Retaining the OEM tank and adding a 75-gallon tank in the bed raises fuel capacity to 109 gallons. That’s enough “sticker shock” when filling up from empty at a diesel pump!

The Dodge Ram 3500 makeover focused on utility and the common interests of 4WD Mechanix Magazine’s viewers. High on the list of utility items was an auxiliary fuel tank to increase the truck’s diesel fuel range.

Having a 140.5″ wheelbase and Quad-Cab, the short bed 2005 Dodge has a single factory fuel tank with 34-gallon capacity. Even at an optimal 24 mpg (running without a load), the fuel range is 816 miles. On last year’s trip to Moab for the annual Jeep Safari, fuel costs en route varied 50-cents per gallon…Towing at 17-18 mpg, the stock tank’s fuel range required purchasing fuel at higher cost outlets.

Seeking a solution led to Transfer Flow, Inc., at Chico, California. Transfer Flow builds high quality auxiliary fuel tanks, precisely engineered and 50-State approved. The company’s primary market is commercial and recreational-use trucks.

Transfer Flow has an excellent approach to short box beds. One upgrade is a bigger under-bed replacement tank. An alternative is the auxiliary cross-bed tank that fits at the front section of the bed. A bed tank provides the best gains for the 2005 Dodge pickup.

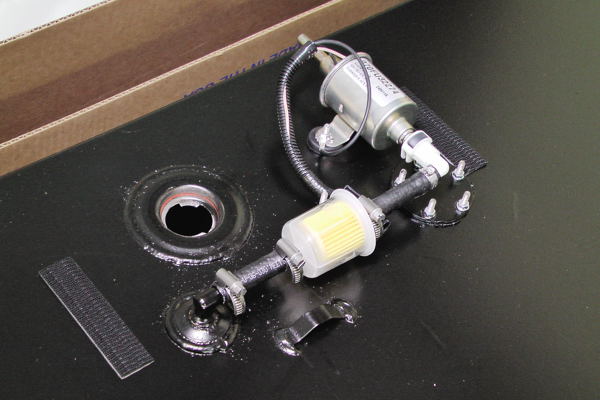

A unique feature of Transfer Flow engineering is automatic fuel transfer. The ‘Trax II’ monitoring system keeps tabs on both the main fuel tank and the auxiliary tank. At given set points, fuel transfers automatically from the bed auxiliary tank into the main tank. The fuel inlet junction is at the lower end of the OEM fill/overflow system. The main tank fills much like the stock method.

The electronically-controlled pumping system works great, without the need for manual switches or steady tracking of the fuel levels. The monitor, mounted at eye level near the windshield, continually reads the main tank level, auxiliary tank level, the combined fuel available, and whether the system is “O.K”. The monitor also signals when the transfer pump is active.

This electronic system troubleshoots itself and requires little maintenance. A common filter on the pump system is readily accessible. Periodic filter changes are simple. The balance of the system consists of the high-quality wiring harnesses and properly routed fuel lines.

Transfer Flow, Inc., will perform the installation at its Chico operation. We elected to have the company install the tank at the plant. Additionally, Transfer Flow now offers spray-in bed liners. (The Dodge Ram has needed bed lining since day one.)

Advanced bedliner materials and a state-of-the art application method encouraged us to have the new 75-gallon tank sprayed as well. These tanks are normally plated or powder coated in-house.

The plant visit provided an opportunity to tour Transfer Flow’s design studios and manufacturing facility. Transfer Flow uses state-of-the-art processes that reflect a work force with several engineers. Nearby California State University, Chico, provides interns and other resources.

Transfer Flow, Inc., specializes in auxiliary fuel tank systems. The company’s research and development does not stop there…Transfer Flow also works with advanced alternative fuel programs, including propane and bio-fuels. The company now offers classes in alternative fuel system technology, staying in step with the changing automotive environment.