lever bushings are replaced and fitted precisely for a long service life. A new lever shaft seal, service of the upper/lower worm cam bearings and replacement of the sector lever shaft with a new NOS item take place before buttoning up the gear with a new cover gasket. Adjustments of the worm-cam bearings and over center preload are critical to the safety and lifespan of the gear assembly. All adjustments must be on spec before a unit ships from our shop. I detail the finished assembly in durable epoxy primer and paint color of your choice. Cost for this level of restoration and use of NOS parts depends upon the latest NOS prices for the lever shaft and the current condition of your gear. Note: I refer to “NOS” parts; the only assurance of high quality and a long service life is use of original Jeep replacement parts. There are off-shore repro parts that simply will not meet the standards for fit-up and metallurgy. Know your parts source and the origins of parts if you attempt to rebuild one of these gears yourself.

Moses Ludel restoring a Ross TL steering gear at his bench.

When checking steering play on stock ’46-’71 CJs, look for looseness and wear at the bellcrank, tie-rod ends and steering knuckle “kingpin” bearings. Some Jeepsters and ’70-’71 CJs use front-mounted Saginaw steering gears with a one-piece tie-rod between steering knuckles. Ross TL applications have the steering gear mounted rearward of the axle and use a draglink, bellcrank, tie-rod to the right side knuckle and a one-piece tie-rod between the knuckles. Make sure you know the origin of the steering play…If you opt for a Saginaw steering gear swap, there are several concerns: 1) mounting the gear properly to the frame, 2) using the correct steering linkage and pitman arm plus 3) fabricating the steering column support if your original column ran from the gear to the steering wheel. In my Jeep CJ Rebuilder’s Manual: 1946-71, I show the steps for rebuilding a Ross gear like yours and also outline the steps for converting to Saginaw manual steering. Historically, Advance Adapters has been a source for Saginaw steering conversion kits for the vintage CJs. Their catalog can also be useful for identifying the parts needed. If your CJ has collectible value or you wish to maintain a stock profile, proper restoration of the Ross TL steering gear can add years of safety and driving satisfaction. To eliminate the more primitive gear design and busy bellcrank, draglink and two tie-rod steering linkage, consider the Saginaw conversion.