HTP America Invertig® 201 TIG/GTAW Steel and Aluminum Welder for Our Shop Needs!

The HTP Invertig© 201 is a highly versatile, cost-effective TIG welding machine. The Invertig 201 works well for Jeep 4WD hobbyists, mechanics and the 4WD shop that specializes in metal fabrication, 4130 chromoly roll cages, engine swaps, axle upgrades and chassis work!

Note: This 201 machine served met our needs before upgrading to the new HTP Invertig® 221 machine. We now use the water-cooled (optional) HTP Invertig® 221 for all of our stick and TIG needs.

HTP America has a full line of TIG welding “consumables”. Stainless steel brushes are a must for aluminum. Deerskin gloves offer sensitivity for pumping filler rod. Tungsten electrodes are available in all popular types and sizes…I stopped using 2% thoriated when I taught adult education welding. Ceriated and lanthanated electrodes make great alternatives! The inverter technology works so well that pure tungsten and “balled” ends are no longer advised for aluminum welding. The Invertig 201 uses a tapered, ground point for all welding.

Worldwide demand for inert gas, tungsten arc welding equipment continues to grow. GTAW or “TIG” welding meets the requirements for chromoly and alloy steel, aluminum, magnesium, titanium, Inconel and other high-tech metals. Like most modern welding applications, Jeep 4WD work can benefit from the use of a TIG/GTAW machine.

A metal’s chemistry and thickness dictate the welding amperage demanded. For light sheet metal work, there are simpler D.C. output, 110VAC machines. For work on larger iron castings, alloy steels like 8620, 4340 and 4130, aluminum, magnesium, stainless and titanium, there are specific, higher amperage TIG/GTAW processes. Industrial or fabrication TIG equipment features AC and DC modes to meet the demands of iron, mild steel and low alloy steel (DC) or the non-ferrous metals like aluminum or magnesium (AC).

Today’s inverter technology has lighter 220V single-phase machines performing work that required massive, 3-phase equipment just two decades ago! As a result, the price of a TIG welder is no longer prohibitive. Whether you are a dedicated Jeep home mechanic or a Jeep 4WD specialty shop, modern MIG, TIG and stick welding equipment is accessible.

Since repairs and fabrication welding on a Jeep 4WD chassis raise safety issues, I prefer the use of TIG/GTAW process in many cases. While production or mild steel plate welding often encourages the use of a MIG/GMAW wire feed machine, the TIG/GTAW process is superior for low-alloy metals and “chromoly” tubing, cast iron restoration and precise chassis, frame or motor mount work. In the 4WD Mechanix Magazine projects, I discuss metallurgy and reasons why the TIG process is often preferred—and when TIG is unnecessary or impractical.

In my view, if you have the patience and desire to master TIG welding, you will want a TIG/GTAW machine. Although I often use the oxygen-acetylene (OAW) welding process, stick arc (SMAW) and wire feed MIG (GMAW) methods, many of my projects require TIG. TIG (GTAW) fills niche needs and is, in many situations, the only way to get quality, failsafe welds.

I have TIG-repaired damaged iron gear cases and even case-hardened gears (after normalizing). For aluminum and many low alloy steel welding tasks, there is no better process than TIG (GTAW). Want a safer, precision built chromoly 4130 roll cage? Use TIG. Though considerably slower and requiring immaculately clean, rust- and oxide-free metal, TIG welding excels. When mastered, TIG provides deep penetration, virtual elimination of undercutting and absolute control of the weld puddle and filler metal!

Note: Successful TIG welding, like any other process, demands the right choice of filler metals and respect for metallurgical properties. I discuss these concerns in each welding project at 4WD Mechanix Magazine! Stay tuned…

Compare your welding chores with the 4WD Mechanix Magazine welding projects. Jeep owners and 4WD shops frequently find that TIG welding is superior for certain repairs and fabrication work!

Dedicated Jeep 4WD restorers and 4WD shops seeking a practical and versatile TIG/GTAW machine will appreciate my choice of the HTP America Invertig 201! With a water-cooled torch option and 200 maximum amps of output, this is a cost-effective package that can fabricate, restore and repair the full spectrum of metals—including aluminum and magnesium. The rugged water cooler is U.S.A. made!

Ideal for alloy steels, stainless steel, cast iron, aluminum, magnesium and mild steel, the Invertig® 201 is a lighter weight, portable machine. Better yet, the Invertig® 201 operates on single phase 220V-230V current, drawing a mere 30 amps of electricity while producing 200 amps of welding current! All of this with better weld penetration, no undercut and a confined heat affected zone (HAZ)!

The Invertig 201 package will readily meet the magazine’s Jeep 4WD project needs. For off-road upgrades, chassis modifications, engine mounts, a roll cage, bumpers, a tire carrier, making a winch mount, mechanical repairs, frame restoration, or bringing a vintage Willys 4WD back to life, the HTP Invertig 201 welder will pay for itself!

A stick/arc mode is also an option with the Invertig® 201 machine. This makes the package even more versatile and flexible, ideal for general shop use as well as precision welding.

Note: If you want to build a utility trailer or quickly fuse old, oxidized metal, use the stick/arc mode or your MIG welder. If your shop is clean and you are willing to thoroughly de-scale, clean and prep metal, then the slower, precise and ultimately superior TIG process is often preferred!

Freshly out of the boxes, the HTP America Invertig 201 machine is now set up to work! An affordable, highly versatile welder, the Invertig 201 provides a wide range of TIG/GTAW welding functions. At 200 amps output capacity, HTP rates DC TIG welding steel to 3/8″ (beveled) or AC TIG welding aluminum to 5/16″ (beveled) in a single pass* weld. The same 201 machine will weld steel or aluminum down to 0.030″ thickness!

*Under optimal, well-prepped welding conditions!

The HTP America welding cart option is a definite consideration! A sturdy, mobile means for keeping all of your TIG welding equipment together, the cart carries the gas cylinder, 201 welder and optional water cooler. Compact, the package parks neatly in a reasonable space.

Hook-up is straightforward. The TIG welding video from HTP America explains the entire operating process. I encourage buyers to review the DVD before assembling the package. Many customers benefit from reviewing the DVD prior to purchasing the Invertig 201 package.

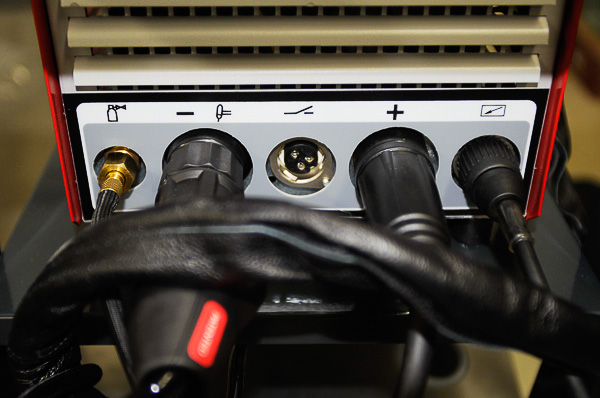

The ground (left) is used with the TIG and stick/arc processes. The remote control foot pedal (right) is essentially a rheostat switch that signals how much amperage to flow. Controls and functions are thoroughly described in HTP’s TIG DVD and operator’s manual. In addition to remote amperage control, there is an automatic “pulse” alternative—plus an optional trigger type torch with on/off switch. Automatic “slope down” is widely adjustable on the HTP Invertig 201.

This is the A.C. or D.C. stick/arc (SMAW) accessory kit. The ground clamp and cable come standard with the Invertig 201 package. An electrode holder with cable for stick welding is optional. The stick process can operate to 200 amps, just like the TIG function.

The HTP Invertig 201 is an AC/DC inverter machine. It performs DC TIG welding and AC or DC stick/arc. In its AC TIG mode, the machine has a balance control for aluminum welding, adjusting the electrode negative to electrode positive percentages. Arc frequency tuning is another function…This machine provides the features found in much more elaborate welders, including automatic pulsing plus a useful TIG spot welding function!

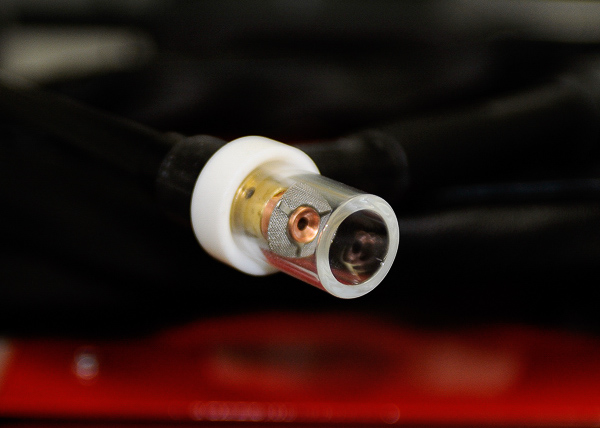

For demonstrating TIG welding, there is nothing better than a Pyrex cup! The HTP system includes a special collet, collet base and gas lens. Improved gas flow with the lens helps prevent gas turbulence and atmospheric contamination of the weld. The clear cup provides the best view of the electrode. A 3/32″ collet (shown) will receive a 3/32″ tungsten electrode. There are also 0.040″, 1/16″ and 1/8″ collets, gas lenses and collet bases available, for each of these common size electrodes.

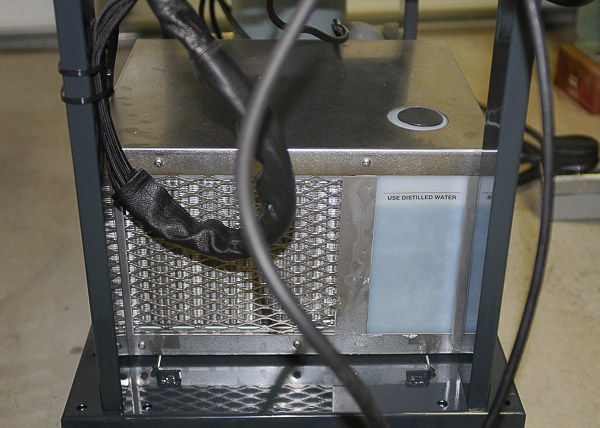

This is the HTP America water cooler (optional). The cooler uses HTP’s special coolant/anti-freeze, which is a must to protect parts and prevent freezing in cold weather. The high quality of this cooler unit is apparent.

Front view of the water cooler shows air intake grille. There is a pump and fan inside the unit, circulating and cooling liquid. Fluid pumps up and through the torch head and returns to the reservoir tank. A cooled torch is easier to handle. Temperatures at the torch head remain manageable for long periods of welding. Note the sheath encasing and protecting the hoses. HTP America provides high quality products.

The most common welding gas for TIG is pure argon. This new cylinder of 100% argon rates 155 cu.ft. volume. Actual fill is 141 cu.ft., which will last a considerable period. I buy new cylinders outright from my welding supply house. They can be refilled or exchanged for filled bottles. Leasing is an option. I find it cost-effective to own my cylinders. The HTP Invertig 201 has a finely adjustable post-weld gas flow provision that can save shield gas.

Flowmeter from HTP America works with 100% argon gas. New, quality parts are practical. Time lost fussing with leaking regulators or fittings is wasteful. Seeping gas can be dangerous; transporting cylinders is costly. New components are cost-effective in the long run. When the time comes, I will likely have my new cylinder refilled rather than exchange it for a “good” filled one. An older exchange tank can have a questionable valve.

This is a torch-mounted, finger control amperage switch from HTP America. Velcro secures the rotary track switch to the torch. The remote control works like a remote foot pedal but is much handier in tight quarters. Imagine constructing a roll cage atop the tub of a Jeep CJ or Wrangler—or inside an XJ Cherokee! Lugging around the remote foot control pedal would be a hazard.

Consumable gas lens and collet pieces come boxed and labeled from HTP America. Finding boxed parts is easier during a project! The HTP electrodes come in 0.040″, 1/16″, 3/32″ and 1/8″ diameter. These are 1.5% lanthanated. (Customarily I use 2% ceriated; I’m trying 1.5% lanthanated this time.) For the HTP Invertig 201, this electrode type will work with all steels and aluminum. Grind to a point; blunt very slightly.

Note: Thoriated electrodes are low-level radioactive. Many old-school welders prefer using thoriated electrodes. I made the switch to ceriated electrodes years ago and have been happy with the results. If you grind electrodes at home, especially with children around, I recommend using non-radioactive electrodes. (Use ceriated or lanthanated instead.) If you have never welded with thoriated electrodes, don’t bother. It’s easy to learn with these alternative, non-radioactive electrodes!

HTP electrode holders have a strong magnet base. This holder provides a place to mount the water-cooled Series 20 torch. When you have expensive, breakable equipment, a protective device like this can prevent damage. While you are beneath a dark welding hood, the torch can slip off the work bench and land on the floor. Pyrex and ceramic cups can break on impact.

The HTP Invertig 201 is now ready for action. Through how-to technical articles and instructional videos, I will demonstrate the Invertig 201’s valuable functions and fine control features. There will always be Jeep 4WD and off-road equipment projects underway at the 4WD Mechanix Magazine website. When TIG is the call, the HTP Invertig 201 will get the job done!