Q&A How-to for Jeep Grand Cherokee 4WD

Enjoy the many detailed, traditional ‘Q&A’ exchanges in these article columns…’Q & A’ has now moved to open, interactive forum discussions. Visit the forums, you’ll want to join—for free!

Have technical questions about your Jeep 4×4, popular 4WD truck, SUV, ATV, UTV or dirt motorcycle—or welding and metal fabrication? The 4WD Mechanix Magazine ‘Tech and Travel’ Forums now feature enthusiastic discussions and input from members and our staff—including comments from Moses Ludel…

For an HD video playlist, featuring the latest Q&A vlogs with Moses Ludel, click here for the “4WD Vlog and ‘Live Tech’ Q&A Channel”.

Want to discuss your technical and outdoor interests with like-minded enthusiasts? Check out the 4WD Mechanix ‘Tech and Travel’ Forums! Click here for a guest visit to the forums!

Oil Filter Position for a ZJ 4.0L Inline Six

From: Paul G.

Sent: Friday, September 21, 2012 1:30 PM

To: 4WD Mechanix Magazine

Subject: 95 Grand Cherokee

I have a 95 Grand Cherokee just bought it and reconditioned the head 168,000 miles. I think the engine was replaced but am not sure of the year the oil filter points straight up. Is this a normal position for the 4.0L Oil Filter and could you tell me the year based on this information?

Thanks,

Paul G.

Hi, Paul…The oil filter position does vary on the XJ and Grand Cherokee models. 4.0L inline engines have featured horizontal, upright (upside down) and slightly downward sloping filters. Motor mount position is the typical determinant. You could very well have an original filter stand on your engine.

To be sure about your engine’s originality, get the casting number from the engine block and head…That would be “proof” of origin, at least a shorter range of years and applications, for the block and head.

Furnish those numbers, and I’d be glad to research and share findings!

Moses

Additional comments…

From: Paul G.

Sent: Saturday, September 22, 2012 1:30 PM

To: 4WD Q & A

Subject: Re: 95 Grand Cherokee

Moses,

Thanks for replying. Another question I am a pretty good backyard mechanic and enjoy working on jeeps especially the 95-98 Grand Cherokee’s. Could you suggest the tools that I might need to rebuild the automatic transmissions found in those years. I know it makes sense to farm them out or just purchase reconditioned from mopar but I would like to perform the work for myself and a small group of other enthusiasts who might share the tools.

Thanks,

Paul

Paul, specialty tools are listed at the back of the factory workshop manual chapter on transfer case and transmission service. A copy of any ’95-’98 OEM manual would be a real asset. I have built automatics since 1969 and never plunge without a factory or equivalent manual!

I’d be happy to PDF those illustrations…In general, a K-D or OTC clutch pack compressing tool and some imagination will go a long way with regard to tools. If you would like a copy of the Chrysler tools (Miller-OTC/SPX), I’ll send your way, Paul.

Moses

Troubleshooting the WJ Grand Cherokee NV247 Transfer Case

From: Douglas O.

Sent: Thursday, August 23, 2012 7:02 PM

To: qanda@4WDmechanix.com

Subject: NV247

I purchased a 1999 Grand Cherokee Limited w/4.7L Quadradrive automatic trans and NV247 transfer case. Was not really up to speed on full time AWD vehicles when I test drove. Maybe the damage was done before I got her home. Realized from a safety message stating only use Mopar gear lube (05016796AA) which I purchased and drained and filled TC with. It felt to me as if AWD was working when I turned in a circle from the jerking on steeering wheel. Did a good once over and give to my son. The next morning he informed me that the 4WD does not work. Checked, and sure enough front wheels do not engage at all. Put all four wheels off the ground and only rear wheels spin. Put both rear and one front wheel off the ground and no power transfered to front wheel on the ground. Pulled the drain plug and noticed chain does not turn at all. Is there anything else I can check before pulling TC out? I must be the only one out here with this transfer case because I can not find any specifics on the NV247. Also, when you try to slip TC into neutral it will not disengage and grinds requiring you to turn off engine to move selector to neutral or 4H/2H. Any advice would be greatly appreciated. Thanks

Doug

Hi, Doug…This is frustrating, I’m sure…I pieced together a factory overview for troubleshooting the NV247. You can break down the diagnostics from the attached information. The “Components” section is very useful, the troubleshooting “chart” is somewhat shallow.

These systems, like others, are “great” when working well. When defective, they can be costly to restore…You’re not alone.

The good news: any 1999-2004 WJ is a good model, the only other touchy area is the control system for the heating and A/C system…Family members did very well with a 4.7L V-8 powered ’99. If “original” and not tampered with, this could be a Jeep worth keeping a long time. I much prefer them for their beam axles front and rear…

Trust this is helpful…

Moses

1999 WJ Headed for Stroker 4.6L Build

From: Dan D.

Sent: Wednesday, August 22, 2012 11:02 AM

To: qanda@4wdmechanix.com

Subject: Need your expertise please – Awaiting your reply before I talk to my mechanic

Hi Moses,

First and foremost – I would like to thank you for taking the effort in making all those [4.6L stroker six] videos on YouTube. They are very useful, especially for a newbie like me who is just getting into off-roading. I have watched most of your videos, and it is one such video series that got my attention and also several articles at the magazine.

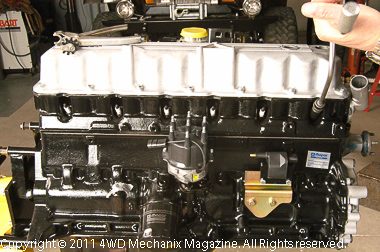

I got my Jeep Grand Cherokee ’99, 4.0L a year back. Recently, I found a hairline crack near the oil pressure sensor region of the block, and after watching your videos and reading your article, I thought this is a good opportunity to go for a 4.6L stroker. I also learned a lot in that one hour of viewing – I had no experience dealing with engines before – so I thought, well here is my chance to learn more.

Now, in your video where you talk to Mr. Hewes – he’s talking about two different configurations where the common parts are 4.0L block, 258 crankshaft from 4.2L with the serpentine belt, the difference in the config being – 258/4.2L con rods (short) with 4.0L pistons or 4.0L con rods(longer) with special pistons.

Configuration Questions: Can you please help me with the following questions that I need your expertise on:

1. What is the special piston called and where do I get it? Which brand is the best? Also, is there know how on where the pin head needs to be set, etc? My mechanic was planning on going with 4.0L pistons as well.

Contact United Engine at Carson City, Nevada, about the pistons, explaining your use of the 4.0L rods with a stroker motor 4.2L crankshaft. You want around 8.7:1 compression, and your machinist will set block deck with a normal “decking cut”. Tony went around 0.008” cut on this block, just a clean-up, and that provided the right compression ratio plus correct piston height location (i.e., including pin height) for these rods and the pistons described.

2. What is the difference in performance in the above two configs?

Negligible if you’re not racing at higher rpm. In the normal 4,200-4,500 maximum rpm (even this is excessive for most Grand Cherokee driving), there would be no great difference.

3. What are they best suited for?

I like the cast pistons rather than forged, although Tony is comfortable with both. Forged pistons are typically for racing or high compression ratios, which would not be my goal for this use. Forged pistons require more piston-to-wall clearance and can be audible on engine start cold and during warm-up…The hypereutectic (cast) piston is very durable and good for normal use over a very long engine life. That’s my opinion. Some prefer forged pistons, regardless. I don’t unless needed.

4. Which one will give me more miles per gallon/ cleaner burn/ more power etc?

Again, as long as your block deck height is correct, compression ratio around 8.7:1 and the camshaft is as described, you will get good fuel efficiency with either of these configurations. Power should be similar, more a product of camshaft choice and compression ratio.

5. I am planning to use my vehicle for regular commuting to work and as a dirt vehicle (mudding, off-roading, sand etc). I don’t do too much of rocks. Also want it to be quick out of the block. I also tow a big U-Haul as I keep moving a lot.

Here, the camshaft prescribed and an rpm ceiling of 4,200-4,500 rpm will deliver. If you want more rpm than 5,000 with a “bigger camshaft”, expect to pay for the added horsepower with lack of fuel efficiency. The camshaft noted produces excellent manifold vacuum at idle and low speeds, optimal for usable, towing power.

Here are some camshaft details:

I dug down into the CompCams catalog online. Here is the page with the camshaft order description. You want a camshaft and lifters kit. This is the basic cam-and-lifters kit, the least expensive approach. There are more expensive approaches with new valve springs, retainers and so forth: click here. Trust this helps. For more details, click on the specifications link. Click here for the website page.

My mechanic (Poteat’s Engine Rebuilding) wants me to go with the longer 4.0L con rods but hasn’t mentioned anything about the piston. This is what he’s using in terms of brands –

Pistons – Silvolite

Rings-Perfect Circle

Gasket-Viton

Main Brgs – Clevite (I noticed that you like King brand.)

Rod Brgs (inserts) – Clevite

Cam Brgs – Durabond

Melling for – Camshaft, T-Chain, Cam sprocket, Crank Sprocket, Lifters (Tappets), Oil pump, Oil pump screen, Oil pump driveshaft, water plugs

Dan, Silv-O-Lite is United Engine. Hypereutectic pistons should be the choice, sometimes the ‘Keith Black’ line, otherwise Silv-O-Lite, but in any case get hypereutectic from United Engine. The rest of Mr. Poteat’s parts list is common and excellent quality. King does do well on the crankshaft bearings, especially mains. Clevite works well, too, for a production engine.

I know you and Mr. Hewes were talking about increased gas mileage by increasing engine performance and throughput. I didn’t understand most of the technical terminology used.

1. 1. Is there anything I should be aware of or take into consideration while my engine is being rebuilt? Any special parts that I can put in there.

Make sure pushrod length is correct for the head and block deck machining, and the valve seat locations…“Ford 302 V-8” injectors are needed in most cases to meet increased engine size and flow needs. See the magazine website for many more tuning details, Dan. I did follow up the videos with tuning suggestions and links at the magazine site:

https://www.4wdmechanix.com/How-to-Tuning-the-Fuel-Injected-Jeep-Inline-Six-Stroker-Motor.html

Spend some time in this entire section of the magazine…

2. Mr. Hewes talks about cleaning the cylinder head (part 3 video) and doing a valve job, but he also mentioned in the end that it’s not much bang for the buck. He says it increases the flow by 20%. How come this is not enough bang? Do I need to ask my shop to do the 3 angle (intake) and Multi Angle (exhaust) valve jobs? How much do you think it should cost?

The valve job is a must. Tony did not do porting and exotic flow improvements. Cost for head improvements pay off for higher rpm and high performance use; for a milder engine, this is not worth the difference for the cost of porting and flow bench work. 3-angle valve seats are the common rebuild approach for a cylinder head, the multi-angle bowl effect is now popular, too.

3. What other items would be a good opportunity for me to change right now since the engine is out and I have easy access (if needed) to change the transmission etc

Make sure the transfer case is in good condition. A rebuilt torque converter for the transmission would be advisable with the engine out.

4. Do I need to change the manifold, better exhaust system, wider air intake (with K & N filters) etc..to give me more performance/fuel mileage? In that case what do I go for? Please give me specifics so I know what to tell my mechanic.

All of this is okay for a high-revving engine, the gains for normal driving are negligible. I do run a quality header (Borla or Banks) with a performance cat. This is well worth the investment, but only if you include a performance cat.

I know this is a bit lengthy but it had to be since I know you appreciate the details. Also I thank you for reading this. I would like to know your expert opinion please! I will be heading to the shop as soon as I hear from you. I am using a rental right now for a week – Till I fix my Jeep. Please help!!

Best regards,

Danny

Dan writes back to the replies…

See below, Dan…On your rebuilt torque converter, make sure it’s a stock replacement and not a high-stall speed type…I like the WJ Grand Cherokee (’99-2004) and would appreciate knowing how the 4.6L works in that application—as compared to a 4.7L V-8 in particular…Keep me posted on your findings…Moses

From: Dan D.

Sent: Thursday, August 23, 2012 6:45 AM

To: 4WD Q & A

Subject: Re: Need your expertise please

Thank you for your immediate response. I now have a better understanding on how it all comes together (I think!)

I have few more questions based on what I understood from your response –

Pistons: I will be contacting United Engine today about the pistons. I’ll also ask my mechanic to go with the KB T6 hypereutectic with the Teflon coated skirts – If possible, can you please provide me with the part number that Tony used?

United will know the line and want your machinist’s actual bore size request. Typical re-bore on good cylinders is 0.030” oversize, which you will likely do. I’m not fond of 0.060” (4.7L result), as this leaves a thinner cylinder wall for cooling.

Compression – I know the standard 4.0L comes with 8.8:1 Compression. 8.7 being lesser than that, wouldn’t a higher compression give better mileage? Your thoughts please? Also I know too much is going to be ping city for pump fuel. When you mention 8.7:1 – is this DCR or SCR?

The 8.7:1 is static compression ratio. There is a lot of DCR buzz in the forums; however, DCR is largely governed by camshaft profile and valve overlap. For dynamic compression ratio, there is no instant figure for a given piston and combustion chamber volume; camshaft profile, altitude and boost (if super- or turbo-charged) must be factored into the equation…For a milder camshaft, SCR works just fine. 8.7:1 is magic for resisting detonation and, most often, allows use of lower octane (i.e., less expensive) fuel…Remember, this is a stroker with inherent torque advantages; extra horsepower equals BTUs and risk of detonation. On that note, make sure your cooling system/radiator is up for the task. At bare minimum, have the radiator cleaned and pressure checked while the engine is out. See my magazine HD video coverage of Griffin’s latest prototype radiator for the XJ Cherokee, they may have a solution for your WJ application if needed.

Also, the CR’s mentioned in this website (linked through yours:

http://jeep4.0performance.4mg.com/stroker.html

– Are the values in DCR or SCR?

Not sure, does not mean much, anyway. Stick with SCR and don’t go down the rabbit hole. Here is a site for DCR computations if you’re curious. Use the camshaft specs on the CompCams 252 grind if that is your choice:

http://www.wallaceracing.com/dynamic-cr.php

Wallace Racing has done the math…

My mechanic tells me it’s not good to go more than 9.0:1 CR if you are going to use regular gas and not premium. Also that there is a higher chance of pinging and that the onboard computer will not be able to handle it. I forgot to ask him whether he’s referring to DCR or SCR.

The 4.0L MPI engines do not use a knock sensor, they rely upon the combustion chamber design and quench to control ping. The PCM is oblivious to ping or solving it, unless you change the base timing through a Chrysler DRBIII scan tool…9:1 is already excessive in my view, and running 92-octane fuel would be costly at best.

Many think they want maximum power and get hung up on horsepower peak. A stroker crankshaft dispels the belief that higher compression or high rpm horsepower is the goal. You will get torque and a quicker torque rise from the 4.6L, a dramatic improvement over the torque curve of a 4.0L configuration. That is the key gain!

You want bottom end torque and mid-range power. Do the math on the vehicle speed in each gear at 4,500 rpm with whatever tire size and axle gearing you run. Do you need a 6,000 rpm horsepower peak and torque peak at 3,600 rpm or higher? See the CompCams catalog online for the 252H flat tappet hydraulic camshaft offering. Compare this performance with “bigger cams” that require higher compression ratios.

Camshaft: Your answer to my 4th question under config – “Here, the camshaft prescribed and an rpm ceiling of 4,200-4,500 rpm will deliver” which camshaft are you referring too? Can you please provide details on which one I should use? Which one do you think will give me more RPM range without sacrificing fuel economy or HP/Torque?

For sensible driving and multipurpose use, I use the CompCams 252 grind—period. So does Tony. Even a step to the CompCams 260 will adversely affect idle, low-end manifold vacuum and fuel consumption at normal driving rpm. The 252 will pull to 5,000 rpm, it’s happiest with a 4,200-4,500 rpm ceiling. I’m not a buff of spinning a stroker crankshaft engine beyond these speeds, although the inline six is the best configuration for durability and inherent balance. On that note, be sure to balance all reciprocally rotating lower engine parts, this will improve smoothness and increase engine life.

Injectors: I am unable to figure out whether using Ford 302 V-8 injectors are needed. Is it a good practice to install them anyway? I am thinking this will not hurt anything. Am I correct?

Try the stock injectors. If you “starve” for fuel at a given speed or experience lean ping, let me know. I’ve yet to discover the absolute point at which you need the 302 injectors. Any injector size will only flow the required fuel to maintain the right air/fuel ratio as per the PCM and oxygen sensor readings. The 302 injectors rate more pounds per hour flow of fuel—if needed. Please let me know how this works out, especially if you do try the stock injectors first, Dan.

Other misc: Header – Unable to find a Borla/Banks header to fit my 99 Jeep Grand Cherokee 4.0L. All I can find is Gibson. Borla has headers till the 96 model. Can this be used for my 99 model as well?

’99 is a distinct chassis change. Not sure if their listings are emissions based or fitment based. Call Banks and Borla and ask if the header will fit within your chassis…Gibson might have value. A header is not going to create a great improvement at lower speeds. Most headers are for mid- to high-rpm gain. That said, the 4.0L factory manifold/header is notorious for cracking. I did a Borla on our ’99 XJ Cherokee just to get a high quality header—and to replace an OEM manifold/header with cracks.

Performance Cat – Which brand do you think is the best?

I did an article at the magazine on the Random Technology header. Read my article: https://www.4wdmechanix.com/How-to-Installing-a-Random-Technology-High-Performance-Catalytic-Converter.htm

This cat does not have a California E.O. on it but does reduce emissions enough to keep the downstream oxygen sensor and PCM happy. The Borla header came alive with this cat.

Also checking my transfer case as there is a ‘clunk’ sound when I put it in reverse.

More likely the U-joints or normal axle ring-and-pinion play…Jeep parked on level ground, E-brake set, with engine off and wheels chocked, rotate the driveshafts back and forth; note the pinion yoke movement and noise. Some ring-and-pinion gear play is normal and acceptable. Worn U-joints, however, need replacing.

Once again, thank you so much for your response!

Danny

Final footnotes…

From: Dan D.

Sent: Thursday, August 23, 2012 1:07 PM

To: 4WD Q & A

Subject: Re: Awaiting your reply before I talk to my mechanic

Moses, Thank you for your response!

Regarding the radiator, I just got it replaced a year ago. Brand name – Reach. As for the GPM or GPH – I called them up and asked them about it. Since their manufacturing base is in China – They said they will get back to me. But it should be same as stock GPM or GPH. That was a nice video you produced regarding radiator and cooling system. I will be getting the griffin installed once I am done with the engine and exhaust. I am guessing this can wait a little longer since I just replaced the radiator a year back.

The current radiator may work if you hold horsepower to 240-260, which is plenty. Click here for a link to a conversion for horsepower to BTUs. You’ll soon see how that radiator performs, especially in the Carolinas with high humidity and the need for A/C. Not sure whether Griffin fit a unit to the ’99-2004 Grand…Is there one available? The all-new prototype for the XJ Cherokee is not public as of this correspondence, Dan, it should be soon.

Regarding compression ratio (Sorry but I have few more questions on this) Poteat said he will bring it back to stock compression which is 8.8:1. Should I leave it there or request for 8.7:1. I am thinking higher the SCR, better the fuel economy and more power. As long as I don’t go overboard – like 9.0:1 or above, I should be good?

You’re good at 8.8:1. Fuel economy does not necessarily increase with compression ratio, in fact fuel knock (detonation/ping) will dictate ignition base timing and spark advance; fuel economy and power have more to do with spark timing than any incremental compression boost. Be at peace with 8.8:1, that’s plenty…especially for a stroked inline six!

When you mentioned “be sure to balance all reciprocally rotating lower engine parts, this will improve smoothness and increase engine life” – Can you please specify what parts need to be balanced? – Sorry newbie here! Not sure what parts exactly need to be balanced.

Crankshaft, damper, rods; match weight the pistons, rings and pins…Flexplate is less important but can be balanced, too.

Regarding the torque converter – I am thinking twice about replacing it. Because I am doubtful whether I will get a good rebuild since after looking around – hard to find shops that carry them. Do you know any shops that are reliable and carry the rebuilt ones. Also makes me wonder what went wrong with the rebuilt one.

Transtar is nationwide…I use a shop at Sacramento, CA, PDQ Transmission Parts. Either should work, I use PDQ for my converter rebuilding and balancing:

Also, what performance gasket do I use? What brand is good? Since this is a crucial part in keeping the piston head clearance.

Felpro is consistently reliable…One-time torque head gaskets are always a plus and Felpro standard.

Again, I can’t thank you enough. I will keep you updated with what feedback I get from my mechanic and also let you know how it runs when it first gets on the SIM.

Best of luck with the build, Dan!

Note: For the benefit of others, I posted Dan’s engine build component list and his research findings at the magazine’s 4.6L stroker six coverage.—Moses

Grand Cherokee owners! Send Moses Ludel your Grand Cherokee 4WD ‘Q & A’ questions…for the 4.0L inline six, 5.2L or 5.9L Mopar ‘LA’ V-8 performance? Transfer case options? Building up an axle with the aluminum center section? You name it…Click here for access to the E-mail question form!

Mario’s Hybrid Weber-Carburetted ZJ!

From: Mario B.

Sent: Wednesday, June 20, 2012 7:24 AM

To: qanda@4WDmechanix.com

Subject: Weber 32/36

Hello, Moses!

I want to thank you again for all the advice you gave that helped me in fixing my Jeep. I have changed all the shock absorbers to gas-charged, and it has given me a good ride.

I have one problem with my carburetor, though: I’m experiencing hard starting whenever the engine is hot. It occurs when I’m starting the engine after I turned it off for about 10 minutes or more. I tried to start it after 30-sec. to one minute after turning off and it has no problem. I converted the choke to mechanical control and it is fully opened when I start. What I do now is to press the gas pedal 1 or 2 times then start the engine with half-throttle and it starts.

My diagnosis for now is that the fuel in the float chamber and line vaporizes after some time because of the heat inside the engine bay. I have routed the fuel lines away from heat sources but I still don’t have any better place to route them as the engine bay temperatrue is high.

Do you have any idea how I can avoid vapor lock and how I can minimize the engine bay temperature. I plan on wrapping the exhaust manifold with a thermal wrap as it may contribute to the heat in the engine bay. Also, the intake manifold and the carburetor sits on top of the exhaust manifold.

Thank you very much!

Regards,

Mario B.

Hi, Mario…A way to avoid vapor lock is either a three-pipe mechanical fuel pump or a fuel filter with a return line to the gas tank. Jeep 4.2L inline sixes used a three-pipe inline fuel filter that returned excess fuel volume to the tank. This constant movement/circulation of fuel prevents the fuel from stagnating in the lines and heating to the point of vapor lock.

Check with a parts source about the three-pipe fuel filter for carbureted Jeep models. You should have a return-to-the-tank fuel pipe from your original two-rail EFI/MPI system. That could be a simple place to send the excess fuel (third pipe on the filter) safely back to the tank. Make sure the pipe goes to the fuel tank and not into the vapor canister!

At the magazine, see Illus. #31: https://4wdmechanix.com/Jeep-4WD-Lube-Oil-and-Filter-Service.html. This is the filter I am describing, and the third pipe is a return to the fuel tank for excess fuel and to prevent vapor lock. Make sure you route the filter properly and with the correct pipe back to the tank. I’m not sure what kind of fuel pump you’re using or the operating pressures. Be aware that this fuel filter was designed for the factory mechanical pump fitted to later 4.2L carbureted engines, rated for 4 PSI pressure.

What kind of fuel pump are you using? The Weber 32/36 has an inlet pressure limit around 3.5 PSI if I recall correctly. Do you use a pressure regulator? You need to limit available pressure at the carburetor. A Grand Cherokee factory electric pump in the tank is way too much pressure! Typical pressure for a Jeep mechanical pump (for carburetion) is around 4 to 5 PSI at 500 engine rpm. Your Weber should have a fuel inlet pressure even less than a Jeep carburetor. Installers use a pressure regulator to accomplish this.

Regards,

Moses

ZJ Won’t Steer to Center After Turns

From: Mario B.

Sent: Thursday, May 10, 2012 3:59 PM

To: qanda@4WDmechanix.com

Subject: inquiry from a friend

Hi, Moses,

My steering wheel will not come back to center whenever I turn, no bad sound, not hard. It’s normal, only it will not center. Can you help me with this? Thank you.

Regards,

Mario B.

Hi, Mario…Sounds like one of several possibilities:

1) Binding steering linkage or ball joints on the steering knuckles

2) A front axle shaft joint that is binding

3) Transfer case binding or a viscous coupler wearing out

4) Steering gear problem with rotary valve/internal troubles

5) Wheel alignment incorrect, in particular the caster angle

Some trouble checks:

1) Check for an axle shaft joint issue. With the front end raised safely and the engine turned off, rotate the front wheels left to right, checking for bind…A worn front axle shaft joint can cause resistance when turning.

2) If you have the 249 transfer case, the viscous coupler is known to act up and fail. This could deliver power to the front end at the wrong times and steering trouble on turns. See which transfer case you have in the Grand.

3) Has the front axle been damaged? Has the steering taken a severe shock? Have an alignment shop check caster, camber and toe-in. If all else checks okay, consider the steering gear.

I would first focus on a viscous coupler or axle shaft problem…

Regards,

Moses

Grand Cherokee Gearing vs. Engine Mods for Big Tires

From: Tony Z.

Sent: Friday, February 24, 2012 5:27 PM

To: qanda@4WDmechanix.com

Subject: 97 grand 5.2l

Hi, I have 2 97 Grand Cherokee’s.

Both are 5.2, one is stock the other has 33’s and long arm’s.

My question is, how can I boost these engine’s to get better performance.

On the long armed Jeep Im hopeing to find more torque.

I seem to hit the power band around 3500 rpm.

Tony

Hi, Tony…These engines have mild camshaft grinds and peak their torque around 3,200 rpm. This sounds consistent with your sensation of “hit the power band around 3500 rpm”. If I were to modify the engine for better response, my camshaft grind of choice would be a CompCams 252H flat hydraulic tappet type or an equivalent roller camshaft, either cam aimed at better bottom end torque and a quicker power rise.

High rpm power is not the objective here…“Bigger” camshafts are only helpful in the midrange and for high rpm horsepower, which is not sensible for typical driving. The aim here is more valve lift without radical valve opening duration or extreme valve overlap. You want high manifold vacuum at lower rpm levels.

Before considering any engine work, however, my first approach would be a change in gearing to get the engine into the power range at lower vehicle speeds. Have you done any gear work? Especially on the Grand with 33” tires, axle gearing would be the first place to improve power. 4.10 or even 4.56:1 would be choices for the 33” tires and overdrive. (4.10 might be acceptable with the V-8’s power.) On the stock Grand with OEM tire size, 4.10 gearing would help considerably. You would need to correct for the speedometer error, not a difficult procedure on these ’97 vintage vehicles.

Let me know more about your Jeep Grand Cherokees…Does the gearing change make the best sense for starters?

Regards,

Moses

A Philippine ZJ 4.0L With Ongoing Issues

From: Mario B.

Sent: Thursday, January 05, 2012 5:08 PM

To: qanda@4WDmechanix.com

Hi Moses,

First of all, thank you very much for everything. I have made a wiring diagram according to what you’ve told me in the email. I’ve attached the file in this email. I made a bypass circuit from the start terminal to the relay to supply the HEI distributor during starting. Then the on circuit would be connected after starting. I don’t know what is the wiring in the ignition switch yet, but the idea is to also supply 12V to the HEI distributor during starting. I’m also planning the same wiring circuit for the choke, with start bypass circuit.

There’s also another problem with the wiper. The wiper turns on at the moment I start the engine. After a few turns, it shuts off and everything back to normal. It just happens when I turn the ignition key for starting. I haven’t touched any wiring connected to the wiper. I suspect it is caused by the ECU. Do you have any idea about this?

My friend, I am very grateful to you. You’ve been active in giving ideas in this project. How will I thank you more?

Again, thank you very much.

Regards,

Mario

Mario…Is the start bypass circuit necessary? When you turn the key to the start position (without the bypass circuit), is 12V current still available? If so, that would eliminate the need for the switch bypass circuit. See if the bypass circuit carries more amperage. Is that circuit’s wiring larger than the ignition “on” wiring?

The HEI distributor is simply looking for a reliable 12V circuit with enough amperage capacity and heavy enough wiring gauge. The wiper issue sounds like you have created current feedback through the ignition switch—maybe with your “bypass circuit”.

Moses

From: Mario B.

Sent: Tuesday, January 03, 2012 10:30 PM

To: qanda@4WDmechanix.com

Hi Moses,

Thanks again for helping me. By the way, is it possible to connect the coil directly to the battery with a relay for switching to the ignition key? What fuse rating should I use with the coil and the choke? I’m planning to do the same way with the choke.

You’ve been very helpful to me Moses. I really don’t know how to thank you. I really appreciate your communication with me.

Thanks again.

Mario

Mario…You could do the battery-to-coil as you describe, with an ignition (key-on) lead switching the relay.

I’m assuming your distributor is a G.M. type design with coil-in-cap. The distributor should have come with installation recommendations…These coils from test reviews run up to 7.5 amp draw at the module, usually 5.6 amps for a stock coil/module. There can be up-surges in voltage during cranking…As a backup for safety, I would fuse the circuit at 10 or 15 amps. You can confirm the coil and choke amperage draw from the manufacturers’ specifications. Add a few extra amps for overload and surge protection.

I would use #12 gauge wire to a cap-style coil lead, nothing thinner. Any ground wire should be this gauge as well. (Some go to 10-gauge, which is heavy.) The coil should be on a separate circuit and fused.

The choke is also ignition switched as key-on. You could use a battery lead switched by the ignition circuit if preferred. Choke amperage draw should be no more than 7 amps, so a 10-amp fuse would likely be enough to handle any current surge. The fuse is for added safety. I would use 12 or 14 gauge wire for the choke circuit.

Be safe and avoid sharp edges when routing wires…Use plastic looms and other safety approaches. Avoid engine heat and hot spots that could damage wires and raise resistance. Source the battery current at the starter solenoid end of the positive battery cable, not at the battery itself. (It is very dangerous to create sparks near a battery.) Use ring terminals at the solenoid/cable stud. Make sure connections are secure, use solder at terminals if possible. (Crimp-type terminals do not capture wire strands like rosin core soldering.) Use rosin core solder at copper wire connections with heat shrink tubing for added insulation and weather-proofing.

Regards,

Moses

From: Mario B.

Sent: Tuesday, January 03, 2012 12:06 AM

To: qanda@4WDmechanix.com

Hi Moses,

How are you friend? I just want to share you the updates about the Jeep. I’ve changed the carb to Weber 32-36 progressive. The Autolite 2100 is very hard on gas and there’s a hesitation during abrupt braking. The hesitation diasappeard when we changed to Weber 32-36. There’s a slight decrease in power but it’s good in city driving. I’ve noticed that tha 2100 gives more power at highway speeds. Also, we’ve wired the HEI Ignition system right now from the ECU Ignition Line but I’ve noticed that the ignition shuts when the ECU harness is touched. There might be loose connection. This also happens when we connect the positive connection for the electrical choke of the Weber 32-36. I plan on re-routing the wiring, bypassing the ECU. Do you have any idea where to get the positive connection?

Jan 3, 2012 10:42:32 PM, qanda@4WDmechanix.com wrote:

Hi, Mario…If the distributor and coil need a pure 12V signal, an ignition “On” circuit wire would work. Make sure the circuit is Key-On current flow only and that it will carry enough amperage. Be sure that circuit is fused to protect the wiring in the event of overload.

If the Weber electric choke needs a pure key-on 12V signal, do the same here. The choke is a variable resistance device that likely is not compatible with the ignition circuit for the PCM. You might start by finding a key-on circuit, away from the PCM ignition leads, for the choke.

Most aftermarket HEI distributors have GM style wiring: A ground, tach lead and 12V hot lead (key on). If no ground is present, the distributor housing must be properly grounded.

Regards,

Moses

From: Mario B.

Sent: Friday, June 17, 2011 9:28 PM

To: qanda@4WDmechanix.com

Subject: ask help from the jeep guru

Sir, hi! Mario from the philippines i have a question regarding my 1994 Grand cherokee limited 4.0 I6 4WD , since the part here in my country is very hard and very expensive , also the mechanics will be trial and error for the trouble codes as less equipment for this model and very heavy troubles with stalling problem , I want your help this car was bought from a friend Doctor who always got the problem with the car.and now the problem was trasffered to me . all i want is to convert it to carb. ill be using a 258Cid intake manifold and carburator and also the distributor. Can i use this set up? how about the transmission do i have a problem i undstand it will not affect the trans. I need your help sir so that the car is going to run again. Thank you.

Mario B.

Philippines

Hi, Mario…The 258 manifold and carburetor, and even the distributor, will fit your 4.0L six. Since this is a retrograde approach, be aware that the last 258 carbureted engines produced 60 horsepower less than your current 4.0L with MPI. The carburetor manifold has inefficient flow, which dramatically impacts performance.

If I were doing carburetion, a Clifford intake manifold and improved carburetor design (Carter AFB or a smaller engine application Rochester Quadrajet with an adapter plate) would make better sense than the AMC/Jeep BBD carburetor. There are aftermarket ignition distributors with HEI that work nicely; the Jeep Motorcraft is acceptable.

Additionally, the transmission (unless a manual transmission or a three-speed 999 or 904) does have electronic controls. They interact with the engine through the PCM (Powertrain Control Module). Carburetion would not provide the signals needed, and the transmission would not function properly.

Considering the amount of work in the conversion to carburetion, plus the loss of performance, it would be wise to troubleshoot your current fuel-and-spark system. Share what you need to fix. I will help troubleshoot the problem.

Happy to assist…I have plenty of information and experience here!

Moses

Mario back…

From: Mario B.

Sent: Saturday, June 18, 2011 6:04 PM

To: qanda@4WDmechanix.com

Subject: Re: RE: ask help from the jeep guru

Moses,

It’s nice of you…The trouble now is the jeep will start, and it will stall and start again it will run after about 5 min. it will stall again, the CPS is new the coil and cams sensor is new, we check the pump pressure its only 31-35psi i change the pcm which i bought from ebay and i wonder that my PCM is very rare kind. the # 56028312, there are for sale but the part number is 56028311 05 56028300 my car is a third hand but it still nice i love my grand cherokee this car does not have the security system as advice from the previous owner the VIN IJ4GZ78SIRCXXXXXX please help me.

Regards to you and yours,

Mario

Moses replies…

Mario, your transmission should be a 42RE. This is electronically controlled. To answer your questions about the PCM and transmission control modules, I have attached a wiring schematic for a ZJ Grand Cherokee (1998—I do not have the ’94 model, but systems are similar for your purposes). The wiring schematic shows the interface between the modules and the transmission. Also, I did an article on upgrading the RE-RH transmission. It is in the Automatic Transmission Workshop at the magazine.

Your ‘312’ PCM is likely an export item, as it fits between the 1994 ZJ 4.0L Fed 311 and ’93-’94 ZJ 4.0L 313 SBEC controllers. I’m not quick to replace a PCM unless a DRBIII scanner test reveals a problem here. The ‘311’ PCM on Ebay may be okay and work, however, I would first see if the fuel pump issue is the problem. Your fuel pressure is too low. Other areas of concern are the ASD, ASD relay or an oxygen sensor.

Before replacing any more parts, I would resolve the fuel pressure problem and be sure to do a DRB (II or III, whichever applies) scan of the system. This scan tool is at all Chrysler dealerships in the U.S. and should be available in the Philippines. The scan tool will narrow down the malfunction and can also “test” individual components within the system. Paying for a scan can save a tremendous amount of hardship and cost in the long run. Most of problems that you describe can be pinpointed with the DRBIII scan test. Start here and with the fuel pressure issue.

The MAP, ASD, ASD relay, PCM, oxygen sensors or other items could cause the symptoms you describe. I would use the DRB scan test to narrow the cause. Do not waste time and money replacing parts unless you know they are defective.

Also, you will find that a factory workshop manual is very valuable. You may find one for your 1994 ZJ on Ebay, and that would be a wise investment. This book would help you find the causes of many problems. You could rebuild the entire ZJ with a factory 1994 ZJ Jeep Service Manual.

Regards,

Moses

Mario back again…

From: Mario B.

Sent: Tuesday, June 21, 2011 7:52 AM

To: qanda@4WDmechanix.com

Subject: Re: RE: RE: RE: ask help from the jeep guru

Hi Moses,

Good day, my friend. Thanks for the information. We’ve been suspecting that the stalling issue might be caused by the fuel delivery system. Funny thing is that the fuel level in the tank is too low so I’m going to fill it up 1/2 level. Fuel pressure on the rail is insufficient. The reading fluctuates between 30-35 psi. The engine runs well if the accelerator pedal is depressed, even when running. When returned to idle, gives a hint of stalling, eventually stalls after a few seconds. It seems that the fuel supplied to the rail is not continuous.

When the fuel pressure regulator is checked, it was found out that the diaphragm has damage. I also noticed that the fuel pressure drops immediately when the engine is turned off. Is it supposed to retain some pressure for a few minutes? Will low fuel level cause fluctuation of fuel pressure? I hope that this is the main cause of the stalling problem so that I will be able to enjoy my Grand Cherokee.

As for the scan tool, I’ve contacted a shop here in Bacolod City. Unfortunately, a schedule must be set because the technician is still called from Manila, capital of the Philippines, to go here and perform diagnostics for Jeep vehicles. That would cost a lot since I may be charged for the plane ticket of the technician, and I’m the only one requesting. Are there other troubleshooting steps you can recommend with regards to my current problem?

Thanks in advance.

Regards,

Mario

Moses replies…

Hi, Mario…I would focus on the pressure regulator and getting the fuel pressure to normal. The pump is within the tank if you need to replace it…The pressure regulator defect could cause your stalling symptoms. Since you’re at such a disadvantage for reaching a technician, concentrate on the fuel pressure remedies before paying for airline tickets!

I heartily recommend investing in the Jeep Service Manual for your ZJ. A used copy is not expensive and often available at Ebay, certainly through used automotive book sources online. Some manuals are now on CD. Having the right information and details is a cost effective alternative to flying technicians back and forth. For the cost of airline tickets, you could probably find a used DRBIII scan tool with all of the accessory hookups.

Keep me posted on the fuel pressure remedy and whether this cures the problem.

Moses

Mario back to the carburetor idea…

Hi, Moses,

How are you? i tried the fuel problem, but no recourse, the shop in the big city is not working for the old model jeep they will work if your model will be 2005 up, so my last recourse will be carb. what i will do is to buy a 258 intake manifold the cj 7 1986 and fit it to my 242cid grand cherokee i like this car it’s only when i bought it, it has lots of trouble, but i know if there’s a will there’s a way… i know that you will help me with conversion… i have a weber 32/36 carb that was given to me. i need a distributor assembly that will fit in the 242cid, may be the 86 jeep distributor will fit, please give some guidance so that we can start working and looking for parts. if you have time… clifford performance manager told me they have converted about 30 customers using their intake manifold for 242. Hoping this jeep of mine will run soon.

Regards,

Mario B.

Philippines

Mario, this is a different approach…In the Philippines, you do not have U.S. emission control requirements, so I guess it’s an option. Of course, your carbon footprint will be greater with carburetion.

Carburetion is basic, and you have the Weber, which you must jet properly for the 242/4.0L engine. Fortunately, from a distributor standpoint, the installation is the same for a 258 or 242/4.0L. I would consider one of the aftermarket HEI distributors designed for this engine, as the wiring is very simple and direct. You would have a tach lead, too, which might work with the OEM tach. (You need to experiment here.) The Motorcraft distributor from the 258 will also fit. You want to use it without frills, just the distributor and vacuum advance with a module. I discuss a conversion to a five-pin Chrysler module, using the Motorcraft distributor, in my Jeep Owner’s Bible.

You want to keep this simple, as the later 258 engines have feedback BBD carburetors and a microprocessor for the distributor. Your approach should be basic: direct wiring hookup to the distributor and a carburetor that will operate without the microprocessor.

I again emphasize that you will be downgrading the performance by using a centrally mounted carburetor. The major gain of EFI/MPI is the port injection, which provides even fuel distribution to each cylinder. This is virtually impossible with an inline six and a centrally mounted carburetor, as the outer cylinders have long runners compared to those closest to the carburetor. One boost here is a Clifford or Offenhauser intake manifold for the 258, which will provide better flow and more even fuel distribution.

Clifford, in particular, worked diligently to improve both the manifold and carburetor offerings “in the day”. (By the late ’80s, Jack Clifford was also working with an EFI conversion for these engines, retrofitting Ford’s early CFI unit.) Check out the current offerings at Clifford Performance, including their carburetor recommendations. The Clifford manifold and an exhaust header are improvements. The stock 4.0L exhaust manifold is acceptable.

Keep me posted on your project…

Moses

Mario back again…

From: Mario B.

Sent: Tuesday, July 19, 2011 9:35 PM

To:qanda@4WDmechanix.com

Hi, Moses,

T hank you for the advice….What can you recommend for the HEI as i dont know what will happen with the drive gear in the distributor. Can i swap the gear of my distributor to the HEI, or can i use the chevy 250, 292 I-6 distributor? i see in the ebay that the price of Chevy is lesser compare to Jeep HEI (brand new). Clifford informed me that since my Grand Cherokee is OBD1, the auto trans will work just fine as the tranny has its own TCM…i dont know about this, can you explain to me regarding with this auto trans if i use carb. also I will be making a bracket for the carb, for the kickdown cable for the 42RE trans. what will happen to the PCM/ECU it will just remain in the car? kindly advise…Thank you very much.

Regards,

Mario

Philippines

Moses replies….

Mario, there are HEI distributors with the correct drive gear. 4Wheel Drive Hardware (www.4WD.com) offers one at an inexpensive price point. It uses common G.M. tune-up parts and has the correct drive gear for the 258/4.0L. Caution: Avoid the Chevy distributor, the drive gear is different!

It’s not clear whether the TCM and PCM are completely independent. I would leave the PCM and all wiring in place to pick up signals from sensors. Since the aftermarket carburetor requires no electrical input, and since the HEI distributor needs nothing more than an ignition-switched hot wire, you can leave everything else intact. This is important for speedometer, ABS and other functions. I would not interrupt these circuits.

The missing signal would be the throttle position sensor (TPS), and I’m unclear how that will impact the transmission shifting performance. (MAP may be important, too, I’d leave that in place.) If the kickdown cable is a primary shift control, there would be no problem. If the TCM is looking for a MAP and TPS signal from the PCM, you would need to improvise a TPS that would work properly with the carburetor and new throttle linkage.

This is no-man’s land, as the Grand Cherokee is built around the MPI system and sensors. I would include the original signals that the transmission requires. Use a “clean” ignition ON source for the HEI distributor. This G.M. based distributor design offers the simplest and least involved wiring. Self-contained, there is no external module or coil to fuss about…

Let me know how this turns out with regard to the TCM functions and how the transmission shifts after the changeover.

Moses

Mario back…

From: Mario B.

Sent: Wednesday, July 20, 2011 12:08 AM

To: qanda@4WDmechanix.com

Hi, Moses,

Can i use a mallory distributor jeep 258 I-6 mallory dual point distributor for my set up? or what can you recommend for HEI? i dont know the model. there are lots in ebay that i can buy. please guide me. i love the jeep to run again… i’m a fan of jeep ever since the Renegade days of CJ5. Thank you.

Cheers,

Mario

Philippines

Moses replies…

The dual-point is unnecessary and requires too much service over time. Check out my recommendation at 4Wheel Drive Hardware, it’s an inexpensive solution ($122 U.S. plus shipping) that uses common service parts. There are more expensive alternatives, including the Mallory, MSD or DUI. This is the inexpensive solution…

Moses

Wrapping up the Q&A exchange between Mario and Moses?

From: Mario B.

Sent: Wednesday, July 20, 2011 6:17 PM

To: qanda@4WDmechanix.com

Hi, Moses,

I’ m happy for your guidance, i’ll be buying the distributor which you recommend, only im still waiting a little time for my money then i will order the distributor. I have a friend who owns a 1987 jeep YJ which is not running anymore the engine was nowhere to be found but he want to give me the intake manifold with carter bbd carb and exhaust manifold this all intact and never separated its a whole attachment the intake, carb and the exhaust. Can i use this intake manifold and just modify it? Do you have a free down load of jeep owners bible? or is this for sale? how much please?

Regards,

Mario B.

Philippines

Hi, Mario…The ’87 YJ 258 uses a Carter BBD carburetor with a microprocessor and Sole-Vac unit. At the magazine website, I detail the rebuilding of that carburetor at both the CJ and YJ Jeep Workshop sections. The Sole-Vac controls main fuel metering, and this makes the carburetor part of a “feedback” system with an oxygen sensor and sensor devices similar to EFI. You are trying to get away from electronics, and your Grand Cherokee has no provision for running the MCU for that BBD carburetor. The distributor on that engine is also regulated by the MCU (microprocessor unit).

I have never run a Jeep CJ or YJ BBD without the complete MCU system. There are BBD carburetors used on older engines without feedback. Chrysler V-8s used the 2-barrel BBD on engines like the 318 V-8. You may find an older BBD without the Sole-Vac and feedback mechanism.

As for the Jeep Owner’s Bible, this has been a bestselling book and is available at 4Wheel Drive Hardware, Advance Adapters and from my book publisher, Bentley Publishers. It is available globally through book stores like Barnes & Noble and similar sources in your country. As you like Jeep, you would enjoy this book.

Regards,

Moses

Mario’s carburetor option…

Ok moses i understand i will not use the bbd carter, i will use the webber 32/36 which i have with me now. it was from my father in law Renault 16 TS it’s still good. what im going to ask you is the 1987YJ intake manifold and exhaust manifold will be adaptable to my engine? will the intake manifold fit? ill be using this one if its o k. and adopt the 2 bbl webber 32/36, and buy the distributor you suggest. ill be buying your book. please advice thank you.

Regards,

Mario

Moses goes full circle on Mario’s plans…

Jul 21, 2011 03:32:40 AM, qanda@4WDmechanix.com wrote:

Mario…The intake manifold will fit. The Grand Cherokee’s exhaust manifold flows better than the Wrangler, however…What is the displacement of the Renault engine? Is it close to 4.0L? You would need a carburetor designed to flow fuel and air to an engine of 4.0L size.

Be aware that this conversion is a lot of work. You will need to fabricate throttle linkage, make sure the transmission will shift properly and reduce the pressure of the fuel supply. Yes, the fuel pump in the Grand Cherokee has way too much pressure for a carburetor needle and seat. (You might use a quality fuel pressure regulator to reduce pressure. Summit Racing and others sell fuel pressure regulators.) The 4.0L engine block does not have a provision for a mechanical fuel pump, and there is no room either…There is also the air cleaner and fuel lines, including the emission control hoses to vent the gas tank.

This conversion is not an easy or “simple” fix, Mario. You are going retrograde with a modern vehicle to a period when there were less emission controls. Many things must be taken into consideration. For instance, you do not want dangerous gas fumes leaking or a vapor-locked fuel supply system. The 4.0L has a two-rail MPI system with the excess fuel flowing back to the tank. The vehicle is equipped with emission controls and an EVAP system.

My view: I would not tear out the EFI/MPI and other devices. As I suggested at the beginning, my approach would be to thoroughly troubleshoot and repair the original MPI and spark system. Did you ever change the fuel pressure regulator? Your fuel pressure was low from what you shared earlier…

Personally, I would not go retro with a vehicle like the Grand Cherokee, which is otherwise in good condition. I would sell the Grand Cherokee and fix up an earlier Jeep if you want a simpler carburetor model with a basic ignition. Converting to a carburetor on a Grand Cherokee would devalue the vehicle considerably in the U.S. If I wanted a carbureted Jeep similar to a Grand Cherokee, I would buy a 1980s to 1991 Grand Wagoneer with the 360 V-8, a carburetor and a conventional distributor.

Perhaps Clifford sees this differently than I do. If so, they may be able to provide the many details you need for safely converting to a carburetor and HEI ignition, including fuel, exhaust, ignition and emissions solutions.

Regards,

Moses

From: Mario B.

July 21, 2011 4:19 AM

To: qanda@4WDmechanix.com

Hi, Moses,

Im very glad for the advice ill just do first to troubleshoot the original components, the renault displacemnet is only 1800cc. Clifford recommends a 2-bbl webber 38/38 350cfm. also they recommend the mallory distributor 4760101 or HEI, ill buy the one you recommend as mallory is very expensive. almost double the price of HEI that you recomend. any way thanks for your time.

Mario B.

Philippines

Moses comments…

This is smart, Mario. Try to find a factory service manual (used) for your Grand Cherokee model, the correct year book if possible. Check Ebay, these books come up all of the time. There are also used automotive book outlets online. With the factory Jeep service manual, you will have enough information to correctly troubleshoot the original MPI and electronics systems.

You will be much happier in the long run with a properly working, original MPI system. Work your way through the original equipment, including the ignition and fuel components, and find the source of the troubles. With the Jeep service manual, you will find the problem and solve it (much quicker than trying to convert the 4.0L to a carburetor!). The MPI works better, and it is safer. You will preserve the value of the Grand Cherokee if you keep the MPI system.

When looking for a service manual, make sure it is the official 1994 ZJ Jeep Grand Cherokee Service Manual. You do not want an owner’s manual, you want the “service manual” by Jeep. In addition to Ebay, there is Powell’s bookstore, used automotive book retailers and Craigslist online. A Google search will find them. I looked at www.books4cars.com. They have your service manual, but they want $70 for it. Perhaps you can do better on the price somewhere else. 1993-95 year books should cover your Jeep ZJ. A 1994 book would be best.

Regards,

Moses

Mario chooses his own fixes…

From: Mario B. [Philippines]

Sent: Tuesday, November 15, 2011 3:46 AM

To: qanda@4WDmechanix.com

Hi Moses,

I just want to inform you that my 1994 Jeep Grand Cherokee runs now. I’ve used Autolite 2100 Carburetor and the HEI ignition that you recommended. The engine runs well. The shifting also works well and the overdrive engages. Only a minor adjustment with the kickdown cable was done. There’s slight pinging during abrupt acceleration; what timing can you recommend with this? The only problem now is the air conditioning. The air is only ducted below the dashboard. The front vent doesn’t work. If I have some time, I’ll be opening the dashboard and see what’s the problem.

Regards,

Mario

Nov 15, 2011 10:50:14 AM, qanda@4WDmechanix.com wrote:

Hi, Mario…Glad you worked out the fuel-and-spark issues…Make sure that the vacuum to the distributor advance mechanism comes from carburetor “ported” vacuum and not manifold vacuum. Manifold vacuum would hold too much advance as you open the throttle. Ported vacuum is easy to identify: Vacuum is highest just as you tip the throttle slightly and drops as the throttle opens further.

The carburetor may have more than one vacuum port. You are looking for the one that offers “ported” vacuum. Do not source distributor vacuum directly from the intake manifold.

Try a base timing of 5-degrees advance, set with the vacuum hose disconnected from the distributor. If ping goes away, try bumping to 8-degrees. Stop at the point the ping just disappears. The centrifugal spark advance in an aftermarket HEI distributor rises quickly. Set the base timing to control the ping point.

You may have an adjustable vacuum advance. If so, you can experiment with backing off the vacuum advance as needed. Try running the engine with the vacuum hose plugged off, then gradually adjust (add) vacuum pull. If the vacuum canister is adjustable, there will be an adjusting screw accessible through the canister’s vacuum pipe.

Good luck with your carburetor/HEI retrofit!

Moses

From: Mario B. [Philippines]

Sent: Tuesday, November 15, 2011 4:03 PM

To: qanda@4WDmechanix.com

Hi, Moses…I will try what you’ve said, and I will update you the result. I am very thankful that you could share information with me. By the way, what camshaft can you recommend for daily driving? I will be using my Jeep for occasional off-road when going to the farm.

Regards,

Mario

Nov 16, 2011 09:33:51 PM, qanda@4WDmechanix.com wrote:

My choice is a CompCams 252H grind. This is mild and offers excellent torque and usable low-end power.

From: Mario B. [Philippines]

Sent: Friday, November 18, 2011 5:28 AM

To: qanda@4WDmechanix.com

Hi, Moses,

Can you give me the part number of this camshaft that will fit my engine? I’ve searched the web and only find the ones applicable to other engines.

Thanks,

Mario

Reply from Moses:

I dug down into the CompCams catalog online. Here is the page with the camshaft order description. You want a camshaft and lifters kit. This is the basic cam-and-lifters kit, the least expensive approach. There are more expensive approaches with new valve springs, retainers and so forth: click here.

Trust this helps. The camshaft is intended for use without fuel injection, which is your current approach. Click on the specifications link. Click here for the website page.

Moses

One Flat and the Tires Low on Tread

From: Jeff T.

Sent: Monday, May 16, 2011 10:59 AM

To: qanda@4WDmechanix.com

Subject: Tires

Good Morning,

A couple of questions, I have a 2001 Jeep Grand Cherokee Limited 4×4. The dealership is telling me that I need to replace my tires at 3/32. They are also telling me that I shouldn’t replace one or two, but all four, even if just one tire is replaced, it will damage my 4×4 vehicle. I recently had a leaking tire due to a nail. I put on the spare and put the repaired tire back in the trunk. While my other 3 tires are in great condition having 4/32 tread left. The spare is greater than 8/32. I’m being told that I should only have 2/32 or less difference, or I will eventually burn up my transfer case. I cannot seem to find any info online to support this. While Jeep recommends replacing all four tires.

Thanks for the help,

Jeff

Jeff, the concern is the traction system and the delivery of the power through the transfer case and axles. The presumption is that one tire too large in diameter will create a false “ratio” for that wheel and stress the transfer case and axle traction systems.

First of all, bias front to rear would likely be little affected by the 1/8” difference at one tire. The bigger concern would be cross-axle diameter difference, which could be a slightly greater issue. If you want to try it, I would place the newer 8/32” tread tire at the front, leaving two rear tires at the same diameter with only the front tires differing. Run the 1/32” off the rear tires then replace the four tires, making the current 8/32” tire your spare.

If there’s an issue, you will know it. The system will seem jerky with possible vibration. Since locked 4WD is only used on surfaces with some slip (ice, mud, snow, etc.), there’s little likelihood that a front tire diameter difference this small will be noticeable. The objective is to get that 1/32” wear from the other tires.

I agree that 3/32” is minimal tread for a 4WD vehicle. Get a fresh set of tires at 3/32”—before foul weather driving.

Let me know how this works out.

Regards,

Moses

Footnote from Moses: Jeff wrote back that he replaced all four tires. This was prudent and the safer approach overall. Tires are not cheap, economic times are tough for many, but your safety and the reliability of a Jeep 4WD system is paramount…

Blown Head Gasket on a ‘ZJ’ 5.2L Pushrod V-8

From: GARY

Sent: Monday, December 13, 2010 2:52 PM

To: Moses Ludel

Subject: Blown head gaskets

Hi, Moses,

Your webpage is bookmarked and I go to it all the time…I have a ’98 Grand Cherokee with the 5.2L V-8. You know anything about blown head gaskets?? I did some wheeling at the backside of Virginia City last summer, and my 5.2L V-8 overheated badly and lost coolant. The engine won’t hold coolant now and charges the overflow tank if I try to run it.

Thanks,

Gary

From: Moses Ludel

To: ‘GARY’

Sent: Monday, December 13, 2010 9:29 PM

Subject: RE: Blown head gaskets

Gary…Are you curious whether you have blown the Grand Cherokee 5.2L’s head gaskets or how to replace them? Let’s begin with how to test for blown head gaskets.

If the radiator is erupting from pressure, this can be a blown head gasket between a cylinder(s) and a water jacket in the block or head. It can also be a crack at an exhaust seat that is deep enough to enter the water jacket of the head. Coolant in the crankcase oil is very telling, too, typically a blown head gasket or casting crack. Some quick tests:

1) With a radiator pressure tester, pressurize the system with the engine cold. You may find a leak revealed by immediate loss of pressure on the gauge. If the engine runs, start it with the pressure tester hooked up on the radiator and be prepared to immediately shut the engine off. If the needle pegs at the high side on the gauge, there’s combustion gas in the cooling system! Shut the engine off immediately before the gauge gets damaged.

2) Another test for combustion gases in the coolant is to simply hold an exhaust gas analyzer wand above the radiator fill neck with the engine idling. If there is measurable HC or CO in the cooling system, you have a severe casting crack or blown head gasket(s).

3) A cylinder leakdown test, for an immobile engine, is a great diagnostic tool. If two adjacent cylinders read low, while the rest seem okay, the head gasket is likely blown between these cylinders. While pressurizing each cylinder during the leakdown tests, watch the cooling system for bubbles at the radiator. This is a sign of 1) a cracked head from an exhaust seat into the cooling jacket 2) a blown head gasket, or a casting crack in the block.

4) Your comment about coolant steaming from the exhaust is apt, too. This is a blown head gasket or cracked head, sometimes (rarely) a cracked block.

Unless you have tools, some experience and a Jeep factory workshop manual, you would be wise not to tackle an engine change. Equally daunting would be removing the cylinder heads with the 5.2L in the chassis. Late model Jeep vehicles like a Grand Cherokee, with its V-8 shoehorned into the engine bay and plenty of accessories to remove, are not easy to service at this level.

There may be a Mopar reman long block or even a new crate engine available at Jeep. Check with the Jeep dealership at Reno or the new franchise at Carson Dodge-Chrysler-Jeep…Mopar offers a well supported warranty, and the dealership techs are more familiar with this chassis and the Jeep engine replacement procedures. In the long run, you want a reliable outcome. I am familiar and skilled at this job, but if I were to sublet it anywhere, the Jeep dealership would be my first choice…

Regards,

Moses

From: GARY

Sent: Monday, December 13, 2010 9:44 PM

To: Moses Ludel

Subject: Re: Blown head gaskets

Moses,

I was basically curious about whether I had a blown head gasket or a cracked block or head. I thought it’s a cracked head or block because there is no steam in the exhaust and that tells me there’s no coolant going into the cylinders on intake but the radiator hose gets rock hard from exhaust. Everything I have ever seen about a blown head gasket says there will be steam coming out of the exhaust pipe. This is very discouraging. I have a Haynes manual for my Jeep but it does me little good because I am not going to tackle this engine. If anything I will have someone replace it. I have only put 1,900 miles on it since Feb ’09.

Thanks for your help and prompt reply!

Gary

Moses’ Note: Gary’s problem is not that unusual. Loss of coolant can catch us unaware, especially when we’re preoccupied with driving on a Jeep 4WD off-pavement trail! Likely, the Grand Cherokee’s 5.2L V-8 problem began with an overheated, perhaps from a loss of coolant, maybe from ‘wheeling in the summer with the A/C on at crawl loads. The 5.2L needs help with its cooling, regardless; there’s a lot of horsepower and BTUs here; the engine is tightly packaged to the point of little air circulation around or out of the engine bay.

1/3 of an engine’s energy dissipates into the cooling system or off the block and cylinder heads as thermal loss, and rock crawling in the summmer becomes a recipe for overheat. I pursue Gary’s 5.2L V-8 issue further and suggest cooling system upgrades as his ZJ Grand Cherokee project unfolds…Below is the update!

Gary writes again:

From: GARY

Sent: Saturday, January 15, 2011 4:45 PM

To: Moses Ludel

Subject: Blown head gasket

Hi Moses,

My grandson Ryan and I got to the ZJ yesterday and today, and this is what we found on the passenger side. Ever see a head gasket blown like this??? Looks like it is rotted away. No signs of any cracking at all nor pitting or rust anywhere on the heads or block deck. Yes, we checked everything for flatness and there is no warpage or space under the straight edge. Heads are perfect…no warpage or damage, so we’ll be putting it back together starting tomorrow. Wish me luck!

P.S.: Thermostat is brand new, only about 2 minutes of run time on it. The old one was bad. It’s just about back together now. My fingers, toes and eyes are crossed.

Moses replies:

This is exciting, Gary…You were justifiably stressed over the ZJ, and your grandson has come through like a trooper! The Jeep should be a winner when completed…Yea! Let me know how this turns out…

Gary…It sounds like steam scorched through the gaskets from the cooling ports during the engine overheating…Your grandson looks happy and content with his work! He’s doing a thorough job, it should turn out well. No sign of cracks anywhere, heads check okay with a straightedge, no warp on the block decks, all good signs!

Felpro gaskets are best and do not require re-torque after running. I bring the bolts up in steps and sequence. After reaching final torque, let the bolts set for several minutes, then re-torque once more. Use heat resistant Teflon paste on any bolt threads that reach into cooling ports…You only want to assemble this 5.2L V-8 once in a ZJ chassis! I’d install a new thermostat for insurance.

Gary, was the coolant “long life” orange or mixed? Your engine would be ethylene glycol era (green, traditional). The head gasket damage looks like corrosion, chemical reaction or steam perforation after engine overheating. Drain the coolant completely, the heater included. Blow out hoses with compressed air if you have a compressor. Stick with traditional anti-freeze/coolant on this application.

I use Copper Coat or a copper-type spray gasket compound if the head gaskets are not coated. If you use Felpro (blue) coated gaskets, follow

instructions and omit the use of additional sealant as directed.

Sounds like your grandson Ryan is very resourceful—or likes the idea of driving the Grand Cherokee!

Gary replies:

From: GARY

Sent: Saturday, January 15, 2011 7:44 PM

To: Moses Ludel

Subject: Re: Blown head gasket

HI Moses,

My coolant has always been green for as long as I have owned this vehicle. I drained the cooling system twice after I got the vehicle but have no idea what the previous owner did to it. My grandson said it looked like the gasket went from over heating and corroding so…Yes, we are using the FelPro blue, so we will follow the instructions to the letter. We’re replacing the water pump for insurance.

My grandson is a good mechanic, and he REALLY likes the idea of driving the ZJ!

Footnote from Gary:

From: Gary Sent: Tuesday, January 18, 2011 5:48 PM

To: Moses Ludel

Subject: Re: Blown head gasket

Hi Moses,

Here’s a short video of Ryan driving the ZJ away from the house for the first time in 5 months. Sounds pretty darn good! BTW- Ryan won’t let me drive it!

Thanks for all your advice and help…Gary

From: Moses Ludel

To: GARY

Sent: Tuesday, January 18, 2011 1:22 PM

Subject: FW: Blown head gasket

Gary, I got your note…Congratulations! I thought you’d nail it…Ryan did a great job, and you’ll both be happy driving the ZJ!

It was wise to replace the water pump as you did. The old one was stressed severely during the overheating. Glad you’re back on the road!

Have fun…Time to hit the trails again!

Slip Yoke Eliminator for a Grand Cherokee

From: Tom H.

Sent: Friday, November 19, 2010 11:48 AM

To: qanda@4WDmechanix.com

Subject: Grand Cherokee transfer cases

Moses:

I have a 1995 Grand Cherokee V-8 model with an automatic transmission. I believe it has the NP229 transfer case in it. With its driver’s side front axle driveshaft, I want to eliminate the slip yoke at the rear of the transfer case. Can I use the rear half of a Grand Wagoneer NP229 transfer case, as they have a bolt on yoke? Or would it be simpler to find a different transfer case that has a factory bolt-on yoke? I prefer a simple, part time 4WD system, but it is not a “must have.”

Tom

From: qanda@4WDmechanix.com

Sent: Saturday, November 20, 2010 1:20 PM

To: Tom H.

Subject: Grand Cherokee transfer cases

Hi, Tom…The NP229 part-time/full-time 4×4 system served well in the Grand Wagoneer era. The NP229 in our ’87 Grand Wagoneer worked flawlessly, never causing a bit of trouble. Some found the controls challenging, but when working properly, the 229 worked effortlessly.

Your 1995 Grand Cherokee does not have an NP229. Look closely at the I.D. plate. You will discover that it is either an NPG/NV249 or NPG/NV242. Likely, you have the 249, the full-time 4WD system that most often came with a V-8. I have rebuilt these NP249 types, mostly due to viscous coupling failures. The viscous coupling is a very spendy item that can fail unexpectedly. The viscous coupler seemed practical for a vehicle driven primarily on-highway and in all-weather conditions. The use of the viscous drive in an off-pavement Jeep, though, is suspect. I would not want to chance a potentially failure-prone viscous in remote backcountry or along a wintry highway.

If you have enough rear driveline space and want a full-time, four-wheel drive mode, you would be better off with the 242 or a Grand Wagoneer NP229. The NP229, with its part-time 2WD high, 4WD high, neutral and 4WD low range worked well in heavyweight models like the 360 V-8 Grand Wagoneers. However, the 229 is a busy transfer case with its combination of vacuum and mechanical shift mechanisms. You would need a donor Grand Wagoneer’s entire shift system to duplicate the original approach, including mechanical linkage, vacuum hardware, a dash switch, the wiring and vacuum circuit schematic and an operator’s manual!

The Grand Wagoneer NP229 does come with a fixed yoke factory output, a U-joint yoke that is equivalent to a slip yoke eliminator approach. Despite its fixed yoke output, the NP229 is still a relatively lengthy transfer case.

The 242 was introduced in the late ‘80s XJ Cherokee models while the full-size Grand Wagoneer stayed with the NP229 through 1991. The 242 has 2WD, 4WD (part-time), 4WD full-time and Low Range 4WD. A slip yoke output makes this a long transfer case, too. I’m not aware of any slip-yoke conversion that will work with the 242; however, in stock form, the 242 would be my preferred transfer case choice between the Grand Cherokee’s 249 and 242.

Jeep used the NP/NV231 transfer case in the XJ Cherokee, YJ and TJ Wrangler and some ZJ Grand Cherokees. Used units are abundant, inexpensive and easier to service, with parts available readily. Advance Adapters’ SYE Kit is in place on this unit, the solution for CV rear driveline conversions!

If simpler, part-time 4×4 and a conventional transfer case are desirable, the Grand Cherokee did use the NP231 with a slip-yoke. An abundantly available XJ Cherokee, Grand Cherokee, YJ Wrangler or TJ Wrangler 231 application, with an aftermarket slip-yoke eliminator kit, would be practical. The best SYE on the market is Advance Adapters’ kit, which retails for around $200. The NP/NV231 is reasonably strong, easy to source and has great parts availability. Used units abound at a reasonable cost. Short of upgrading to an Atlas II transfer case, an NP231 in good condition would work!

Trust this is helpful…

Front Axle Pinion Nut Torque

From: Mike L.

Sent: Sunday, December 05, 2010 2:46 PM

To: 4WD Q & A

Subject: RE: 1992 ZJ Grand Cherokee

Moses, I need to change the front axle pinion seal on the Grand Cherokee. How much torque does the nut take?

Thanks,

Mike L.

From: 4WD Q & A

Subject: 1992 ZJ Grand Cherokee

To: Mike L.

Date: Sunday, December 5, 2010, 7:00 PM

Mike, your front axle’s pinion shaft likely has a collapsible preload spacer. When new, the full-length spacer takes 160-260 ft-lbs to begin collapsing. The actual rotating torque setting for the pinion bearings is 15-35 in/lbs (yes, inch-pounds) with new pinion bearings. (I like 20-25 in-lbs with new bearings. See my article link below.) To reuse original bearings, you read the torque necessary to rotate the pinion (wheels and tires removed to reduce drag) before removing the pinion flange. Add 5 in/lbs to that measurement when you re-adjust the pinion bearings with a new crush/collapsible preload spacer.

Before removing the pinion nut, read the rotating torque at the flange. Record it. (It should be around 20 in/lb with the wheels and tires off the axle.) Now you can hold the flange with a large pipe wrench and remove the nut (counterclockwise) with your impact. The nut should loosen readily, although it is a self-locking type and needs replacing with a like-kind new nut on reassembly. You will need a puller to remove the flange from the pinion shaft. When the flange and outer pinion bearing are removed, you should find a crush/collapsible sleeve fitted between the inner and outer pinion bearings. It is always best to install a new sleeve. Tighten the nut to collapse the new sleeve. Keep tightening 5 ft/lbs at a time and do keep checking the rotation torque of the pinion. Do not exceed the correct rotating torque, or you will have crushed the sleeve too far! If by chance you have a shim-type pinion shaft without a crush/collapsible sleeve, you can follow the steps in my article link below. Read the article thorough in any case, many steps apply to both shim and sleeve pinions.