At the 2012 Moab Jeep Safari week, the Warn Media Run tackled the ‘Rose Garden’ rock trail. The lead vehicle’s tie-rod snapped, and a Ready Welder fix enabled the Jeep 4×4 to complete the run! See this temporary, emergency trail repair unfold. (HD video footage by Moses Ludel.)

Main components in the Ready Welder system include a popular ‘spool gun’ for welding with wire. Dave Logan will use flux-core 0.035″ for his field repairs. You can also use bottled gas with solid wire, including Argon for aluminum welding. The gun will work with D.C. welder power sources and even the Premier Welder, an alternator-based frequency type power supply. (Photo courtesy of Dave Logan.)

Years ago, some innovative trail runners used battery cables, vehicle batteries and welding rod to make trailside repairs. Welding is a resistance process, and batteries are fully capable of producing a huge amount of amperage/resistance. Just think of the accidental shorting together of two jumper cable ends!

Welding with a vehicle battery and jumper cables is very risky, however. Amperage draw is high, and battery heat plus gas emissions can lead to a volatile battery explosion! Though the principle of creating resistance with D.C. batteries does have merit, the use of battery jumper cables, a stick electrode holder and standard automotive batteries is not only a crude approach but also very hazardous.

As the years passed, Ready Welder developed a field welding alternative. This system employs 12V batteries in series. Based upon amperage needed, the Ready Welder II can supply enough current to weld and repair common steel and other flux-core wire applications to as much as 3/4-inch welding depth (using three 12V batteries in series for 36-volts and 350 amps at 100% duty cycle).

The spool gun can also be used with an existing shop MIG or stick machine if desired. These units have been tested in rugged outdoor and military environments with proven success. Units are available with quick connects for use with the more common NATO/D.C. vehicle plugs (typically 24V).

Overall, I praise the Ready Welder II system for its simplicity, versatility and lower initial cost.

For a Ready Welder corporate perspective and testimonials visit: www.readywelder.com.

Dave Logan of the 4WD School shares his experience at putting together a Ready Welder kit for trail use:

Dave Logan: “I had the opportunity to purchase a used Ready Welder II unit and received just the MIG gun, cables and manual.

I asked the previous owner what batteries he had used, and all he could tell me was small, deep cycle golf cart batteries. Another Ready Welder owner said he used batteries from old computer UPS systems. (UPS = Uninterruptible Power Supply.) Neither person could give me any specifics about battery group size, capacity and so forth, so I called Ready Welder and was told that any car battery will work.

Not satisfied, I kept searching. I was hoping for a pair of small lightweight batteries that were portable. On Ready Welder’s web site I found the following under FAQs:

‘ What type of batteries and charger should I buy, and what type of maintenance do I need to perform on the batteries? Answer: We highly recommend the purchase of good quality,12 volt deep-cycle marine/RV batteries ranging from group 24 to group 31, which is our preference. Get the kind with vertical posts capped with wing-nuts for easy power connections to the RW-II. Regular auto batteries and other batteries not designed for deep cycle discharging and recharging will have a shorter life span if drawn too low too many times. For occasional welding this shouldn’t be a problem. For home use a 10 amp overnight charging will work well. Maintenance of batteries should be according to manufacturer’s instructions.’Elsewhere, I read that Absorbed Glass Mat (AGM) batteries were preferred for pure, deep-cycle use.

High end batteries for solar systems were too expensive for my use, so I looked at the Optima Blue Top batteries. Then I read that Ready Welder recommended Optima batteries. That clinched it.

I knew that Sam’s Club had Blue Top Optimas and when I visited they had Group 34 size batteries for $155 each. I bought two.

Now I needed a way to charge these batteries and keep them maintained. Battery Tender came to mind. I wanted to leave the two batteries wired in series and ready for use. So, I bought a 24 volt marine unit from my local Batteries Plus store for $90.

Pulling out the instruction manual for the Ready Welder, I connected the jumper cables. It was easy when you find the correct diagram for what you want. Connecting the Battery Tender was easy, too. I love having the wing nuts on the battery terminals.

Eventually I will buy or build a carrier for the batteries and plan to leave them wired up and ready to go.”—Dave Logan, 4WD School, www.4WDschool.com

Dave selected the Optima ‘Blue Top’ AGM marine, deep-cycle batteries. He will wire the two 12-volt batteries in series to produce 24 volts and a considerable amount of amperage! These batteries will mount separately from the vehicle chassis and not be part of the Jeep charge circuit. (Photo courtesy of Dave Logan.)

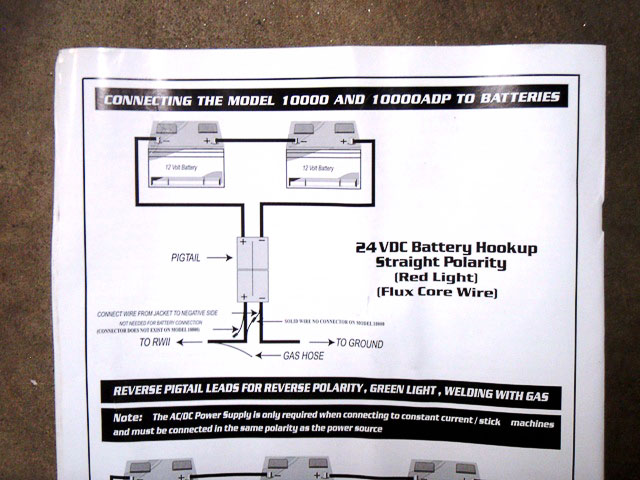

Ready Weld includes an instruction booklet with wiring diagrams for the battery circuit. Shown here is a pair of 12-volt batteries in series, producing 24-volts. (Photo courtesy of Dave Logan.)

Note the routing of the cables to produce series (not parallel) voltage. Rear jump cable goes from negative (-) at left battery to positive (+) post at right battery. Leads to plug come from the positive (+) battery terminal at left battery and the negative (-) post at right battery. This arrangement produces 24-volts D.C. for 200 available welding amps! (Photo courtesy of Dave Logan.)

The balance of the system is the ground clamp and the lead to the spool gun. Cable plug is failsafe and only fits one way. MIG-type spool wire is available for carbon steel, stainless steel and even aluminum. This makes the Ready Welder II versatile and a good emergency tool. (Photo courtesy of Dave Logan.)

The Ready Welder II spool gun simplifies welding. Common spool size contains enough welding wire for most field chores, and changing spools is not difficult.

Dave chose the Battery Tender for 24V marine use. This system can charge both batteries simultaneously without damage. Though slow, the Battery Tender is an exceptional way to charge and maintain any automotive or marine battery system. I use a Battery Tender on each of our vehicles and trailer batteries, especially in colder weather. The charger will not overcharge or sulfate a battery, extending battery life considerably. (Photo courtesy of Dave Logan.)