Q&A: Willys, Jeep CJ and Jeepster Fuel & Spark Answers

Enjoy the many detailed, traditional ‘Q&A’ exchanges in these article columns…’Q & A’ has now moved to open, interactive forum discussions. Visit the forums, you’ll want to join—for free!

Have technical questions about your Jeep 4×4, popular 4WD truck, SUV, ATV, UTV or dirt motorcycle—or welding and metal fabrication? The 4WD Mechanix Magazine ‘Tech and Travel’ Forums now feature enthusiastic discussions and input from members and our staff—including comments from Moses Ludel…

For an HD video playlist, featuring the latest Q&A vlogs with Moses Ludel, click here for the “4WD Vlog and ‘Live Tech’ Q&A Channel”.

Want to discuss your technical and outdoor interests with like-minded enthusiasts? Check out the 4WD Mechanix ‘Tech and Travel’ Forums! Click here for a guest visit to the forums!

From: John N.

Sent: Thursday, November 29, 2012 1:41 PM

To: 4WD Q & A

Subject: Holley 1920 for Jeep six

Hi, Moses,

Been a while since we last E-mailed. Hope you had a nice turkey day vacation and are enjoying good health.

Have completed the A999 installation in my CJ7, and it is a pleasure to drive. Ceena now tries to monopolize the Jeep!

Have you ever heard about using a Holley 1920 one barrel carb on a 258 CJ7 as a replacement for the troublesome Carter BBD?

Best regards,

John N.

Hi, John…Good to get your note…Glad the CJ is working well with the 999 automatic transmission!

I have an in depth step-by-step at the magazine on setting up a BBD carburetor. My experience has actually been good with the BBD, especially on engines that require emission compliance and the range of BBD features (like the Sole-Vac stepper for fuel metering and so forth). They worked okay when new. We took new CJs and YJ Wrangler 4.2Ls with the BBD onto the Rubicon Trail…Perfect? No, but they did function. I would attempt a BBD rebuild before opting for a retrofit.

The Holley 1920 is an okay carburetor dating to the ‘Fifties/’Sixties, and I worked with many of them as a light truck fleet mechanic in the late ‘60s. Ford and I-H were fond of this carburetor for inline sixes, and my fleet responsibilities included many inline sixes in surplus Ford, G.M. and I-H truck models.

All Holley carbs are altitude sensitive, and like the 2300 2-barrel and other end-bowl Holleys, the 1920 has bowl/float quirks that can create real problems on a side-slope. They require jet changes for as little as 1,500 feet of altitude change—or will otherwise suffer from poor fuel economy and flooding.

You’re at a variable altitude zone and would be better off with a swap I did for my Jeep Owner’s Bible: a genuine OEM 2300 series carburetor from a 266 I-H V-8. This is a rare carburetor but has nearly ideal jetting, plus the right metering block and power valve. Do not attempt use of a 350 or 500 CFM Holley “universal” 2300 carburetor, they cannot be brought into A/F balance for a 4.2L Jeep inline six!

If you’re curious, I changed the main jet sizing (slightly) in the I-H 266 V-8 version of the 2300 to compensate for altitude—nothing more than an idle adjustment beyond that…I used a two-barrel to two-barrel adapter for the BBD intake pattern. It worked nicely, and this application carburetor actually came in manual and automatic choke varieties…If you have my Jeep Owner’s Bible, note the comments about this swap.

Otherwise, if you can handle the cost, the Howell EFI system will provide far more return and driving satisfaction. I recently did a pilot project with the new MSD Atomic EFI. (See that coverage at the magazine site for details and ideas on EFI alternatives.) However, that system is neither emission compliant (no California E.O. as of this date, though we did achieve a Smog Check tailpipe reading) nor does it currently offer the bolt-on ease of a Howell EFI package. MSD is in the price range of the Mopar EFI/MPI conversion—which I have promoted for decades…

I have a plate full, or Tierra Del Sol would be fun. I covered that event in the late ‘80s, when we lived at San Diego County. Almost went last year. It will be a good way break up your Lamoille winter! I do the Moab Jeep Safari, an industry “must”, and I do look forward to Moab…On that note, perhaps we could grab a cup of coffee at “Cowboy Joe’s” in Elko when I pass through on the way to Moab…That’s a definite stop en route!

Keep me posted, John…I always enjoy news from Elko County…Still plan to get out to your area for recreation and HD video travel footage!

Best at the Holidays,

Moses

Solex Carburetor Needle-and-Seat Pressure

From: Raymond

Sent: Monday, October 22, 2012 6:08 PM

To: 4WD Mechanix Magazine

Subject: solex carbs on Jeep L/F head motors

the instructions and a number of articles i’ve seen claim a fuel pressure regulator is required when installing a solex. some mention articles even had pictures of completely installed, ready to run solex carbs, but no regulator anywhere. most blog and forum writers claim either one is not needed or have tried that dial type regulator but had it crap out in only a short time. the Holley adjustable is heavy, hard to find a place for, and a bit expensive. so thoughts…….

Raymond

Hi, Raymond…There is a needle-and-seat pressure recommendation for the Solex carburetors, like Weber and any other carburetor. The best approach with a Weber is to search the aftermarket product listings. I’ve found these in the past.

As for Solex, the same rule applies. If the carburetor is an OEM replacement, find the OEM application and note the fuel pump pressure rating for that engine. If aftermarket, seek the product’s recommended pressure range. An alternative is to try the existing fuel pump pressure and see if the Solex needle-and-seat will tolerate the pressure. If too much pressure, flooding and fuel enrichment will occur; too little pressure may not unseat the needle. Typically, vintage Jeep fuel pumps are not high pressure designs.

I have used pressure regulators with success. You’re right, some are cumbersome and require elaborate plumbing. Check out Summit Racing’s online catalog, they deal with pressure regulation on a variety of levels.

Keep in mind that many pressure regulators do not have check valves. This means that they require a steady, consistently pressurized flow of fuel (like a gear/rotary or vane type pump or a rapid pulsation pump). If a mechanical, diaphragm fuel pump stroke is slow or has a pause, some regulators will not be able to sustain a given pressure. In any case, a mechanical pump’s check valves must work properly.

Let me know what you find…

Moses

50-State Legal Distributor Upgrade for 258/4.2L Jeep Inline Six

From: Rick C.

Sent: Tuesday, September 04, 2012 9:06 AM

To: 4WD Mechanix Magazine

Subject: distributor

I Have a 1980 jeep with a 258 staight six and would like to upgrade to a HEI distributor. I live in California and need a CARB compliant distributor. Can you reccomend some?

Thanks,

Rick C.

Yes, Rick…MSD’s 8516 Pro-Billet unit is 50-state legal. It does require an MSD 6-series matching digital box, too, click here for details from MSD! A Blaster 2 coil is also 50-state legal and recommended… Contact MSD for details.

DUI also has an HEI for the Jeep 258: http://www.performancedistributors.com/amcdui.htm. Check to make sure this is 50-state legal, I do not see a CARB E.O. number mentioned.

Trust this helps…I’m here if you have further questions…

Moses

Mopar EFI for a 1974 4.2L Inline Six?

From: Bill K.

Sent: Wednesday, April 18, 2012 9:07 AM

To: 4WD Mechanix Magazine

Subject: 1974 EFI upgrade?

Hello Mr. Ludel,

My name is Bill and I would like some information please. I have a 1974 CJ5 with the original 258-six, T-18 tranny, Dana 20 tc, Dana 30 and Dana 44 axels and no power steering or brakes.

My question is this: Would the Mopar 4.0L EFI upgrade work for this 1974 block or would the engine itself need to be upgraded to a newer vintage before the EFI unit would bolt on? The current 1974 engine would be rebuilt at the same time of course.

Thanks for your time,

Bill K.

From: “4WD Q & A”

To: Bill K.

Sent: Wednesday, April 18, 2012 9:19:15 PM

Subject: RE: 1974 EFI upgrade?

Hi, Bill…Your goal is sensible. The concern is intake port/manifold matching. I have done this EFI swap on ’81-up 258s, using the Mopar EFI Kit, with great results. However, the HESCO listings say the Mopar EFI Kit will only fit back to ’76. Why, I’m not clear, since the intake/exhaust ports on 1971-80 AMC 4.2L/258s all use the same intake/exhaust gasket set. Ignition distributors are the same fit from the 232/258 to the 4.0L.

4.0L sixes use a Hi-Port intake arrangement from 1991-up, yet the Mopar EFI kit is patterned from this engine era (1994-95 YJ Wrangler, originally). The issue seems to be the exhaust manifold and header choice, in particular which exhaust manifold will work with the Mopar EFI kit or 4.0L intake manifold.

What you apparently need here is: 1) intake and exhaust manifolds with ports that line up with your 258 head design, 2) an exhaust header that will be compatible with both your head and the 4.0L MPI intake system, and 3) cylinder head fittings and ports to accept the necessary accessories in the Mopar EFI kit.

My suggestion would be a call to HESCO’s tech line, phone (205) 251-1472, with these basic questions. Ask why the 258 is listed back to ’76 and not ’74. (There may be a cylinder head difference.) Ask whether the kit will fit your engine/head, and if so, what exhaust manifold, manifold stubs and hardware do you need to complete this installation.

HESCO has a forum, which like others on these topics, is from the lay level and can lead to more confusion than answers, but here it is:

http://www.hesco.us/forum/forum_topics.asp?FID=3&title=jeep-mpi-kit

I would like to know what HESCO shares. Your question and the 4.0L cylinder head swap to the 258 block question are common. HESCO is a higher level source, they developed the EFI conversion kit with Mopar; if contacting HESCO does not prove useful, contact me again. I’ll research head castings and engineering changes between your 1974 engine and the 1976-up 258.

Regards,

Moses Ludel

From: Bill K.

Sent: Thursday, April 19, 2012 9:45 AM

To: 4WD Q & A

Subject: Re: 1974 EFI upgrade?

Thank you for the speedy reply. I’m…. impressed. I’ll check with Hesco and see what they say. Clifford Performance has some interesting approach to upgrading the 258 as well. Although, perhaps in a more traditional way. Haven’t really made up my mind which way to go. But, again, thank you for the response.

Regards,

–Bill K.

Bill, I did not mention Clifford; however, if you are considering carburetion, they have a lot to offer. Also, MSD introduced the “Atomic” system at SEMA, and this looks promising—perhaps on a Clifford intake manifold for better intake flow, and add a header…? Let me know your thoughts and findings. This is all very topical now.

Regards,

Moses

Mopar 4.2L EFI Conversion and the 4.0L Inline Six-Cylinder Head

—–Original Message—–

From: John M.

Sent: Friday, July 01, 2011 3:32 PM

To: 4WD Mechanix Magazine

Subject: Jeep 258 head swap

Hello, I am researching swapping a 4.0 head and EFI onto my 72 CJ 258. Do you have any details of this on your website? I have a ’79 CJ that my son and I did a complete restoration in 2008. I purchased both of your books, and they were great help.

Thanks,

John M.

Hi, John…If you have my Jeep CJ Rebuilder’s Manual 1972-86, I included details on the Mopar EFI conversion. The 4.0L cylinder head has extra cooling ports and must be modified to fit a 4.2L/258 cylinder block. Valvetrain and pushrod design must also be considered, as AMC uses pushrod length to set the lifter clearance on engines without adjustable rocker arms.

The easier route is to use your 4.2L cylinder head with either the Mopar Performance conversion or, if you’re on a budget and want to pursue it, use a 4.0L (1991-up) MPI intake and all the factory parts that make up the Mopar EFI conversion. The latter route (piecing together your own system with OEM parts) requires the aftermarket TDC crankshaft pickup or a 4.0L flywheel and bellhousing changeover, plus fabricating/mating a wiring harness and several other rabbit holes that you can go down. On that note, there is not a 4.0L factory bellhousing that resembles your OE transmission’s face pattern. Advance Adapters does make a conversion bellhousing that has a pickup provision, but this is still work and extra parts.

When Chrysler/Mopar Performance first offered the EFI/MPI conversion, it was a TBI system with aftermarket parts. The next and logical step was a 50-State legal MPI system patterned off the 1995 YJ/XJ 4.0L components. The simplicity and virtues of off-the-shelf parts makes this a very good approach. These kits were followed by a ’97-up single fuel line system, and that kit is also relatively easy to install. All of these pieces work with a 258 cylinder head, as by good sense, AMC maintained the same manifold-to-head configuration from the 258 to 4.0L transition. You do have the earlier 258 head, so take the time to confirm the intake/exhaust gasket similarities.

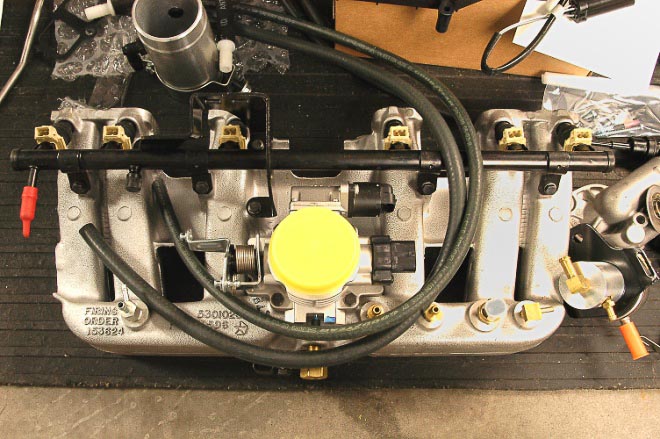

I believe the cost of the conversion kit is justified by the considerable time saved, the fact that all wiring, the high-pressure fuel pump, the induction system, air intake and sensors make this a virtual turn-key approach. I’m especially drawn to the OEM parts and diagnostics capability. The current kit is actually OBII era components. You can get a trouble code from these PCM units (included, too!), as the supplied wiring harness has that provision. The kit includes the distributor, coil, injectors, rail and pressure regulator, sensors and other needed items.

For use on a ’72 258, you will need to plumb the exhaust head pipe for an oxygen sensor. This is a non-issue, bungs are available readily, and any muffler shop can install the threaded bung. (You can, too, if you MIG weld.) Of course, there is time and work involved in any conversion, but the gains are really worthwhile; there is nothing better than MPI. A TBI alternative does not provide the uniform fuel distribution per cylinder, which is even more noticeable with an inline six.

While the 4.0L head does offer flow and combustion chamber improvements, a 258 head is more than adequate for normal highway driving and any kind of trail use. The alternative is a 4.6L stroker engine build, using a 4.0L block and heads, a 258 crankshaft and the Mopar EFI conversion kit (or combination of recycled parts and some pieces from the Mopar kit). Since you have already restored the ’72, including the engine presumably, you are probably not in the mood for scrapping the 258 long block.

One cautionary note: I would keep compression at 8.5:1 to 8.7:1 maximum for use with the MPI conversion. Otherwise, you will be running 91-octane fuel to overcome detonation with the leaner, factory-programmed mix and a 258 cylinder head. (This is a footnote that comes with the ’81-’90 4.2L Mopar EFI conversion kit. Mopar Performance recommends 91-octane fuel and a 195-degree F thermostat for complete combustion at a stoichiometric air/fuel mixture of 14.7:1.) There is minor room for timing retard/adjustment, done through the PCM. At Denver and in the Rockies, detonation should not be an issue, as the atmosphere will in essence reduce your compression. 87 to 89-octane could work just fine at your altitude.

Look at the system in my Jeep® CJ Rebuilder’s Manual…This is Mopar’s ’95 4.0L MPI prototype, the current Mopar Performance kit is similar but with single rail fuel supply…If you have further questions, I’m available!

Regards,

Moses

John M. comes back…

From: John M.

Sent: Tuesday, July 05, 2011 10:56 AM

To: 4WD Mechanix Magazine

Subject: Re: Fw: Jeep 258 head swap

Okay—I think you have talked me into the Mopar kit. I am slightly curious on the 4.0 head swap. I did do a full rebuild on my 258 with about 2500 miles, so everything is tight. If the 4.0 head would add another step increase in performance/hp/ mileage I would consider though. If you can elaborate a bit more on that idea, I would appreciate it.

Do you have a recommended source for the MPI kit? I understand I will need a new front damper on my engine—do you have a part number for this unit?

Thanks—I appreciate your help and response.

John M.

Moses replies…

Hi, John…The Mopar Performance kit should be available through Mopar dealers and Jeep dealerships. 4Wheel Drive Hardware and HESCO have been parts suppliers as well. HESCO did some of the development work.

With your full rebuild and recent cylinder head work, I would not bother with the labor and parts involved with head swapping. The 2000-up 4.0L head has small valves; previous 4.0L heads offer some gains in combustion chamber design and resistance to detonation as I have shared. Claims of a “40 horsepower gain” sound extreme, I’d like to see dyne results. Later smog era 258/4.2L sixes have a 110 horsepower rating stock…That’s a 36% increase in power from a change in combustion chamber and port design. EFI/MPI port fuel injection is another story. A 50-plus horsepower gain is possible.

I would bring into the equation combustion chamber size. Keep in mind that the 258/4.2L has a longer stroke and more displacement. This means that if the combustion chamber for a 4.0L engine is too small, there will be an increase in compression, not a good idea with regard to detonation. I would compare chamber cc’s before plunging into this one in any case.

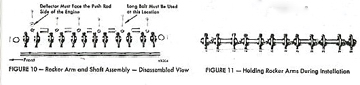

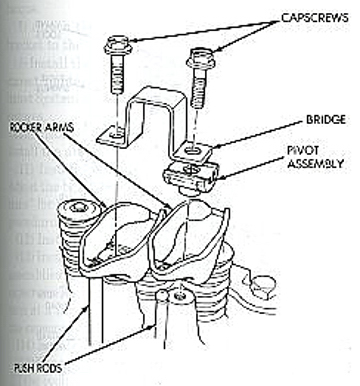

While some convert these heads by using the right cooling port plugs and even a complete 4.0L “head kit” available through various sources, there is a real issue with oiling the rocker arms. Later 258 and all 4.0L engines oil through the lifters and pushrods. The 1965-72 AMC 232 or 258 sixes, and the early 1974 engines (not the 1973 engines), have a pressurized rocker shaft oiling system. The 1973 and late-’74-up engines oil the rocker arms through the pushrods. You have a 1972 CJ, and if the engine is that origin, the 4.0L head will have no provision for oiling the rocker arms. This is an issue!

Note: The 258 first appears in 1971 AMC references, using a “type one” cylinder head with a rocker shaft (above). Back and forth AMC parts availability clouds the head applications from 1972-74. The distinction is a rocker shaft with cast rocker arms versus canoe-type pedestal rocker arms (below illustration). 1975-up 232-258-4.0L use the basic design below.

For the engine speeds involved in normal highway and trail running, and considering your primary driving venue at Colorado, I see little incentive to change the head. I would stay with the 4.2L/258 head and concentrate on installing the Mopar EFI kit. Below is one source for the kit from 4Wheel Drive Hardware. There are kits for automatic and manual transmission, each referenced as “1981-90” model year but suitable for use back to 1972. Below these listings are the vibration dampers, one for automatic transmissions, the other manual transmissions. All part numbers are official Mopar Performance product numbers:

Click here for access to the section on Mopar EFI at 4Wheel Drive Hardware!

Note the additional mounting kit for the damper when used on a 1972 engine. There is also the Howell TBI system described, an alternative if cost is critical. If affordable, MPI is superior to TBI.

Regards,

Moses

John comes back…

From: John M.

Sent: Thursday, July 14, 2011 8:24 AM

To: Moses Ludel

Subject: Re: Footnotes from Moses…

Thank you Moses – I did actually purchase a ’95 4.0 head that had a complete valve-job just completed and had not been installed—so is was definitely going that way! Thanks for the follow up—maybe I should sell the 4.0 head and just go with the original 72 head?

My jeep is a ’79 but the engine is a ’72 from the casting code “410 A 18” on the side of the block. You are right—I was a bit mesmerized by the “40 hp gains.”

I did order the Mopar MPI kit and should be here next week. I appreciate your thoughts and welcome any others you may want to share.

Thanks, John

John, glad I brought the oiling issue up. You would have gone down the rabbit hole on that one. So much for anecdotal enthusiasm on the forums, you can wind up way short of facts.

Although there are gains in the 4.0L head design, we’re talking about a low-speed engine for all intents. AMC was not that off the mark in 1972, it’s ridiculous to assume a cylinder head in that era flowed “badly”—realistically, the 258 head was somewhat less efficient than a 4.0L head; the older heads were prone to detonation due to less efficient combustion chambers.

AMC’s aim was quick torque rise and fuel efficiency, always gained by the highest manifold vacuum at real operating speeds. Frankly, for me and others familiar with the 4.2L, the bore/stroke of the 4.0L was a great disappointment in terms of tip-in performance and speeds under 2,600 rpm. The 4.2L reaches its peak torque by 1,600-2,000 rpm (depending upon year and tune). This rivals a 5.9L Cummins diesel’s torque rise and peak at 1,600 rpm!

The weak link of all inline carbureted sixes with a centrally located one- or two-barrel carburetor is the induction system. I had many discussions with the late Jack Clifford (Clifford Performance) on this very topic. His ram induction manifold for the 4.2L claimed major horsepower gains through more uniform distribution of fuel/air volume to individual cylinders. You’re way beyond this with the pending electronically managed fuel-and-spark system: MPI for the most part eliminates any differences in A/F or volume per cylinder!

For off-roading, the performance you want is bottom end, quick torque rise and a nice ceiling in the 4,200-4,500 rpm range, each characteristic of the 258 bore/stroke and cylinder head design. If I were doing a stroker motor (4.6L or 4.7L) with the oversized 4.0L bore size and 4.2L stroke, I would use the 4.0L cylinder head.

I have always run a late tubular OE exhaust manifold with these Mopar EFI conversions. Either the stock stainless OE or a Borla makes the best sense. There are gains in performance here, as the OEM iron manifolds are a hindrance. Make sure port shape and gaskets match up to your cylinder head.

Won’t it be nice to concentrate on the induction and exhaust installation and not have to remove that bulky cylinder head in the chassis? You’ll be very pleased with the outcome here, and I predict 87-89 octane will work without detonation at your altitude and manifold vacuum.

Keep me posted. I trust you’ll get a sensible deal on the Mopar MPI/EFI kit and be happy with how much product it contains. You might save the 4.0L head for when you build a 4.0L block into a stroker with your 258 crankshaft—200,000 miles from now. Have a good time ‘wheeling!

Regards,

Moses

Keeping the Vintage CJ’s 196 Rambler Six

From: Jason T.

Sent: Monday, March 28, 2011 6:37 PM

To: 4WD Q & A

Subject: Re: ’64 CJ5

Mr. Ludel,

The engine has a flat, machined pad on the front of the driver’s side just below the head. It has the code 801 C06. As near as I can guess the motor is a mid sixties, iron, OHV 196.

The carburetor is a Carter. There is an aluminum tag that is folded and beat-up. The first number is hard to see. The tag could say either 3706S with an E7 underneath that, or it could say 5706S E7.

Once again, thank you for your help.

Jason T.

Reply from Moses…

The carburetor is a 1964 build, the last 196 two-barrel type. Carter model is a WCD 3706S. The design continues into the 199/232 era. It incorporates two (separate) floats and requires some time on the bench to set up properly. The carburetor probably needs rebuilding, with care, and you don’t want to get an “exchange” carburetor when you have such an original timepiece.

I recommend a “blueprint” rebuild of this carburetor to alleviate the flooding on hills. A carburetor kit should still be available. You would order it as 1964 Rambler 196 2-barrel under the tag number 3706S. There are aftermarket carburetor options, but this carburetor is jetted and engineered precisely for this engine application—if it is rebuildable, you have a way to go here. To offset your flooding and starvation issues, I would set floats at precisely the height recommended in specifications, just high enough for adequate fuel supply.

If you would like to quickly confirm your problem, try adjusting the float heights to specification. A thorough rebuild would rule out clogged passageways and other restrictions. I have rebuild steps and specifications if you need them. I can scan and PDF a copy your way.

Regards,

Moses

A New CJ-7 Owner Seeks Carburetor Solutions

From: Chad A. Sent: Saturday, January 15, 2011 4:27 PM

To: 4WD Mechanix Magazine

Subject: Iowa CJ7

Mr. Ludel,

I recently bought my first CJ, and I am very excited. It is a 82 CJ7 Renegade, a project that ran when I purchased it, but the 232 that a previous owner swapped into it did need to be rebuilt. I would like to build a daily driver Jeep that I can drive in every season. In Iowa, we have the coldest winters and the hottest summers. We get tons of snow and deal with icy roads. Luckily The CJ7 does have a hard top, and I am looking for hard doors. I am looking to build a modest utilitarian Jeep. I will need it to travel 60 miles round trip to work on the interstate yet be able to hit the mud and trails. My concerns are the icy roads and winters. I am not concerned with my driving. I know when to go slow and when to stay home. Hitting a patch of ice with possibly the wrong tires or too much height of a lift that would increase my center of gravity is what scares me. I am looking for recommendations in tires and lift height. Currently, I have a 2.5″ BDS suspension lift kit, taller shackles, and no sway bar. I’m not sure how much longer than stock the shackles are but, it does fit 33 x 12.5 x 15″ M/T tires without any rubbing. We have a great small town local tire shop that advises me to keep the width of my tire contact down for good traction in Iowa driving conditions. I have been thinking about replacing the shackles with heavy duty stock ride height, changing my tires to 31 x 10.5 x 15″ BFG all terrain tires, and installing a sway bar with sway bar disconnect links.

Here are a few more specs on my Jeep:

Currently rebuilding 232 (I tried to find a 258 locally with no luck) 2140 Holley 2V conversion

T5 trans

Dana 300 transfer case

Stock axles

Frame is in great shape (not sure how it survived in the Midwest!) Tub has some rust but very repairable Painless Wiring harness (to be installed)

I would appreciate your advice on my tire and ride height selection. I would also appreciate any other advice. I hope I have given you all of the information you need. I really enjoy reading your Jeep Owner’s Bible and CJ Jeep Restoration Manual. Both of the books have been a great source of information. Your website also has some great information. Thank you for posting the videos of the Wounded Vet Ride. As a veteran, I really appreciate what you and the organizers are doing for vets. I hope one day that my family and Jeep could join you on one of the rides.

Thank you for your time…Chad A. at Independence, IA

Reply from Moses Ludel…

Hi, Chad…Thanks for the comments on my books and your enthusiasm for the magazine’s content! You have acquired a great Jeep. It can meet each of the needs you describe, especially with a hardtop and doors. If you need hard doors, consider placing a “wanted” ad at the magazine’s free private party classified ads. The ads get wide circulation…

I appreciate your attention to center-of-gravity, which I emphasize in my books. For an ’82 CJ, I would limit any lift to a maximum of 4-inches. Running 33″ tires (traditionally 33×12.50×15), I would use 8-inch or even 10-inch wide wheels with shallow backspacing to increase the track width. If you’re not after maximum lift, 31-inch tires (traditionally 31×10.50×15) on 8-inch rims would work with a 2-inch suspension lift. In my view, any lift should be chassis/spring and not a body lift. Use quality shock absorbers. Your current 2.5″ suspension lift is okay for the 31-inch diameter tires. 31×10.5×15 tires with a multi-purpose tread would work here. Wheels should have shallow backspacing to widen the track width and offset the lift.

If 31″ tires will do, I would install a shackle reverse kit at the front springs and do as you suggest: bring the lift down to 2-inches or so. The front sway bar is always an asset on the highway, causing the vehicle to squat on turns, reducing body roll and lowering its C.G. on corners. The question is really whether you need the 33″ tires or not…At 2.5″ true lift, you might be able to fit 32″ tires. Your local tire store’s advice is sound: the narrower tires do have more pounds-per-square inch of vehicle weight on the contact patch. This provides less “flotation” and works better on slick, icy highways. Another aid for icy asphalt is a tire design with extensive sipes. Years ago, I tested the Goodyear GSA tread with its multi-purpose design and considerable sipe count. They worked great, even to 33″ diameter…By contrast, the last thing you want is a wide-spaced cleat or “high-flotation” tire on icy pavement! High flotation tires work best for mud and sand.

Since your concern is family safety, I would emphasize that the distinct difference between your CJ and a longer wheelbase vehicle is handling in an evasive maneuver. You can offset C.G. issues with a track width increase, and should do so. The sway bars help on the highway with cornering. You do not mention whether the Jeep has manual or power steering. Power has a quicker ratio and reacts promptly. Manual steering is slower and does not create as much risk of over-steer in an evasive maneuver. Get used to driving a shorter wheelbase vehicle, know how it handles and reacts. As a rule, steering input should be thoughtful and precise, not jerky if avoidable.

I have the advantage of an 81-inch wheelbase CJ in my earliest driving experience. To this day, even at higher speeds in the desert, I have a sixth sense for the twitchy reactions of a short wheelbase, higher C.G. chassis…You can learn this, too, Chad.

The 232 is actually okay if you keep overall vehicle weight in check. It should deliver good fuel efficiency. I’m envisioning a likely original axle gearing of 3.73:1. You have an overdrive with the T-5 and a slight overdriving effect from 31″ tires—even more effect with 33″ tires. This should make fuel efficiency decent if the Holley carburetor has correct jetting. Since you’re at a constant altitude, you can jet that carburetor accurately for your Iowa driving environment.

If you’re currently committed to the Holley 2140 carburetor, I’m curious what the original application was. This is a most unusual carburetor choice, a carburetor best known from vintage V-8s. Often called the “Christmas Tree” design, the first 2140 I worked with fit a Mercury V-8 from the early ’50s. Most Holley carburetors are altitude sensitive and require re-jetting to perform well at higher altitudes. An alternative might be a Quadrajet (Rochester) non-feedback carburetor from a smaller displacement G.M. engine. If built properly, with a brass float upgrade, a non-feedback Quadrajet will deliver excellent fuel efficiency on the small primary bores and maximum performance on the large secondaries. Despite the wide range of opinions about the Quadrajet, in “blueprint” form, this is one of the best carburetors available and far less sensitive to altitude changes.

If you want to stay with the 2V configuration, a Motorcraft 2V (2100-2150 series), used on engines like the Ford 302 or 304 AMC V-8s, is also a great carburetor. (Similar Autolite carburetors were fitted to 221/260 Ford V-8s and other smaller applications.)

Making an adaptation to your intake manifold would be a consideration.

I trust this helps, and your questions are welcome, Chad. Ask more when necessary.

Reply from reader Chad A:

From: Chad A.

Sent: Sunday, January 16, 2011 5:00 PM

To: 4WD Q & A

Subject: RE: Iowa CJ7

Mr. Ludel,

Thank you for your advice, it really helps, and I appreciate it. You were correct to think the 2140 was a strange combination. I purchased a new 2300 and adaptor plate that are still in the box. The intake I am using is a stock ’82 258 intake with the coolant passages and electric intake heater. For our cold winters, I thought it would be good to keep the stock intake.

I chose the 2300 because our local parts stores have an extensive Holley section. I wanted to be able to stop anywhere for parts. I thought about the Motorcraft 2100 and found a local junkyard with plenty of rebuildable cores. What I didn’t like about the Motorcraft was our local parts stores could not support it as well as the Holley. The stores can order anything that I need but are very limited on what is on hand. I do like Motorcraft 2Vs and I have experience rebuilding them. I am up for reconsideration if you think the Motorcraft would make a better carb. I am more of a Ford/Mercury guy, but I do appreciate the Qjet. A close friend of mine in the service taught me that a Qjet performs excellent if treated properly.

Is there an adapter I can use for the stock intake? I am up for any carb options. I still have the stock BBD. I really wish my budget could afford the Mopar EFI.

Thank you again for your time…Chad

Reply from Moses Ludel:

Chad…In ranking order, the Mopar EFI would be the number one choice (costliest, too, I know). The BBD can be rebuilt as I describe in the ’72-’86 CJ Rebuilder’s Manual and also in an article that I have posted at this website: click here for BBD rebuilding details. The BBD can be a success story if done right—despite the bad press. In your case, however, the OEM peripheral feedback devices are likely gone. A feedback type BBD carburetor should be considered only if the whole regalia of factory ignition and fuel system equipment is in place.

The 2100 series Motorcraft is an excellent choice, trouble-free and easy to rebuild. An off-the-shelf 2300 “universal” carburetor is, in my view, a poor choice. I have two universal 2300s in my stack of old parts, one a 350 CFM, the other a 500 CFM. Using all of the tuning parts available from Holley and a borrowed $10K Horiba portable (real time) A/F meter, I could not get either carburetor to tune right for a 258 Jeep six. (In off the shelf tune, either version would over-fuel a 232 and fuel-wash your freshly rebuilt block.)

I did find a Holley solution, however. In researching OEM Holley carburetors, I found the part numbers for OEM 2300 series carburetor versions used on the 266 I-H Scout V-8 (late ’60s era). I located a correct, original carburetor for a 266 engine and rebuilt it by the book. That carburetor, by its design, was still hyper-sensitive to altitude, but at your elevation, the Scout (or I-H pickup) 266 V-8 carburetor might work—at least for a 258 six.

For your 232 six, a clear OEM application would be the 2300 carburetor used on the Jeep Tornado OHC sixes of the 1963-65 period. These engines were 230 cubic inches, even closer to the 232 in displacement. Here is the Holley model and “List Number” for that application:

Model 2415—with automatic choke, the Holley List Number is an R-2934A. This is a 2300-C style carburetor.

For simplicity sake, I believe you would be better off with a 2100 Motorcraft from a smaller displacement, popular engine application like the 304 AMC V-8 or a Ford 302 V-8…Another possibility is a 2G or 2GC Rochester two-barrel designed for a Buick 225 or 231 V-6. Any of these carburetor choices require a matching air cleaner with the right base size.

My overall approach for your application: Find an OEM carburetor that originally fit an engine close in cubic inch displacement to your 232 six. (A 260 Ford V-8 Autolite 2-V, for example, might work well.) The idea is to use the OEM engineering and provide the right fuel metering and jetting for a particular engine displacement. Trying to attain this with a universal “high performance” carburetor is virtually impossible. On the 2300 universal carburetor, I changed the metering block, power valve, main jets, float block and pump lever, and still did not reach the right flow for a 258 cubic inch six! (The 2300 universal carburetors must be for circle track racing or patterned for a large displacement truck V-8.)

Carburetors designed for engines closest in displacement to your

Jeep’s 232 cubic inches will work best. This is ultimately about flow rate (CFM) and proper fuel metering (tuned jetting, power valve flow, metering passage sizes, etc.). Pick your favorite carburetor design!

This California based 1982 CJ-7 has a high performance V-8 transplant and fuel injection. For video details of this Jeep, click here!

Chad provides an update:

From: Chad A.

To: 4WD Mechanix Magazine

Subject: Carburetor

Moses,

Thank you for posting my door ad. I decided to return the 2300 Holley and universal base plate and go with the 2100 Motorcraft. I found a gentleman off Ebay (Michael Erhmann) who sells 2100s for Jeep applications. The carb will be built for my application: 232, Iowa’s altitude, daily driving with occasional off-road use, and manual choke.

The carb comes with a machined adapter plate to go from the 2V BBD base to the 2100. I like that better than the universal. I was afraid I would be chasing vacuum leaks. I also bought a short ram air intake from him. I like the looks of the air intake; I attached a photo for you.

My next item I have to research is the ignition system. Along with rebuilding the 232, I will be replacing the wiring harness. The original was a mess w/burned wires and bad splices. I appreciate the Duraspark ignition, but I have been toying with the idea of an HEI for simplicity. There are pros and cons to each, and I do not know what is the better application for a Jeep. I am also a fan of MSD ignitions. This may be another budget restraint. Thank you again for all of your help!

Reply from Moses Ludel:

You’re welcome, Chad! Nice looking induction system…If set up for your 232 cubic inch engine, a 2100 will work well. Manual choke is a failsafe…4WD Hardware has a bargain basement price on an HEI retrofit distributor. It has the advantage of G.M. replacement parts and the coil-in-cap…That’s the best deal price-wise. See my PDF article (https://www.4wdmechanix.com/https://www.4wdmechanix.com/wp-content/uploads/2015/01/Jeep-Ignition-Upgrades-for-Pre-EFI1.pdf) for details on ignition system options…MSD is tops but expensive when you need the “box”, too. DUI makes a quality G.M. HEI based distributor. See my article…Also, in my Jeep Owner’s Bible, I share the use of a Chrysler “5-pin” module with the Jeep/Motorcraft type distributor. This makes the OEM Jeep distributor more reliable. Jacobs recommended this approach.

CJ-7 and a Quick Discourse on Closed Crankcase Ventilation and EGR Valves!

—–Original Message—–

From: Chad A.

Sent: Saturday, March 19, 2011 11:20 PM

To: Moses Ludel

Subject: RE: Fuel System Questions

Moses,

Thank you for the words of wisdom. I will be using the charcoal canister and along with it, the EGR system. I have a few parts to order but, it

looks like I will be able to find everything. As far as the EGR, do you

think it would be all right to run the hose straight from the CTO valve to the EGR? The schematic you sent (thank you) shows the hose running from the CTO valve, to an EGR TVS on the air cleaner, then to the EGR. I want to run the new intake system I ordered and it won’t have the TVS.

I also have a canister question for you. Once I cleaned all of the caked mud out of my canister I found the external filter deteriorated and I lost a small amount of charcoal. I believe there may have also been some sort of a cloth screen inside the canister to keep the charcoal from spilling out. Is there supposed to be a screen inside or does the external filter keep everything in place?

Now that I am learning how my emission system works, I am regretting ordering the MC 2100 with a manual choke and open vented fuel bowls. I am starting to wish I had ordered the carb with the electric choke and the correct fuel bowls that I could connect to the charcoal canister.

Unfortunately, the carb I have was built to my request and for my application. It doesn’t feel right to ask Mike to allow me to return the carb so he can build me another. I may ask and offer a restocking fee but I am going to have to think about it. Any advice, do you think I would be better off with a more emissions friendly carb? I hate to put you in the middle of my moral dilemma but, I really respect and appreciate your advice. You have been a great asset and I cannot thank you enough.

Thank you,

Chad

Reply from Moses on the value of an EGR valve…

Hi, Chad…Great idea to run the EGR. This will keep upper cylinders of the engine cooler and preserve your fresh rebuild. Many disconnect the EGR as a “smog” part, but the EGR serves a quality function, especially in reducing risk of detonation on low octane fuels. (Cylinder temps can reach 4,800 degrees F without EGR; EGR drops temps to 2,500 or less degrees F for defeating NOx. Good gain!)

The EGR gets its signal from manifold vacuum routed through a coolant temperature switch. The goal is to keep the EGR off-line until the engine warms to a certain temp (usually 140-degrees F or so, sometimes hotter) before the EGR will open under vacuum. The CTO and TVS switches accomplish this. Check the vacuum circuit again. The EGR uses CTO (coolant temp) and its own EGR TVS (thermal vacuum switch). As long as you have a sufficient vacuum signal at the right temps, the EGR will function well.

TAC is a separate function. If you choose to eliminate TAC (thermal air cleaner) due to an aftermarket air filter, you can route the EGR as described, using CTO and the EGR/TVS if necessary. CTO routes vacuum via a thermo coupler valve in the cooling system. The thermal coupler is typically a wax pellet valve that melts wax as the temp rises. As the wax melts, the switch opens vacuum ports. By itself, a thermal coupler can operate an EGR. The TVS may be an additional safeguard that AMC built into the system, or it may regulate or stabilize the vacuum signal. Using a simple vacuum gauge and blipping the throttle as the engine coolant temp rises will indicate the vacuum available to the EGR. You can test EGR opening with a hand vacuum pump. Yes, you can keep it simple and clean, as long as there is an adequate vacuum signal to the EGR at the right temperatures.

EGR should not open at an engine idle or when the engine is cold. Make sure you draw the vacuum signal from the correct vacuum supply port. Typically, this is a “ported vacuum” source at the carburetor that will not provide a strong enough vacuum signal at engine idle to open the EGR. (If you hook to manifold vacuum, the signal will be high at an idle and open the EGR, which should not occur.) Ported vacuum is typically used for distributor spark advance vacuum.

As for the EVAP canister, these are usually not serviceable. They get replaced as a unit. Years ago, cleaning the canister was possible and part of emission service. Unless you can compare your canister with one in good condition, it’s hard to say whether all material is in place. There are no workshop measures described; however, I copied a 1981 Mopar parts section that shows a filter available as a separate part. (See attached PDF.) The filter is shown, no other parts are removable.

Regarding manual choke, bowl vents and non-vented air cleaner, there are emission era engines with manual choke like the Toyota Landcruiser F and 2F engines. A vented 2100 fuel bowl will hardly cause global warming, there are far larger contributors, and, yes, we should be concerned about the environment. There are some minor advantages of not having a vent port on an off-road vehicle, but again, the CJs with Buick V-6s had vented bowls and sloshed around plenty without a lot of grief. If it’s a hassle to return the carburetor, allow yourself the minor fume venting from the float bowls. Most states do not require gas pump nozzles with capture and return vapor systems, and a single fill-up of gasoline will vent more fumes to atmosphere than your 2100 carburetor will in a whole day of hard off-roading. Typically, the vent is only open with the throttle closed to idle speed, and this is necessary…Later 2100 and 2150 carburetors do not vent their bowls to atmosphere, but that would require a carburetor change, too…Use the manual choke appropriately, and you can control cold engine fuel mixtures wisely.

Regards,

Moses

[Beige text is the reply from Moses Ludel.]

—–Original Message—–

From: Chad A.

Sent: Sunday, March 20, 2011 8:59 AM

To: Moses Ludel

Subject: RE: Fuel System Questions

Moses,

Thank you again for all of your insight. I have attached a vacuum diagram that I found for a Howell TBI that I think may work for my application.

The only line not shown is the inlet hole at the rear of the valve cover.

That inlet hole at the rear of the valve cover should be the crankcase return to the air cleaner that enters inside the air filter element.

I will install an enclosed filtered breather and route it to a port on my air cleaner or a through port on the Motorcraft 2100’s air filter base. I hope this will cover all of my bases.

You’ve got it…A PCV valve creates low pressure (vacuum) at one end of the valve cover and draws through the crankcase. The breather hose from the air cleaner to the rear of the valve cover will provide the air supply for the crankcase. This makes for a closed system.

As far as the carb, I think I may keep what I have. The carb vents are inside the air filter so hopefully some of the gasses will get drawn back in and get burnt. I also like the fact that the carb came with a manual choke and throttle cable.

If the vents are inside the air filter, you have it made. Risk of fumes escaping through the air filter is minimal, and as you say, the fumes, if any, get drawn into the intake stream with the engine running. Note that Howell’s diagram shows manifold-sourced (not ported) vacuum to the middle pipe of the EVAP canister and the PCV valve. The CTO and distributor source is ported vacuum (very low at idle, increasing dramatically just as the throttle opens, tapering off as the throttle opens wide). Use this approach for your system.

Hopefully I have this section of my build covered. Next project; the front diff. I knew I had a bad rear pinion bearing out but upon further investigation, I found the inner pinion bear bad and a diff case half way full of dirt. Looks like a total rebuild and a new learning experience.

I honestly can’t wait.

In my Jeep CJ Rebuilder’s Manual 1972-86, you will find a low pinion Dana 30 axle build step-by-step. Follow it for best results. At the website, I also cover the high-pinion 30 with an ARB Air Locker; many of the fundamentals are the same. The book also covers your Dana 300 transfer case and the rear axle (AMC Model 20)…There is a lot of detail in that book—tailored to your needs!

Thanks,

Chad

Next Step: Chad’s Carburetor Leads to EVAP Restoration

—–Original Message—–

From: Chad A.

Sent: Thursday, March 17, 2011 10:10 PM

To: Moses Ludel

Subject: Fuel System Questions

Hi Moses,

The weather is starting to warm up in Iowa so I am back out into the

garage trying to wrap up my 232 rebuild. I am happy to report that the long block is complete and going to start installing the intake and fitting my rebuilt Motorcraft 2100. Moving to this phase of the build has brought new questions that I am having a hard time finding the correct answers to. My questions have more to do with the fuel system. The fuel tank has more ports coming out of it than I have ever seen. From the sender I have a fuel outlet and return. At the driver’s side of the tank I have two ports for fuel vapor release.

I plan to use both fuel outlet and return with my Motorcraft carb and the stock Jeep fuel filter. Is there any reason that I should not, I have read where folks have only used the outlet and plugged the return.

For vapor release, I have the two ports coming out of the fuel tank

connecting to the liquid check valve then to the rollover check valve. From there, a line runs to the engine bay to the charcoal canister. I am missing everything after the canister. The pieces I do have look rough, and it looks like I will have to repair or replace what I have and find what I am missing. From my initial research, this may not be an easy task.

I am debating removing a portion or all of the fuel vapor release system even though I know it is not the right environmental decision. If I removed the canister and kept the rollover protection, I am concerned where to release the vapors. I am thinking about running a hose then filter above the rollover check valve but I am concerned with collecting gas vapors. I have also read about folks plugging the vapor lines at the tank and running a vented fuel cap. One forum stated that a vented fuel cap might suck in water during a water crossing. If I went the vented fuel cap route, I am concerned with fuel spillage in the event of a rollover.

I don’t have the off-road experience to answer my questions and I would really appreciate your advice.

Thank you for all of your help.

Chad

Reply from Moses Ludel:

Hi, Chad, happy to assist! Glad your project is progressing…

Always use the three pipe fuel pump with a return line. The return line keeps fuel circulating through the fuel pump and helps resist vapor lock. Using a two-pipe pump or plugging the return will defeat this function. Although an emission-era addition, the three-pipe return pump is an advantage.

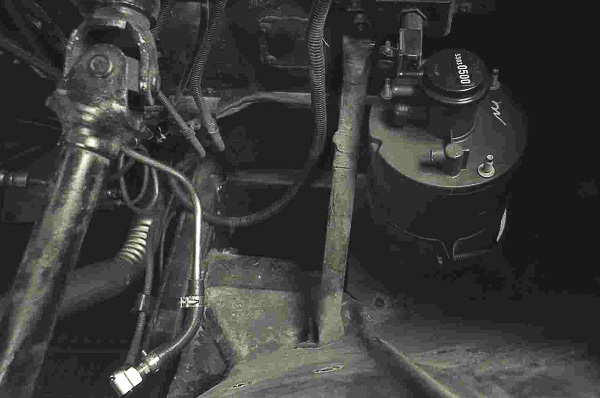

Folks screw up these systems constantly, thinking that stripping off and plugging components will simplify the approach. EVAP is a closed system, which is safer and more environmentally friendly. It is also passive and does not tax power or performance in any way—when hooked up properly. I have attached a scan of the typical ‘80s CJ EVAP vacuum hose circuit for your benefit. It should be self-explanatory and helpful for restoring your system.

Click here to download a PDF copy of a typical ’80s era CJ 258 Jeep vacuum circuit.

Restore this EVAP system to function properly and as intended. Even though some of the emission devices will likely not be restored in your case, you can at least make the EVAP functional—and safe!

Regards,

Moses