Spark plug thread damage is increasingly more common, mostly due to the popularity of aluminum cylinder heads on automotive and powersports engines. This HD video how-to demonstrates the Time-Sert® permanent repair for damaged spark plug threads on an aluminum cylinder head. This insert kit allows for head-in-place installation of new spark plug threads. The candidate shown is a popular Honda XR650R motorcycle. The affordable insert repair saved a lot of time while providing a major improvement over the OEM aluminum spark plug threads.

Time-Sert® is a permanent repair for spark plug threads. The #4412 Kit that we used in this project came with each of the tools shown at right. The #44111 16.8mm length inserts were selected. (Sold five to a package, we only used one on this single cylinder “thumper”.) This tooling permitted a repair with the cylinder head in place on this Honda XR650R motorcycle engine. Follow the comments and steps in the video, and consult the Time-Sert® catalog or online listings at http://www.timesert.com.

A viewer expressed concern about cutting threads with the cylinder head in place. There are other Time-Sert spark plug thread insert installations at YouTube with the cylinder head in place. A popular Time-Sert® installation is the repair of Ford Triton engine aluminum spark plug threads with the aluminum head(s) still in place. According to Time Fastener Company (manufacturer of Time-Sert® kits), the tapping and insert installation can be done with the cylinder head in place. The instructions suggest use of heavy grease on the step tap flutes to capture chips, following up with a shop vacuum to draw out any remaining residue: https://www.timesert.com/html/faq.html#10.

In this demonstration with the Honda XR650R aluminum head in place, the intake and exhaust valves are closed completely, which is noted in the steps. (Backing off the valve rocker adjusters will assure that the valves are seated.) The piston is positioned just low enough on the compression stroke for the tap to safely clear the piston. With the valves still closed and piston still in this position, a powerful shop vacuum with a tapered nozzle pulls aluminum tap chips and residue from the cylinder and combustion chamber area.

The Time-Sert® installation technician can decide whether to remove the cylinder head or whether to use heavy grease on the step tap flutes. When using heavy grease on the step tap flutes, it may be difficult to remove all grease and residue. With the softer aluminum thread material, I chose to run the tap dry and draw out aluminum debris from a dry cylinder and dry combustion chamber with the strong shop vacuum and tapered nozzle.

Although many do this procedure for cast iron spark plug threads with the head in place, iron chips or residue would be more abrasive than aluminum. As a precaution for a cast iron cylinder head, I would likely remove the head and install the Time-Sert® on the bench. Clean-up of all tap chips and residue would be done before reinstalling the iron head.

Note: After cutting/tapping the insert threads, be certain to remove all debris from the cylinder. I performed the tapping operation with the piston rising on its compression stroke and all valves closed. On this Honda motorcycle engine with a decompression mechanism, the valve lash adjusters must be backed off to provide full seating of the valves before performing this procedure. All valves are seated and the piston is down in the cylinder on the compression stroke, enough to clear the cutting and installation tools. After tapping, the strong shop vacuum with a tapered nozzle pulls debris through the spark plug hole. Make sure all debris is removed.

If you like this kind of coverage, see Moses Ludel’s channel devoted strictly to motorcycles. “Motorcycle Tech and Travel” features dirt, dual-sport and ADV riding routes, technology, in depth how-to, tools, gear, readiness for back country travel, safety tips, motorcycle reviews and the latest news. Subscribe and stay up to date at:

https://youtube.com/@MotorcycleTechandTravel

Keep your motorcycle ready for “100 miles from nowhere” rides!

At left are the damaged spark plug threads, the cause is overuse and heat distortion. At right is the 16.8mm length replacement insert package, one of these inserts made a permanent repair on the Honda XR650R aluminum cylinder head. Motorcycle engines with aluminum heads are even more vulnerable than the automotive applications, as motorcycle plugs get removed far more often.

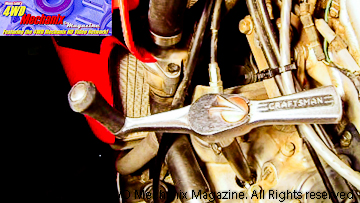

Cutting threads with the Time-Sert® two stage tap uses the first stage to align the tool with the original spark plug threads. The “Standard” inserts work with loose or slightly damaged threads that can still support the pilot portion of the tap. There are even “Oversize” inserts available, and these kits address common washer seat, tapered seat and Ford Triton type spark plug designs.

The cutter at left is a unique part of the Time-Sert® spark plug thread repair kit. This is a two-phase cutter that first cuts the chamfer for seating the top edge of the Time-Sert® copper-coated steel insert. At right is the driver tool and special lubricant that thread the insert into freshly cut threads, pushing through the insert to form and expand the insert’s special locking threads. See the video for details.

CAUTION: After cutting/tapping the insert threads, be certain to remove all debris from the cylinder. I performed the tapping operation with the piston rising on its compression stroke and all valves closed. On this Honda motorcycle engine with a decompression mechanism, the valve lash adjusters must be backed off to provide full seating of the valves before performing this procedure. All valves are seated and the piston is down in the cylinder on the compression stroke, enough to clear the cutting and installation tools. After tapping, the strong shop vacuum with a tapered nozzle pulled debris through the spark plug hole. Make sure all debris is removed.

At left is the finished Time-Sert® insert installation. The spark plug washer’s seat is like new, the insert seating squarely and neatly, flush with the washer threads. This provides a perfect compression seal and restores threads to, in this case, better than new! At right is a sensible method for installing spark plugs into recessed, difficult to access aluminum spark plug threads: A rubber hose on the plug end enables finding the threads with the lightest of pressure. This helps prevent false starts and forced damage to the spark plug threads. Many performance engine builders install Time-Sert® spark plug inserts into their custom aluminum cylinder head work on the bench!