Jeep Q&A: YJ and TJ Wrangler Fuel, Spark & Emission Systems

Have technical questions about your Jeep 4×4, popular 4WD truck, SUV, ATV, UTV or dirt motorcycle—or welding and metal fabrication? The 4WD Mechanix Magazine ‘Tech and Travel’ Forums now feature enthusiastic discussions and input from members and a steady flow of content from Moses Ludel.

PCM and Sensor Issue on ’06 Jeep TJ Wrangler 4.0L

From: Brison P.

Sent: Monday, August 27, 2012 12:44 PM

To: 4WD Mechanix Magazine

Subject: 06 Wrangler 4.0L

Hi Moses love the website! My problem is with my 2006 Wrangler with the 4.0 engine. I am having problems with the motor cutting out and going into limp mode when too much throttle is applied. It feels as if the motor loses all power and happens while driving at various speeds but only when the throttle is applied while shifting or accelerating. The check engine light flashes and the motor goes into limp mode and I have to restart the engine to cancel the limp mode. The check engine light goes out when the engine is restarted.

Brison P.

From: 4WD Q & A

Sent: Monday, August 27, 2012 3:39 PM

To: Brison P.

Subject: RE: 06 Wrangler 4.0L

Brison, thanks for the compliments on the magazine site! Regarding your 4.0L, a trouble code should be stored in the PCM, regardless of whether you see the MIL light go out. If you have access to a code reader for OBDII, take a read. If you don’t have a code reader, buy an inexpensive one at Harbor Freight for $30 or so.

The code reader will pick up any code that has been recorded in the PCM and not yet cleared. The reader is not a full-on diagnostic scanner but does help if there is a factory code stored for your problem. I’m unclear of the mileage, however, a ballpark concern would be the upstream oxygen sensor or a fuel supply issue.Let’s not guess, see if a code can be read. Even the inexpensive Harbor Freight code reader comes with a book of OBDII standardized code troubles. You’ll like having this tool, I take mine on backcountry trips!

Let me know what you find. Do not disconnect the battery in the meanwhile, as this will cancel codes. You can clear codes with the code reader whenever you want.

Regards,

Moses Ludel

Brison replies…

From: Brison P.

Sent: Tuesday, September 04, 2012 9:11 AM

To: 4WD Q & A

Subject: RE: 06 Wrangler 4.0L

Hey Moses, looks like I have a bad PCM. I could not get it to give me any codes when I scanned it, so I decided to take it to a local shop, the head mechanic/owner had the same problem his scanner could not get any codes from the PCM so he tried a couple other scanners with no luck. So he took if for a drive and it went into limp mode on him when he got it back to the shop it threw every code in the book he said. I hope the new PCM will fix my problem, the Jeep only has 98000 mile and the 4.0 seems to run great other than the cut out problems. I think if the new PCM does not fix it I will have to take it to the local Jeep dealer for a full diagnostic scan, I hope it doesn’t come to that. Thanks for your help!!!

Moses response…

Thanks for the update, Brison. Make sure the crankshaft position sensor is not dirty, defective or having a wiring problem. The PCM could be the cause, for sure. Keep me posted, I’m interested in your getting that typically reliable Jeep TJ Wrangler back in form!

Regards,

Moses

Additional back and forth…

From: Brison P.

Sent: Tuesday, September 04, 2012 10:04 AM

To: 4WD Q & A

Subject: RE: 06 Wrangler 4.0

Thank you ! The mechanic did change the crank position sensor, after he researched the problem on the internet, but of course it did not fix the problem.

Well, at least you do have a new crank sensor, Brison! We’ll see what the PCM does, they do go “bad”, flash out erratic codes and retreat into limp mode…This is in character with that problem…I use a Chrysler DRBIII (i.e., dealership level) scan tool when I can borrow one, and they do have a broader range of functions and troubleshooting abilities, including operation of devices in simulation to “live” powertrain functions…There are some quality aftermarket scan tools, too, high end ones will do many factory functions when using the right software…Moses

Final comments…

From: Brison P.

Sent: Saturday, September 08, 2012 7:45 AM

To: 4WD Q & A

Subject: RE: 06 Wrangler 4.0

Hey Moses looks like that replacing the PCM did the trick, Jeep runs great but as soon as I drove 5 miles down the road the check engine light came on. I went back to my mechanic he ran a scan and it showed a bad 02 sensor on bank 2 downstream so the new PCM is doing its job. I am going to replace the 02 sensor and the light should go away, might help my mileage a bit but I am thinking not much. Much thanks!

Great, Brison…The one thing the PCM cannot do well is troubleshoot itself. (Chrysler says otherwise, but I know better!) When our ’05 Dodge Ram was virtually brand new, the Cummins 5.9L engine started acting erratically, and being under warranty, I did (somewhat reluctantly, as I have done my own work since the late ‘sixties) seek the dealership’s attention.

At our regional Dodge dealership, the Cummins tech is very well versed, and Eric shared with Chrysler that the PCM on our truck and several others parked throughout the zone was defective. Since the PCM was defective, it threw a bunch of erroneous codes, yet Chrysler insisted that the tech replace each of the parts indicated (injectors got replaced, then swapped, entire wiring circuits were lamped tested for faulty grounds, and so on). Eventually, with some consumer pressure from yours truly, Chrysler reluctantly authorized a PCM replacement, the first of 25 trucks that had suffered this same problem/symptoms.

The PCM not only cured the troubles, it has worked flawlessly for 113K miles. Recently, Chrysler put out notice that anyone owning a Dodge Cummins truck in our cohort group is entitled to indefinite warranty claim on a PCM (engine controller) failure…Sometimes, it’s technician over computer!

Glad you’re enjoying your Jeep again. The downstream oxygen sensor will not do a lot for performance, it’s main function is to compare pre- and post-cat emissions to make certain the cat is doing its job.

Pleased that the tech nailed down the PCM issue…

Moses

TJ Wrangler Gearing and Gas Mileage

From: James C.

Sent: Saturday, February 25, 2012 4:57 AM

To: 4WD Mechanix Magazine

Subject: TJ Question

Hi, I have a 2006 TJ Sport, 4.0L, auto, 3.73 gears(stock) 2″ lift, 33″x10.5″x15″ TSL Super Swamper Radials for trails, 31″x10.5″x15″ Good Year Wrangler Territory (like a Duratrac) for daily use. My question is in regards to performance on street/highway with the different sets of tires. With the 31s, on hills and on the highway, the transission shifts like crazy and it seems to be very lethargic. Gas mileage is crappy too because of the contant shifting, even with the OD off. With the 33s it doesn’t shift so much (especially on highway hills) and doesn’t bog down like with the 31s. Almost like running stock size tires, plus the gas mileage is much better with the 33s, as good or better than stock, with no lift. Why would this be, i figured if I went down a tire size for daily use, it would be better for my stock gearing in performance and gas mileage. Do you have an explanation for this?

Thank you,

James

Hi, James…The late model Jeep vehicles with automatic transmissions are highly sensitive to load and gearing. (So is the Ram, as I recently discovered by lifting the ’05 Dodge 3500 and adding 35” tires in place of 32”.)

In your case, the 33” tires create enough load to hold the vehicle in gear without the processor thinking it’s time for a downshift or upshift. 31” tires (slightly oversize for a Sport edition) fit into the awkward zone: The powertrain processor cannot match up the transmission gear ratios with the 3.73 gears under that load, road speed and tire diameter.

Composed with HTML Editor

In simple terms, the engine load, road speed and gear ratios are not a good fit for the 31” tires. The 33” tires create both overdriving effect (effective gearing change) and a more stable match for load, road speed and ratios.

There is one other possibility: Did you correct the speedometer for the 33” tires? If so, that could permit proper shifting with 33” tires but not with 31”. The improved mileage with 33” tires is likely the result of the overdriving effect from greater tire circumference.

On our Ram 3500, the effect is just the opposite. With 3.73 gears and 35” tires, the mileage dropped two MPG empty and 6 MPG when towing! I will cover this in an article on installing truck 4.10 or 4.56 gears.

Trust this helps. We can carry the conversation further…

Regards,

Moses

4.2L Conversion Carburetor Troubles

From: Randell B.

Sent: Tuesday, December 06, 2011 10:46 AM

To: 4WD Mechanix Magazine

Subject: Technical YJ Question

Hi Moses –

Read your jeep Owner’s bible and refer to it often—very good work!

I have an 87 YJ I bought as a rebuild project – it’s my hot rod.

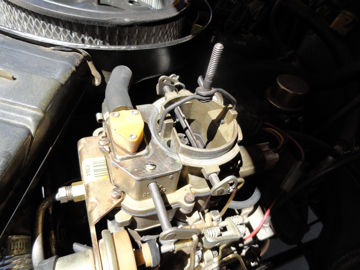

I was required to remove the old BBD because it would hardly run, and I replaced it with a Weber. I have replaced the Weber due to its finicky tuning and installed a Holley 4-barrel 390 CFM. Im happier with this one – either one gave me a nice increase in horsepower and RPM. Emissions are great either way. The engine seems to run smoother with the Holley.

I am experiencing, under either carb, a surging/bucking at around 2000 RPM – sometime 2500. It acts like fuel starvation, but if I floor the accelerator, it will power through and run on up to redline. Its always at 2000-2500, no matter what my operating conditions. Its more prevalent with the engine hot. I have checked thoroughly for vacuum leaks, and have redone all my vacuum lines. Distributor advance is set correctly, vacuum advance works, and I have no other complaints about the motor – just this bucking at part-throttle, 2000 RPM.

Any ideas what it could be, or where to check next?

Already done: Carb install and tuning, checked EGR for function, replaced all old vacuum lines, tune engine, set timing, replaced spark plugs and wires, replaced distributor cap and rotor, and replaced throttle linkage to work without binding.

Randell B.

From: 4WD Q & A

Sent: Tuesday, December 06, 2011 3:26 PM

Hi, Randell…Thanks for the comments on the Jeep Owner’s Bible. I am quite familiar with Holley carburetion and can emphasize that, by design, these carburetors are altitude and fuel metering sensitive. That said, it sounds like the transition between the low-speed metering and the main jet flow is lagging.

Main jet resizing or a power valve change (likely enriching slightly in your case) is the probable cure. An inexpensive air/fuel ratio meter, one that reads “Rich/Lean” (like the Edelbrock unit) would help with diagnosis. The rich/lean is from a gasoline stoichiometric of 14.7:1 A/F, so you will have to determine the actual ratio where the LEDs go lean or rich, usually in 0.5 A/F increments on the A/F meter.

These A/F ratio devices require an oxygen sensor, so a bung must be installed on the exhaust pipe for mounting the oxygen sensor. You may have that provision on the 4.2L if the OEM system had an oxy-sensor. (Any muffler shop can install an oxy-sensor bung.) The approach is to gradually apply throttle around the rough zone, observing the A/F transition.

At the rpm you describe, it sounds like a power valve change would help, perhaps some work with the main metering jets, too. If the engine runs well above this rpm at steady throttle, I would steer away from the main jets and toward the power valve function. The power valve works with actual engine manifold vacuum, and 2000-2500 rpm would be a sensitive vacuum zone. Make sure the carburetor’s mounting method and mounting gasket allow for a vacuum signal to the power valve…

Trial and error gets costly. Use of an air-fuel ratio meter would be quicker, more precise and useful in the long run for maintaining fuel efficiency. A simple manifold vacuum gauge (with a long hose into the cab) or an ancient “Mileage Minder” gauge (essentially a vacuum gauge) would also work for this diagnosis. You would note the engine hesitation point, observe the manifold vacuum at that rpm, and compare this with the carburetor’s power valve vacuum setting. Holley power valves are numbered to reflect their vacuum setting. The power valve is relatively easy to change out, and valves are available through Holley dealers and outlets like Summit Racing.

If you decide to delve into Holley carburetors on a regular basis, there are books on Holley carburetor tuning. Once you know the functions of the idle circuit, power valve transition, accelerator pump operation and main jet metering, the Holley mysteries dissolve…

Let me know how this turns out, Randell.

Best,

Moses Ludel

From: Randell B.

Sent: Tuesday, January 17, 2012 11:51 AM

To: 4WD Q & A

Subject: RE: Technical YJ Question

Oh, and there appears TO BE FUEL LEAKING FROM the intake manifold on the bottom side. It’s dripping onto the hydraulic line going into the bellhousing and then pooling on the deck. ????

Randell B.

It sounds like the Holley power valve became damaged from the backfire, a common Holley weakness. This could account for the fuel spilling, although that could be a float/needle and seat issue. Check your bowl fuel height and adjust the needle/valve if necessary. Check the power valve, which could be damaged from the backfire. A bad power valve could cause fuel spill, which you see at the manifold.

Backfire is usually a lean condition. Consider the fuel pump pressure and fuel volume to that Holley 390. Make sure you have sufficient pressure and flow. A clogged fuel filter or plugged in-tank sock filter can create a lean condition, too.

Trust this helps, Randell…

Moses

YJ 4.2L Ignition System Remedies

From: William G.

Sent: Wednesday, January 04, 2012 10:08 AM

To: 4WD Mechanix Magazine

Subject: Distributor for 4.2L

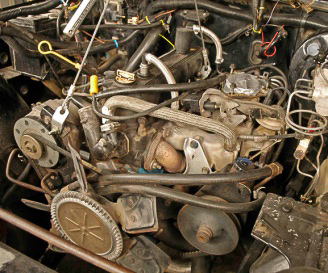

I am finally getting back to a stalled ’88 YJ project. It has the 4.2L 6 which has been rebuilt. The Carter BBD carb was replaced with a Motorcraft 2100, because during the engine rebuild moisture got into the carb and started rusting, and all the forums I went to said it was better to replace the BBD than rebuild it. Because I replaced the carb I also performed a “Nutter bypass” which bypasses the computer.

I want to upgrade the ignition, and I read on your site the best distributor for this engine is an HEI distributor from 4Wheel Hardware for $122.98, which is for a CJ.

My question is: Will this distributor work with on my Jeep, or do I need to look at something else? On some Jeep forums there is articles about putting on a GM HEI, distributor on as well as adapting the existing base to use a Ford style distributor. I am getting quite confused, and really hope you will guide me in the right direction.

Thanks you in advance for your assistance.

Bill

Hi, Bill…The HEI distributor from 4WD Hardware is decent and will work with your engine. There are more expensive solutions from MSD, DUI and others. Avoid the GM inline six distributor that many discuss. This is an HEI distributor at the upper end but does not account for the drive gear size of the AMC/Jeep 4.2L sixes. You need a distributor that has an identical drive gear diameter and depth to match the original AMC/4.2L design. Otherwise, you will damage the gear, possibly the camshaft, or worse yet, find that the gear strips at speed and stops spinning the oil pump.

An alternative is use of your OEM Motorcraft distributor with a five-pin Chrysler module. I illustrate this approach in the Jeep Owner’s Bible. This offers a decent (OEM) distributor, free of the ECU controls. In any of these approaches, you will wire the distributor away from the ECU and original spark control system. I have run these OEM Motorcraft distributors with the Chrysler module and a simpler wiring approach—successfully. Jacobs Electronics turned me onto this five-pin module (Chrysler) alternative many years ago.

Trust this helps, Bill…

Moses

Holley Troubles After the BBD Woes

From: Randell B.

Sent: Tuesday, December 06, 2011 10:46 AM

To: 4WD Mechanix Magazine

Subject: Technical YJ Question

Hi Moses –

Read your Jeep Owner’s Bible and refer to it often – very good work! I have an 87 YJ I bought as a rebuild project – it’s my hot rod.

I was required to remove the old BBD because it would hardly run, and I replaced it with a Weber. I have replaced the Weber due to its finicky tuning and installed a Holley 4-barrel 390 CFM. Im happier with this one – either one gave me a nice increase in horsepower and RPM. Emissions are great either way. The engine seems to run smoother with the Holley.

I am experiencing, under either carb, a surging/bucking at around 2000 RPM – sometime 2500. It acts like fuel starvation, but if I floor the accelerator, it will power through and run on up to redline. Its always at 2000-2500, no matter what my operating conditions. Its more prevalent with the engine hot. I have checked thoroughly for vacuum leaks, and have redone all my vacuum lines. Distributor advance is set correctly, vacuum advance works, and I have no other complaints about the motor – just this bucking at part-throttle, 2000 RPM.

Any ideas what it could be, or where to check next?

Already done: Carb install and tuning, checked EGR for function, replaced all old vacuum lines, tune engine, set timing, replaced spark plugs and wires, replaced distributor cap and rotor, and replaced throttle linkage to work without binding.

Randell B.

From: 4WD Q & A [mailto:qanda@4WDmechanix.com]

Sent: Tuesday, December 06, 2011 3:26 PM

To: Randell B.

Subject: RE: Technical YJ Question

Hi, Randell…Thanks for the comments on the Jeep Owner’s Bible. I am quite familiar with Holley carburetion and can emphasize that, by design, these carburetors are altitude and fuel metering sensitive. That said, it sounds like the transition between the low-speed metering and the main jet flow is lagging.

Main jet resizing or a power valve change (likely enriching slightly in your case) is the probable cure. An inexpensive air/fuel ratio meter, one that reads “Rich/Lean” (like the Edelbrock unit) would help with diagnosis. The rich/lean is from a gasoline stoichiometric of 14.7:1 A/F, so you will have to determine the actual ratio where the LEDs go lean or rich, usually in 0.5 A/F increments on the A/F meter.

These A/F ratio devices require an oxygen sensor, so a bung must be installed on the exhaust pipe for mounting the oxygen sensor. You may have that provision on the 4.2L if the OEM system had an oxy-sensor. (Any muffler shop can install an oxy-sensor bung.) The approach is to gradually apply throttle around the rough zone, observing the A/F transition.

At the rpm you describe, it sounds like a power valve change would help, perhaps some work with the main metering jets, too. If the engine runs well above this rpm at steady throttle, I would steer away from the main jets and toward the power valve function. The power valve works with actual engine manifold vacuum, and 2000-2500 rpm would be a sensitive vacuum zone. Make sure the carburetor’s mounting method and mounting gasket allow for a vacuum signal to the power valve…

Trial and error gets costly. Use of an air-fuel ratio meter would be quicker, more precise and useful in the long run for maintaining fuel efficiency. A simple manifold vacuum gauge (with a long hose into the cab) or an ancient “Mileage Minder” gauge (essentially a vacuum gauge) would also work for this diagnosis. You would note the engine hesitation point, observe the manifold vacuum at that rpm, and compare this with the carburetor’s power valve vacuum setting. Holley power valves are numbered to reflect their vacuum setting. The power valve is relatively easy to change out, and valves are available through Holley dealers and outlets like Summit Racing.

If you decide to delve into Holley carburetors on a regular basis, there are books on Holley carburetor tuning. Once you know the functions of the idle circuit, power valve transition, accelerator pump operation and main jet metering, the Holley mysteries dissolve…

Let me know how this turns out, Randell.

Regards,

Moses

From: Randell B.

Sent: Tuesday, December 06, 2011 12:29 PM

To: 4WD Q & A

Subject: RE: Technical YJ Question

Thanks for the answer. I had hoped it would not be the power valve, since I didn’t want to tear into the Holley. And now, the idel has increased up to about 1000 RPM. That’s as low as I can get it. Grrrrrr

Does that change your analysis any?

Would it be better to go back to the Weber and play with it’s jets and emulsion tubes and so forth? Overall, I do like the Holley better.

Randell B.

Reply from Moses:

Randell…Sounds like an air leak at the carburetor adapter, base gasket or manifold. That could also account for a lean condition as the power valve transitions the fuel flow.

A quick check for the leak would be a non-volatile spray (WD-40 works) at the carburetor base, intake manifold flange (avoid excessive heat!) or carburetor base gasket. You’ll hear a noticeable change in engine rpm if a leak is present. While at it, check the throttle shaft ends. Slight leakage at the throttle shaft is normal, anything more than slight will dramatically alter rpm and show up as side movement of the throttle shaft.

Simple test, this may pinpoint a leak/trouble spot…

Moses

Another YJ 4.2L With ‘BBD’ Woes

From: Shawn B.

Sent: Monday, June 20, 2011 7:56 AM

To: 4WD Mechanix Magazine

Subject: vacuum hoses

Hello Moses,

I rebuilt my bbd carb yesterday on my 87 YJ l6. Everything went great until I went to put everything back in the engine. I hadn’t labeled my hoses and now can’t figure out which hose goes where. I don’t want to misplace a hose and destroy the engine!

I’ve looked at the vacuum hose schematic for this model but it is way too confusing for me. Is there a resource that has stock photos of all hoses and their placement?

Any help is appreciated!

Thank you,

Shawn

Moses replies…

Hi, Shawn…I was about to send a copy of the vacuum schematic until I read your comment about the confusion. I rely on these schematics; however, you do need to understand their “logic”.

Is the schematic from the factory manual? I can furnish a copy of the vacuum circuit from OEM data. One thing that helps when following the schematic is to understand the various components described. Also, the good news is that the hoses usually fall naturally within inches of their original hookup. You can use the schematic, become familiar with components, and note the location of the hoses. This will confirm their attachment points.

As for photos, you’ve made an interesting point. When I have access to a pristine example of the vacuum circuit on a real world 4.2L, I’ll video the hose circuits.

Still photos would not provide enough continuity to help here. It would be better to “trace” hoses along their paths, just as our eyes follow them…

If I can be of further assistance short of a video, let me know. I can decipher the components readily and describe what the schematic is trying to share. I will gladly copy the vacuum schematic from the OEM service manual if you need it, Shawn. Specify whether California or Federal emissions.

Regards,

Moses

Shawn comes back…

From: Shawn B.

Sent: Monday, June 20, 2011 3:42 PM

To: 4WD Q & A

Subject: Re: vacuum hoses

Moses, thank you for your quick response.

I’ve since properly hooked up the hoses. I’ve got a new issue now though.

The idle is rough, at about 400-500 rpms, I have to give it a bit of gas when I first turn it over. Once I get past 800-1000 rpms it’s fine and I can drive OK, but I can’t tap the accelerator too quickly, cause it bogs down. If I do that at a stop, it kills the engine. So I’m thinking it’s getting too much gas and getting bogged down. Would that be adjusted via the Idle mixture screws? I assume with the rebuild on the carb adjustments would have to be made and I thought I got everything correct the first time.

I replaced all those hoses we talked about earlier so none of them are leaking.

Any thoughts? Thanks in advance!

Moses replies…

Shawn, could be as simple as idle mix adjustment. If you built the carburetor to specification, it is common for the mixture to need adjustment. You’re likely too lean now. (The idle speed is too slow, too.) Do you have the factory adjustment steps? If not, I can walk you through it.

Moses

Shawn back again…

From: Shawn B.

Sent: Monday, June 20, 2011 6:14 PM

To: 4WD Q & A

Subject: Re: vacuum hoses

I don’t have the factory adjustment steps, and I would appreciate your help!

Thanks

Reply from Moses…

Hi, Shawn…I’ve scanned and attached the factory spec and procedures for adjusting the BBD idle and mixture. I included all carburetor specifications plus the idle speed and idle mix specifications.

On the “Idle Speed Specifications” (see page 5), the right edge of the page is cut off. The Sole-Vac Adjustment chart reads “OK Range” in the right column with +/-50 rpm described for both M and A. In the bottom chart, the “Idle Drop” for both manual and automatic transmissions reads 50 rpm.

The PDF will open in Adobe Acrobat or Adobe Reader. You can zoom-in to read text and see details.

Trust this helps…

Moses

From:Shawn B.

Sent: Tuesday, June 21, 2011 7:45 AM

To: 4WD Q & A

Subject: Re: vacuum hoses

Moses,

Thanks, the information helped. I tuned my idle mixture according to the specs you’ve given me. However, it still stalls when given gas too fast, or when in gear and wanting to accelerate from a dead stop. I’ve attached a video for your study.

Two things, I hear popping and sputtering while driving from underneath the passenger floorboard, could the cat be getting clogged?

In the video, that choke valve isn’t moving. Isn’t it supposed to?

Thank you again Moses for helping out this novice.

-Shawn

On Tue, Jun 21, 2011 at 10:24, 4WD Q & A qanda@4wdmechanix.com> wrote:

Hi, Shawn…How do I open the video ‘dat’ file? I use formats like ‘.flv’ (Flash video).

Regardless, the choke should be almost closed when completely cold; it should open fairly quickly with the key on. If you have the key on and the engine cold, the choke will open despite the engine temp. This can be confusing, as the engine will behave poorly due to no choke when needed.

If the choke is either closed, stuck open or opening too soon, you will have troubles. The popping and sputtering could be either too rich from the choke not opening or too lean from the choke being open with the engine cold.

The choke is electric. If you had the choke cover off, the spring might be out of position. Test it fully cold. Key on and throttle open to unload the linkage, the choke should open before your very eyes. First determine whether it is staying closed or stuck open.

Moses

On Tue, Jun 21, 2011 at 10:30, Shawn B. wrote:

I think it’s staying closed and running too rich as you suggested. Could the solenoid be broken? I’ll have to test it again when cold but I’m pretty sure it’s staying closed.

Sorry about the video file, I sent the wrong one… here’s a YouTube video link:

http://www.youtube.com/watch?v=resRiUTV7zc

And this is a video of me driving yesterday… the audio is of the catalytic converter popping, slowing down from 50mph and back up again. I think it needs replacing…

http://www.youtube.com/watch?v=h_k-dUaC2m0

Thanks again Moses.

From: Shawn B.

Sent: Tuesday, June 21, 2011 2:02 PM

To: 4WD Q & A

Subject: Re: vacuum hoses

Hi again Moses. I took a spark plug out and the tip is white. This means too rich, correct? Also, should I be replacing these if they are white?

I included some more photos and did as you suggested. I started it while cold and the choke was somewhat closed. It gradually opened as it warmed up, which is when the problems occur. . .It clogs up.

Thanks again.

Reply from Moses…

Shawn, the choke looks very normal: 1) nearly closed when cold; 2) immediately opens slightly as the engine starts and the vacuum pull-off works; 3) stands upright with the engine warm. If the cold position and pull-off opening gaps match factory specs, you’re good to go here. It appears that the choke opens completely when warm. Correct?

The spark plug is not oil fouled or showing rich running. Rich would be sooty with dark brown carbon, which also occurs with a stuck (closed) choke. Not the case here. These plugs are, however, long overdue for replacement with properly gapped new plugs. This could help considerably.

The YouTube video was helpful. Your nudging the throttle produced a response, which is a good sign and indicative of the accelerator pump working.

With the engine safely shut off, you can also check the accelerator function by opening the choke and opening the throttle from the closed to ¼ throttle position. Looking down the carburetor throat, you should see fuel spurting from the accelerator pump’s discharge nozzles. That being so, the engine sounds like very low fuel supply.

Low fuel supply could be a shallow bowl of fuel from misadjusted float levels. If you did not change the float adjustments much, that is unlikely. Low fuel supply can also be the result of a weak fuel pump. You can check pressure and volume as per the workshop manual. Even simpler, you can get these symptoms from a plugged fuel filter or kinked fuel line. Other causes include impaired EVAP hoses or a malfunctioning EVAP system.

If you did not change the fuel filter, do so. OE paper element filters can clog from just one bad tank of fuel. Water causes the paper to swell and block fuel flow.

Keep me posted!

Moses

Shawn back again…

On Fri, Jun 24, 2011 at 11:30, Shawn B. wrote:

Hello Moses,

I’ve since changed out the plugs, wires and fuel filter as suggested. A couple of the plugs weren’t even gapped anymore; they had some buildup between the post gaps. I thought this would fix things for sure, seeing that, but things actually got a little worse.

I at times can’t even start the engine without first depressing the gas pedal all the way. My only conclusion as you suggested is that the fuel pump is going out. This may explain the hesitation if I hit the gas too fast, which should respond immediately, but I have to go slowly otherwise it stalls out on me. Especially climbing hills or making a slow turn.

As far as the adjustments during the rebuild process, I hardly did anything. I didn’t want to change anything as I was afraid of screwing things up. So when I replaced certain parts, I didn’t adjust them as I probably should have. The float level I did adjust, so that the top was parallel to the top of the bowl. I may have to look at that again.

Thanks again for your time in trying to help me. Wish you were close by to help me with this but if I can’t get it fixed soon I’ll be forced to take it to a mechanic and unfortunately there aren’t many that I can trust. Mechanics often “find” things that have gone bad that otherwise would have worked just fine.

That being said, the jeep is running worse now with my own ministrations. 🙂

Hope to hear from you soon again,

Shawn

From:Shawn B.

Sent: Friday, June 24, 2011 12:51 PM

To: 4WD Q & A

Subject: Re: vacuum hoses

Update:

I adjusted the vacuum piston gap and that seems to have helped with starting. I broke down and took the Jeep to a mechanic, and after I explained the symptoms he told me right away that my float level was too low. So I’ll be adjusting that tomorrow when I can start early in the morning. It’s hitting a 100F outside so that’s a morning job 🙂 I printed out the factory specs for this model carburetor for float level and I’ll keep you posted once I have this adjusted.

Moses replies back…

Hi, Shawn…I mentioned the float level earlier…The engine is starving for fuel. You eliminated the other causes, like the fuel filter.

The float adjustment, by the book and specs I provided in the PDF, should do. Did your carb kit come with illustrations of how to adjust the float? Follow the details.

Here’s the philosophy: The likelihood of additional parts failing coincidental to work we perform is slim to none. If the fuel pump was okay prior to the carb rebuild, go back to the carb work before replacing additional parts. In an earlier missive, I suggested testing the fuel pump for volume and pressure. That can rule out fuel pump troubles. As a practical consideration, if “new” troubles develop after work done, look to the work done…

Case scenario: I’m currently experiencing an engine check light on our ’99 XJ Cherokee. A simple code reader (OBDII era magic) points to the upstream oxygen sensor. Now, I could race out and buy that sensor (at 135K miles, it’s likely defective), however, the cause can also be the oxy-sensor’s heater relay. So, I’ll begin by checking the oxy-sensor by the book—ohms resistance across the white poles. If that’s okay, I’ll check or likely replace the far less expensive relay. If neither appears the culprit, I’ll test wires for fatigue or opens…That’s systematic, I haven’t spent much yet, diagnostics. You’re in the learning phase of a process—automotive troubleshooting. If you like this kind of challenge, you’ll get better and better over time! I promise…

Regards,

Moses

Stumbling 2.5L TBI Four and a Long List of Solutions!

Reply from Moses:

My son-in-law has a stock ’87 YJ, originally equipped with a 2.5L/AX-5 like yours and a hardtop. The engine had a header, low-restriction exhaust and air intake modifications…A friend of his modified a 2.5L (later MPI version) with a turbocharger. Neither made impressive performance. We installed a 4.0L MPI six, and the Jeep works very nicely with 33″ tires and 4.56 gearing.

Considering the weight of a trail equipped YJ Wrangler (winch, bumpers, tire carrier, roof rack, oversized tires/wheels, possibly a hardtop, etc.), a smaller V-8 proves cost-effective. The later 5.3L Gen V-8 engines have been popular, and again, Advance Adapters makes the array of adapter pieces for a conversion. Either Ford or G.M., the efficiency of EFI/MPI makes a V-8 both practical and more likely to get fuel economy than a taxed, built up or turbocharged 2.5L four. The four would be an option only if weight could be kept to a minimum: a cloth top, vehicle stripped of any bulk, accessories at a minimum and so forth.

Ironically, the ’91-up MPI four has a higher horsepower rating than the later CJ and YJ application 4.2L sixes. Unfortunately, that rating is at a much higher rpm than practical, so the torque rating at a lower rpm makes the inline six superior. A swap to the 4.2L or 4.0L six does involve considerable work, since EFI/MPI requires a computer, harness and other parts in the process. By the time you do all of this, and fabricate motor mounts and an exhaust system, the V-8 is just as easy to install.

Moses

—–Original Message—–

From: Tim H.

Sent: Tuesday, May 10, 2011 1:58 PM

To: 4WD Q & A

Subject: RE: high and rough idle on 89 Wrangler YJ 2.5L

Moses,

I was curious if these 2.5L engines can be cost effectively modified for more horsepower?

—–Original Message—–

From: 4WD Q & A

Sent: Tuesday, May 10, 2011 11:20 AM

To: Tim H.

Subject: RE: high and rough idle on 89 Wrangler YJ 2.5L

Thanks for the compliments on the website, Tim…Nice feedback.

A Ford 302/5.0L engine from the 1989-up period would comply with emissions. I prefer the 351W MPI engines from Ford trucks. They offer efficiency and a stronger crankshaft design. Either is a relatively easy swap into a YJ Wrangler. (Again, Advance Adapters is full of insights and offers conversion parts.)

You need a complete engine with all emissions and computer, the same year or newer than your YJ, with all of the chassis components in place as well…Conversion wiring harnesses are available for the 302, not sure about the 351W.

Moses

—–Original Message—–

From: Tim H.

Sent: Tuesday, May 10, 2011 7:43 AM

To: 4WD Q & A

Subject: RE: high and rough idle on 89 Wrangler YJ 2.5L

My idea was to do a light weight swap with an engine that won’t require me to swap any of the drive train, etc, but give me enough power to run some bigger axles and tires at some point. I don’t have any desire right now to get crazy with this Jeep, but I would like to run up to 35’s. My eventual goal is to run something like a D44 in front and a Ford 9 in back. I watched the videos you did of the two brothers with the radically built YJ’s. Those would be fun Jeep’s to build. I also read your Stroker 6 article, which I would do in a heartbeat if I could drop $4K+ on just an engine swap.

Ultimately, I just want a simple swap to get a few more highway horses out of this jeep and still be able to stay compliant with Texas State Inspection laws.

By the way, I think you have a fantastic website and I thoroughly enjoy reading the information you have on there. I wish I had a fragment of your Jeep knowledge.

—–Original Message—–

From: 4WD Q & A

Sent: Tuesday, May 10, 2011 8:24 AM

To: Tim H.

Subject: RE: high and rough idle on 89 Wrangler YJ 2.5L

Check out the Advance Adapters catalogs for ideas. The Ford 302 is a compact V-8 and makes a good swap engine. With EFI, they deliver good fuel efficiency. This can be attained with a 2-barrel carburetor in good tune.

Any non-Jeep swap will require the parts I describe. EFI engines need a wiring harness and computer. There are aftermarket sources for EFI harnesses to facilitate these conversions. A V-8 is not a bad idea. Even a 6-cylinder Jeep engine requires motor mount changes in your frame, as the 2.5L models use welded motor mount brackets in a different location than the sixes. I have an article at the website on the 4-to-6 conversion, involving new weld-in mounts and such. The V-8 requires a few more considerations. A Ford 302 is a worthwhile consideration if you’re not happy with the 2.5L four.

Moses

—–Original Message—–

From: Tim H.

Sent: Monday, May 09, 2011 8:26 PM

To: 4WD Q & A

Subject: Re: high and rough idle on 89 Wrangler YJ 2.5L

I apologize for sending you the question about the 302, that was meant for another friend of mine that helps me tinker with this Jeep. I would be interested in hearing your thoughts though on the simplest and most cost affective engine swap I could do in this Jeep. I’ve been tossing it around for awhile now.

>On May 9, 2011, at 6:42 PM, “4WD Q & A” wrote:

> The TPS switch pivots around the axis of the throttle shaft, so it is

self-centering. Given that, the switch simply rotates clockwise or counter-clockwise within the range of the adjusting slots. The degree of rotation (either way) is determined by the voltage output. The switch must allow for full throttle opening and closure. Voltage should be within specs, with the throttle in the described position(s).

>

> As for the 302 V-8, this is a relatively easy swap that does require

adapters. The AX-5 is light duty and should be replaced with an AX-15 or equivalent manual transmission. If you have ideas of an automatic, the C-4 and Ford overdrive automatic are prospects. See Advance Adapters’ online catalog for ideas and costs involved. The $100 could easily turn into $1500 by the time that engine is in the chassis and running. Motor mounts must be fabricated, a radiator added, the adapters purchased, any driveline length changes made and the exhaust system fabricated, conversion throttle linkage, belts, hoses, etc. On second thought, try $2000 + $100.

>

> Moses

>

> —–Original Message—–

> From: Tim H.

> Sent: Monday, May 09, 2011 7:53 AM

> To: 4WD Q & A

> Subject: RE: high and rough idle on 89 Wrangler YJ 2.5L

>

> Thanks for all your help. Any tips on adjusting this new switch? It

> looks like the two screws can be used for either small, or larger adjustments.

>

> —–Original Message—–

> From: 4WD Q & A

> Sent: Monday, May 09, 2011 9:29 AM

> To: Tim H.

> Subject: RE: high and rough idle on 89 Wrangler YJ 2.5L

>

> Frankly, if this is the original switch, for $30 it would be a wise

investment to replace the switch. Yes, you should set the voltage for the new switch. Note that idle speed and smoothness are a good indication of correct settings…It does not take long to confirm voltage readings during the installation of a new switch.

>

> Let me know if this is the cure…

>

> Moses

>

> —–Original Message—–

> From: Tim H.

> Sent: Sunday, May 08, 2011 9:22 PM

> To: 4WD Q & A

> Subject: Re: high and rough idle on 89 Wrangler YJ 2.5L

>

> I followed the instructions per the attachment you sent on Friday.

> Since I checked the TPS several times with a Fluke Volt Meter and I did not get any readings across the jumpers, would you agree that it is probably bad? I think the part is about $30, so I wondering if replacing it would just be the easiest thing to do at this point. If I do go ahead and change it with a new one, will I need to adjust it afterwards?

>

>

>On May 8, 2011, at 11:06 PM, “4WD Q & A”wrote:

>

>> Tim, the 5.07V is normal for the lead voltage. The readings for the

>> TPS require jumper leads to apply hot voltage at appropriate terminals. If there is no voltage available, you will not get a reading. (The factory manual is vague on this point.) Normally, you fabricate jumper leads to provide live voltage.

>>

>> The DRB-II or DRB-III scanner tool will cut through these voltmeter

jumper tests. Dealerships use these scan tools, and there are aftermarket equivalents used by independent shops. If you cannot perform an accurate test with the jumpers and voltmeter, it might pay to have the system diagnosed with a scan tool.

>>

>> As for finding a TPS switch, NAPA/Echlin carries them, as do other

aftermarket retailers…This is a fairly common Jeep part for aftermarket sale.

>>

>> Let me know what you discover…I’m here.

>>

>> Moses

>>

>> —–Original Message—–

>> From: Tim H.

>> Sent: Sunday, May 08, 2011 7:42 PM

>> To: 4WD Q & A

>> Subject: Re: high and rough idle on 89 Wrangler YJ 2.5L

>>

>> It was a little hard getting to, but I checked it and double checked

>> it and I did not get any reading from it at all. I also checked the plug side just to verify I could get some kind of reading and I got 5.07v on both. So, nothing at all from the TPS itself. I called a local Jeep dealer and they can know longer get the part. Any suggestions on where to get it from?

>>

>>

>> On May 6, 2011, at 10:08 PM, “4WD Q & A”wrote:

>>

>>> Tim, the item you’re depicting is the ISA (idle speed actuator)

>>> motor, not the TPS switch. Look at the firewall side of the throttle shaft (opposite the cable end). That’s the TPS switch.

>>>

>>> I have attached a second PDF describing and illustrating the ISA

>>> motor and the TPS switch. Diagrams will clarify. You will find specs for adjustment/voltage readings in the first PDF.

>>>

>>> Let me know what you find…

>>>

>>> Moses

>>>

>>> From: Tim H.

>>> Sent: Friday, May 06, 2011 2:29 PM

>>> To: 4WD Q & A

>>> Subject: RE: high and rough idle on 89 Wrangler YJ 2.5L

>>>

>>> Moses,

>>>

>>> I’m at work, but I grabbed a Fluke 2 III Multimeter and went out to get some readings. I have the 2.5l, 4-cyl, with 5 speed manual trans. I have included a picture of what I believe is the TPS. It looks different than what is shown in the diagram for the Manual trans. In fact, it looks different than both diagrams actually. I’m not the original owner of this jeep, so I can’t say for sure if the motor is actually the original, or from another vehicle/year.

>>>

>>> On the left hand side of this 4 prong connecter is a silver looking

canister. You can see the throttle cable here and the throttle lever. The adjustment screw is about 1/16″ off the lever itself, so it’s not touching it at all basically.

>>>

>>>

>>> I went ahead and checked the voltage on the actual 4 prong connector (side with the wires), which I don’t know if it was the right thing to do or not. I apologize if I’m way out in left field here.

>>>

>>> I’ll wait to hear back from you before I go forward with anything else. I’m headed home now, so I will be in a better position to do more testing.

>>>

>>> From: 4WD Q & A

>>> Sent: Friday, May 06, 2011 12:10 PM

>>> To: Tim H.

>>> Subject: RE: high and rough idle on 89 Wrangler YJ 2.5L

>>>

>>> Hi, Tim…I happen to be near the computer, so I’m happy to reply. I’ll be back later today and will check for your update(s).

>>>

>>> Think of the TPS as a rheostat switch. The signal from the TPS

correlates to the throttle position. The voltage signal goes to the microprocessor or ECU/ECM. If you notice, there are two elements to

testing: the voltage reading from the switch and the throttle valve angle. (The throttle valve is much like a carburetor throttle valve.)

Since the system is electronic, the microprocessor or ECU needs a voltage reading to understand the amount of throttle opening. As the throttle valve position changes, the TPS tells the ECU how much angle there is on the throttle valve. The throttle is controlled by cable from the accelerator pedal.

>>>

>>> So, the tests and adjustments are to coordinate voltage output with the amount of throttle opening. If the switch is out of adjustment or defective, it will send an erratic or incorrect voltage signal to the ECU.

When you perform the test described, you are essentially coordinating the throttle valve opening with the voltage signal over the full range of throttle positions. Like a rheostat, this voltage changes as you open and close the throttle.

>>>

>>> Tools for this task are a quality digital voltmeter that reads in

1/1000ths of a volt and, if you pursue the whole test, a protractor to measure throttle valve angle.

>>>

>>> Try these tests to determine whether the TPS switch is defective.

Unless the two adjusting screws are loose (the TPS has slotted adjusting screw holes), the adjustment should be close to spec. If not, suspect the switch. Let me know what you find, Tim.

>>

>>>

>>> Moses

>>>

>>> From: Tim H.

>>> Sent: Friday, May 06, 2011 7:37 AM

>>> To: 4WD Q & A

>>> Subject: RE: high and rough idle on 89 Wrangler YJ 2.5L

>>>

>>> Moses,

>>>

>>> I’m pleasantly surprised that you responded. I really enjoyed

>>> reading much of the material on your website yesterday, so I was really hoping to hear back from you. Thank you very much for taking the time to respond. I’m not an accomplished mechanic by any means, but I understand the steps needed to test the TPS from reading your attached document. I was checking vacuum lines the other day and unplugged the TPS and noticed that there was absolutely no response from the engine while it was idling. I assumed that the switch was bad, but wasn’t sure how to test it. Now I understand. I also did not realize that it could be adjusted from either the top or bottom screws. What am I looking for when adjusting it?

>>>

>>>

>>> From: 4WD Q & A

>>> Sent: Friday, May 06, 2011 8:42 AM

>>> To: Tim H.

>>> Subject: RE: high and rough idle on 89 Wrangler YJ 2.5L

>>>

>>> Hi, Tim…You may have an issue with the Throttle Position Switch. I have attached the ’89 2.5L factory procedure for checking the TPS switch settings. (ISA and WOT settings are also discussed.) A defective switch will act up cold and hot as well. Confirm the switch condition and voltage settings.

>>>

>>> If the problem persists, let me know. I will take you to the next

level.

>>>

>>> Regards,

>>>

>>> Moses

>>>

>>> From: Tim H.

>>> Sent: Thursday, May 05, 2011 9:42 AM

>>> To: 4WD Mechanix Magazine

>>> Subject: high and rough idle on 89 Wrangler YJ 2.5L

>>>

>>> Hello,

>>>

>>> My ’89 Wrangler YJ 2.5L engine struggles for several seconds on a

>>> cold start before it finally catches and settles at around 900rpm. As it starts to warm up to operating temperature, the idle creeps up to around 1400 and is fairly rough sounding. I believe this is affecting how the vehicle performs overall as I’m driving. It seems sluggish and rough as I’m driving. I’ve noticed that it seems to get worse the hotter the temperature is outside.

>>>

>>> Thanks,

>>>

>>> Tim

>>>

>>>

Vexing Ignition Problems with an ’89 YJ Six

Hi, Rick…Sounds like you have a lifetime of exposure to the electronic side of this problem and a wealth of practical experience with ignitions. This must be frustrating!

Two areas that drew my attention were the distributor pickup and coil. The pickup is less likely a problem if the ohms-resistance checks okay. The symptom for the problem existed before the distributor change-out, anyway. According to your account, two coils made no difference, and you can ohms-test the original coil for an open when hot. I would do so to be sure this coil is okay.

There is an “open” in the circuit. Since this is a D.C. system, I would look for a ground problem first. Make sure the grounds from the battery to engine, engine to frame, and frame to body are each intact and read proper resistance. Another area of concern is the tachometer. Be certain that the tach is not defective and grounds are correct at the instrument panel.

You have replaced each of the ‘plug and play’ devices. Check harnesses for ohms resistance when hot to confirm opens in these circuits. I have encountered problems with crimp type, solder and Solid Seal type connections that open when warmed up. Another area of concern is the ignition switch connections and the switch itself.

Work your way through these suggestions, and we will pick it up from there. You need a constant, sufficient voltage to the coil with the ignition circuit “On”. There is a straightforward cure in replacing the distributor with a popular “HEI” type that has the coil built into the cap (G.M./Delco style). As long as you have a continuous, adequate amperage flow of current to the distributor, the unit will fire. Consider an HEI distributor the final approach if you cannot exact a fix otherwise.

You have replaced all of the parts integral to the ignition except the tach and ignition switch. There is very little else to consider…Check the ignition switch, switch wiring circuit and tach ohms readings. The test tool of choice is your ohm meter.

As you know, voltage is easy to achieve—amperage may not be. Check the ignition switch circuit: key on, key off and when in warmed mode. Ohms resistance between the key switch “ON” and the coil will reveal any defects in this circuit. A quick check without removing the switch is the “lamp test”. Use a fog or headlamp (higher amp draw) to make a 12VDC lamp tool. Use a lamp that will not draw more amperage than the wiring circuit’s gauge can handle. Create two leads, one a ground, the other one fused to prevent damaging any lighter gauge wire. You can quickly load and test the wiring circuits that terminate at the coil, module and other points. Compare the brightness of the various circuits with direct battery voltage. This will pinpoint circuit opens or voltage drops.

Let’s work our way through this one… Share your findings.

Regards,

Moses

From: Rick M.

Sent: Sunday, April 24, 2011 7:28 PM

To: 4WD Mechanix Magazine

Subject: 89 Wrangler ignition driving me nuts !

Dear Mr. Ludel,

Got a problem with 89 Wrangler ignition system. Has been to a local shop, spent hundreds of dollars, and problem still exists. Two weeks ago, engine quit on 16 mile trip home from work….a bang, two sputters, and quit. Would crank over fast, but no start. Pulled air cleaner and checked to see if fuel reaching carb (4.2L, wt/ aftermarket motorcraft carb..) and accel pump squirt was fine. Tried 4-5 start attempts, no-go. Had it flat-bedded to our local mechanic that the wife and I have used for years with total confidence. He put in an Echlin TP40 module and a NAPA remaned distributor p/n NRD 484691. (322.95 parts/labor). Went to pick it up and it wouldn’t start like before. He tried after my 4-5 attempts and it started right up, but his nest 5 attempts, same as mine.

He kept it overnight and put in a 2nd module. Started it next day and let it heat-soak. Passed several start attempts with no further probs at his shop. Strangly enough, he had cut leads off of Jeep harness at dist end and the module end. Dist p/u was soldered / heatshrunk onto mating normal 3 pin end. At the mod end, the original mod Two pin conn’r was soldered on , but the rest of the four wires were spliced directly into the jeep module harness leads. The purple lead was cut and shoved into the spiral wrap w/o a connection to the dist. No idea why he did this or how Jeep even ran as this is shown as the p/u negative lead. He relocated module to driver side fender well for ease of future replacement and to enhance cooling.

Brought Jeep home and after starting it, it quit on it’s own after 3-4 miutes. An inline spark tester reveals no fire. Run and start power o/k at module.

I went online and found wiring info for module and p/u and bypassed original orange lead from mod to p/u and added a new purple lead from mod to p/u after buying a new BWD CBE39P module from Advanced a/p. I also obtained the proper 4 pin mating conn’r and female contacts and wired this to Jeep side of 4 wire harness using the orig. black dist gnd wire and green/white (-) coil lead. Spliced opposite end of new wires onto dist p/u mating conn’r.

Everything ohms out…wiring, pickup, coil…Wiring has been restored so dist p/u and module are ‘plug and play’.

Got vehicle start

ed .on first attempt and it quit instantly after 2-3 minutes. Power to module run and start leads has been verified and are hot at proper ign key settings, with run power still hot with stalled engine and key on.

Coil ballast is new and coil recieves full bat votltage during start and about 9 1/2volts when running. followed green wire from mod and foud three wires spliced to it….one going to coil neg., at least one going to tacometer, and the third one unknown. I’ve lost he tach as expected, but Jeep fired up and ran for 20 minutes. Shut it down and started up several times, no prob., then 20 mins later, ‘no start’ again.

I am at my wits end. 59 years old, 43 years as an electronics tech…built a blown small block Chevelle and ran Pro bracket at the local strip. Have also built and flown my own ultralight airplane, 172 hours, and a Rotorway Scorpion 133 Full size experimental helicopter. I have at least $475 in this and feel it is going nowhere. The mechanic is swamped with work, and I have no clue how he will react plus I am not happy with the cut ‘n’ splice work he did……….

P.S. A new Duralast (Wells) C832 breakerless ign Coil also made no difference, so I re-installed the original coil marked for 12 volt electonic dist. use.

Any suggestions ? My last thought is that the dist p/u may be incompatable with the mod or has some type of thermal prob., even though it was supposed to be new with the reman’d dist.

No clue where to go from here. Any info or help will be greatly appreciated! I haven’t even blogged this as I figure that you guys are the true experts!!!!!!!

Rick M.

YJ 2.5L Engine, Tuning and Performance Quirks

Hello! First, thanks for the great books, Moses, and for answering my questions! To begin, Mopar used to issue a book on Jeep engines, and I’m not sure how to get a copy. Any idea where to get a copy? I have a 1989 Wrangler YJ with the mighty TBI 2.5L AMC four!—Brian L.

Brian, the book is Mopar Jeep Engines, Speed Secrets & Racing Modifications for Jeep-Built 4, 6 & V-8 Engines, published as Mopar part #P4529529. It covers AMC-design engines, winning formulas from off-road and compact truck racing of the late ‘80s. Compiled from factory workshop manuals and racing data, this is the only official reference to racing these AMC engines. If you cannot find a copy through used literature sources, secure a copy of the Mopar 1989 Jeep Service Manual, a two-book set that includes your YJ Wrangler.

Brian’s questions— continued…

My 2.5L has non-adjustable, stamped steel rocker arms. The Federal Mogul stock pushrods for this are 9.486″ length, and Clevite’s are 9.520″. What kind of lifter preload should I have when it comes to fitment of pushrods? I’m getting preload ranges from 0.085″ to 0.100″. It is my understanding that lifter preloads should be more in the 0.030”-0.040″ range, my reason for double-checking. The engine is a stock remanufactured long-block from ATK and now has 15K miles on it. The vehicle has just over 111K miles, and I installed the remanufactured engine at 97K. The camshaft is within a few thousandths of new specs for lobe height and duration. Questioning local engine machine shops has left me with a variety of answers, and I’m not too sure which ones to trust. (One shop reassembles everything and doesn’t check preloads.) It seems like this type of engine runs pretty warm although it may be just this particular unit. I have noticed that after 30 minutes or more of freeway driving, at idle, the oil pressure drops much lower (to 20-25 psi) than where it usually runs in town (40 psi). Bringing it just off-idle brings pressure back up to around 40 psi. It appears that this is due to the oil being so hot, as though its viscosity really thinned out temporarily. Once the motor idles for a while or is off for a bit, it returns and stays at the more normal 40 psi. Taking the vehicle on extensive or even moderate off-road use has the same effect in increasing the oil temp. When the engine gets this hot, and I notice the oil pressure, I can also tell that it is much more apt to want to knock/ping if I am doing something that requires mild lugging at idle. Is this high oil temp scenario typical for the 2.5 liter? Could the EGR valve and flame temps too high create abnormally high coolant and oil temps? I tried a new EGR valve, which didn’t seem to fix the temps. Should I install an oil cooler? The vehicle sees 90 degrees F to -45 degrees F. If an oil cooler is called for, which style may perform better: one with an electric fan and thermal switch or an older-fashioned unit with a built-in thermal valve assembly?

Brian, oil temperature does play a role here. The “normal” factory-rated oil pressure for a 2.5L four of your vintage is a minimum of 13 psi @ 600 rpm and maximum of 37-75 psi @ 1600-plus rpm. (Normal at an 800 rpm warm idle speed is 25-35 psi, which your engine may also achieve.) Despite the drop you describe at idle when hot, this is still adequate for lubing the engine. An engine oil cooler, unless thermostatically controlled, would be overkill in your cold winter conditions…If you do either kind of thermal control, make sure that there is no winter issue with oil temps being too cold…Also, if you want to know how “hot” the oil is actually getting, try using an infrared-sensing thermometer to check the surface temp at the oil pan after running. You can spot check the engine at the valve cover, block and timing cover. The block surface temp should pinpoint effectiveness of the cooling system. Check the radiator for hot spots or lack of flow, using the infrared to track heat…This can be a simple and effective diagnostic tool! As for the EGR valve, this valve actually lowers the upper cylinder temps if working properly. Its purpose, reducing the NOx emissions, demands lowering the upper cylinder temps to below 2500-degrees F. Without the EGR working properly, temps can reach 4800-6000-degrees F, much like an acetylene torch! I always recommend leaving the EGR in place and making sure it functions correctly…Pushrod lengths, which affect the valve clearance, are critical. (If needed, adjustable pushrods are available from Clifford Performance for the 4.2L inline six and other AMC-derivative inline engines.) There are two ways to measure lifter clearance: 1) preload, which is essentially zero valve lash with the plunger fully extended then add a fixed amount of compression of the lifter plunger and 2) lifter plunger travel, measured at the valve stem-to-rocker arm gap, with the lifter’s plunger fully collapsed. Non-adjustable stamped rockers usually can only be checked for lifter travel with the plunger collapsed. Correct specs for plunger or valve stem clearance (with the plunger collapsed fully) should be available through ATK or Clifford. Make sure you measure clearance at the correct reference point—specified typically as the valve stem-to-rocker arm gap with piston at TDC of its compression stroke, both valves closed and seated, the hydraulic lifter collapsed (without any oil in the lifter). Specified clearance should account for the valve rocker arm ratio. (The stock ratio is 1.6:1 for a 1989 2.5L Jeep engine.) The blueprint build of an AMC inline six or four should include cutting the installed valve stem heights to compensate for both the cylinder head resurfacing and the amount of valve seat inset from reconditioning the valve seats…A bled-down clearance of 0.085″-0.100″ at the rocker arm-to-stem gap is not out of the ordinary for modern hydraulic lifters. (Engines like Ford’s ‘FE’ big-block V-8s rely on pushrods in various lengths to correct lifter clearances.) Mopar manuals do not offer a specification; they assume that the cylinder head has not been surfaced excessively, pushrod lengths are correct, head gasket thickness is right, and the valve seat depths and valve stem heights are correct. It’s wise to confirm this and check actual bled-down lifter clearance if possible…Engines need adequate valve clearance to permit valves to seat. Shorter Federal-Mogul pushrods may be for remanufactured engines with a surfaced cylinder head and ground valves and seats. If your 0.085”-0.100” is clearance measured at valve stems-to-rocker arms with the lifter plungers collapsed, note that Ford ‘FE’ V-8s (with a 1.73:1 rocker ratio and non-adjustable rocker arms) call for 0.100”-0.150” gap at the valve stem-to-rocker arm with the lifter plunger collapsed. Ford FE pushrods come in different lengths for adjusting valve clearance.

Brian’s 2.5L tuning issues—continued…

I have found on this vehicle a normally energized-closed solenoid valve that controls vacuum to both the EGR valve and the fuel vapor charcoal canister. When I did the engine change, I put on a new EGR valve and replaced the rest of the engine sensors. Jeep discontinued supplying the G.M. Rochester vapor canister; it appeared to be intact. Recent troubleshooting led me to the canister’s vacuum-operated control diaphragm. It turns out that this little rubber diaphragm has holes in it from being 18 years old. With a breach in the diaphragm, the vacuum that is constantly applied at the canister purge port can leak through and back-feed through the diaphragm to the canister’s purge signal port. Instead of the EGR solenoid valve controlling the vacuum to the canister’s purge signal port, there was vacuum continuously coming from it. This was no real problem except that the EGR valve is also tee’d into the line for the signal port. When the canister back-fed vacuum, it constantly supplied vacuum to the EGR valve. This kept the EGR valve always on, during every aspect of driving. I don’t know how long this went on, but when I recently tested my EGR valve, it had failed. I have replaced it and now am shopping for a replacement canister. Even with the canister’s interlink to the EGR valve disabled so that the EGR solenoid controlled just the EGR and not the vapor canister, and even with a new Mopar EGR valve, the engine oil temp still gets so hot that it operates as I’ve described…

Brian, the EGR open at idle will dilute the mix and confuse the oxygen sensor into leaning out the air/fuel mixture…Such a lean mix can cause engine heat-up…This could cause the oil temp to rise, too. The EGR is a valuable device that lowers upper cylinder temperatures. It is also passive and has little impact on performance with the 2.5L four.

Brian added this question…

One last question that I don’t believe is related: This motor has vacuum fluctuations from 20″/hg to around 15″/hg. I can hear the idle hunt a bit, and see it on the tach—up to 200 rpm fluctuation at times, sometimes barely any. Any vacuum gauge sits there and flutters very fast. The vacuum flutter seems to narrow when the engine rpm is brought up, yet it still does it to some degree. After going through every vacuum line on the engine to hunt for possible leaks (hence finding the charcoal canister to be bad) and after double-checking intake and exhaust manifolds (the engine pipe and rest of the exhaust system are all new), I am unable to figure this one out. I have verified all my valvetrain to the point of degree’ing everything out, removing valve springs and checking stems-to-guides for any excessive wear, etc. Do I need to remove my exhaust manifold and check for cracks, as the factory manifolds love to crack at the Y’s, which are hidden by the preheat ducting? Is it possible that I am seeing the vacuum flutter from the power impulses since it’s just a 4 cylinder, whereas a 6 or 8 might be smoother? Would some small cracks in the exhaust manifold have any effect on intake vacuum?

Four-cylinder power pulses should not be a factor. Vacuum flutter can be valves that do not seat completely. This can cause engine heat-up as well. Pushrod length and/or valve stem length control the lifter clearance on the AMC fours and sixes. The rebuilder must restore lifter clearance, and if valve clearance is too close, valves will not seat, which worsens at higher engine temps…This can cause heat buildup and eventually burn valves and seats. The EGR not seating at idle/low speeds also causes a vacuum drop or vacuum fluctuation. Lean fuel mix, air leaks, ignition timing errors and degrees of spark advance will also affect vacuum. Ignition timing is electronically controlled on your engine, with sensors feeding input to the module. The oxy-sensor “averages” oxygen readings from all four cylinders and adjusts air/fuel ratio accordingly. 2.5L fours are reasonably smooth by nature and shouldn’t pulse or surge dramatically. This, again, points to dilution from the EGR or a vacuum leak, which can also be caused by an EGR that does not seat properly at idle. Make sure that the throttle position sensor is working properly and giving the right voltage readings from idle through open throttle…A defective TPS can cause idle roughness, fuel mix problems and tip-in issues.

Since you’ve ruled out valve timing and lift issues, the best diagnostic steps now would be a cylinder leakdown test (engine still, with each piston at TDC of its compression stroke). This will pinpoint any valve leakage or ring seal losses. Also check for intake manifold-to-cylinder head leaks and seepage at the throttle body base and shaft. Engine at idle, use a non-volatile penetrant spray; leaks will show up as a change in engine speed.