The air compressor is the most important piece of equipment in our shops and home garages. Maintaining the air compressor includes draining the tank regularly. Moisture can damage the tank, compressor unit, air pipes and important shop air tools.

Quality air is also important. This means a dry and water-free air air supply. Spray painting, plasma cutting and bead blasting are operations that demand dry air. Air tools, oiled daily for service use, also benefit from a water and rust-free air supply.

Our shop air tools and the new tire changer have inline oilers. For other shop chores, the HTP Max Dry dryer systems can dramatically improve your spray painting, plasma cutting and bead blasting work. Episode 6 of Road Ready shares practical upgrades to your air system, including the installation of an automatic tank drain and the HTP Max Dry XXL dryer.

HTP Max Dry Dryers for Clean and Dry Shop Air

Whether you spray paint, plasma cut or run a bead blaster, your shop can benefit from clean, dry air. Our climate is dry, yet the amount of moisture in the compressor and air lines has been noticeable at each draining. An automatic drain, adjusted properly, will help eliminate compressor air tank moisture. This will also mean far less moisture in the air lines. For equipment that requires completely dry air, however, that’s not enough.

Our solution is the HTP Max Dry XXL air dryer system. Well constructed and based up the proven desiccant drying method, the system and desiccant will last considerably longer at our shop/studio. Intended use is not ongoing, though the Max Dry and Max Dry XXL systems will serve shops that do have daily dry air needs.

Note: Discussion with HTP/USA Weld determined that our common air tools, cleanup blower chores and airing tires does not demand desiccant drying if the compressor is drained regularly. You will see in the video coverage that some chores can get by with common water trap air filters. Our air tools are always used with an inline oiler. This means that the desiccant filter feeds the dedicated air supply at the single HTP Max Dry XXL’s air coupler. That air will be used for the plasma cutter, bead blasting and spray painting, each occasional use. Depending upon climate and usage, some shops may need the dry air for air tools and airing tires as well.

HTP Max Dry Dryer Specifications and Details

HTP America/USA Weld provides a wealth of customer support and product details. The best description of the Max Dry and Max Dry XXL design, function and usage is directly from HTP. Here are the details furnished by HTP America:

DESCRIPTION:

Max Dry and Max Dry XXL function as the ultimate air dryer/regulator and the perfect workstation dryer for the serious home or body shop. Humidity can wreak havoc on your air tools because, as air cools off down the line in your air hose, the humidity in the air condenses and turns into moisture, which creates headaches for you. The Max Dry and Max Dry XXL eliminate the humidity and moisture problem. (See how below.)

The Max Dry and Max Dry XXL provide a five-stage filtration process in an all-in-one unit. The first stage consists of a self-draining, 5 micron filter, which filters out, down to 40 microns, all liquid water, liquid oil, dust, dirt, rust, and pipe scale.

The second stage features a coalescing filter, which functions differently than a standard particulate filter. Air flows from inside to outside through a coalescing media. Small aerosols come in contact with the fibers in the media and unite with other aerosols caught in the fibers. The aerosols continue to unite and emerge as a droplet on the outside of the media, and gravity allows the droplet to drain away. The second stage filters, down to .03 microns, all oil mist, water mist, and submicronic particles.

The third stage separates our Max Dry and Max Dry XXL from all of the rest! Air enters the third stage and passes through a 70 micron filter, which evenly disperses the air through either a 2-quart (Max Dry, #25310-2) or a 4-quart (Max Dry XXL, #25310-1G) desiccant bed. The desiccant removes humidity from the air to a temperature of -3° F, which eliminates the possibility of any moisture condensing in your air lines and being pumped through your plasma cutter, sander, air ratchet, grinder, or spray gun. The Max Dry comes setup with 2-quarts of desiccant, and the Max Dry XXL comes with 1-gallon (4-quarts) of desiccant.

Best of all, you can reuse the desiccant. The desiccant is dark blue in color when dry and ready to absorb moisture, and then turns a clear, orange-like color after absorbing as much water vapor as possible. When the desiccant turns to a clear, orange-like color, simply pour the desiccant into a baking pan, pop the baking pan into the oven at 325° F, and bake for approximately one hour. The desiccant turns back to blue and provides you, once again, with clean, dry air.

Stage four and stage five consist of a final filtration and a precise regulator. The regulator accurately controls the secondary pressure between 2 and 125 psi, the self-bleed venting feature permits use on dead-end applications, and the inlet and outlet is 1/2″ NPT female.

The Max Dry & Max Dry XXL both have overnight drains. This means that when the compressor is turned off and there is no pressure then the unit will drain. If you do not turn the compressor off or if you have a lot of water build up during the day you might want to consider purchasing the automatic drain part number 25310-5300.

Inlet pressure rated at 250 PSI. Even though the regulator pressure range only adjusts from 5 to 125 PSI, the regulator can handle 250 PSI. Designed to flow 25 SCFM @ 50 PSI; if you run a higher PSI, then the SCFM will go down.

Warrantied for a period of one (1) year, from the original date of purchase, this warranty only covers against defects in material and workmanship. Replacement filters and repair kits are not warrantied items.

SPECIFICATIONS:

| Pipe Size | Model No. | Max Flow SCFM* | Max Flow SCF* | Desiccant Weight | Desiccant Charge |

| 1/2″ | 25310-2 | 15 to 25 | 5000 | 2-1/2 Lbs. | 2 Qt. |

| 1/2″ | 25310-1G | 25 to 50 | 12500 | 6 Lbs. | 1 Gal. |

*SCFM and SCF based on 70ºF inlet temp. @ 100 PSIG

Installing the Max Dry XXL Dryer

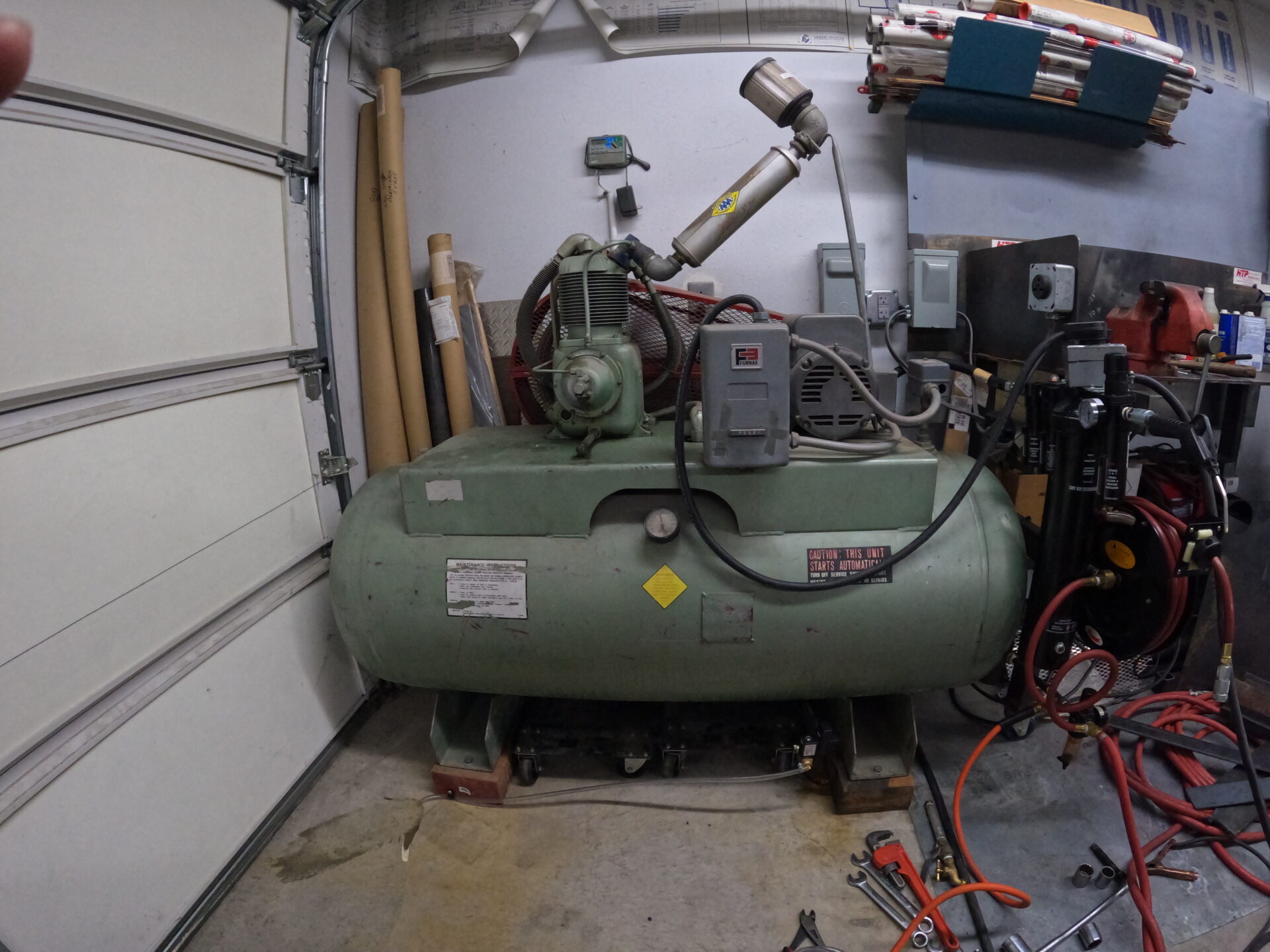

Compressors vibrate. Our industrial strength AirBoy with an R-15 Champion compressor, dual-belt drive, large fan flywheel and a 120-gallon horizontal tank vibrates plenty. It is advisable to mount the HTP Max Dry or Max Dry XXL away from this vibration.

At our shop/studio, the welding table/bench is adjacent to the air compressor. Metal side panels with sealing welds prevent slag, spatter or hot metal from reaching the compressor components and cables. This is an optimal location for mounting the HTP Max Dry XXL assembly. Separating the air tank from the filter assemble inlet is a Rapid Air 3/4″ low restriction jumper hose. The hose provides strain relief and eliminates vibration transfer from the air tank to the HTP Max Dry XXL’s inlet.

In the video, you will see our mounting method for the HTP Max Dry XXL assembly. A sturdy piece of 3/16″ channel was welded to the table. “L” brackets provided in the Max Dry the kit mount to the channel bracket with 5/16″ graded hardware. Space being limited in our shops, this mounting position is perfect, protecting the filters and our access to the single air coupler attached to the filter assembly. Our couplers and air plugs are low restriction 3/8″ size to match our 3/8″ air hoses.

This HTP Max Dry XXL has a one-gallon desiccant capacity, which will last for a very long time at our high desert climate and selective use of ultra-dry air. The addition of the Rapid Air™ CP-0177 automatic drain on the compressor tank will further reduce the desiccant’s exposure to moisture. We switch on the compressor and the automatic drain when using air tools, airing or changing tires, bead blasting, plasma cutting and spray painting. After switching off the air compressor, the automatic drain works intermittently for an hour or so before we shut the auto-drain off.

Getting the Most from Your Shop Equipment

Remarkably, our AirBoy and the Champion R-15 compressor, with two live air hoses and couplers attached, will hold nearly full air pressure for weeks on end. The compressor shut-off pressure is 148 psi. Setting as long as a month with two live hoses and air couplers attached, the pressure will drop no lower than 125 psi. This is the first compressor that has delivered this kind of sealing ability. Some of this is due to careful sealing at joints, which is emphasized in the video. We use quality couplers.

Though purchased used, the decades old compressor at our shop is in top condition. We intend to keep it that way for a long time! The HTP Max Dry XXL dryer will now provide us with dry shop air when needed while auto draining helps keep the tank from rusting. Other service includes routine compressor oil changes, a fresh air intake filter when needed and periodic checks of the belt tension and condition. These steps will extend the life of our air compressor. The dryer improves spray painting, bead blasting and plasma cutting chores, giving our shop more versatility.