I endorse the use of EFI/MPI systems like the well-conceived, 50-State emission-legal Mopar kit. For the Jeep CJ or YJ Wrangler owner expecting peak horsepower output, maximum fuel efficiency and optimal performance at all altitudes, EFI can be worth the cost! Many 258/4.2L Jeep engines have undergone the Mopar conversion with highly satisfactory results.

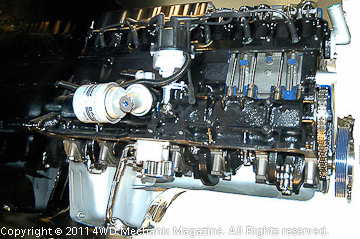

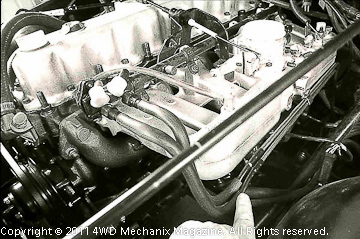

The AMC/Jeep-design inline six dates to the mid-1960s! Originally a Rambler passenger car engine, the 232 cubic inch displacement, seven-main bearing design was outsourced by Jeep Corporation for the 1965-up J-trucks. The 2.5L AMC/Jeep four, 258/4.2L six and 242/4.0L (shown here) engine share common features with the 232. A proven overhead valve, two-valve per cylinder “pushrod” design, the 232/258/242 platform has provided Jeep vehicles with more than four decades of reliable, efficient powerplants! Its most efficient and advanced form is the MPI 4.0L package.

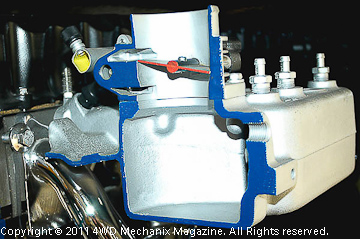

The intake plenum cutaway of a 4.0L manifold shows why MPI brings out the full potential of 4.2L and 4.0L engines. Port fuel injection eliminates the inherent fuel distribution problem of inline engines with carburetors or TBI. Uniform fuel delivery at each cylinder allows more control of air-fuel ratios plus a cleaner tailpipe. This was the measure that turned a superior engine into the most reliable, versatile powerplant in Jeep history. MPI engines will often run well over 200,000 trouble-free, reliable miles.

In my experience with these multi-point EFI systems, an otherwise purely stock 258 engine can gain up to 50 additional horsepower and several miles per gallon in improved fuel efficiency from the Mopar MPI/EFI conversion. The clean-burning 258 with Mopar MPI/EFI easily meets 50-State emission requirements and is fully legal. 1987-90 YJ 4.2L owners will benefit from a Mopar Performance MPI conversion.

EFI conversions are not for every builder. Cost may be prohibitive. For some, there is another type of engine, perhaps an EFI V-8, planned for the next phase of the Jeep’s life. Regardless, a good number of owners do not want EFI, yet they also need to meet emission compliance.

Carburetor retrofit kits that meet 50-State emissions requirements are currently non-existent. As alternatives, you either restore the factory BBD carburetor and emission system or convert to an emission legal EFI or MPI system.

While EFI would add horsepower and high altitude improvements, the carbureted 4.2L six with BBD carburetor (even those loaded with OE California emissions equipment) can run well. For nothing more than the cost of a quality Mopar carburetor kit, a new Echlin choke unit and several hours of labor, the carburetor overhaul pays off. You may want to try this before condemning your CJ or YJ’s original equipment emissions hardware or the Carter BBD!

Mopar Performance 4.2L MPI Conversion: An Orientation to Multi-Point Fuel Injection

A major breakthrough for the early YJ 4.2L six-cylinder engine is the Mopar MPI Conversion Kit. The AMC-design 232, 258/4.2L and 242/4.0L inline engines have proven highly reliable and the longest lasting engine platform in Jeep history—remarkably, more than four decades of rugged and dependable service! MPI brings out the full potential of the 2.5L four and the 4.2L and 4.0L six-cylinder engines.

The 258 and 4.0L sixes offer a rugged seven-main bearing design. This is by far the most reliable of six cylinder engine types. Inline sixes are inherently smooth and balanced. Ruggedness characterizes the 258 and 4.0L, the 258 having seen service in full-size J-trucks and even International-Harvester trucks and Scouts. If there was ever a “weak link” in the 258, and other carbureted inline sixes, it is the induction system.

Use of the BBD carburetor was a step in the right direction. With a two-barrel manifold that more evenly distributes fuel to the intake ports, the 1979-90 CJ and YJ powerplants were a better design than earlier 232 and 258 one-barrel carbureted versions. EFI, or more precisely, MPI/multi-port injection, fully resolves the fuel distribution issue. The Mopar retrofit kit for the 1987-90 4.2L/258—essentially the system found on 1991-up 4.0L Wrangler powerplants—is a dramatic improvement for the YJ’s carbureted 258 six.

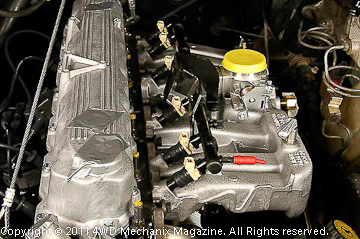

Mopar has offered two versions of EFI retrofits. The first design was a bolt-on throttle body approach that used some outsourced parts and some OEM Mopar pieces. The later kit, available today, takes a pragmatic and useful approach. This bolt-on kit is based upon a ’94-’95 Wrangler YJ’s 4.0L induction system, using some TJ era updates and OEM peripheral hardware. With the intake manifold machined to fit the 4.2L engine layout, programmed for 50-State legal emissions certification (earning a California E.O. “exemption” number), the Mopar Performance MPI Conversion Kit is packaged complete with all necessary hardware and installation instructions.

Here is 50-plus horsepower the easy way! If a 4.2L engine has good oil pressure and normal compression/cylinder seal, the kit will boost power without compromising reliability. In fact, considering the precise metering of fuel to achieve complete combustion and the lowest possible tailpipe emissions, the Mopar Performance MPI Conversion Kit should actually increase engine longevity. Add to this the famous low-end torque inherent to the long stroke and ample bore of the 4.2L engine. Many would argue that the 4.2L MPI retrofit creates an even better off-pavement “stump-puller” than the donor 4.0L MPI inline six!

The installation of a Mopar Performance MPI Conversion on a 4.2L six provides an overview of the system and its key components. In this series of articles, I share diagnostics and troubleshooting guidelines for the 4.0L MPI engine that also apply to this conversion package. The MPI conversion steps will orient owners and tuners to the OE Mopar MPI system common to 1991-up Wrangler 4.0L and 2.5L engines. Even the 2003-up DOHC 2.4L four, despite its advanced cylinder head and induction system design, includes features much like the Mopar MPI packages described in this section of the magazine.

MPI Conversion Kit is complete in every way. Offered through Mopar/Jeep dealerships and aftermarket Mopar Performance suppliers like 4WD Hardware, this system provides all of the components needed to convert a 1981-90 CJ or YJ 4.2L six to 50-State legal MPI. The original BBD carburetor, intake manifold and emissions hardware will be replaced by factory parts from mid-‘90s and later, 50-State legal Wrangler 4.0L MPI and emissions systems—all included in the package.

The intake manifold of the Mopar Performance MPI Conversion package is essentially a ’94-’95 circa 4.0L MPI type. This manifold is machined slightly to fit the 4.2L engine and its accessories. The same manifold design follows into the TJ era, making this a useful example of 4.0L MPI induction. MPI manifold comes with port injectors at each of the engine’s six intake ports. MPI provides precise, uniform fueling of cylinders, the largest advantage of MPI over throttle body injection.

The Mopar kit comes complete with a throttle cable. This is the throttle body end. Fit-up is like original equipment—because it is! Here, I compare cable end size with an older OE cable. YJ 4.2L engines used a Carter BBD carburetor, requiring a cable linkage change with the MPI conversion.

The cable should be routed in a way that does not create kinks or the possibility of binding. I make sweeping bends to assure easy operation of the cable and a long service life from this part. Cable has a plastic clip holding the sweep in place at the valve cover.

On the return sweep that brings the cable in line with the throttle body arm, I use an insulated clamp for support. The clamp holds the cable housing securely but does not squeeze hard enough to cause binding of the cable. Always check the cable for free movement without roughness.

These high pressure lines come with the kit. They have OE couplers that quickly snap into place at the fuel rail. The steel tubing is very high grade stainless type to resist corrosion and provide a safe, long service life. I value the OE integrity of components and the Jeep/Mopar service parts access. Most pieces come directly from the late YJ or TJ 4.0L MPI engines and chassis.

Note—The latest Mopar Performance MPI kit uses a single line (supply only) to the fuel rail. This approach is patterned after TJ-era 4.0L off-the-shelf components. In these EFI articles, I illustrate both the later style (single rail) and the 1991-95 4.0L two-line system.

On the six-cylinder YJ Wrangler 4.2L chassis, the fuel tank has a gauge sender only. There is a supply line for the low pressure mechanical fuel pump, a fuel return line and the evaporative emissions line. I mark these hoses to keep track of their roles, as the Mopar Performance MPI conversion uses an in-line, high pressure electric fuel pump. OE pickup and return hoses would be sufficient, since the pressure boost is on the pump-to-engine section of the new in-line fuel pump.