Note: The PCM is responsible for a number of emissions and evaporative canister functions. As a monitor, the PCM protects the catalytic converter from overheat or damage by watching for engine misfire. Uniquely, the PCM knows when the engine misfires by sensing subtle changes in crankshaft rpm. A PCM also maintains the cruise speed 14.7:1 air/fuel ratio during closed loop mode, which keeps emissions to a minimum and reduces wear on the catalytic converter.

Tailpipe Emissions and the PCM

PCM monitoring of the upstream and downstream oxygen sensors helps determine how well the catalytic converter stores and uses oxygen to complete the CO and HC burn cycle. If the downstream reading is out of specification, indicating that the catalytic converter is less effective at cleaning up tailpipe emissions, the PCM will send a MIL (engine/system check) signal to the instrument panel. In essence, the two-oxygen sensor (upstream and downstream) system is an on-board “smog check” station!

The downstream cat signal indicates oxygen stored at the converter. PCM monitoring and comparison of the upstream and downstream O2S readings can determine the catalytic converter’s ability to store oxygen vitally needed for oxidation of carbon monoxide and hydrocarbons. As the vehicle operates, the PCM provides an ongoing “smog check” of the emissions system!

Oxygen sensors help keep fuel mixtures on track and also monitor the effectiveness of the catalytic converter. The familiar upstream sensor(s) help the PCM adjust injector pulse width or flow for an optimal fuel burn A/F ratio of 14.7:1. The 1999 XJ Cherokee has an upstream O2S (like the one shown) and a downstream O2S sensor located downstream of the catalytic converter.

The PCM keeps the fuel mixture (air/fuel ratio) on track. This is its best method of assuring a clean tailpipe. PCM monitoring will discover the factors that richen the mixture or reduce ignition of fuel. Incomplete, rich burn can be the result of high fuel pressure, poor spark or injector faulting and misfire. By monitoring sensor voltage readings, the PCM compares values from interacting devices and determines whether a given device is within its normal high and low operating voltage range.

Despite the wealth of useful information available through the PCM, the PCM cannot peer into a filter and know that it is clogged and causing poor combustion. Nor can the PCM determine low or uneven compression in the cylinders, oil burning, a dirty air cleaner, vacuum leaks (unless they widely affect MAP sensor readings) or poor grounds—unless they impact a whole circuit of functions. By knowing the normal high and low limits of monitored devices, however, the PCM can do a good job of storing a DTC if a device or sensor functions outside of its normal range.

Segments of the evaporative emissions system also fall within the PCM functions. On MPI systems using an EVAP purge solenoid (shown), the PCM controls the duty cycles of the valve. On later model TJs, the PCM also controls the Leak Detection Pump (LDP) on evaporative systems. These late additions to the evaporative emissions systems help keep fumes to an absolute minimum.

The TJ Rubicon (2003-up) has a busy fuel tank and fuel/vapor lines. Purging fumes and ventilation reach a refined level with these models. System shown meets advanced California and Federal emissions control standards and EVAP requirements. Despite the TJ Rubicon’s fun design and intent, the MPI, PCM and EVAP functions are serious! Attempts to modify or tamper with this system would violate emissions law and create a safety hazard. Stick with the OE engineering.

The evaporative system also incorporates safety devices like the rollover valve(s) at the fuel tank. While the tank must vent correctly, these valves prevent fuel from pouring into the vent hose and filler in the event of a vehicle rollover. Nobody plans to roll over a Jeep; however, the rollover valves are there if ever needed.

Make certain that the evaporative emissions system is intact and operative to OE specifications and design! Proper venting and containment of fuel tank fumes is as much a safety issue as an emissions concern. Do not tamper with or eliminate any portion of the evaporative emissions system.

When to See Your Jeep Dealership

This section of the magazine familiarizes owners and technicians with the functions, needs and overall service requirements of later Jeep fuel-and-spark management systems. You should now be more aware of the fuel, spark and emissions needs of these vehicles, including functions of the MCU, ECU and PCM “computer”, sensors and switching devices. This information should enhance your troubleshooting skills, repair work and, if necessary, the success of emergency field fixes.

There are testing details, bulletins, periodic service updates and software “re-flashes” (OBD-II) supplied to your local Jeep dealership. A factory workshop manual for your year and model Jeep provides model-specific details and specifications. Your local Jeep dealership offers service and parts, including access to a factory service manual for your Jeep.

Equipped with the knowledge gleaned from these articles, a factory workshop manual and the right tools, you may want to perform much of the work described. There are times, however, when it is neither prudent nor cost effective to tackle a particular task.

You may lack the diagnostic advantages of a Chrysler DRB-III® scanner, a fuel injection pressure testing kit or specialty tools for the removal and installation of expensive components. Or, with a busy work schedule and family needs, you may simply not have the time for “on-the-job training” at a complex task. Often, doing a task just one time does not warrant purchasing the necessary specialty tools.

Your local Jeep dealership’s service department can furnish prompt, professional care for your Jeep. Technicians familiar with the DRB-III® scan tool can quickly work through systems tests, DTC information and the actuation of suspected devices. Pinpoint diagnostics can save considerable guesswork, time and labor. Considering the cost of parts, it is far wiser to have the dealership perform a scan test than to start the “parts replacement” approach on your own. Labor charges for scanning could be a fraction of the expenses you might otherwise incur.

The DRB-III® scan tool provides the platform for modern Jeep service. DRB-III® and next-generation StarSCAN® service tools fit the needs of the modern Five-Star® Jeep dealerships and their satisfied customers. We all want prompt, accurate solutions—especially for a vehicle that will wind up miles from a paved road, clawing at a rocky trail with cargo and a cab full of precious family members!

A Five-Star® Jeep dealership will have the tools and technicians to meet your Jeep’s advanced troubleshooting needs. A late model Jeep is often still under vehicle or emissions warranty, and repairs can be far less costly, sometimes even free of charge. (Before having the work done, discuss warranty coverage with the service manager to determine who will pay for the repairs!)

In any case, the DRB-III® and next-generation StarSCAN® approach to service will provide the degree of accuracy and thoroughness your Jeep deserves. When maintenance or a repair moves beyond your skills or tool access, consider the ‘Vehicle Checkup Center’ and service department at your local Jeep dealership!

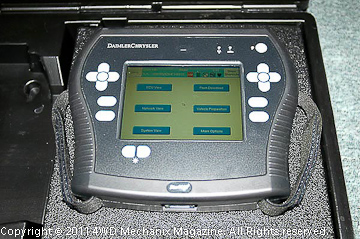

The DRB-III® scan tool is a Chrysler dealership mainstay. Loaded with the correct software, this tool can perform diagnostic work on all YJ and TJ Wrangler models. A dealership investment for quick, accurate assessment of DTC troubles and faulty systems, the DRB-III® serves technicians at Chrysler, Dodge and Jeep dealerships. There is an interface cable set in this package that covers every YJ or TJ Wrangler—each model, year and engine.

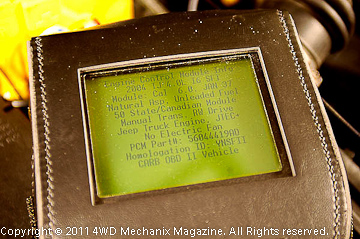

Hooked to a 2004 TJ Wrangler test subject, the DRB-III® immediately identifies the PCM and vehicle details. A PCM is “burned-in” to the legal VIN number of the vehicle, preventing anyone from changing the software or modifying pertinent OBD-II functions. In 1996, OBD-II began the era of on-board programmable PCM units. The computer stores “driving habits” and also knows of any changes to the E-PROM (like a performance “chip”) or other fuel-and-spark management modifications.

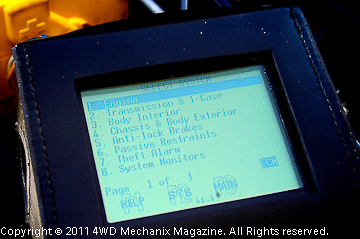

This menu provides a list of systems that we can check. I focus on the engine at this stage. Other areas impact engine performance. Checks of these circuits would be useful, too. DRB-III® is quick and easy to use. On the 2004 TJ Rubicon subject vehicle, I hook the cable link to the 16-Way Data Link Connector at the base of the dashboard just left of the steering column.

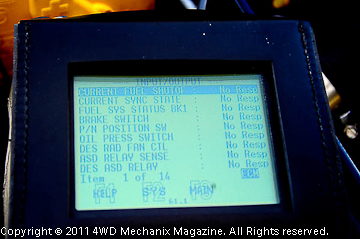

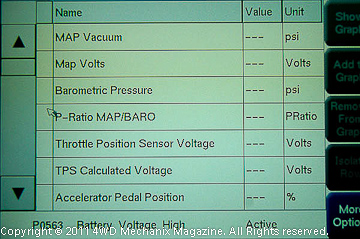

Voltage readings, vacuum functions and actual readouts from sensors will be available. Unlike a simple code reader, DRB-III® can determine operating values for these devices with the engine running. A code is useful for pointing to trouble. DRB-III® actually tests devices to see whether they meet specified values.

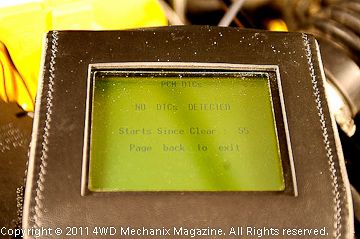

Ah, good news! Not a single DTC stored. Codes were cleared 55 start-ups ago. When I discussed findings with the 2004 Rubicon’s owner, he confirmed that the dealership had scanned the engine awhile back. He wasn’t quite sure when, but the DRB-III® knew! Yes, the computer could count the startups since a scan and last clearing of DTC findings.

These are the systems tests that DRB-III® can run. Actuator tests will actually switch devices on and off, checking their values and functions while doing so. The scan tool does work that once took painstaking steps with a volt-ohmmeter, ammeter and power jumper leads. In minutes, this method of troubleshooting can perform work that would otherwise require hours of labor.

Look familiar? These devices, discussed within the MPI articles in this section of the magazine, now will be checked by the DRB-III®. Input/Output devices communicate with the PCM. Imagine the time involved to check these individual circuits and devices with a volt-ohmmeter. This screen comes up in an instant and reads values precisely.

I am running this test from the right side of the TJ’s engine bay, the 16-Way cord and plug reaching through the TJ’s driver side window and to the Data Link Connector.

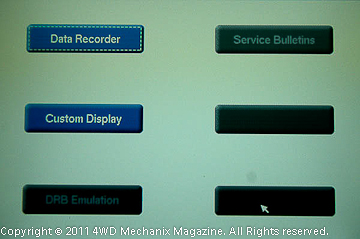

Here is the StarSCAN® ‘Next Generation’ scan tool. Introduced with the 2004 Dodge Durango, StarSCAN® meets the requirements for the new Controller Area Network (CAN) systems on Chrysler cars and trucks. CAN systems will enable area “bus” networks to communicate through common gateways on the vehicle. Processing is faster, more thorough and covers a broader range of functions to meet 2008 Federal and California requirements. The 2005 Grand Cherokee became the first StarSCAN® Jeep candidate with CAN-bus networking.

StarSCAN® is fast and expedient. With OBD-II and OBD-III capability, the tool can not only scan the vehicle’s modules and devices, StarSCAN® can upload and download on-board software quickly. DRB-III® can also “re-flash” a system but does not have the range of functions required for CAN bus circuits. StarSCAN®, like DRB-III®, begins by identifying the vehicle and its ECU or PCM.

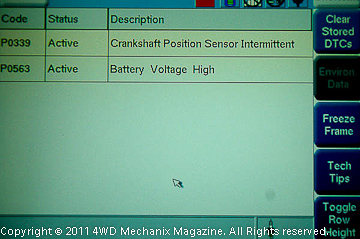

StarSCAN® was to eventually work with DRB-III® emulations. (To this point it does not, and Chrysler has moved beyond StarSCAN® to WiTech®, which does offer DRB-III emulations.) The equipment wound up model-specific for CAN-bus vehicles engineered for StarSCAN® diagnostics. Here, I run simulations to show how StarSCAN® works. Following from the main menu, you can now see simulations for fault codes on a vehicle. Two DTC faults appear here.

I am asked if the DTC information should be cleared. The environmental data will also clear. If I am confident that the causes of high battery voltage and erratic crankshaft sensor signals have been repaired, I will clear the DTC information. If the system still is not functioning correctly, a retest will once again bring these fault codes up.

The “next generation” Chrysler vehicles have CAN bus circuits. Each bus circuit or network has an assigned letter. The vehicle’s systems operate from controllers as listed in the left column. In this simulation, the PCM controller has two active DTC items as we discovered during previous tests. Note that the PCM engine controller is on CAN B bus in this system. ABS and several other controllers share this Controller Area Network. Networks communicate through gateway units on the vehicle.

Like DRB-III®, the StarSCAN® tool can read actual operating values for devices and sensors. This is troubleshooting by way of the communication links, gateway(s) and controllers. Like DRB-III®, StarSCAN® quickly alerts a technician to a problem area or device that operates out of its range limits. Comparing this information, a controller like the engine PCM will send a MIL signal to the instrument panel. This may be the driver’s first sense that anything needs attention.

This spark plug icon is actually flashing. It shares that the #1 fuel injector is under surveillance by the scan tool actuator function. Advanced scan tools can switch on devices like an electric fan then read the voltage draw or efficiency of that device. Actuating door locks, sound system components and a variety of accessory devices falls within the scope of the StarSCAN® tool. Controllers and gateways communicate with the StarSCAN®, and the tool can simulate the role of some control modules.

For its time, StarSCAN® was the most advanced diagnostic tool for on-board troubleshooting. This scanner also uploads and downloads information from the dealership TechConnect network system. (DRB-III® has also made good use of this function.) Tests and recorded data can be uploaded to Jeep or Chrysler engineers for analysis. Prompt discovery of problems can lead to the release of service bulletins and software re-flashes or patches when available. TechConnect pools information from the entire dealership base and improves customer satisfaction.

A range of tests and data are available at your local Jeep dealership. DRB-III®, StarSCAN® and WiTech® can each go on a “road test” with your vehicle if necessary, providing real-time information on functions and intermittent problem issues. If your tools cannot communicate on this level with on-board controllers and the PCM, enlist the services of your nearest Five-Star® Jeep dealership’s service department.