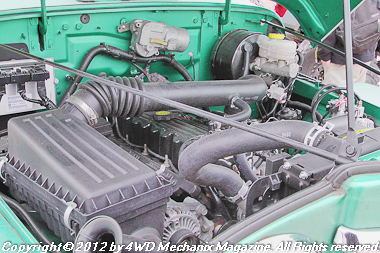

When this vintage Willys Wagon was new, the Super Hurricane 226 six took a 180-degree F thermostat for winter driving. A 160-degree F ‘stat was often substituted during hot summer months. The 4.0L TJ Wrangler engine transplant (above) calls for a 195-degree F thermostat.

This ‘Q&A’ question from a Jeep TJ Wrangler owner provides an opportunity to discuss thermostat settings. In this exchange, learn why your Jeep thermostat setting is important—and which thermostat will work best!

A Q&A Exchange on Thermostats

From: Peter M.

Sent: Tuesday, July 10, 2012 8:27 AM

To: qanda@4WDmechanix.com

Subject: 2003 year Jeep Wrangler – Installed 160F thermostat recently removed orig. 195F thermostat

Hi Moses,

When the local Chrysler dealership removed my old leaking radiator (vehicle had 130,200 miles on it, I told them to remove the original 195F thermostat and put in a 160F thermostat. The original 195F thermostat was sticking anyway. With the 160F thermostat in, I felt: 1) the engine would run cooler and last longer, 2) oil wouldn’t break down so quick (although I dump my oil every 2,000 miles) and, 3) mostly it will extend my auto tranny life (I think my trans fluid is cooled thru my radiator). Now I’ve read on the internet that running too cool can cause engine problems due to engine running too rich (carbon build-up??) and condensation of water in oil pan. My only problem is visually, the engine light will not go out on my dash board. I own a 2003 Jeep Wrangler Freedom edition, which is in otherwise, in mint condition. Academically I have an engineering degree, but am not a hands on mechanical person, but do know about mechanical things – to a point. With all of the above noted, should I just re-install the 195F thermostat and keep going. Your input will be very much appreciated.

One other comment and question. My engine is a 4 liter displacement (243 CID) 6 cyl. Is this base engine block the same as the Mitsubishi 243 CID 6 cyl. diesel block used in the Dodge 1980 series 100, ½ ton diesel powered pick-up trucks – offered only in 1980?

Best Regards,

Peter M.

Moses replies…

Hi, Peter…I’m old enough to remember when the norm was a 160-degree F thermostat in the summer, 180-degree F in the winter. That era also meant radiators without coolant recovery/overflow systems. If coolant expanded, it overflowed from the radiator and onto the road. Today, hot coolant expands into the recovery tank and contracts back into the radiator, constantly maintaining a radiator full of coolant.

As for operating temperatures, there is no harm done by 195-degree F engine operation. There are OE engines that use 205-degrees F as the opening point. Temps like this do require a 50/50 mix of anti-freeze/coolant to raise the boiling point of the coolant to 265-degrees F or so. The radiator cap must hold proper pressure, as this also contributes to the boiling point.

For emissions and the catalytic converter function, it is imperative for engines to operate at higher temperatures. Vehicle manufacturers program the powertrain management (PCM on Jeep) computer to monitor that warmed-up temperature. There is an additional and important reason for a higher temp setting on the thermostat: The engine must get off the warm-up cycle to avoid an over-rich (cold-start) fuel mixture. (This is for emissions as well as complete combustion.) If the engine fluctuates around the warm-up cycle temperature, fuel efficiency will suffer, the catalytic converter life will suffer, oxygen sensors will struggle—and there is nothing gained…As an aside, you would be quite uncomfortable in a Jeep with a 160-degree F heater in the winter.

195-degrees F will not shorten engine life nor cause any kind of trouble in the long haul. The 4.0L six should run 200-250,000 miles without a hitch, especially with your short service cycles (stock up on replacement drain plugs!). What you should do with the engine cooling is assure efficiency, the ability to maintain a 195- to 200-degree F operating range when warmed and under load.

A new radiator of the right size should help. Fan cooling is important, and keep exhaust restriction to a minimum. Overall, you have little to fret about with the 4.0L inline six, its cooling potential and longevity are renown. See the new engine cooling section at the magazine, including the Griffin Radiator products I’m testing in the XJ Cherokee 4.0L. Also see details on the Random Technology cat and Borla header.

The 4.0L (actually 242 cubic inches) Jeep inline six is an AMC derivative and in no way related to the Mitsubishi naturally aspirated inline six diesel. That late-’70s engine was a joint-venture through the Chrysler-Mitsubishi connection. Chrysler did not have access to the 4.0L AMC inline six until 1988, when Jeep Corporation became a member of the Chrysler family. See my article on the 4.7L Mopar stroker, I walk through the history of AMC inline six development in the seven-main bearing era. The 4.6L Tony Hewes video interviews are insightful, too. The stroker six hybrid build-up is popular—and adds BTUs for new cooling system demands!

As an aside, Peter, I drove the Cherokee today in 101 degree F ambient temp with the A/C running. The engine hovered around 200 degrees F under load in traffic and dropped to thermostat opening temp (195) at an idle with the A/C operating. The fan run-on after shutdown dropped temp at the lower portion of the radiator to 165 degrees F in just over two minutes—typical for this Griffin radiator prototype with twin Spal fans…A point worth mentioning is the difference between an engine under load and when idling. Horsepower equals BTUs, and at an idle, the engine has far less horsepower output. (The twin Spal electric fans obviously work!)…Simply put, the real test is under horsepower load, when the BTUs increase.

As for the drain plug, my remark was somewhat tongue-in-cheek. The threads are just fine (do not torque beyond spec). The plug’s built-in gasket material is vulnerable, however. I did the math: My OEM drain plug sealed well for around twenty drains. If you’re doing 2K oil changes, quality plug seal would last approximately 40K miles. Not a big issue, a new plug is cheap at the local Jeep dealership.

What concerns me more is engine start-up with each oil change. Approximately 95% of engine bearing stress/wear is at start-up, before the engine delivers oil to the bearings under pressure. Worse yet (obvious when you do your own oil changes) is the start-up after changing the oil. If the oil filter is not mounted horizontally, I prime the new filter with fresh, clean oil during the oil change. By filling the oil filter to a reasonable level, picking up oil the first time is quicker. Beyond that, a quality oil (either synthetic or with synthetic behavior) helps leave an oil film on the bearing surfaces that can carry the load briefly while oil pressure builds.

I watch oil coloration for determining change intervals. 3K-5K is surely acceptable with a modern, high-quality engine oil. Synthetics that go longer than this should have an oil filter change at 3,500-5,000 miles; topping off the oil provides a slight replenish…My approach.

Enjoy your Jeep, Pete, and stay tuned at the magazine!—Moses

Footnote from Moses: In the era of the Dodge/Mitsubishi venture, I was fond of the International Scout II with the Nissan marine turbo-diesel option, years ahead of its time…Here’s some info on your Mitsubishi diesel question, Peter, a direct quote from Wikipedia:

Courtesy of Wikipedia—”The 1978 saw also the introduction of the first Diesel powered Dodge pickup truck. Available as an economy choice in the light duty trucks was Mitsubishi 6DR50A 4.0 L inline 6-cylinder naturally aspirating diesel, rated at 105 hp (78 kW) at 3500 rpm, and ~230 N·m (~169 lb·ft) @ 2200 rpm. The diesel used standard Dodge manual and automatic transmissions via specially made adapter plate which had the LA V8 bolt pattern. This rare factory option, VIN code H, was the result of fuel crisis and the collaboration of Chrysler and Mitsubishi. The engine, while being trustworthy and having far better economy than any other engine in the Dodge lineup at the time, suffered from its low power output and was considered to be underpowered by American standards, even though it was previously used in the Japanese 3.5-ton cab-over Mitsubishi T44 Jupiter Truck and in industrial applications. Because of the low sales it was phased out quickly and as a result it became practically a single year specialty.”

I’m a big Cummins fan and actually tested the earliest Dodge truck models with the 12-valve 5.9L engine (late ‘80s) when new. In the day, those engines were torque monsters compared to these Mitsubishi diesel remarks.

Our 5.9L 24-valve Cummins-powered ’05 Ram 3500 has been a delight since day one, 610 ft-lbs of torque on tap! Cummins brought Dodge Ram trucks into prominence, overcoming the era of emission constrained, stodgily-powered light trucks and cars.

—Moses Ludel