Saginaw Rotary Valve Integral Power Steering Gear

The Saginaw Rotary Valve integral power steering gear is reliable and durable. Its serviceability is much easier than other designs. Like any automotive steering system, wear eventually leads to the need for at least resealing and ultimately rebuilding. There are exchange rebuilt gears available in the aftermarket and from OEM sources, yet many shops and DIY owners prefer rebuilding the original steering gear. Often, due to age and availability, this is the only assurance that the rebuilt gear is an exact match for the original.

For those servicing a leaking or worn GM, Jeep®, Ford, Chrysler or I-H Saginaw 800-type (four-bolt cover) power steering gear, the magazine’s exclusive “how-to” HD video provides step-by-step details for resealing or completely rebuilding the integral power steering unit. The steps focus on preserving expensive components and properly setting up the gear for superior vehicle handling/control plus a safe and long service life. Whether your gear simply needs seals or a complete and thoroughly clean-up, restoration and adjustment, the steps outlined within the how-to video are important.

Many of these steps and safety tips also apply to variations of the Saginaw power steering gears, including the 605 series and the later Delphi or Nexteer designs. This information and step-by-step details are now available for free, exclusively at 4WD Mechanix Magazine! Emphasis is on safety, the use of specialty tools and best practices for quality results. Rebuilding or re-sealing a Saginaw power gear? Click here to access the HD video!

History: Designs Leading to Saginaw Rotary Valve Power Steering

Long before the introduction of the Saginaw Rotary Valve power steering gear in 1959, Saginaw Steering Gear Division was well known for its patented recirculating ball-and-nut manual steering gear. Manual recirculating ball-and-nut steering first appeared in 1940 Cadillac models. Saginaw Rotary Valve integral power steering gears first appeared in the 1959 GM high-end “big” cars. Rotary Valve power steering replaced the short-lived recirculating ball “Inline” integral power steering gear.

Saginaw Inline power steering served the big GM cars of the 1955-59 era and GMC (not Chevrolet) light trucks. 1955-59 GMC light trucks were upscale during that era and offered a Pontiac/GMC V-8 option that could be easily fitted with a Pontiac-style power steering pump. Inline Power Steering of the 1955-59 era (Studebaker continued to use this Inline gear for a few years more) clearly led to the more modern and streamlined Rotary Valve Power Steering that dominated integral power steering design for the next half-century.

Footnote: The predecessor to Inline Power Steering was the pioneer Saginaw “Offset” gear of the early 1950s. Found on high-end GM cars, this gear does not use a recirculating ball worm design. Its layout is like a GM worm-and-sector manual steering gear with an elaborate and bulky power assist mechanism. The gear is quite large and was only used for a few years before the introduction of Inline power steering.

This mid-‘fifties Saginaw Inline gear involves the entire steering column and is typical of these 1955-59 Inline applications. In this design that predates the 1959-up Rotary Valve gears, many of the features that appear in modern Rotary Valve power steering (1959-up) are in place although somewhat primitive. This unit has an elaborate control valve and spring-loaded sensing system. The control valve is mounted externally. Rebuilders find the streamlined Rotary Valve gear with a stub shaft much easier to service!

This is just part of the elaborate adjustment process with the 1955-59 Saginaw Inline steering gear design. The sensing mechanism was complex. The successor design, the Saginaw Rotary Valve, revolutionized and simplified steering gear assembly and service adjustment procedures. The modern, 1959-up Saginaw Rotary Valve steering gears (popular four-bolt cover 800-series and round cover 605-series) offer much simpler setup and adjustment procedures.

Characteristic recirculating ball-and-worm feature is present in the Inline gear. However, compared to the Rotary Valve design that followed, this Inline worm-and ball mechanism is a much busier and more complex design. From both a manufacturing standpoint and for servicing in the field, the Inline gear was costly. Note that the sector shaft is not supported by roller bearings but rather by a traditional bushing (shown at right). These primitive bushings deliver far less service life than the Rotary Valve’s caged roller bearing. The Inline Saginaw gear is clearly a mix of old and more modern technology.

These Saginaw Inline gears were popular options on the GM “big cars” and even the GMC light trucks from 1955-59. The short history of its use provided engineering insights and led to the improvements that appear in the 1959 to present Saginaw Rotary Valve designs. Not surprisingly, the elaborate and awkward service features of the Inline gear were not appreciated by service technicians of the day. This unit depicted was a complete restoration project done to strict factory standards on my work bench in 2007. Cost of rebuilding with rare NOS parts was considerable. By contrast, a Saginaw Rotary Valve gear’s resealing and rebuilding can be performed for a small fraction of the cost and labor time. Service parts are still readily available for the Saginaw Rotary Valve gears.

Resealing and Rebuilding a Saginaw “Rotary Valve” Integral Power Steering Gear

Many makes of automobiles, light trucks and SUVs use Saginaw rotary valve integral power steering gears. The “700-series” and “800-series” plus derivative designs, including the “605” gears, each trace back to Saginaw Gear Division’s patented innovation, the recirculating ball-and-nut, worm and sector mechanism. The Rotary Valve design introduced in 1959 took steering gear technology to the next level and survives to this day. When resealing or rebuilding the Saginaw Rotary Valve integral power gear, the kind of parts to be replaced will be similar for all Saginaw Rotary Valve integral power steering gears. The OEM or aftermarket “complete rebuild kit” will include specific parts for the year, model and casting number of the gear on the workbench. When identifying a Saginaw power steering gear or ordering parts, be certain to note the year, model and, most importantly, the casting number of the steering gear being serviced.

The HD video how-to project’s prototype vehicle is a Jeep® YJ Wrangler. The YJ Wrangler’s Saginaw power gear shares features and service procedures with other Saginaw Rotary Valve integral power steering gear applications, specifically the 800-series gears. This includes common disassembly steps, inspection procedures and safety concerns that apply when rebuilding any Saginaw rotary valve integral power steering gear built from 1959 onward. The Jeep® YJ Wrangler gear is the popular four-bolt cover or “800 Series” gear design. The procedures shown in this how-to video provide basic steps and concerns plus the in depth details for working on this design of the Saginaw Rotary Valve power steering gear. The information also proves helpful for rebuilding any Saginaw derivative power steering gear, including the round sector cover “605” style gear.

Note: When rebuilding a Saginaw 605 gear, refer to the rebuild kit details and factory service manual steps and specifications that apply specifically to that gear. The magazine’s how-to video is in-depth and specific to the 4-bolt cover or 800-series gear. Many of the general steps and safety concerns do, however, apply to the 605 gear.

Adjustments can be readily performed on the Rotary Valve Saginaw gears. Care taken here can provide many years of safe and reliable service.

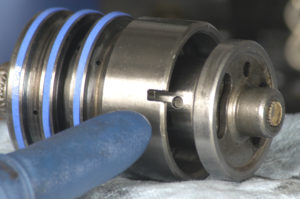

Features found in the Saginaw 800 gear design, like the valve body and stub shaft shown here, are common to other Saginaw Rotary Valve units. Precise machining requires proper assembly to avoid damaging these components. The how-to HD video available at the magazine details best practices for safely and correctly assembling a Saginaw Rotary Valve power steering gear.

Key distinctions when ordering parts are the power piston bore size and the shaft or seal diameters. When setting up a Saginaw integral power steering gear, always use the torque tightening and adjustment specifications for the specific year, make and model vehicle. The casting number on the steering gear housing is a significant identification feature for any Saginaw steering gear.

Wide Use of Saginaw Rotary Valve Integral Power Steering Since 1959

The Rotary Valve power gear with its tough recirculating ball design offers a much improved power piston/rack. These Rotary Valve gears have delivered optimal service and performance in passenger cars and light trucks. Rotary Valve engineering was first put to the off-pavement test in mid-‘sixties Jeep® 4x4s. Since its introduction in GM’s big cars in 1959, the Rotary Valve gear has now delivered superior technology and reliability for more than a half century.

Rotary valve design eliminated a large number of components found in the earlier Saginaw “Inline” power steering gear. This is the simpler rotary valve and valve body and approach. (For a comparison to the earlier Inline gear, see the illustrations above. Be glad you’re working on a Saginaw Rotary Valve steering gear and not the Inline!)

Rotary Valve integral power steering also put an end to the use of linkage type power steering. By 1965, all GM car lines offered a Rotary Valve integral power steering option. Chevrolet and GMC 2WD light trucks soon optioned these gears. By the end of the decade, GM’s 4×4 light trucks, the last GM vehicles to use linkage power steering, abandoned linkage type power steering. Saginaw’s Rotary Valve integral power steering became the mainstay option for GM light trucks.

Footnote: Oddly, GM’s own 4×4 trucks lagged behind Kaiser’s Jeep® Corporation. By the mid-‘sixties, Jeep® had the foresight to retire its linkage type power steering option. (This was a dated Gemmer worm-and-roller manual steering gear with power assist on the steering linkage, an approach that was popular with Ford cars and 4×4 F-trucks as late as the ‘seventies.) Saginaw Rotary Valve integral power gears, found in GM cars at the time, became an option for the Gladiator J-truck, Wagoneer (FSJ) and the new Jeepster.

General Motors’ Saginaw Steering Gear Division (renamed “Saginaw Division” in 1985) built its patented recirculating ball-and-nut manual and integral power piston steering gears for GM car and truck brands as well as Kaiser’s Jeep® Corporation, AMC/Jeep®, Chrysler/Jeep®, Dodge and Ram trucks, International-Harvester (I-H light trucks and the Scout/Scout II) plus Ford SUVs and light trucks (2WD and 4×4).